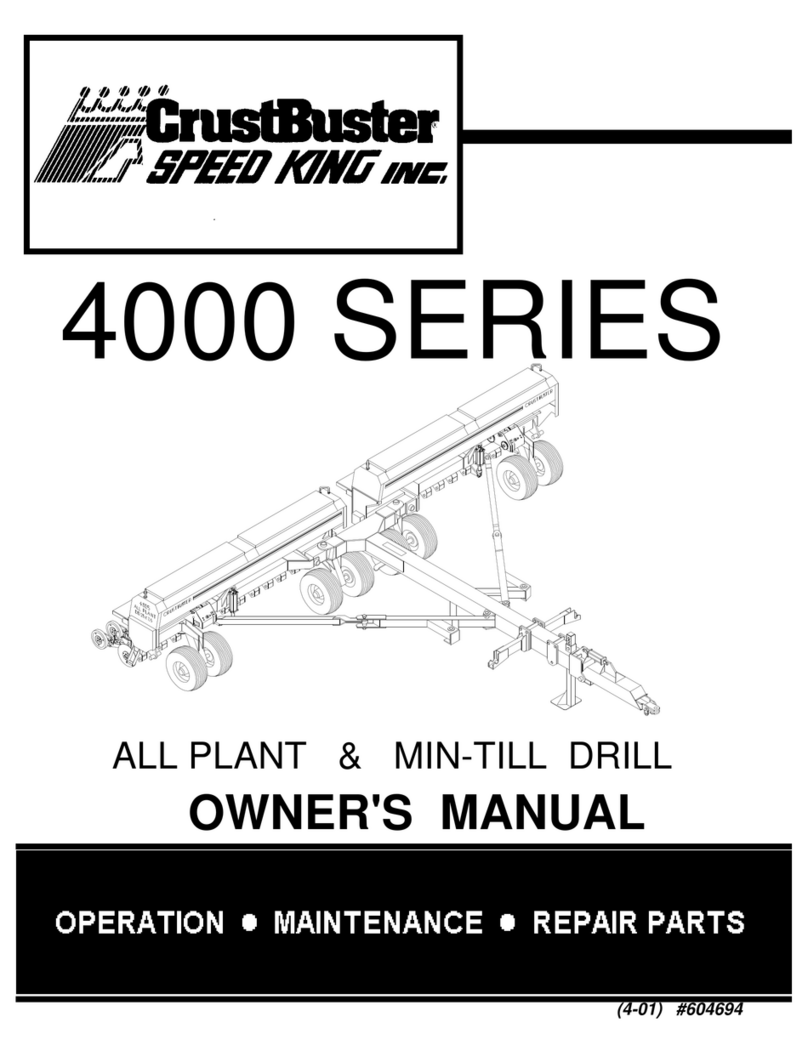

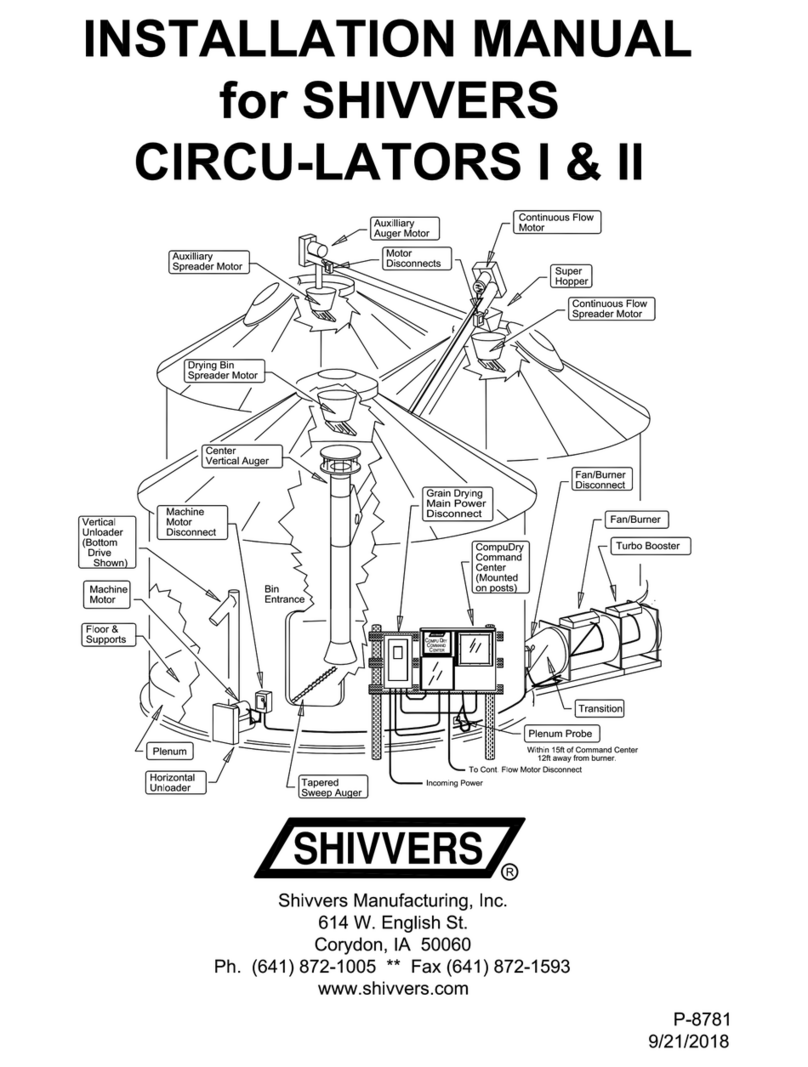

Blade Gap Adjustment

Offset blade designs form better seed furrows

and penetrate and cut in tougher planting condi-

tions. If using the ALL PLANT opener, as the

blades wear the gap between blades will

increase. Removing each blade from the opener

bracket allows the operator to take shim washers

from behind the bearing and re-adjust the blade

gap for better performance. Shim washers that

are removed must then be placed on outside of

blade to maintain length of bolt. Maintain a 1/8" to

3/16" clearance between blades, measuring at

the pinch point. Inadequate clearance will in-

crease wear on the inside of the lead blade and

mean quicker replacement. The lead blade

changes sides on the opener on each half of the

drill. The right blade on ALL PLANT openers is

installed with a right hand threaded bolt. The left

blade is installed with a left hand threaded bolt.

If the MIN-TILL opener is used, the offset design

is achieved by using a 15" leading blade and a 13"

trailing blade. One bolt and lock nut secures both

blades in the proper angle by tightening the bear-

ing races against the opener bracket. Be sure to

hold the bolt as the nut is removed or replaced.

The bolt is bent to the proper angle for the blades

to meet at the front pinch point. Since it is mount-

ed with one bolt, the MIN-TILL opener blades

require no gap at the pinch point. Shim washers

may be needed to achieve this. When tightening

blades, rotate the bent bolt until bearing races are

flat and flush against beveled surface of opener

blade bracket.

ALL PLANT opener shown

Tandem Wheel Drive Clutch

The tandem wheel on the center section that

drives a seed shaft is manufactured with a man-

ual throw-out type clutch.

