DLM DL Series User manual

DLM • Division of Systems, Inc. • W194 N11481 McCormick Drive • Germantown, WI 53022

Printed in U.S.A.

Copyright ©2011

Manual No. 4111-0025

March 2011

May 2012

DL-NL-TS SERIES

EOD Dock Leveler

Owner’s/User’s Manual

Page

Safety

Recognize Safety Information.................................................................1

General Operational Safety Precautions ................................................1

Operational Safety Precautions ..............................................................2

Maintenance Safety Precautions ............................................................4

Safety Decals ..........................................................................................5

Owner’s/User’s Responsibilities ..............................................................6

Introduction

General Information ................................................................................8

Dock Leveler Stock Specifications..........................................................8

Installation

Installations Details .................................................................................9

Flush Mount-Weld On ........................................................................... 10

Ramp Mount-Weld/Bolt On ................................................................... 12

Flush Mount-Bolt On ............................................................................. 14

Ramp Mount-Weld On w/Formed Angle............................................... 16

Formed Angle ....................................................................................... 18

Ramp and Face Plate ........................................................................... 20

Installation Check List ........................................................................... 22

Operation

Operating Instructions DL ..................................................................... 23

Operating Instructions NL & TS ............................................................ 24

Maintenance

Periodic Maintenance ........................................................................... 25

Troubleshooting

Troubleshooting .................................................................................... 26

Parts

DL-X Series........................................................................................... 27

NL-X Series........................................................................................... 28

TS Series .............................................................................................. 30

Extension Spring Components ............................................................. 32

Torsion Spring Components.................................................................. 34

Current vs. 2005 and Older................................................................... 35

Handle Options ..................................................................................... 36

Operating Link Options ......................................................................... 37

Bumper Components ............................................................................ 38

Sliding Bumper Components ................................................................ 39

Notes

Customer Information ........................................................................... 41

Warranty................................................................................. Back Cover

Table of Contents

1

Manual No. 4111-0025

March 2011

May 2012

SAFETY

Recognize Safety Information

Read and understand the operating instructions and

become thoroughly familiar with the equipment and its

controls before operating the dock leveler.

Never operate a dock leveler while a safety device or

guard is removed or disconnected.

Never remove DANGER, WARNING, or CAUTION

signs or decals on the equipment unless replacing

them.

General Operational Safety

Precautions

Do not activate the equipment until all unauthorized

personnel in the area have been warned and have

moved outside the operating zone.

Remove any tools or foreign objects from the operating

zone before starting.

Keep the operating zone free of obstacles that could

cause a person to trip or fall.

The use of the word DANGER signifies the presence

of an extreme hazard or unsafe practice which will

most likely result in severe injury or death.

Safety-Alert Symbol

The Safety-Alert Symbol identifies important safety

messages on equipment, safety signs, in manuals,

or elsewhere. When you see this symbol, be alert to

the possibility of personal injury or death. Follow the

instructions in the safety message.

The use of the word WARNING signifies the

presence of a serious hazard or unsafe practice

which may result in serious injury or death.

IMPORTANT

The use of the word IMPORTANT is to draw

attention to a procedure that needs to be followed to

prevent machine damage.

The use of the word CAUTION signifies possible

hazard or unsafe practice which could result in

personal injury.

O

p

e

r

a

t

i

n

g

Z

o

n

e

O

p

e

r

a

t

i

n

g

Z

o

n

e

2Manual No. 4111-0025

March 2011

May 2012

SAFETY

Operational Safety Precautions

Stay clear of dock leveling device when freight

carrier is entering or leaving area.

Do not move or use the dock leveling device if

anyone is under or in front of it.

Keep hands and feet clear of pinch points. Avoid

putting any part of your body near moving parts.

Chock/restrain all freight carriers. Never remove

the wheel chocks until loading or unloading is

finished and truck driver has been given permission

to drive away.

Do not use a broken or damage dock leveling

device. Make sure proper service and maintenance

procedures have been performed before using.

Make sure lip overlaps onto trailer at least 4 in.

(102 mm).

Keep a safe distance from both side edges.

Learn the safe way to operate this equipment. Read and understand the

manufacturer’s instructions. If you have any questions, ask your supervisor.

3

Manual No. 4111-0025

March 2011

May 2012

SAFETY

Do not use dock leveling device if freight carrier is

too high or too low.

Do not overload the dock leveling device.

Do not operate any equipment while under the

influence of alcohol or drugs.

Do not leave equipment or material unattended on

dock leveling device.

Operational Safety Precautions

4Manual No. 4111-0025

March 2011

May 2012

4

SAFETY

Maintenance Safety Precautions

ALWAYS stand clear of dock leveler lip when

working in front of the dock leveler. Failure to do this

may result in serious personal injury or death.

To put handle into maintenance prop position,

remove bolt and locknut at base of handle

assembly. Pull handle out of roller arm assembly

and place into maintenance prop receiver, if

equipped.

