TO THE OWNER

Your new DMI “Turbo-Tiger” is the most versatile machine you can own. The ease of operation and ability to hydraulically adjust

on the go from the tractor seat, make this a non-stop tillage tool. The Turbo-Tiger will do an excellent job and give years of reliable

service when used according to these simple principles listed below.

SHANKS

SHANK DEPTH IS NOT TO EXCEED 16”. The points on the Turbo-Tiger shanks are designed to work at the plow sole level.

Best results are when the very point is about 2” or just above the plow sole. The winged points will fracture the soil, lift, twist, &

turn this layer without creating a new plow sole. The Turbo-Tiger is not designed to be a deep sub-soiler implement. The fracturing

of the plow sole allows moisture, freezing and thawing action to extend the crop root zone, provides a loosened soil for faster warm

up in the spring and better drainage of spring moisture.

LEVELING MACHINE

THE “A” FRAME OF THE TURBO-TIGER MUST BE LEVEL. The hitch clevis can & must be positioned to provide a level A-

frame. A low front end will surely result in excessive disc depth and “floating out” of the shanks. The disc frame itself must be

level. The distance from level ground to the bottom of the discs must be the same for both front & rear disc rows. The long

turnbuckle provides adjustment. NOTE: WHEN LEVELING THE DISC FRAME DO NOT MEASURE THE REAR, OUTSIDE

BLADES; THEY ARE DESIGNED TO RN 1 INCH LESS DEEP. Performance will suffer and machine damage is certain if the

front discs are higher or lower that the rear discs and the discs are run deep.

DISC BLADES

THE DISC DEPTH MUST NOT EXCEED 5 INCHES. Best performance is in the range of 3 to 4 inches. Excessive disc depth

increases horsepower, fuel consumption, reduces tractor forward speed below the optimum 5-6 MPH, decreases trash mixing &

coverage and leads to excessive wear and tear on equipment. Running the discs over 5” deep causes the shanks to float up. The

winged shank points are not down in the plow sole and not lifting, turning, and breaking up the soil in the plow sole area as the

Turbo-Tiger is designed to do.

The Turbo-Tiger is not designed to till deep and not designed to leave the field “black”. The customer who wants to grind the soil

and trash up finely and run the disc hub deep would be better off with a heavy-duty tandem disc with 32-36 inch disc blades.

The front discs are designed to cut trash, , mix trash with soil, and windrow the mixture, and move the windrow into the path of the

rear discs. The windrow is then re-cut remixed, and moved sideways in the opposite direction to leave the ground level.

A solid 2-1/4” x 2-1/4” solid steel bar attaches each disc hub to the vertical disc post. The 2-1/4” square bar is designed to fail

under extreme loading to prevent damage to the signed to disc frame. BREAKAGE OF THE BARS IS A SURE INDICATION OF

EXCESSIVE DISC DEPTH.

When discs are run over 5” deep, the nut on the top of the long disc spring bolts will be “peened”. This is because the discs are

constantly raising and lowering & slamming the nut against its seat. The constant up & down movement of the disc will also cause

premature wear of the pivot pin mount holes where the disc arm attaches to the disc vertical post. IT IS IMPORTANT TO RAISE

THE DISCS IN HARD PACKED END ROWS AND WHEN TURNING AT FENCE CORNERS.

