Dormakaba SafeRoute User guide

EN

WN 059722 45532 – 2019-03

System manual

SafeRoute®-System

Mini, Basic und Standard

Contents

1 About this document 2

1.1 Contents and purpose 2

1.2 Target group 2

1.3 Other applicable documents: 2

1.4 Documents storage 2

1.5 Abbreviations 2

1.6 Symbols used 2

1.6.1 Hazard categories 2

1.6.2 More symbols 2

2 Safety 3

2.1 Intended use 3

2.2 General safety instructions 3

2.3 Personnel qualification 3

3 Product description 3

3.1 Parts included 3

3.2 Technical information 3

3.3 Basic components 3

3.3.1 SafeRoute® Control Unit 3

3.3.2 Emergency button with connected key

switch 3

3.3.3 Electrical door lock STV xxx 3

3.3.4 Power supply unit 4

3.3.5 DCW® bus 4

3.4 Extension of the SafeRoute® system 4

3.4.1 Additional DCW® components 4

3.4.2 Inputs and outputs on the SCU 4

3.4.3 RS232 interface at the SCU (available

from Basic license) 4

3.5 Functional scope 4

3.5.1 Release and unlock 4

3.5.2 Relocking 4

3.5.3 Monitoring 4

3.5.4 Visual and audible indicator 4

4 Mounting 5

4.1 Requirements for mounting a SafeRoute®

system 5

4.1.1 Door unit 5

4.1.2 Requirements for fire and smoke

protection doors 5

4.2 Mounting the components 5

4.2.1 DCW® bus addressing (door entry

system) 5

5 Commissioning 5

5.1 Put the SafeRoute® system into operation 5

5.1.1 SCU-UP and SCU-TL as SafeRoute®

Control Unit 5

5.1.1.1 Configure an SCU-UP/SCU-TL 5

5.1.2 SCU-DR as SafeRoute® Control Unit

(from Basic license) 6

5.1.2.1 Configure an SCU-DR 6

5.2 Parameterization with TMS Soft® (from Basic

license) 6

5.3 Handover of the documentation to the facility

operator 6

6 Status query of a configured unit 7

6.1 Querying the status of an SCU-UP/SCU-TL 7

6.2 Querying the status of an SCU-DR 7

7 Troubleshooting 8

7.1 Illuminated ring display in case of alarm and

malfunction 8

8 Replacement and removal of components 11

8.1 Replace non-safety related DCW® components 11

8.2 Remove non-safety related DCW® components

completely 11

8.3 Replace/remove safety-related DCW®

components 11

8.4 Update internal DCW® table 11

8.4 Reset configuration to factory settings 11

9 Maintenance 12

10 Disassembly, recycling and disposal 12

11 Manufacturer's declarations and test

certificates 12

12 Annex 13

2SafeRoute® System 2019-03

WN 059722 45532

dormakaba About this documentSystem manual

1 About this document

1.1 Contents and purpose

This document contains the information and

instructions for the installation and operation of

a SafeRoute® system on an emergency exit door

unit according to EltVTR (12/1997 version) and DIN

EN13637:2015. The functional scope information

refers to a SafeRoute® system with the Standard

license.

1.2 Target group

This document is intended for assembling technicians

and specialists authorized by dormakaba for the

installation, operation, maintenance and testing of a

SafeRoute® system.

1.3 Other applicable documents:

The following documents belong to the unit’s

complete documentation and must be observed:

• The installed individual components’ assembly

instructions and documents

• The operation manual

• The inspection log for the door unit on which the

SafeRoute® system was installed

• The TMS Soft® handbook

• The approved components’ declaration of

conformity

1.4 Documents storage

This document and the other applicable documents

must be handed over to the facility operator after

commissioning. The facility operator must keep

the documents for the entire service life and make

them accessible to the persons responsible for the

inspection and maintenance of the emergency exit

door unit.

