22023-08 / 16676

DORMA-Glas

WN 059546 45532

UNIQUIN Mounting profile About this manual

1 About this manual

1.1 Information about the manual

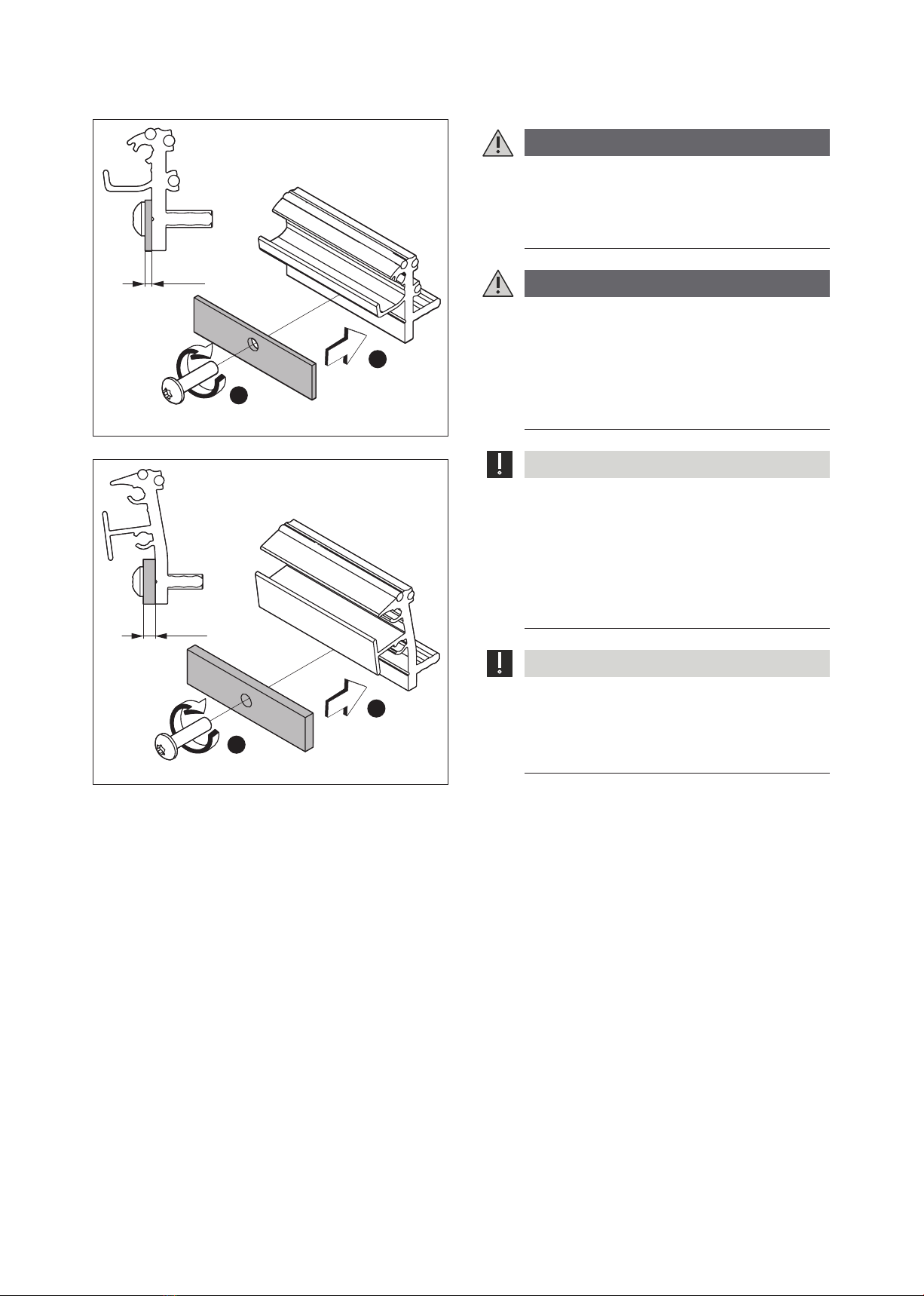

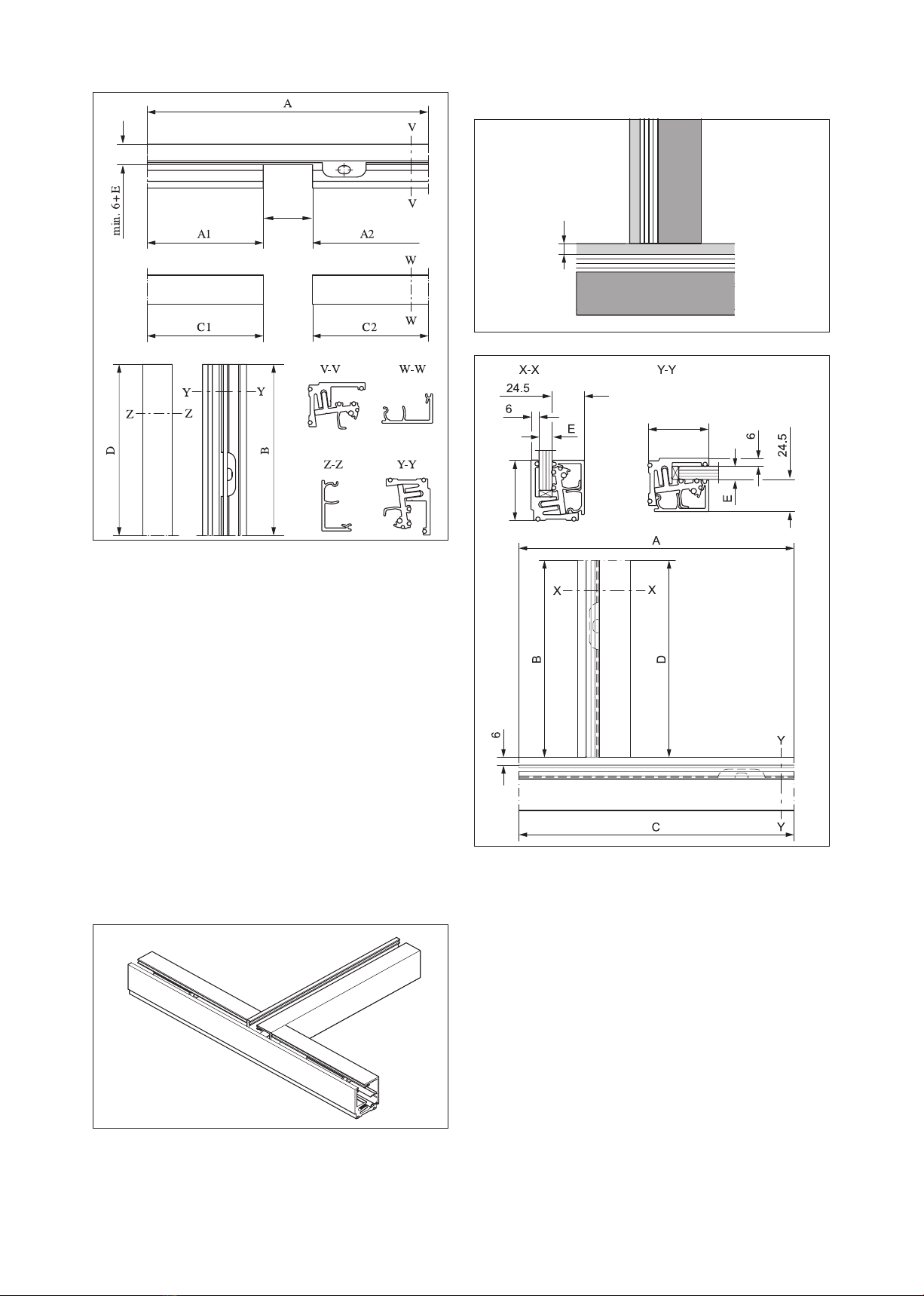

This manual describes how to install a UNIQUIN mounting

profile as part of a UNIQUIN partition wall system and provides

maintenance and care information.

Further unit components and mounting instructions may be

required to complete the UNIQUIN partition wall unit’s mounting

according to the project-related unit drawing, e.g. for the

door frame unit with hinges and overpanel. The illustrated unit

components and configurations are exemplary and do not show

every possible mounting situation.

1.2 Other applicable documents

Refer to the following technical documents for the product:

• The project-related unit drawing

• The mounting instructions of all unit components

• The UNIQUIN system manual

1.3 Target group

The target group of these mounting instructions is qualified

personnel who have been specially trained in glazing installation.

1.4 Symbols used

1.4.1 Safety instructions

Safety instructions are marked with symbols. The safety

instructions are introduced by signal words that express the extent

of the hazard, e.g.:

WARNING

This signal word indicates a situation of potential

risk, which could lead to death or serious injury if not

averted.

CAUTION

This signal word indicates a situation of potential risk,

which could lead to minor or slight injury if not averted.

ATTENTION

This signal word indicates a situation of potential

risk that could lead to damage to property or the

environment if not averted.

NOTE

This signal word indicates useful information for

ecient and trouble-free operation.

