1118 Wireless Remote Indicator Light

Description

The 1118 Wireless Remote Indicator Light provides one remote LED indicator that can be used to visually notify the

user that a panic alarm has been activated. The 1118 is designed to operate on one CR123A battery or connect to an

optional 12 VDC power supply.

The 1118 operates with the XR500 or XR100 Series Command Processor™ panels version 119 using the 1100X Wireless

Receiver version 104.

What is Included

The 1118 includes the following:

• One 1118 Wireless Remote Indicator Light

• One 3.0V Lithium CR123A battery

• Hardware pack

• Serial number label

Optional items available:

• One Model 376 DC Power Supply

• One Model 378 Barrel Connector with Cord

Serial Number

For your convenience, an additional pre-printed serial number label is included. Prior to installing the indicator

light, record the serial number or place the pre-printed serial number label on the panel programming sheet. This

number is required during programming.

Programming the 1118 in the Panel

In Output Information enter the output number, output name, eight-digit serial number, and supervision time.

Specic output numbers are available for wireless. Output numbers 450-474 indicate whether the LED responds

within 15 seconds (slow response) or 480-499 indicate whether the LED responds within 1 second (fast response).

Program the 1118 Wireless Remote Indicator Light in Output Options as a Panic Alarm Output. Refer to the XR500

Series Programming Guide (LT-0679) or the XR100 Series Programming Guide (LT-0896).

Note: When a receiver is installed, powered down and powered up, the panel is reset, or programming is complete,

the supervision time is reset. If the receiver has been powered down for more than one hour, the 1118 may take

up to an additional hour to send a supervision message unless tripped, tampered, or powered up. This operation

extends battery life. A missing message may display on the keypad until the supervision message is sent.

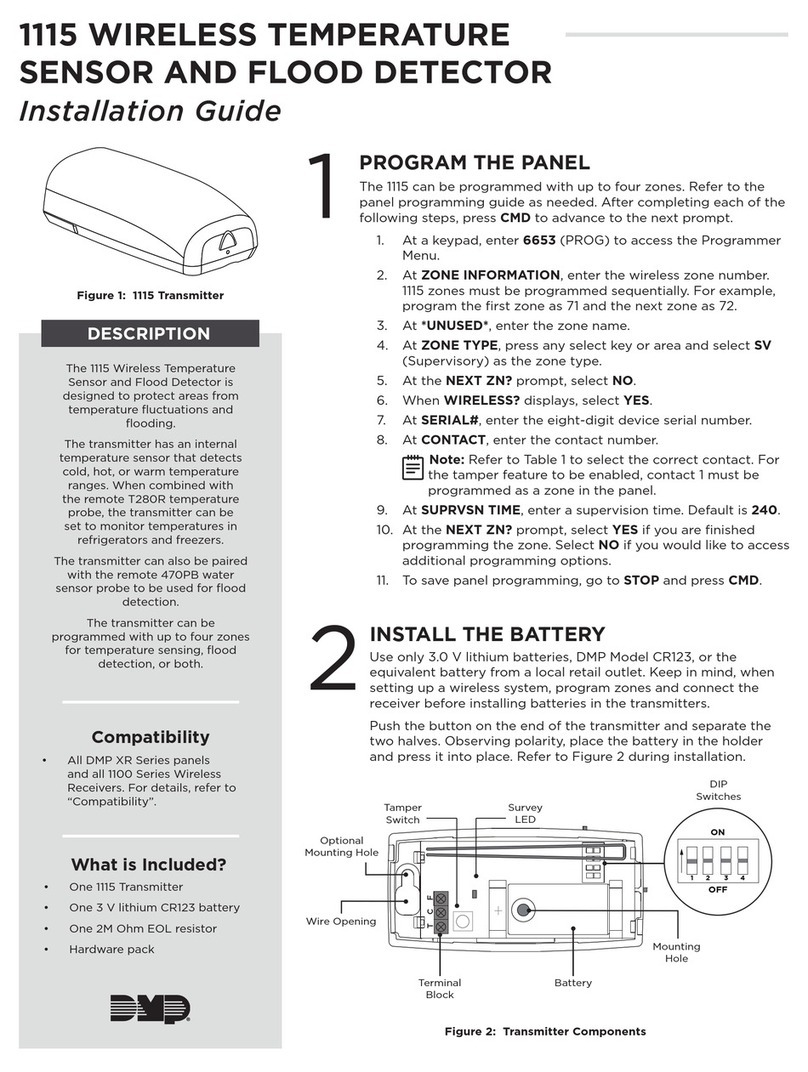

Selecting the Proper Location (LED Survey Operation)

The 1118 provides a survey capability to allow one person to conrm communication with the receiver while the

cover is removed. The 1118 PCB Red Survey LED (see Figure 2) turns on whenever data is sent to the receiver then

immediately turns off when the receiver acknowledgement is received. Pressing the tamper switch is a convenient

way to send data to the receiver to conrm operation. When the 1118 does not receive an acknowledgement from

the receiver, the survey LED remains on for about 8 seconds to let you know communication is not established.

Communication is also faulty when the LED ashes multiple times in quick succession. Relocate the 1118 or

receiver until the LED immediately turns off indicating the 1118 and receiver are communicating properly. Proper

communication between the 1118 and receiver is veried when for each press or release of the tamper switch, the

LED blinks immediately on and immediately off. Repeat this test to conrm ve separate consecutive LED blinks.

Any indication otherwise means proper communication has not been established.

1118 Indicator Light Operation

When a Panic Alarm is sent, the indicator light is on steady for ve (5) minutes and then turns off. When a Panic

Test is sent to the 1118 from the 1100 Series Receiver, the indicator light ashes quickly for ve (5) minutes and then

turns off.

Squeeze to

Remove Cover

Squeeze to

Remove Cover

Power Supply

Plug Location

Red Remote

Indicator Light

Figure 1: 1118 Wireless Remote Indicator Light

INSTALLATION GUIDE