1.5 Abbreviations

Abbreviation Definition

SCU-xx

SafeRoute® Control Unit - Control

unit of a SafeRoute® system in three

versions:

• SCU-UP = Flush mounting

• SCU-TL = in the door terminal

STL-G

• SCU-DR = DIN rail mounting

SLI License card

SLI-A Application

STL-G Door terminal with emergency

button SCU-TL and key switch ST

STV xxx Electrical door lock

ST Key switch

1.6 Symbols used

1.6.1 Hazard categories

WARNING

This signal word indicates a situation of

potential risk, which could lead to death or

serious injury if not averted.

1.6.2 More symbols

TIPS AND RECOMMENDATIONS

This signal word indicates useful information

for efficient and trouble-free operation.

3SafeRoute® System 2019-03WN 059722 45532

dormakaba System manual Safety

2 Safety

The following instructions must be observed by the

installer and facility operator. The installation of

escape route security systems must not impede the

unhindered escape of persons in the event of danger.

Only use dormakaba spare parts or spare parts

approved by dormakaba.

2.1 Intended use

The escape route security system SafeRoute® is an

electrical locking system on doors in emergency and

escape routes, which counteracts any misuse of the

escape route. When using the dormakaba escape

route security system SafeRoute®, the technical data

and environmental conditions of the components

used must be taken into account. Only components

and parts approved by dormakaba for a SafeRoute®

system may be used (see current list www.

dormakaba.com).

The intended use also includes compliance with

all information in this document and in the other

applicable documents (see also Ch. 1.3).

2.2 General safety instructions

WARNING

Danger to life due to blocked escape routes

Mounted devices and components as

well as their settings can prevent people

from escaping in an emergency if they are

handled improperly.

2.3 Personnel qualification

Mounting, commissioning, testing and maintenance

of the SafeRoute® system may only be performed by

persons authorized by dormakaba.

3 Product description

A SafeRoute® system is an electrical locking system

for emergency exit doors. The SLI license card

defines the SafeRoute® system’s functional scope. A

SafeRoute® system consists of various components

depending on the requirements.

3.1 Parts included

• Mini, Basic or Standard license card

• Battery (for the clock function from license

standard)

• System manual

• Operation manual

• Inspection logbook

3.2 Technical information

• Systems according to EltVTR must be operated

with 24 V ± 10% (to maintain the retention force for

locking devices).

• Systems outside the scope of the EltVTR can be

operated functionally safe with 24 V ± 15%.

