01/24/2020 SCM008 - REV H 3

Smart Chock™

---Sequence of Operations---

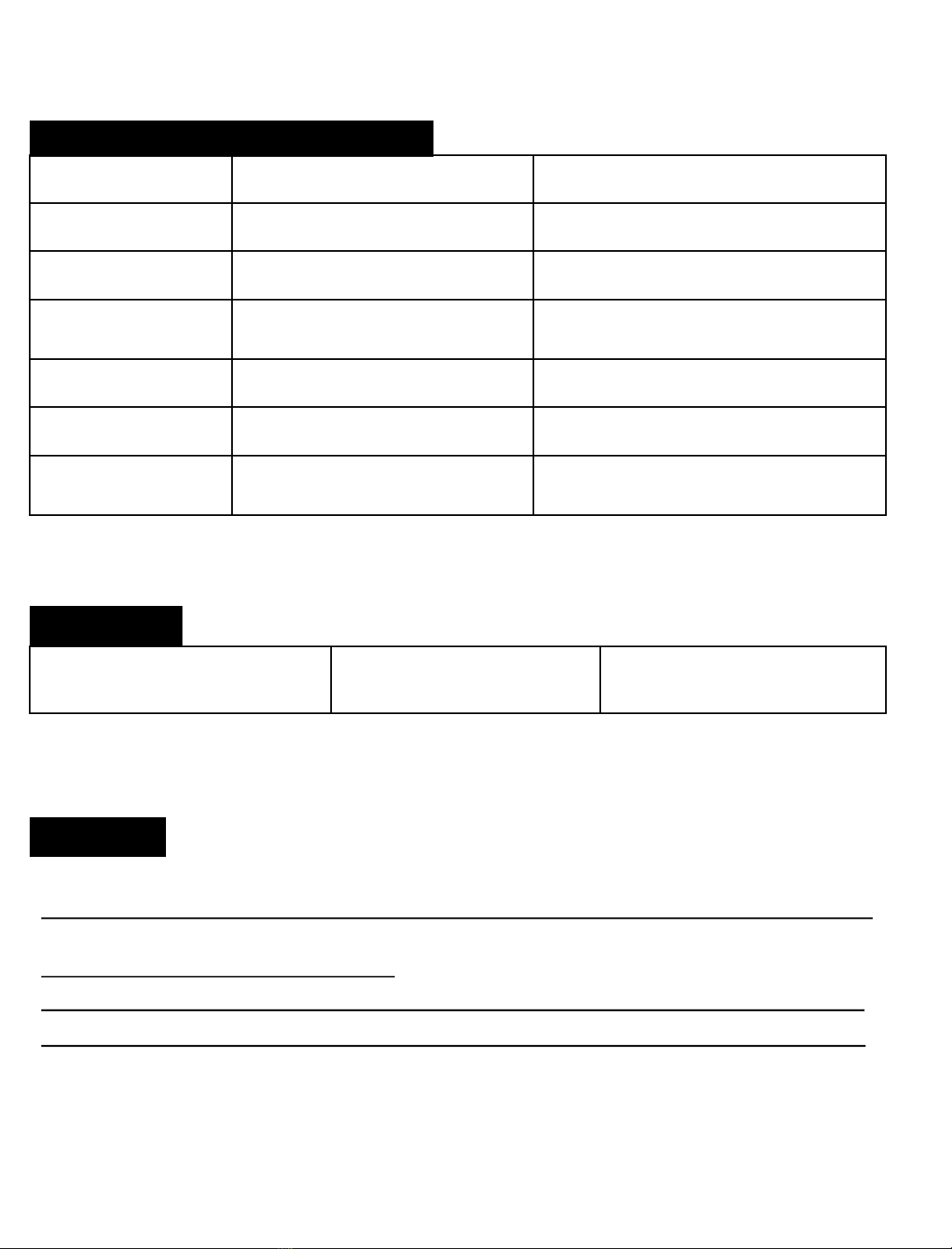

Testing

POWER ON – Smart Chock enters a startup routine that turns the LED’s and Relays on and off a few times. The startup routine

runs for approximately 20 Seconds.

Loading Dock Door is Closed, Wheel is Unchocked

•Inside Red Light is on

•Outside Green Light is flashing

Wheel gets Chocked and after a 0 to 5 Second Delay

•Outside Red Chock Icon turns on

• Inside light changes from red to green “CHOCKED”

•Outside Green Light turns off

Door Open

•Outside top Red Light starts flashing

•Interlocks turn on –the outlets for a fan and dock light are enabled

(1) See note for Optional Sensor information

Door closes and after a (2) 5 to 15 Second Delay

•Outside flashing Red Light turns off

•Interlocks turn off –the outlets for a fan and dock light are disabled

Driver Removes Chock

•Outside Red Chock Icon turns off

•After a 5 to 15 second delay, Outside Green flashing light turns on

• Inside light changes from green “CHOCKED” light to Red Light

Safety Situations

*** Chock Pulled Prematurely with Door Open (After a (2) 3 to 15 Second Delay)***

• Inside light changes from green “CHOCKED” light to Red Flashing Light

•Versa Light® Dock Light flashes and Inside Audible Alarm Sounds for 5 minutes, fan outlet is disabled

•Interlocks are disabled

•Outside Red Chock Icon turns off, outside red stay on

•Outside Alarm turns on for 10 minutes

***Door opens without a truck wheel chocked***

•Versa Light® Dock Light flashes and Inside Audible Alarm Sounds for 5 minutes, fan outlet is disabled

•Interlocks are disabled

•Outside Red Chock Icon turns off, outside red stay on and Outside Alarm comes on for 10 Minutes

***Chock Cable gets Cut or Disconnected from Chock***

•Inside lights alternately flash from green to red, on board yellow system LED comes on

•Outside Red comes on and if wheel was chocked, Chock Icon turns off and Outside Alarm comes on for 10 Minutes

•Interlocks are disabled

•Inside Alarm turns on and does not turn off until power is turned off or cable is plugged back in

(1) An Optional Second Sensor can be connected to the Control Board at J3 or OPT2 (See page 12 for connection information). The Optional

Second Sensor negates the actions caused by the Door Sensor when the Door is Open. The Outside Red Light, Interlocks and Outlets are

turned off.

(2) At the core of the Smart Chock Control Board is an embedded microcontroller. Under preprogrammed control, the Smart Chock Time

delays, Light Outputs and Relay Outputs can be modified to suit any Customers individual needs. For example, the Time Delays could be

preprogrammed anywhere from 3 to 15 seconds.

Smart Chock™ Installation Guide