Post safety warnings and barricade the work area at

dock level and ground level to prevent unauthorized

use of the dock leveler before installation has been

completed.

Failure to follow the installation instructions can

result in damage to dock leveler, the facilities, and/

or serious personal injury or death.

5

Manual No. 4111-0025

March 2011

May 2012

5

SAFETY

1

3

2

2

Unsupported dock leveler

ramps can lower unexpectedly.

Before allowing vehicle to leave

the dock always:

Ensure that no equipment,

material or people are on the

dock leveler.

Return the dock leveler to its

stored position at dock level.

Failure to follow posted instructions will result in death or serious injury.

SAFETY INFORMATION

Call 262.255.1510 for replacement placards, warning labels, or owner’s/user’s manuals.

Operation

1. Read and follow all instructions and

warnings in the owner’s/user’s

manual.

2. Use of dock leveler restricted to

trained operators

3. Always chock trailer wheels or

engage truck restraint before

operating dock leveler or beginning to

load or unload.

4. Never use hands or equipment to

move the ramp or lip

5.

6. Ensure that truck bed supports

extended lip or the leveler frame

Before activating dock leveler:

Ensure trailer is backed in against

bumpers.

Remove any end loads if required.

Check trailer alignment to avoid lip

interference. If lip does not lower to

trailer bed, reposition vehicle.

Supports the ramp before driving on

ramp.

7. Stay clear of hinges and front and

sides of moving dock leveler.

8. Never use damaged or

malfunctioning dock leveler. Report

problems immediately to supervisor.

1. Read and follow all instructions,

warnings and maintenance schedules

in the owner’s/user’s manual.

2. Maintenance/Service of dock leveler

restricted to trained personnel.

3. Place barriers on the driveway and on

dock floor to indicate service work is

being performed.

Maintenance/Service

4. DO NOT ENTER PIT unless dock

leveler is securely supported by

maintenance prop.

5. If electrically powered turn off and use

OSHA lockout/tagout procedures.

DANGER

Unsupported dock leveler

ramps can lower unexpectedly.

Before allowing vehicle to leave

the dock always:

Ensure that no equipment,

material or people are on the

dock leveler.

Return the dock leveler to its

stored position at dock level.

Failure to follow posted instructions will result in death or serious injury.

SAFETY INFORMATION

Call 262.255.1510 for replacement placards, warning labels, or owner’s/user’s manuals.

Operation

1. Read and follow all instructions and

warnings in the owner’s/user’s

manual.

2. Use of dock leveler restricted to

trained operators

3. Always chock trailer wheels or

engage truck restraint before

operating dock leveler or beginning to

load or unload.

4. Never use hands or equipment to

move the ramp or lip

5.

6. Ensure that truck bed supports

extended lip or the leveler frame

Before activating dock leveler:

Ensure trailer is backed in against

bumpers.

Remove any end loads if required.

Check trailer alignment to avoid lip

interference. If lip does not lower to

trailer bed, reposition vehicle.

Supports the ramp before driving on

ramp.

7. Stay clear of hinges and front and

sides of moving dock leveler.

8. Never use damaged or

malfunctioning dock leveler. Report

problems immediately to supervisor.

1. Read and follow all instructions,

warnings and maintenance schedules

in the owner’s/user’s manual.

2. Maintenance/Service of dock leveler

restricted to trained personnel.

3. Place barriers on the driveway and on

dock floor to indicate service work is

being performed.

Maintenance/Service

4. DO NOT ENTER PIT unless dock

leveler is securely supported by

maintenance prop.

5. If electrically powered turn off and use

OSHA lockout/tagout procedures.

DANGER

2

2

DANGER

!

Ramp swings toward you.

Stand Clear.

Use maintenance strut while servicing.

Failure to do so will result in death or

serious injury.

1

Decal 2 will have two positions, one on the outside of the left bumper and

one on the outside of the right bumper.

Decal 3 represents the placement of the serial tag (left side of gusset).

3.25"

9.12"

Unsupported dock leveler

ramps can lower unexpectedly.

Before allowing vehicle to leave

the dock always:

Ensure no equipment,

material or people are on

dock leveler.

Return dock leveler to its

stored position at dock level.

Failure to follow posted instructions will result in death or serious injury.

SAFETY INFORMATION

Call 262.255.1510 for replacement placards, warning labels, or owner’s/user’s manuals.

Control Box Size:

Decal Size: 9.12 x 3.25

File Name: 1751-0730 Rev A

DANGER OPERATION 7. Stay clear of hinges and front and

1. Read and follow all instructions and sides of moving dock leveler.

warnings in owner’s/user’s manual. 8. N e v e r u s e d a m a g e d o r

2. Use of dock leveler restricted to malfunctioning dock leveler. Report

trained operators problems immediately to supervisor.

3. Always chock trailer wheels or

engage truck restraint before MAINTENANCE/SERVICE

operating dock leveler or beginning to 1. Read and follow all instructions,

load or unload. warnings and maintenance

4. Never use hands or equipment to schedules in the owner’s/user’s

move ramp or lip manual.

