4

Donaldson Company, Inc.

1. TIMER DESCRIPTION

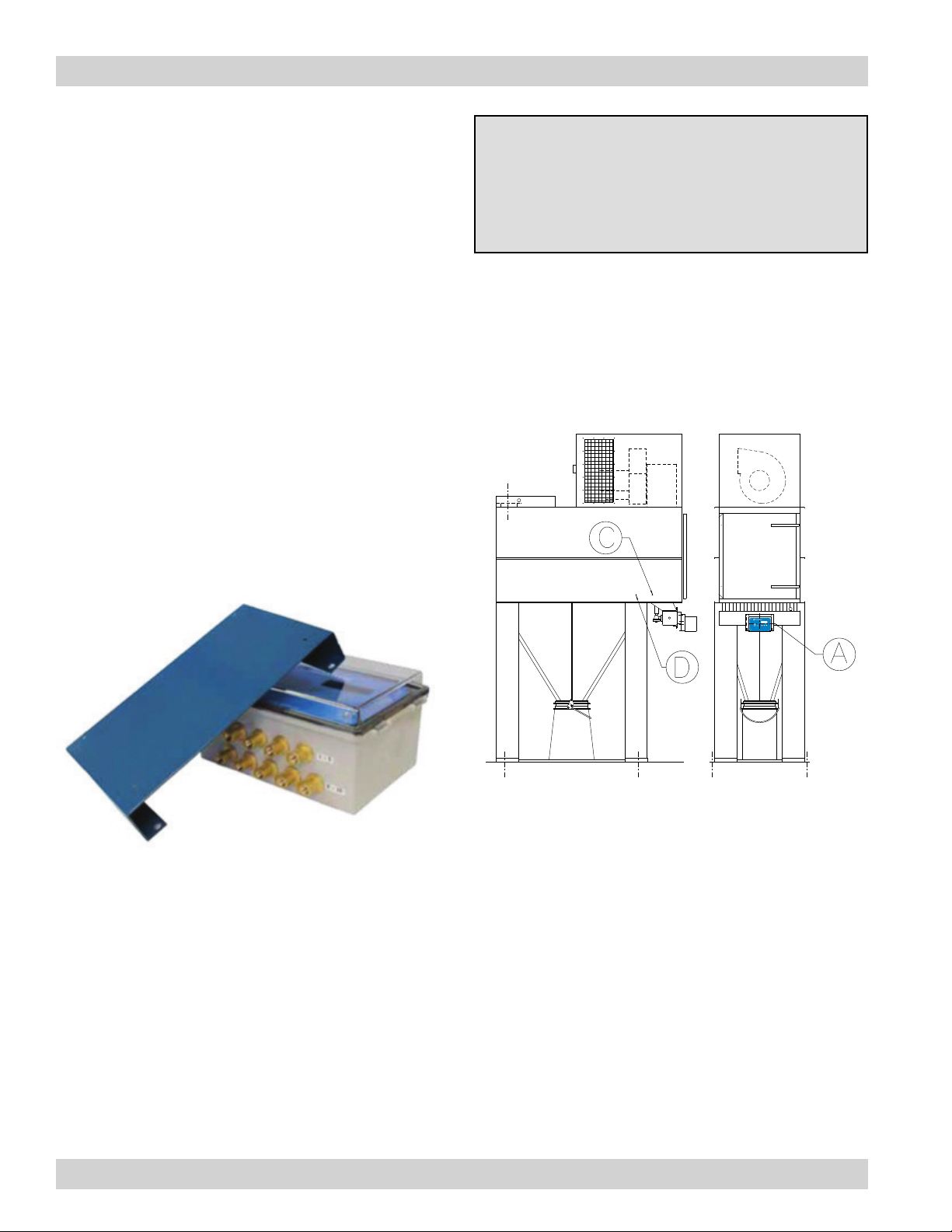

The Solid state pulse Timer intelligent (STi) is the newest

addition to the Donaldson range of timers. This timer

gives a versatile range of options for controlling the

reverse pulse cleaning jets in continuous duty dust

collectors.

The STi timer consists of a master card which is able

to pulse up to 10 solenoid valves. If the timer needs to

control more than 10 valves, the master card needs to

be connected to one or more extension cards using

the supplied CAT5 cable. The master card talks to the

extension cards through differential signalling using the

RS 485 protocol. The addition of each extension card

increases the maximum number of valves that can be

controlled by 10.

At present, three versions are available within the

Donaldson STi timer range:

a. STi timer basic (STi) version. This version fulfills the

basic functions of pulsing the diaphragm valves on

a dust collector and comes with automatic fault

detection features.

b. STi timer with on demand cleaning (STi-ODC) version.

This version monitors the pressure difference

between the clean and dirty air plenums and uses

this information to determine if the filters are clean

or dirty. When the differential pressure crosses the

preset levels, the timer activates cleaning of the filter

media.

c. STi timer with on demand cleaning and tube cleaner

(STi-ODC-TC) version. This version augments on

demand cleaning with its tube cleaner. The tube

cleaner passes a jet of compressed air through

the hose connecting it to the dirty air plenum side

of the collector to dislodge any product that may

accumulate in the tube blocking it. This ensures

reliable measurement of differential pressure

between the dirty and clean air sides of the collector.

The timer is available in two standard configurations. In

the DC configuration these timers drive 24VDC valves

where the input to the timer can be between 110-240

VAC or 24VDC. The timers are also available in a legacy

AC configuration wherein the timers can drive either

110 VAC or 240 VAC solenoids supplied in older dust

collectors, where the input and the output from the timer

are the same (e.g. if the timer is intended to drive 240VAC

solenoid valves then the power input to the timer should

be 240VAC). The timer can be reconfigured to suit special

requirements – please contact your Account Manager to

discuss your specific requirements.

The standard program design of these timers is such

that when only one valve is to be pulsed at any instance

(sequential mode), up to 60 valves can be controlled

by the timer. When more than one valve is to be pulsed

at the same time (parallel mode) there can be up to 4

groups each containing 60 valves. The STi timer can be

custom programmed to allow for a higher number of

valves to be controlled – please contact your Account

Manager to discuss your specific requirements.