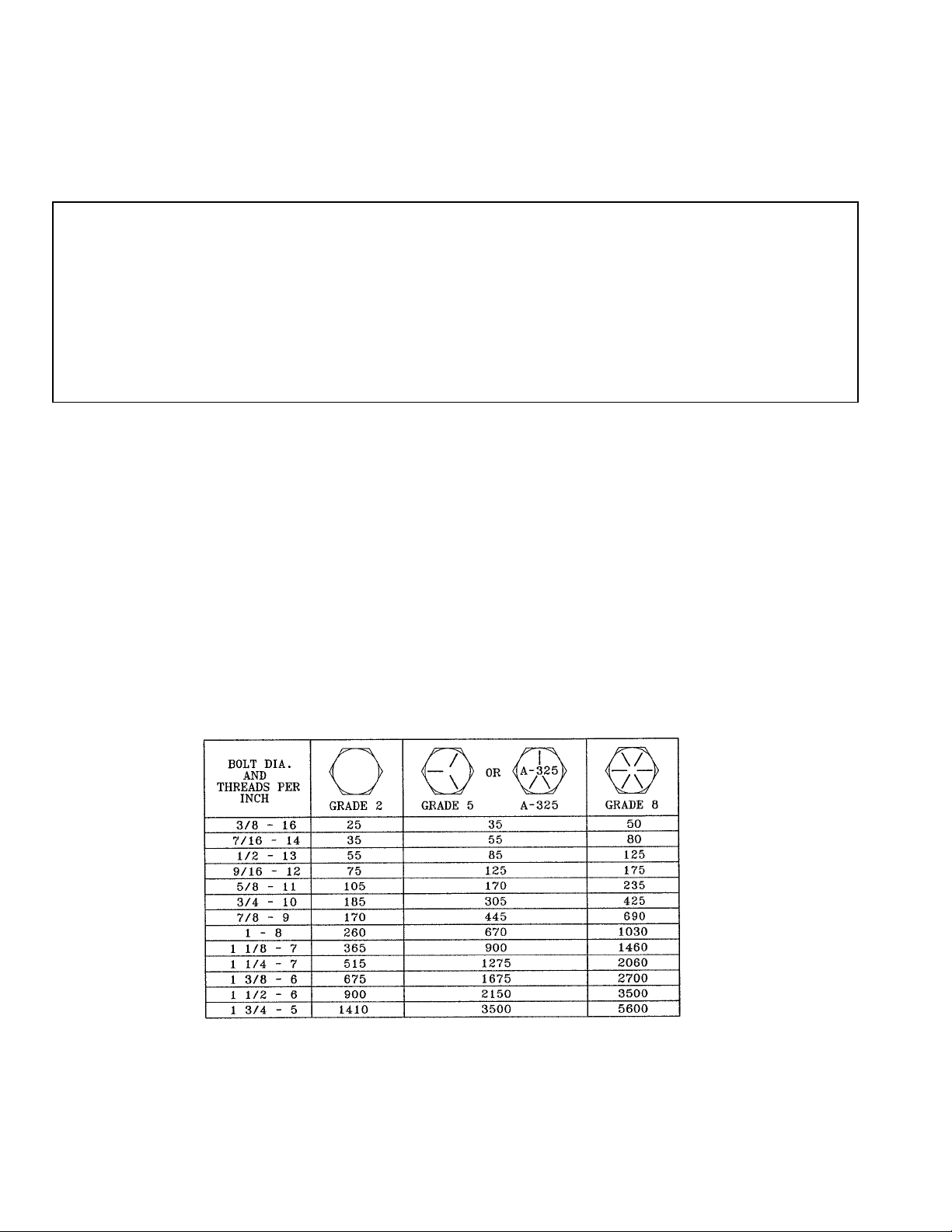

TORQUE

ALL BOLTS ON THE TURBO-TIGER MUST BE FULLY TIGHTENED, AND KEPT TIGHT. This is a massive machine doing

a massive job. Loose bolts mean loose parts and then parts breakage. Below are listed several areas where fully tightened bolts are

of extreme importance because of the expensive damage that can result.

A. The 7/8” dia bolts fastening disc hub to disc mount. Torque to full 450 ft-lbs. Use a 3’ long (minimum) “cheater bar” and

socket with ¾” drive.

B. The 1-3/4” nuts on disc hub spindles. DMI will factory torque these nuts to 1200 ft-lbs. or more.

C. The ¾” dia shear bolt and 7/8” to 450 ft-lbs. – using 3’ long (minimum) “cheater bar” & socket with ¾” drive. Retighten after

a few hundred feet.

2turbo-tiger® – 04 – DMI 10/04