5. Before activating dock leveler: 2. Maintenance/Service of dock leveler

Ensure trailer is backed in against restricted to trained personnel.

3. Place barriers on the driveway and

bumpers.

dock floor to indicate service work is

Remove any end loads if required.

being performed.

Check trailer alignment to avoid lip 4. DO NOT ENTER PIT unless dock

interference. If lip does not lower to leveler is securely supported by

trailer bed, reposition vehicle. maintenance prop.

6. Ensure truck bed supports extended 5. If electrically powered turn off and use

lip or leveler frame supports the ramp OSHA lockout/tagout procedures.

before driving on ramp.

3.25"

9.12"

Unsupported dock leveler

ramps can lower unexpectedly.

Before allowing vehicle to leave

the dock always:

Ensure no equipment,

material or people are on

dock leveler.

Return dock leveler to its

stored position at dock level.

Failure to follow posted instructions will result in death or serious injury.

SAFETY INFORMATION

Call 262.255.1510 for replacement placards, warning labels, or owner’s/user’s manuals.

Control Box Size:

Decal Size: 9.12 x 3.25

File Name: 1751-0730 Rev A

DANGER OPERATION 7. Stay clear of hinges and front and

1. Read and follow all instructions and sides of moving dock leveler.

warnings in owner’s/user’s manual. 8. N e v e r u s e d a m a g e d o r

2. Use of dock leveler restricted to malfunctioning dock leveler. Report

trained operators problems immediately to supervisor.

3. Always chock trailer wheels or

engage truck restraint before MAINTENANCE/SERVICE

operating dock leveler or beginning to 1. Read and follow all instructions,

load or unload. warnings and maintenance

4. Never use hands or equipment to schedules in the owner’s/user’s

move ramp or lip manual.

5. Before activating dock leveler: 2. Maintenance/Service of dock leveler

Ensure trailer is backed in against restricted to trained personnel.

3. Place barriers on the driveway and

bumpers.

dock floor to indicate service work is

Remove any end loads if required.

being performed.

Check trailer alignment to avoid lip 4. DO NOT ENTER PIT unless dock

interference. If lip does not lower to leveler is securely supported by

trailer bed, reposition vehicle. maintenance prop.

6. Ensure truck bed supports extended 5. If electrically powered turn off and use

lip or leveler frame supports the ramp OSHA lockout/tagout procedures.

before driving on ramp.

DANGER

!

Control Box Size:

Decal Size: 4-5/16 x 4-1/4

File Name: 1751-0763 Rev A

Ramp swings toward you.

Stand Clear.

Use maintenance strut while servicing.

Failure to do so will result in death or

serious injury.

Refer to owner’s/user’s manual for proper procedure.

Decal 2 will have two positions, one on the outside of the left bumper

and one on the outside of the right bumper.

Decal 3 represents the placement of the serial tag (left side of gusset)

2

2

1

Safety Decals

6Manual No. 4111-0025

March 2011

May 2012

OWNER’S/USER’S RESPONSIBILITIES

1. The owner/ user should recognize the inherent dangers of the interface between the loading dock and

the transportation vehicle. The owner/ user should, therefore, train and instruct all operators in the safe

operation and use of the loading dock equipment in accordance with manufacturer’s recommendations

and industry standards. Effective operator training should also focus on the owner’s/user’s company

policies and operating conditions. Maintaining, updating and re training all operators on safe working

habits and operation of the equipment, regardless of previous experience, should be done on a regular

basis and should include an understanding and familiarity with all functions of the equipment. Owner’s/

user’s shall actively maintain, update and retrain all operators on safe working habits and operations of

the equipment.

2. The manufacturer shall provide to the initial purchaser all necessary information regarding Safety

Information, Operation, Installation and Safety Precautions, Recommended Initial and Periodic

Inspections Procedures, Planned Maintenance Schedule, Product Specifications, Troubleshooting

Guide, Parts Break Down, Warranty Information, and Manufacturers Contact Information, as well as

tables to identify the grade(slope) for all variations of length or configuration of the dock leveling device

and information identifying the maximum uncontrolled drop encountered when sudden removal of support

while in the working range of the equipment.

3. It is recommended that when the transportation vehicle is positioned correctly in the dock opening and

in contact with both bumpers, there shall be a minimum of 4.00 inches (100mm) overlap of the leveling

device and the transportation vehicle at all times during the loading and unloading process.

4. The Owner/User must review all name plates, placards, decals, instructions and posted warnings and

place the same in view of the operator or maintenance personnel for whom such warnings are intended

for. Contact manufacturer for any replacements.

5. Manufacturer’s recommended periodic maintenance and inspection procedures in effect at the date of

shipment shall be followed at all times. Written documentation of maintenance, replacement parts or

damage should be retained. In the event of damage notification to the manufacturer is required.

6. Loading dock equipment that has been structurally damaged or has experienced a sudden loss of main

support while under load (such as what might occur when a transport vehicle pulls out from under the

leveling device) shall be removed from service, inspected by a manufacturer’s authorized representative,

and repaired or replaced as needed before being placed back in service.

