16 1

BATTERY SYSTEM TESTER

1.Brief Introduction

DI-216/DI-217 battery storage testers are used for

activated style lead-acid storage battery, along with checking

the following conditions of the battery, starting up, charging,

and electrical loading. With great design, easy operation,

precise reading, complete functions, this tester supply the

readings by a large LCD and hints by sound and light when

testing. Precise circuit and strong digital processing unit make

it complete collection of a series of complicated data and figure

out every test data, which availably by 4-wire Kelvin test

connection. Besides it strengthens input protection inside , in

order to prevent such situations as polar reversal connection ,

over-high voltage input, poor contact of the test clamps and so

on. That makes sure safer and more convenient when testing.

This tester is the best tool for battery sales, vehicle repair

and condition check of all kinds of lead-acid batteries that used

in equipment system associated with lead-acid battery.

2.Safety Rules And Attentions

This manual includes instruction, operation warning and

maintenance. It is possible to damage the tester without

regulations in this manual. This tester is designed and

produced strictly according to GB4793.1 electronic

measurement instrument safety requirement and

IEC/EN61010-1 safety standard. It also reach double insulation

over voltage standard CATⅢ 600V and pollution degree 2 .

(1) DI-216/DI-217 is available to vehicle of 12V storage battery.

(2) The working voltage of DI-216/DI-217 is DC 9V to 18V. Make

sure do not check the series connection battery.

(3) The voltage value will be higher than that in the normal

situation after the checked battery being fully charged . Please

turn on the headlights for 2 to 3minutes, then check the battery

when it’s voltage value drop to the normal value.

(4) Check the insulating layer of the clamps before measuring.

Damage, bareness and disconnection are unacceptable. It is

8-2 It is unavailable to know the electric quantity of

storage battery by intuition

Hydrometer can be used to check the condition of the

battery. Battery water is distilled water and pure sulfuric acid of

the proportion of 1.260/20°C to allocate. For a new battery, it is

supposed to supply distilled waterwith reduction of battery water

for the reason that the degree of acid is fixed when the quantity

of battery water remain the normal range. Distilled water

supplement can maintain a certain amount of water, but alsothe

PH value. If the battery works normally, in addition to the PH is

fixed, the proportion of the value will be in a certain range.

If the battery finishes charging, the proportion of battery

water does not reach 1.26-1.28, along with the tested voltage

under 12.7V, the storage capacity of this battery has descended.

It is impossible to recover its life by deliberately adjusting the

proportion to 1.26 (Increase the sulfuric acid water), on the

contrary shorten its life fast for the reason that it will increase

the acidity of battery water, not the voltage however.

8-3 Some common abbreviation meaning of storage

★ RC Reserve Capacity

Every storage battery has the ability to load averagely 25A

electric perminute and maintains lowest 10.5V more or less in

the situation of 80°F(27°C).

