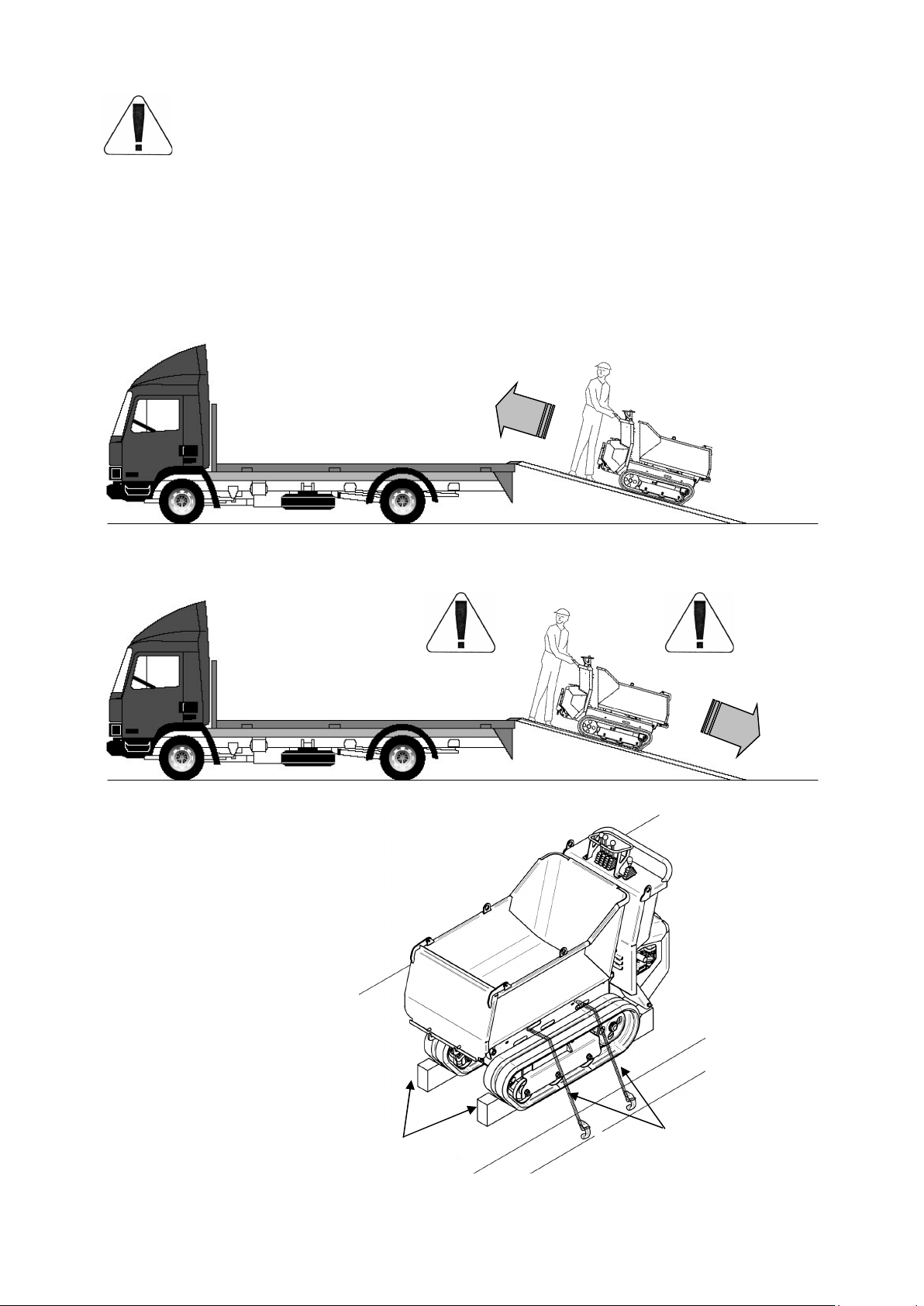

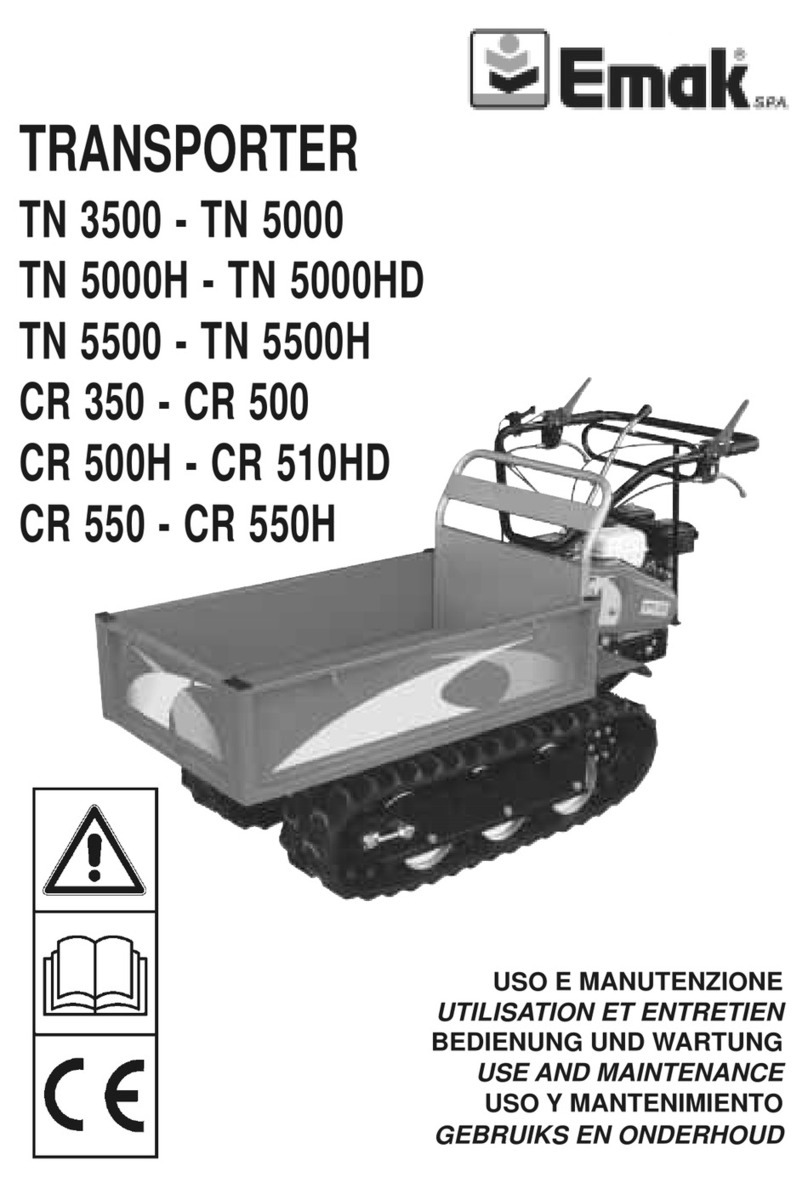

3.3 LIFTING AND TRANSPORTING

See section 2.3 of this manual for the “overall dimensions of the machine”, while for the

loading on a lorry by using ramps, follow what explained below.

Close the loading/unloading areas, forbidding the entrance to foreign people and

clearing the zone from obstacles and dangerous stuffs.

Loading and unloading operations have to be done in a flat and compact surface.

Check that the transport vehicle is in perfect condition. Apply the hand brake and

insert safety wedges at the front and rear of the rear axle tyres. The vehicle engine

must be off and the key removed from the ignition. The body must be level.

Position the machine at the rear of the truck, ensuring that the longitudinal axle

coincides with that of the truck.

Check that the ramps are suitable for the vehicle to be loaded. Only use

homologated and/or certified ramps.

Check that the ramps are perfectly clean and free of grease and that there is no risk

whatsoever of the tracks slipping.

Check that the ramps are long enough to avoid problems during ascent and

descent of the machine. Particularly check the length of the ramps, taking note their

angle with the lorry loading platform has to be between 15° and 16° (30%).

Check that the ramps are properly coupled to the transport vehicle and

appropriately spaced. The width of the ramp must be such as to allow comfortable

passage of the track.

The ascent and descent operations must always be carried out with the machine

running and the hydraulic oil at operating temperature.

Do not use the ramps as a gangway for crossing from one vehicle to the next.