7. Any modifications or alterations of loading dock equipment shall only be done with prior written approval

from the manufacturer and the same shall be at least as safe as the original equipment was prior to

the modification and shall also satisfy all safety requirements of the manufacturer for the particular

application of the leveling device.

8. When industrial moving devices are being used in the loading or unloading of product from the

transportation vehicle, this vehicle shall have the brakes and wheel chocks applied appropriately or

all other positive restraining device shall be fully utilized. It is recommended that trailers with air-ride

suspension systems shall have its air exhausted prior to performing loading and unloading operation to

minimize trailer bed drop.

9. Loading dock safety equipment should never be used outside of its intended use, vertical working range,

or capacity. Please consult the manufacturer if you have any questions as to the use, vertical working

range or capacity of the equipment. Only properly trained and authorized personnel should operate the

equipment.

10. When selecting loading dock safety equipment, it is important to consider not only present requirements

but also future plans and any possible adverse conditions, environmental factors or usage.

7

Manual No. 4111-0025

March 2011

May 2012

NOTES

This page intentionally left blank

8Manual No. 4111-0025

March 2011

May 2012

INTRODUCTION

General Information

DL-NL-TS Series Edge-of-Dock levelers are available

in the following sizes, weight capacities, and options:

Congratulations on your choice of a DLM Edge-of-

Dock leveler. This manual covers the DL-NL-TS series

mechanical Edge-of-Dock levelers.

Designed by DLM to be a marvel of simplicity and

efficiency, your dock leveler, when properly installed,

will provide many years of trouble-free performance

with an absolute minimum of maintenance. To obtain

maximum performance and longest possible use,

a simple program of preventive maintenance is

recommended.

Once again, thank you and congratulations on your

purchase of a DLM mechanical Edge-of-Dock leveler.

Dimensions and Capacities

Model # - Deck - Total Unit

Width Width Comparative Industry Rating

DL-66 66” 104”

DL-72 72” 110”

DL-78 78” 116”

20,000

25,000

30,000

(N/A for DL-78)

Dimensions and Capacities

Model # - Deck - Total Unit

Width Width Comparative Industry Rating

NL-66 66” 104”

NL-72 72” 110”

NL-78 78” 116”

NL-84 84” 122”

20,000

25,000

30,000

35,000 (N/A for NL-84)

Dimensions and Capacities

Model # - Deck - Total Unit

Width Width Comparative Industry Rating

TS-66 66” 104”

TS-72 72” 110”

TS-78 78” 116”

TS-84 84” 122”

20,000

25,000

30,000

35,000 (N/A for TS-78 & 84)

9

Manual No. 4111-0025

March 2011

May 2012

INSTALLATION

INSTALLATION DETAILS

IMPORTANT

DO NOT remove the shipping bands around the

dock leveler lip until instructed to do so.

Post safety warnings and barricade the work area at

dock level and ground level to prevent unauthorized

use of the dock leveler before installation has been

completed.

Failure to follow the installation instructions can

result in damage to dock leveler, the facilities, and/

or serious personal injury or death.

Only trained installation professionals with the

proper equipment should install this product.