3.3 Basic components

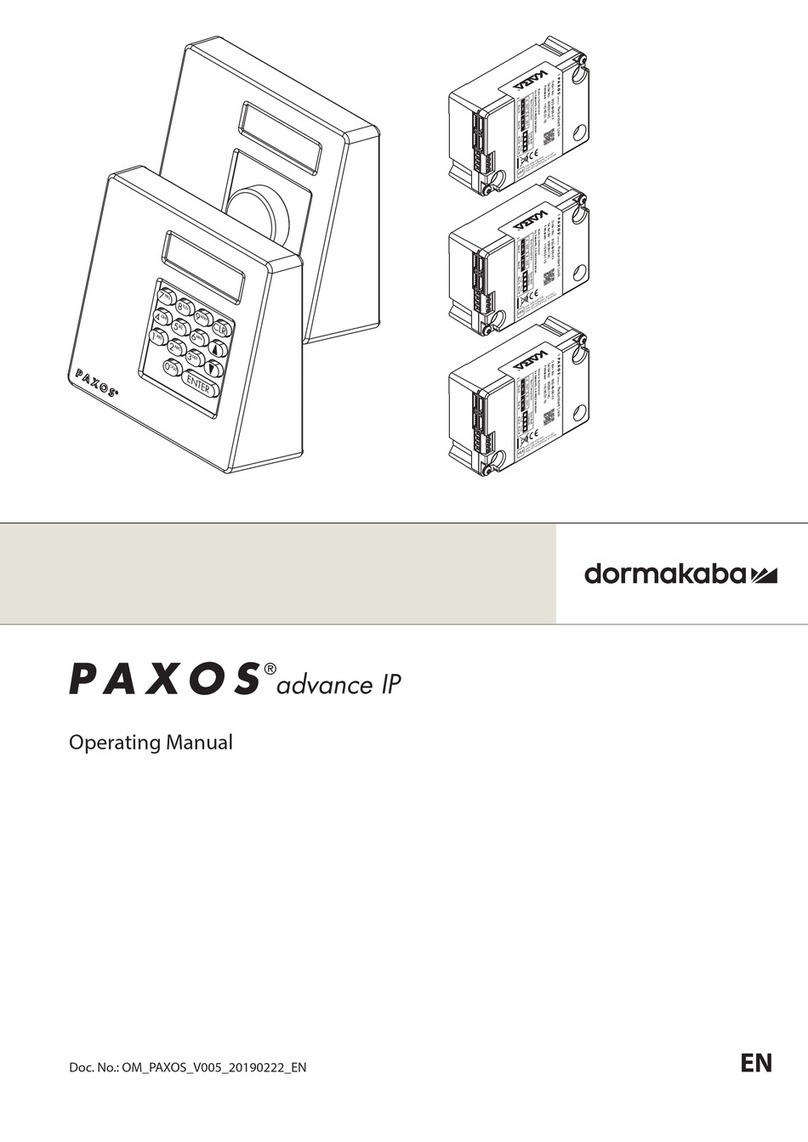

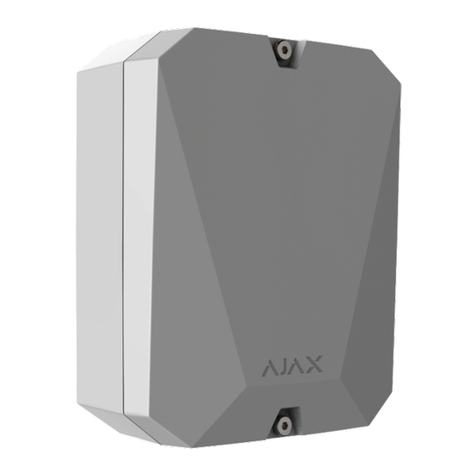

6

5

4

1

2

3

Fig. 1 Example execution of a SafeRoute® system

A SafeRoute® system consists of at least the

following basic components:

1an emergency button

2a key switch ST connected to SCU

3a SafeRoute® Control Unit SCU

4an SLI license card

5an electrical door lock STV xxx

6a power supply, e.g. power supply unit NT-S24-1.5

The basic components are connected via a four-core

control cable (DCW® bus).

The connection of additional components is possible.

3.3.1 SafeRoute® Control Unit

The SCU with the inserted license card is the

SafeRoute® system’s control unit. The license card

defines the SafeRoute® system’s functional scope. The

SCU is available in three versions:

• SCU-UP: consists of an SCU with emergency button

for flush mounting

• SCU-TL: consists of an SCU with emergency button

in the door terminal STL-G

• SCU-DR: consists of an SCU for DIN rail mounting

(SCU-DR can be used from the Basic license.)

3.3.2 Emergency button with connected

key switch

The emergency button releases the electric locking

device when pushed. The emergency button’s multi-

colored illuminated ring provides information about

the current door status. A key switch (ST) must be

connected to the emergency button.

The key switch offers the following functions:

• Locking and unlocking

• Alarm acknowledgement

4SafeRoute® System 2019-03

WN 059722 45532

dormakaba Product descriptionSystem manual

3.3.3 Electrical door lock STV xxx

The electric door lock locks the door and releases

the door on request. Up to four different as well as

identical door locks can be connected to a SafeRoute®

system via the DCW® bus. All dormakaba STV xxx

door locks are permitted. Door locks without DCW®

bus are integrated via the STV-A adapter.

3.3.4 Power supply unit

The power supply unit feeds the 24V DC voltage for

all SafeRoute® and DCW® components at any point

in the DCW® bus. If there is an increased demand for

power, several power supply units can be connected

(the +24V line between the power supplies must

then be disconnected). Any power supply units used

must meet the dormakaba requirements (definition

of power supplies: see Declaration of Conformity at

www.dormakaba.com).