★ CCA-Cold Cranking Ampere

With the fixed current, every battery can be cooled in the

situation of 0°F(-18°C) ~ -20°F(-29°C)for 30 seconds and

-

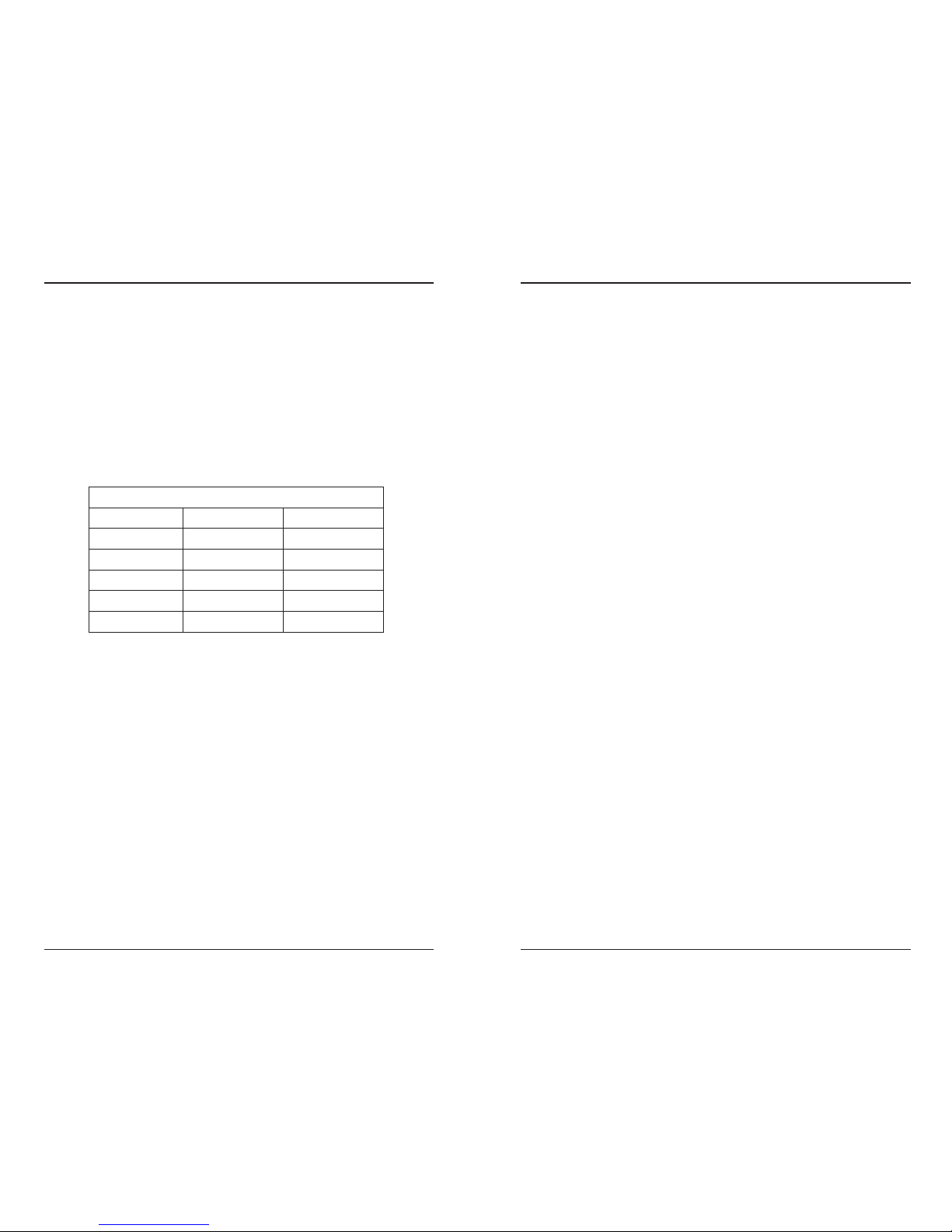

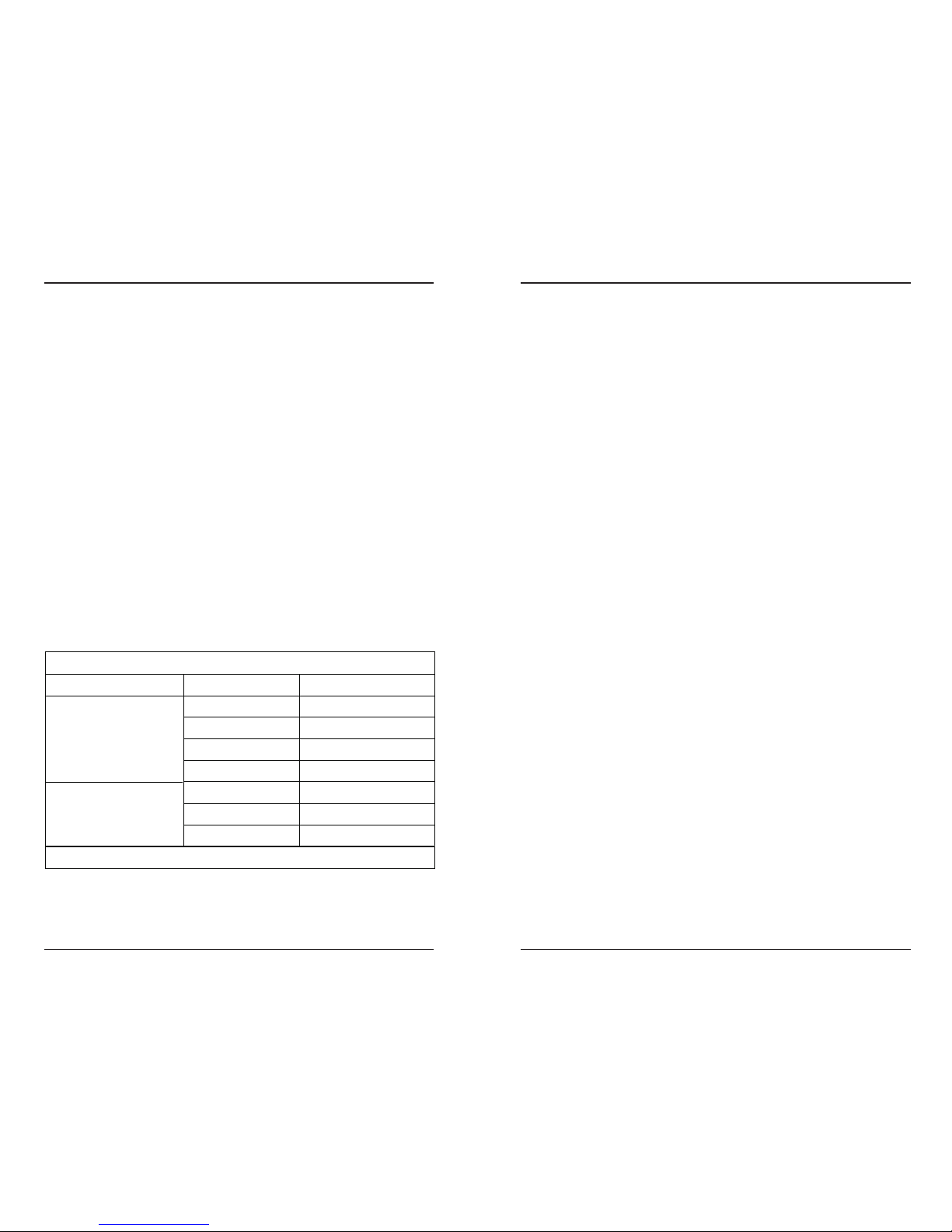

Battery of small type vehicle

Voltage(V)

Electric(%)

Proportion

>12.7

100%

1.26~1.28

12.6 90%

1.24

12.4 70~80% 1.22

12.1 50% 1.16

<12 25% <1.13

USER MANUAL