50 INCH

PREFERRED

10 Manual No. 4111-0025

March 2011

May 2012

INSTALLATION

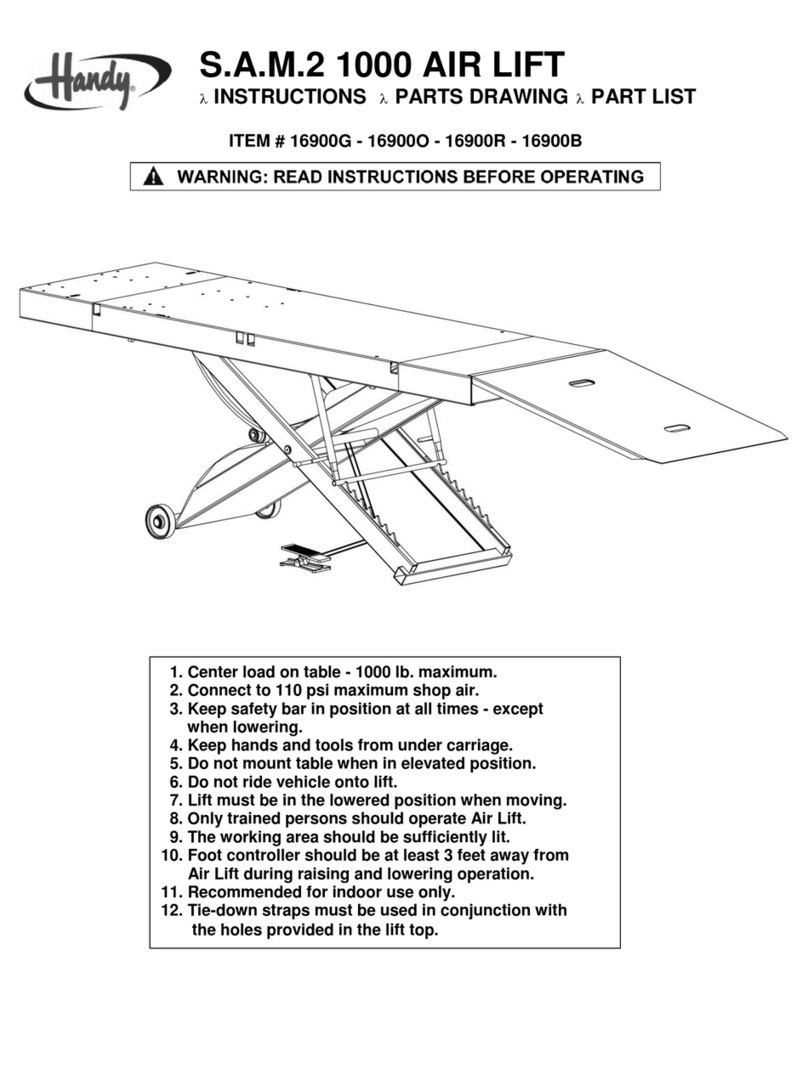

E.O.D. Installation Instructions - Flush Mount - Weld On

A flush mount weld on application is used when an 8”

wide (minimum) embed channel is securely anchored

into the concrete at the dock edge, and the dock height

is adequate.

Installation Steps:

1. Remove all existing bumper material and

protruding objects from dock edge. Clean and

sweep dock edge free of debris and flammable

chemicals before installing unit.

2. At chosen location for Edge-of-Dock leveler,

locate the center of space and mark a point half of

the base plate width to the left and right.

3. Using a proper lifting device, raise and position

leveler on dock face with the top of the base plate

being flush with the top of the embedded channel.

Position ends of base plate to match up with

marks made previously.

4. Tack weld base plate to dock steel on left hand

end of the leveler. Check right hand end of base

plate, ensure that end is against dock steel and

that the top of the base plate is still flush with the

top of the embedded channel. Tack right hand

end to dock steel.

5. Position bump blocks out approximately 5/8” from

the edge of the inside flange of the bump block

to the end of the base plate. This will allow for

vertical welding of both the base plate and the

bump block flange back to the dock steel. Top of

the bump block cover plate should be flush with

the top of the embed channel. Tack weld bump

blocks to dock steel.

6. Check the positioning of the base plate and the

bump blocks.

7. Complete welding of tacked parts as follows:

A. Apply a continuous weld across top of each

bumper and base plate to dock steel. Skip

welding is acceptable to prevent warpage,

but complete weld across the top must be

completed.

B. Weld vertically along each end of base plate

and on both inboard and outboard flanges of

bump blocks.

C. Fully plug weld all holes in base plate.

8. Installer must remove all welding slag, and repaint

welded areas.

9. Installer must adjust springs on all mechanical

Edge of Dock levelers to provide desired tension

for smooth operation. Stand in front of leveler, with

the unit raised and secured in the maintenance

position, loosen jam nut on the underside of the

linkage pin. To start allow about 3/4” to 1” of

threads between top of jam nut and linkage pin.

Using an open faced wrench, hold locknut on

inside of spring while tightening threaded bolt until

washer on top side of spring closes up tight to jam

nut. Test operation of unit. Further adjust spring

tension if needed by advancing jam nut toward

linkage pin and tightening threaded rod. After

desired unit operation is achieved, tighten jam

nut to outer washer on spring. Springs must be

adjusted alternately to have equal spring tension.

10. Before install is complete, installer must make

a final operational check of dock leveler to

verify all phases of install are correct. Installer

must complete, sign and return the Installation

Checklist upon completion. Reference page 22

Follow all safety precautions prior to installation.

11

Manual No. 4111-0025

March 2011

May 2012

NOTE DESCRIPTION

1

Top of base plate and bumper

cover plate to be flush with top of

dock floor and embedded channel

2

Apply continuous bevel weld

across both bumpers and length of

base plate.

INSTALLATION

Securely block or support ramp and lip when in

vertical positions. Lack of proper bracing can result

in ramp dropping during adjustment or installation

causing personal injury or damage to unit.

12 Manual No. 4111-0025

March 2011

May 2012

INSTALLATION

A ramp mount weld on application is used when adequate

dock steel is securely anchored in the concrete at the dock

edge, but the existing dock height is too low and the dock

leveler must be installed above this height to correct this

situation.

Installation Steps:

1. Remove all existing bumper material and protruding

objects from dock edge. Clean and sweep dock

edge free of debris and flammable chemicals before

installing unit.

2. At chosen location for Edge of Dock leveler, locate the

center of space and mark a point half of the base plate

width to the left and right.

3. At the points marked to each side of center, measure

and mark points 7 - 3/4” below dock level less height

the unit is to be raised to locate bottom of base plate.

This will locate the top of the base plate X” above dock

level.