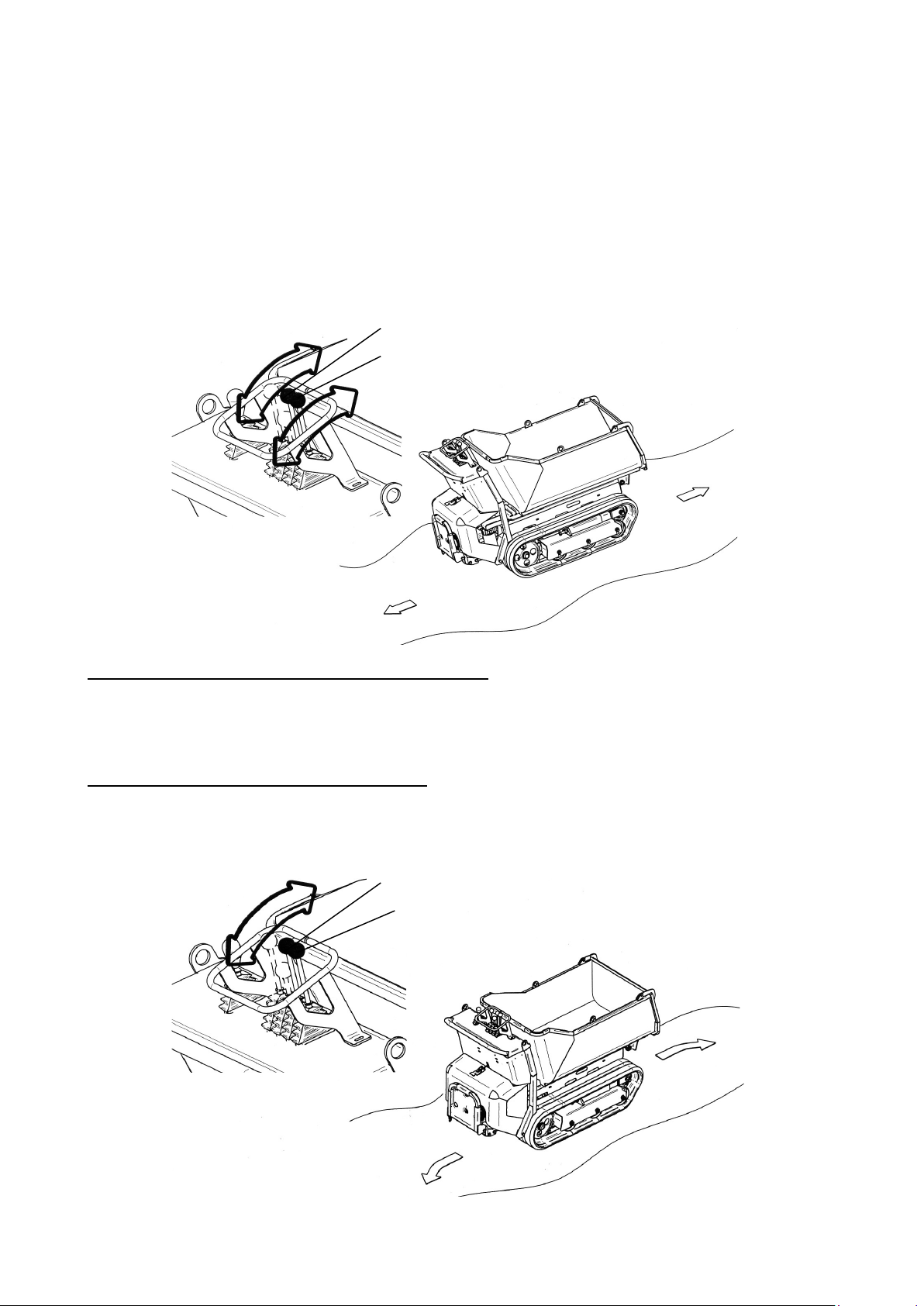

Load and unload the machine in correct driving ways, as explained below.

Before ascending or descending, check perfect alignment between the tracks and

the ramps. Do not steer or adjust direction while on the ramps. If necessary, return

to the point of departure, repositioning correctly.

Caution with pivoting in the connection area between the ramps and the loading

platform of the truck; the steep slope must be negotiated by moving very slowly and

with extreme caution. Be twice as careful in the descent phase since the unbalance

towards the bottom in this case is much higher.

All the loading and unloading operations of the machine must be carried out and co-

ordinated by at least a second person who controls good progress of the

operations.