Your still has two output lines, one for the distilled water, and the other for the

excess source water. Two lengths of silicone tubing feeding into a GAC post-filter

attached to a 2-holed silicone carboy bung have been provided. Once you have

your carboy situated, place the bung in the carboy, then cut and attach these two

lengths of tubing to the two stainless steel pipes on either side of the still. The

reason there are pipes on either side is to ensure good drainage from the still, in

cases where the still is not level. The lengths of the tubing should be such as to

allow for smooth downward fall of the distilled water from the still into the GAC

post-filter. The GAC post-filter should be as vertical as possible to provide even

filtration.

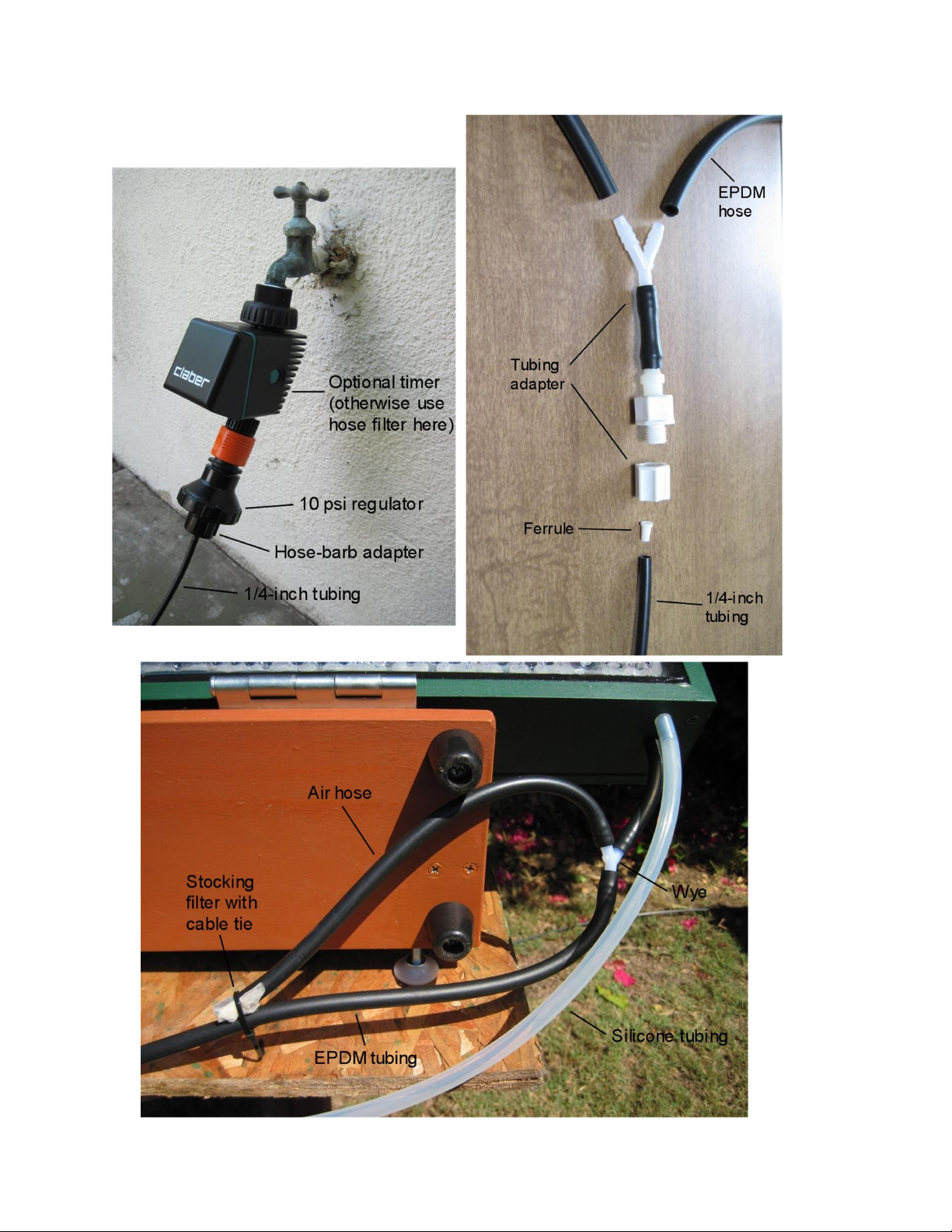

Similarly, there are two copper pipes on either side for the excess source water to

exit. Black EPDM tubing has been provided to attach to these copper pipes. There

is an additional wye in this line to allow for air flow in and out of the still,

necessary to avoid pressure differentials. Attach to this wye a short length of

EPDM tubing with a small piece of stocking on the end to keep bugs from entering

(see photos). This air hose should go up from the wye, but then the stocking end

should point down to prevent dust and rain from coming in. Also, attach the air

hose on the side of the still that is opposite where the water tends to exit (when you

turn on the water later, you’ll see which side the water exits).

There is a second wye for combining the two EPDM tubes together into a single

line. If you choose to collect the excess source water in a pail, then just attach

another short length of EPDM tubing and direct it to the pail. On the other hand, if

you choose to direct the water to a tree or mulch basin, then attach 1/4″drip

irrigation tubing using the tubing adapter that is provided.