4. Using a proper lifting device, raise and position the

leveler base plate to marked position. While holding

base plate tight against dock face, tack weld securely

to dock steel on left hand end of leveler. Check right

hand end of base plate, ensure that end is against dock

steel and that the bottom of the base plate is even with

the marks made previously. Tack right hand end to

dock steel. Support unit until final welding is ready to

complete.

5. Position bump blocks out approximately 5/8” out from

the edge of the inside flange of the bump block to the

end of the base plate. Position the top of the tread

cover plate on the bump blocks to be flush with the

top of the base plate. Tack weld bump blocks to dock

steel.

6. Place steel ramp plate in position, flush with top

backside of base plate. Mark along full length of back

edge of ramp plate. Slide ramp plate forward over dock

leveler the width of bushing tool, approximately 2”.

7. Place bushing tool on marked line at each end of ramp

to ensure proper alignment at both ends, and tack weld

ramp plate to dock leveler to hold ramp plate in place

while bushing. A Skil Roto Hammer #736 or similar tool

is recommended.

8. Using the back edge of the ramp plate as a guide,

groove concrete approximately 3/4” deep by 2” wide,

and should be the entire length of ramp plate.

9. Break tack welds holding ramp in place, slide ramp

plate back into position with the top of the ramp plate

flush with the top of the base plate. Tack weld each

end and center of ramp plate to base plate.

10. Drill 5/8” dia. by 5” deep holes through ramp plate at

back edge. Install anchor bolts per manufacturers

specifications, and tighten securely. Weld anchor bolt

nuts to ramp plate using a 1/4” fillet weld all the way

around the nut. Cut off any portion of the anchor bolt

exposed through the nut, and plug weld around the top

of the nut to the anchor bolt. Ensure the top of the nuts

are well rounded for smooth rollover.

11. Complete welding of tacked parts as follows:

A. Apply continuous weld across top of each bumper

and base plate to ramp plate. Skip welding is

acceptable to prevent warpage, but complete

weld must be completed.

B. Weld vertically along each end of base plate and

on both inboard and outboard flanges of bump

blocks.

C Fully plug weld all holes in base plate.

12. Installer must remove all welding slag, and repaint

welded areas.

13. Installer must adjust main springs on all mechanical

Edge of Dock levelers to provide desired tension for

smooth operation. Stand on ground in front of leveler,

with the unit raised and secured in the maintenance

position, loosen jam nut on the underside of the linkage

pin. To start allow about 3/4” to 1” of threads between

top of jam nut and linkage pin. Using an open faced

wrench, hold locknut on inside of spring while tightening

threaded bolt until washer on top side of spring closes

up tight to jam nut. Test operation of unit. Further

adjust spring tension if needed by advancing jam nut

toward linkage pin and tightening threaded rod. After

desired unit operation is achieved, tighten jam nut to

outer washer on spring. Springs must be adjusted

alternately to have equal spring tension.

14. Before install is complete, installer must make a final

operational check of dock leveler to verify all phases

of install are correct. Installer must complete, sign,

and return the Installation Checklist upon completion.

Reference page 22

E.O.D. Installation Instructions - Ramp Mount - Weld/Bolt On

Follow all safety precautions prior to installation.

13

Manual No. 4111-0025

March 2011

May 2012

NOTE DESCRIPTION

1

Top of base plate and bumper

cover plate to be flush with top of

ramp plate.

2

Apply continuous bevel weld

across both bumpers and length of

base plate.

3

To figure ramp plate length, need

12” ramp for every 1-1/2” of rise

to ramp.

INSTALLATION

Securely block or support ramp and lip when in

vertical positions. Lack of proper bracing can result

in ramp dropping during adjustment or installation

causing personal injury or damage to unit.

14 Manual No. 4111-0025

March 2011

May 2012

INSTALLATION

A flush mount bolt on application is used when there

is no steel on dock edge, and the dock height is

adequate. Additional steel ramp plate and bolting is

required with this type of installation.

Installation Steps:

1. Remove all existing bumper material and

protruding objects from dock edge. Clean and

sweep dock edge free of debris and flammable

chemicals before installing unit.

2. At chosen location for Edge of Dock leveler,

locate the center of space and mark a point half of

the base plate width to the left and right.

3. At the points marked to each side of center,

measure and mark points 7-1/2” below dock level

(for 1/4” ramp plate) to locate position for bottom

of base plate. This position will place the top of

the base plate 1/4” above the dock floor. This

position will vary with ramp plate thickness.

4. Mark line connecting these points and position

support angles. Position angles as shown in

installation drawing provided. Mark center of

holes in each of the support angels.

5. At center marks, drill holes 5/8” dial. by 5”

deep in concrete. Install anchor bolts with

washers through support angles into holes in

concrete. Tighten bolts until support angles are

secure. Follow anchor manufacturers installation

instructions for proper installation.

6. Using a proper lifting device, raise and position

the leveler base plate to marked position, while

resting on the support angles. While holding base

plate tight against dock face, tack weld securely

to support angles.

