Preventative Maintenance Procedure (Every 6 to 12 Months)

A preventative maintenance visit should be performed every 6 to 12 months depending on the usage and environ-

ment where the unit is placed. (Ex. seasonal machines - once before season, year round machines - twice per year).

The following procedures should be performed during a preventative maintenance visit. This does not take the place

of daily care and cleaning procedures as described by local health codes and the manual. PM kit #W0890157 con-

tains the standard replacement parts needed for preventative maintenance including o-rings, standard seal kit stator

bearings and drive belt. Units with a coconut oil product seal should order all parts separately. Units with scraper

blade beater bar will require the scraper blades be ordered separately.

• Verify ventilation is adequate (Air-cooled units: 6” minimum on both sides, open at top, and as far as possible from

dust sources; Water-cooled units: 0” on both sides, 3-6” at rear of unit and open at top).

• Verify adequate water flow and drain connections on water-cooled versions.

• Check product temperature and consistency for proper setting (refer to product manufacturer’s recommendation) -

adjust if necessary. Where equipped be sure to check the temperature in both the hopper and cylinder.

• Ensure product is being mixed properly and is within specification (check brix - most products should be around

13% - refer to product manufacturer’s recommendations for exact recommended brix).

• Check for any leaks.

• Empty product from the unit. Disassemble unit completely (as if for cleaning).

• Clean and sanitize all disassembled parts following the cleaning instructions in the manual.

• Clean and sanitize hopper, freezing cylinder and splash zones on the machine.

• Check condition of all panels and lids - replace if necessary.

• Check beater bar scraper blades for wear if equipped - replace once per year minimum.

• Check beater bar for signs of wear - replace if necessary. Verify alignment when replacing.

• Check valve body gasket for wear - replace once per year minimum.

• Check valve body knobs (used to hold valve body in place) - replace if necessary.

• Check condition of shaft seals and stator bearings - replace once per year minimum.

• Inspect drip cup at back end of freezing cylinder for signs of seal leakage.

• Replace o-rings on hopper float (where necessary), dispense valves and feed tubes (lubricate).

• Lubricate parts where appropriate (dispense valve o-rings, feed tube o-rings, rubber boot of stationary shaft seal).

• Re-assemble unit and sanitize hopper and freezing cylinder by running CLEAN cycle.

• Clean and sanitize spinner if equipped.

• Check operation of merchandiser and mode lights - replace light bulbs if necessary.

• Clean reusable filter if equipped. Check condition of filter and replace if necessary.

• Clean condenser.

• Inspect the drive shaft and motor shaft bearings for excessive wear (drive shaft hole rounding out) - replace if

necessary. Verify alignment when replacing.

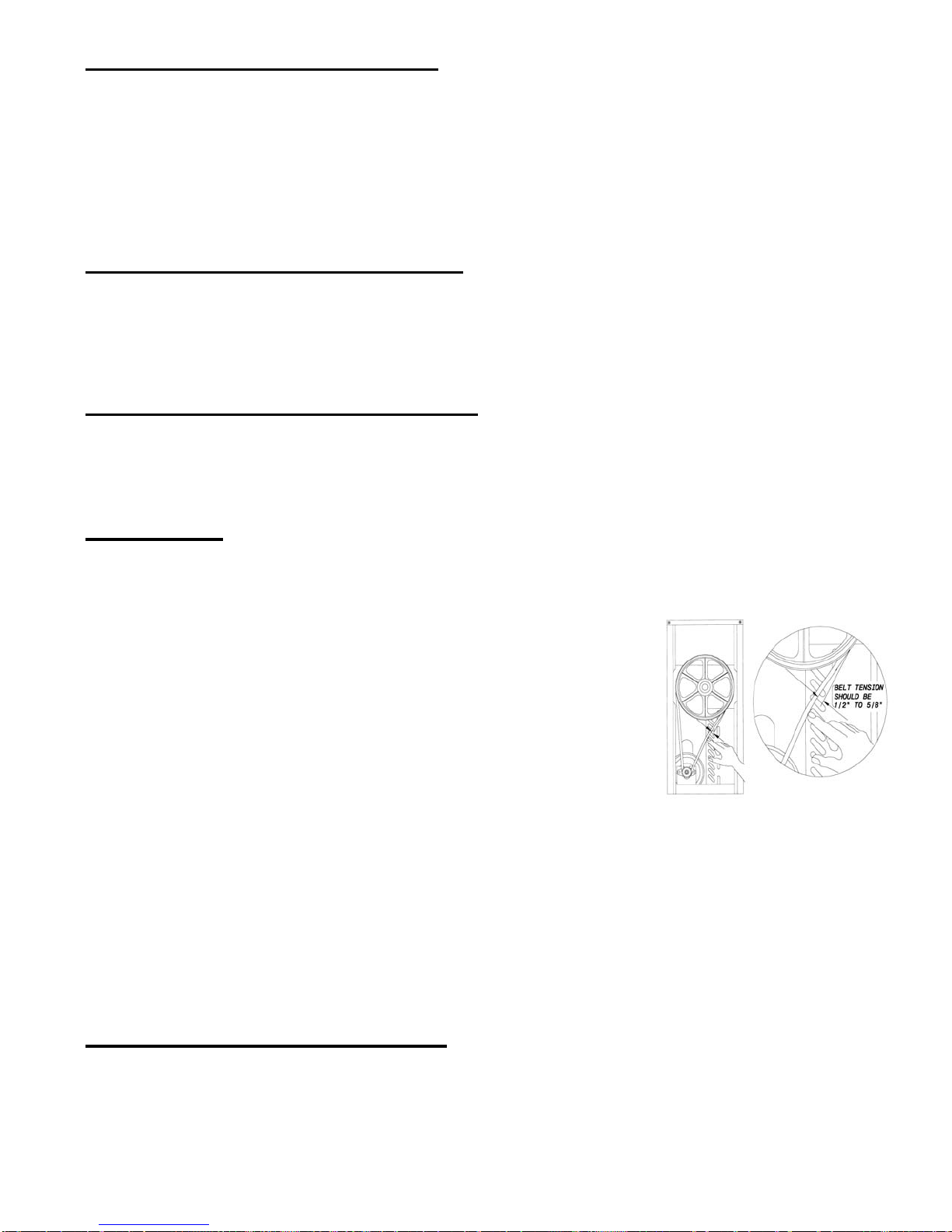

• Check V-belt tension (should be 1/2” - 5/8”) and verify all set screws are tightened - adjust if out of range. Replace

belt once per year minimum.

• Verify compressor operation and machine controller operation.

• Check electrical connections (outlet should be properly grounded with amperage capacity equal to or over the

amperage specified on the serial tag).

• Check fan operation (condenser fan) and clean fan blades if necessary.

• Review proper periodic care and cleaning instructions (disassembly, cleaning, sanitizing, lubrication, and

re-assembly) with store personnel. Train store personnel to follow proper procedures (stress importance of store

level maintenance ie. lubrication, filter cleaning, etc.).

• Make sure store personnel have appropriate supplies (lubricant, cleaning brushes and sanitizer) to care for

machine.