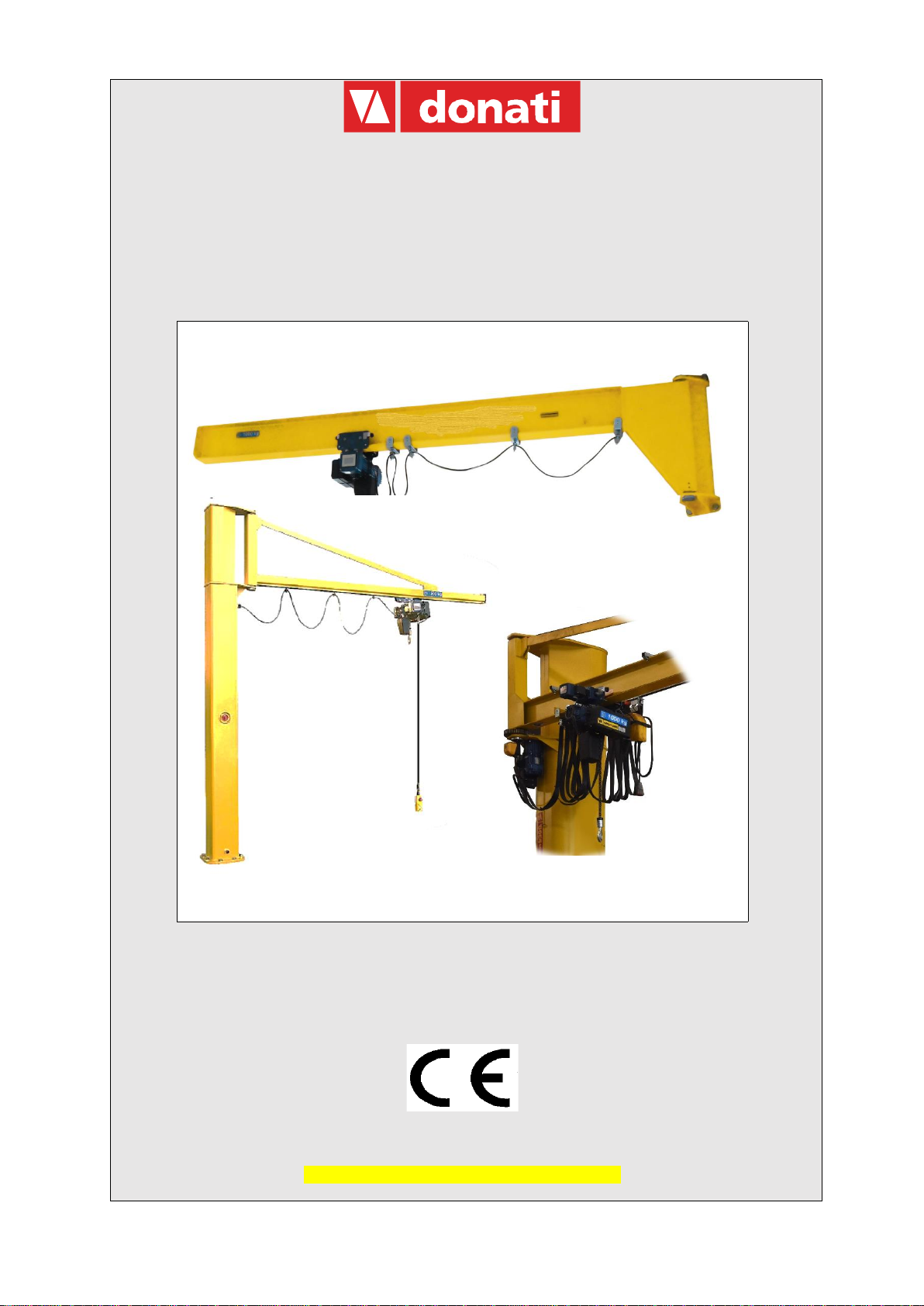

USO E MANUTENZIONE GRU A BANDIERA SERIE

GBA-GBP-CBE-MBE

INDICE DEL CONTENUTO

1PRELIMINARY INFORMATION.........................................................................1

1.1 Contents and use of the manual ............................................................................................... 1

1.2 Symbols: meaning and use ....................................................................................................... 1

1.3 Collaboration with the user........................................................................................................ 2

1.4 Regulatory compliance............................................................................................................... 2

2DESCRIPTION OF THE MACHINE AND TECHNICAL INFORMATION...........4

2.1 The jib cranes with manual/electric rotation............................................................................ 4

2.1.1 Intended use - Expected use - Intended purpose .................................................................4

2.1.2 Installation restrictions...........................................................................................................4

2.1.3 La composizione delle gru a bandiera...................................................................................5

2.2 Technical information and service conditions ........................................................................ 9

2.2.1 Regulatory reference framework ...........................................................................................9

2.2.2 Protection and insulation of electrical parts...........................................................................9

2.2.3 Electrical supply.....................................................................................................................9

2.2.4 Ambient use conditions .........................................................................................................9

2.2.5 Noise - Vibration....................................................................................................................9

2.2.6 Use criteria and operating conditions..................................................................................10

2.2.7 GBA-GBP Series - Manual rotation jib cranes: characteristics and technical data.............11

2.2.8 CBE-MBE Series - Electrical rotation jib cranes: characteristics and technical data..........14

2.2.9 GBA/GBP and CBE/MBE: Fixing systems for jib cranes ....................................................16

3SAFETY AND ACCIDENT PREVENTION .......................................................19

3.1 Authorised operator qualifications ......................................................................................... 19

3.2 General safety regulations....................................................................................................... 20

3.3 Safety symbols.......................................................................................................................... 20

3.4 Warnings on residual risks...................................................................................................... 21

3.5 Safety devices and instructions.............................................................................................. 22

3.5.1 Control devices....................................................................................................................22

3.5.2 Safety and emergency devices for GBA- GBP....................................................................22

3.5.3 Safety and emergency devices for CBE e MBE..................................................................23

3.5.4 Warning and notice devices - Signage summary................................................................23

4HANDLING - INSTALLATION - COMMISSIONING.........................................25

4.1 General notes for delivery........................................................................................................ 25

4.2 Packaging, transport and handling......................................................................................... 26

4.2.1 Standard packaging.............................................................................................................26

4.2.2 Transport .............................................................................................................................26

4.2.3 Handling...............................................................................................................................27

4.2.4 Removal of the packaging and/or checking of the crane parts ...........................................28

4.3 Jib crane installation ................................................................................................................ 28

4.3.1 Installer duties and responsibilities......................................................................................28

4.3.2 Preparation of the installation site .......................................................................................29

4.3.3 GBA –CBE: Assembly of the pillar (foundation plate, counterplate, pillar) ........................30

4.3.4 GBP –MBE: Assembly of the bracket (stir-ups, bracket) ...................................................33

4.3.5 GBA/CBE –GBP/MBE: Assembly of the arm .....................................................................36

4.3.6 S profiles channel arm.........................................................................................................38

4.3.7 Mounting of the trolley block inside the S profile channel arm............................................38

4.3.8 Assembly of the electric system with the connector block ..................................................39

4.3.8.1 Commissioning of the rotation limit switch ..................................................................... 41