7. Drill 5/8” dia. by 5” deep holes in concrete through

holes in base plate, and install anchor bolts with

washers and tighten securely.

8. Position bump blocks out approximately 5/8” out

from the edge of the inside flange of the bump

block to the end of the base plate. Position the

top of the tread cover plate on the bump blocks to

be 1/4” above dock level. Note that this placement

will vary with ramp plate thickness. Mark centers

of holes in bump block flanges.

9. Drill 5/8” dia. by 5” deep holes at center marks.

Reposition bump blocks, insert anchor bolts with

washers and tighten securely to dock face.

10. Place steel ramp plate in position, flush with top

backside of base plate. Mark along full length

of base edge of ramp plate. Slide ramp plate

forward over dock leveler the width of brushing

tool, approximately 2”.

11. Place bushing tool on marked line at each end of

ramp to ensure proper alignment at both ends,

and tack weld ramp plate to dock leveler to hold

ramp plate in place while bushing. A Skil Roto

Hammer #736 or similar tool is recommended.

12. Using the back edge of the ramp plate as a guide,

groove concrete approximately 5/8” deep by 2”

wide, and should be the entire length of ramp

plate.

13. Break tack welds holding ramp in place, slide

ramp plate back into position with the top of the

ramp plate flush with the top of the base plate.

Tack weld each end and center of ramp plate to

base plate.

14. Drill 5/8” dia. by 5” deep holes through ramp plate at

back edge. Install anchor bolts per manufacturers

specifications, and tighten securely. Weld anchor

bolt nuts to ramp plate using a 1/4” fillet weld all

the way around the nut. Cut off any portion of the

anchor bolt exposed through the nut, and plug

weld around the top of the nut to the anchor bolt.

Ensure the top of the nuts are well rounded for

smooth rollover.

15. Complete welding of tacked parts as follows:

A. Apply continuous weld across top of each

bumper and base plate to ramp plate. Skip

welding is acceptable to prevent warpage,

but complete weld must be completed.

B. Weld bottom of base plate support angles

using a 1/4” fillet weld.

16. Installer must remove all welding slag, and

repaint welded ares.

17. Installer must adjust main springs on all mechanical

edge of dock levelers to provide desired tension

for smooth operation. Stand on ground in front

E.O.D. Installation Instructions - Flush Mount - Bolt On

Follow all safety precautions prior to installation.

15

Manual No. 4111-0025

March 2011

May 2012

of lever, with the unit raised and secured in the

maintenance position, loosen jam nut on the

underside of the linkage pin. To start allow about

3/4” to 1” of threads between top of jam nut

and linkage pin. Using an open faced wrench,

hold locknut on inside of spring while tightening

threaded bolt until washer on top side of spring

closes up tight to ram nut. Test operation of

unit. Further adjust spring tension if needed

by advancing jam nut toward linkage pin and

tightening threaded rod. After desired operation

is achieved, tighten jam nut to outer washer on

spring. Springs must be adjusted alternately to

have equal spring tension.

18. Before install is complete, installer must make

a final operation check of dock leveler to verify

all phases of install are correct. Installer must

complete, sign and return the Installation Checklist

up on completion. reference page 22

INSTALLATION

NOTE DESCRIPTION

1

Top of base plate and bumper

cover plate to be flush with top of

ramp plate.

2

Apply continuous bevel weld

across both bumpers and length of

base plate.

Securely block or support ramp and lip when in

vertical positions. Lack of proper bracing can result

in ramp dropping during adjustment or installation

causing personal injury or damage to unit.

16 Manual No. 4111-0025

March 2011

May 2012

INSTALLATION

A ramp mount-weld on used with a formed angle application

is used when dock edge is damaged, there is no dock steel

securely anchored into the concrete, and the dock height is

too low and leveler must be installed above this height to

correct this situation.

Installation Steps:

1. Remove all existing bumper material and protruding

objects from dock edge. Clean and sweep dock

edge free of debris and flammable chemicals before

installing unit.

2. Review and follow formed angle installation instructions

prior to leveler installation. Page 18

3. At chosen location for Edge of Dock leveler, locate the

center of space and mark a point half of the base plate

width to the left and right.

4. At the points marked to each side of center, measure

and mark points 7-3/4” below dock level less height the

unit is to be raised to locate bottom of base plate. This

will locate the top of the base plate X” above dock level.

5. Using a proper lifting device, raise and position the

leveler base plate to marked position. While holding

base plate tight against dock face, tack weld securely

to dock steel on left hand end of leveler. Check right

hand end of base plate, ensure that end is against dock

steel and that the bottom of the base plate is even with

the marks made previously. Tack right hand end to

dock steel. Support unit until final welding is ready to

complete.

6. Position bump blocks out approximately 5/8” out from

the edge of the inside flange of the bump block to the

end of the base plate. Position the top of the tread

cover plate on the bump blocks to be flush with the

top of the base plate. Tack weld bump blocks to dock

steel.