IMPORTANT: This will need to be disengaged

before road transport.

On the wing sections, tandem wheels that drive a

seed shaft are manufactured with a friction disc

type clutch. If the drive wheel encounters a hole,

ridge, or other situation that may cause a delay in

adequate ground contact, the other wheel will "take

over" driving the seed shaft. During turns, or in the

folding operation, it is necessary the non-drive

wheel can free wheel.

The tire is bolted to the hub using three tap bolts

with tapered wheel nuts and three wheel bolts.

The three tap bolts also bolt on the clutch drive

plate to the backside of the hub. If the wheel must

be removed for service, remove ONLY the three

tapered wheel nuts and three wheel bolts. Pres-

sure on the two friction discs has been factory set.

As drill is used, this may have to be adjusted. This

is done by tightening the four nylock lock nuts and

compressing the four rubber springs to the desired

pressure for wheel slippage. This must be done

with equal pressure on all four springs. DO NOT

over tighten the four rubber spring bolts, as this will

cause damage to the tire and wheel assembly, and

the clutch housing.

CAUTION!

At the start of a new drilling season, or anytime the

drill is going to be used, especially if the drill has

been stored out in the weather all winter long,

make sure the clutch drive is not frozen up.

Failure to do this will result in damage to the clutch

assembly.

To make sure the clutch is not frozen up, loosen

up the clutch bolts. This should free the disc

torque limiter. If not, use a knife to free the torque

limiter from one or the other. Reset clutch back to

where it was. Do Not use any oil or penetrating oil

of any kind.

ENGAGED DISENGAGED

CENTER DRIVE CLUTCH

WING DRIVE CLUTCH

15