1.4.2 Further labeling

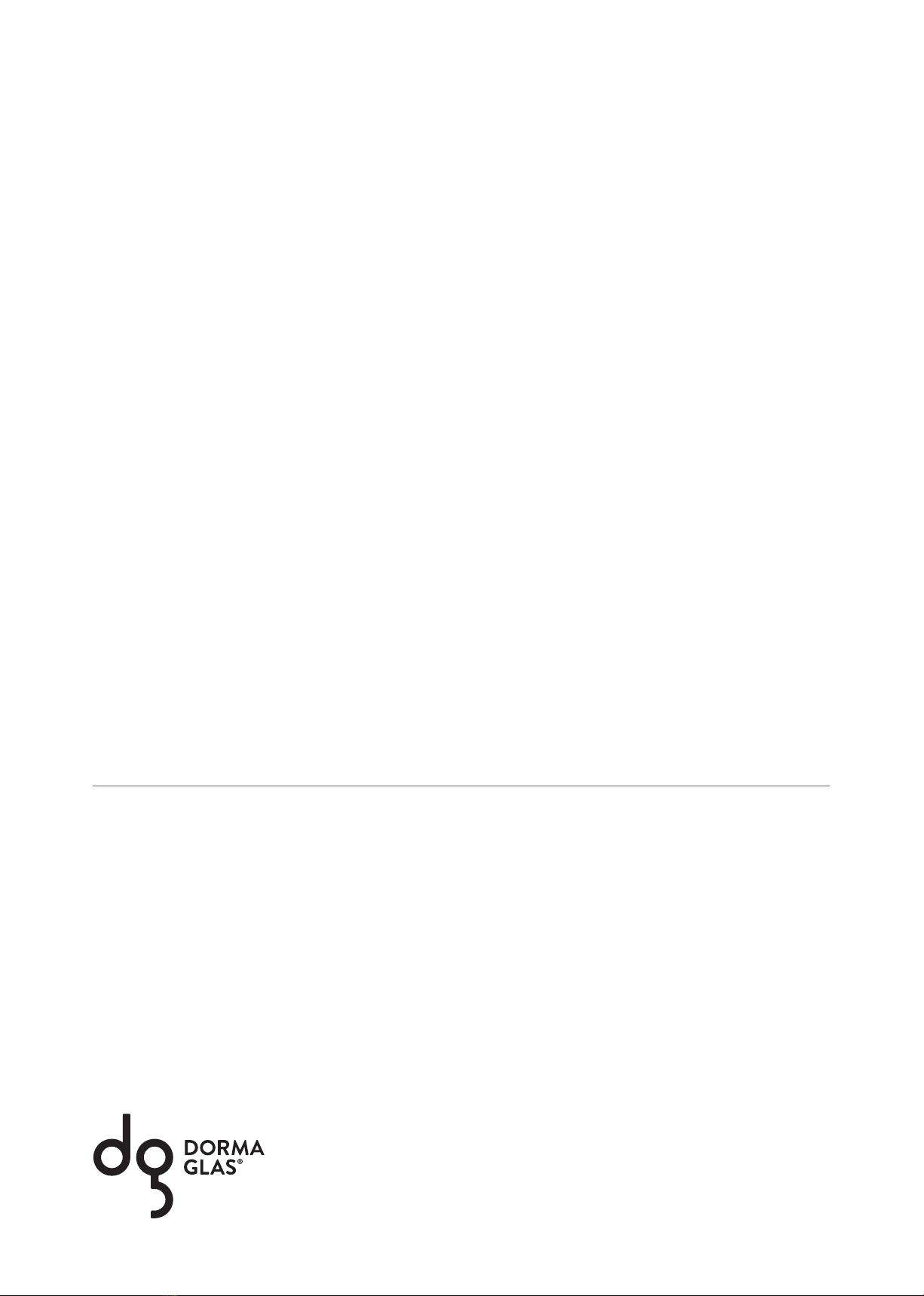

2.1. Step-by-step graphics

1 2 Position numbers for parts

in diagrams

2 Safety

2.1 Intended use

The product is designed to connect a UNIQUIN partition wall

system to the floor, wall and ceiling from the inside.

The product may only be mounted with unit components designed

by dormakaba for the installation situation and approved according

to the project-related unit drawing.

• The product may only be mounted undamaged and in accordance

with the requirements of the assembly location.

• The product may only be mounted by qualified personnel who

correspond to the defined target group.

• Only toughened safety glass (TSG) or laminated safety glass

(LSG) made of TSG may be installed with the product.

• The use of other composites must be checked by the designer or

contractor and the stability assured.

• The product may only be attached to a surface capable of bearing

loads using suitable fixing materials.

• The product is only suitable for indoor use.

• The product is suitable for use in tropical countries.