7. Place steel ramp plate in position, flush with top

backside of base plate. Mark along full length of back

edge of ramp plate. Slide ramp plate forward over dock

leveler the width of bushing tool, approximately, 2”.

8. Place bushing tool on marked line at each end of ramp

to ensure proper alignment at both ends, and tack weld

ramp plate to dock leveler to hold ramp plate in place

while bushing. A Skil Roto Hammer #736 or similar tool

is recommended.

9. Using the back edge of the ramp plate as a guide,

groove concrete approximately 3/4” deep by 2” wide,

and should be the entire length of ramp plate.

10. Break tack welds holding ramp in place, slide ramp

plate back into position with the top of the ramp plate

flush with the top of the base plate. Tack weld each

end and center of ramp plate to base plate.

11. Drill 5/8” dia. by 5” deep holes through ramp plate at

back edge. Install anchor bolts per manufacturers

specifications, and tighten securely. Weld anchor bolt

nuts to ramp plate using a 1/4” fillet weld all the way

around the nut. Cut off any portion of the anchor bolt

exposed through the nut, and plug weld around the top

of the nut to the anchor bolt. Ensure the top of the nuts

are well rounded for smooth rollover.

12. Complete welding of tacked parts as follows:

A. Apply continuous weld across top of each bumper

and base plate to ramp plate. Skip welding is

acceptable to prevent warpage, but complete

weld must be completed.

B Weld vertically along each end of base plate and

on both inboard and outboard flanges of bump

blocks.

C Fully plug weld all holes in base plate.

13. Installer must remove all welding slag, and repaint

welded areas.

14. Installer must adjust main springs on all mechanical

Edge of Dock levelers to provide desired tension for

smooth operation. Stand on ground in front of leveler,

with the unit raised and secured in the maintenance

position, loosen jam nut on the underside of the linkage

pin. To start allow about 3/4” to 1” of threads between

top of jam nut and linkage pin. Using an open faced

wrench, hold locknut on inside of spring while tightening

threaded bolt until washer on top side sprint closes

up tight to jam nut. Test operation of unit. Further

adjust spring tension if needed by advancing jam nut

toward linkage pin and tightening threaded rod. After

desired unit operation is achieved, tighten jam nut to

outer washer on spring. Springs must be adjusted

alternately to have equal spring tension.

15. Before install is complete, installer must make a final

operational check of dock leveler to verify all phases

of install are correct. Installer must complete, sign,

and return the Installation Checklist upon completion.

reference page 22.

E.O.D. Installation Instructions - Ramp Mount - Weld On w/Formed Angle

Follow all safety precautions prior to installation.

17

Manual No. 4111-0025

March 2011

May 2012

INSTALLATION

NOTE DESCRIPTION

1

Top of base plate and bumper

cover plate to be flush with top of

ramp plate.

2

Apply continuous bevel weld

across both bumpers and length of

base plate.

3

To figure ramp plate length, need

12” ramp for every 1-1/2” of rise

to ramp.

4To install formed angle, see formed

angle installation instructions.

Securely block or support ramp and lip when in

vertical positions. Lack of proper bracing can result

in ramp dropping during adjustment or installation

causing personal injury or damage to unit.

18 Manual No. 4111-0025

March 2011

May 2012

INSTALLATION

A formed angle is used when there is no existing

dock steel and concrete at the dock edge has been

damaged. The formed angle is required to rebuild the

damaged concrete edge for a proper installation if the

dock height is adequate.

Installation Steps:

1. Remove all existing bumper material and

protruding objects from dock edge. Clean and

sweep dock edge free of debris and flammable

chemicals before installing unit.

2. At chosen location for the formed angle, locate

the center of space and mark a point half of the

angle width to the left and right.

3. Using a proper lifting device, raise and position

the formed angle to marked position, slide formed

angle against dock face.

4. Mark along full length of back edge of formed

angle. Slide angle forward the width of brushing

tool, approximately 2”.

5. Place bushing tool on marked line at each end of

formed angle to ensure proper alignment at both

ends. A Skil Roto Hammer #736 or similar tool is

recommended.

6. Using the back edge of the formed angle as a

guide, groove concrete approximately 5/8” deep

by 2” wide, and should be the entire length of the

formed angle.

7. Slide formed angle back until tight against dock

face. drill 5/8” dia. by 5” deep holes through

formed angle at back edge. Install anchor bolts

per manufacturers specifications, and tighten

securely. Weld anchor bolt nuts to formed angle

using a 1/4” fillet weld all the way around the nut.

Cut off any portion of the anchor bolt exposed

through the nut, and plug weld around the top of

the nut to the anchor bolt. Ensure the top of the

nuts are well rounded for smooth rollover.

8. Drill 5/8” dia. by 5” deep holes in dock face

through holes in formed angle. Install anchor

bolts with washers and tighten securely per

manufacturers specifications.

E.O.D. Installation Instructions - Formed Angle

Follow all safety precautions prior to installation.

This manual suits for next models

13

Table of contents

Other DLM Lifting System manuals