3.3.5 DCW® bus

The DCW® bus connects the components. Power is

supplied via the DCW® bus (four-core control cable).

dormakaba recommends the following type of lead:

• For bus routes up to max. 300 m: J-Y(St)Y 2x2x0.8

3.4 Extension of the SafeRoute® system

3.4.1 Additional DCW® components

Depending on requirements, the SafeRoute®

system can be supplemented with additional DCW®

components, e.g. additional emergency button, key

switches, self-locking panic locks, etc.

List of all approved components:

The list of approved components and parts and the

declaration of conformity are available at www.

dormakaba.com.

3.4.2 Inputs and outputs on the SCU

Each SCU has inputs and outputs where alarm and

signaling systems, external access control systems

and other components can be connected or switched.

The input and output functions can be parameterized

with TMS Soft® from the Basic license.

3.4.3 RS232 interface at the SCU

(available from Basic license)

The SCU with the inserted license card can be

connected to TMS Soft® (PC computer) via the RS232

interface. The connection can also be made via an

LON or LAN network adapter.

3.5 Functional scope

The functions of a SafeRoute® system result from

the connected components and the license card

(see Chap. 12). The preconfigured functions (default

values) can be changed with TMS Soft® and the

SafeRoute® configuration software (possible from

Basic license).

The SafeRoute® system’s functional scope can be

expanded by additional components and SLI-A

application cards (from Basic license).

3.5.1 Release and unlock

The following functions are available (default values):

• Release via emergency button (with alarm trigger)

• Release in case of power failure

• Temporary unlocking

• Long-term unlocking (from Standard license)

• Permanent unlocking

• Release by an alarm system (fire, danger, smoke

detectors, sprinklers, etc.)

3.5.2 Relocking

The following functions are available (default values):

• Automatically after power failure

• Temporary unlocking: Automatically after expiry of

the set relocking time

• Long-term unlocking: Automatically after expiry of

the set relocking time

• Permanent unlocking: Automatically after closing

the door and operation via key switch

3.5.3 Monitoring

The default values are:

• Tamper monitoring

• “Door open” monitoring with two different time

ranges for pre- and main alarm (from Standard

license)

3.5.4 Visual and audible indicator

The following displays are possible:

• Operating of the emergency button

• Alarm trigger

• Activation of locking and unlocking

• Relocking failed

• Pending maintenance

• Malfunction and error reports

• Connected components

5SafeRoute® System 2019-03WN 059722 45532

dormakaba System manual Mounting

4 Mounting

4.1 Requirements for mounting a

SafeRoute® system

4.1.1 Door unit

All door unit components must be approved by the

manufacturers for use as part of an emergency exit

unit and must function properly.

4.1.2 Requirements for fire and smoke

protection doors

When mounting a SafeRoute® System in preventive

fire protection, the fire and smoke protection doors’

properties must not be impaired.

Mounting is only permitted if the proof of usability

for the fire and smoke protection door allows for

mounting and the proof of usability’s stipulations are

observed.

Further information can be found in the report

“Permissible changes and additions to fire protection

closures” from the Deutsches Institut für Bautechnik

(DIBt 1/1996), Berlin.

4.2 Mounting the components

The SLI license card and the battery (from Standard

license) are plugged into the SafeRoute® Control Unit.

The further mounting and connection of the

SafeRoute® system’s individual components is carried

out according to the unit configuration and the

assembly instructions. All connected components of

the SafeRoute® system are entered in the respective

door unit’s inspection log.

4.2.1 DCW® bus addressing (door entry

system)

Each DCW® component has a DCW® bus address.

Similar DCW® components must have different

DCW® bus addresses. The setting is made via the

DCW® DIP switches on the components.

5 Commissioning

5.1 Put the SafeRoute® system into

operation

Depending on the SafeRoute® Control Unit used

(SCU-UP, SCU-TL or SCU-DR from Basic license), the

procedure and status displays differ.

5.1.1 SCU-UP and SCU-TL as SafeRoute®

Control Unit

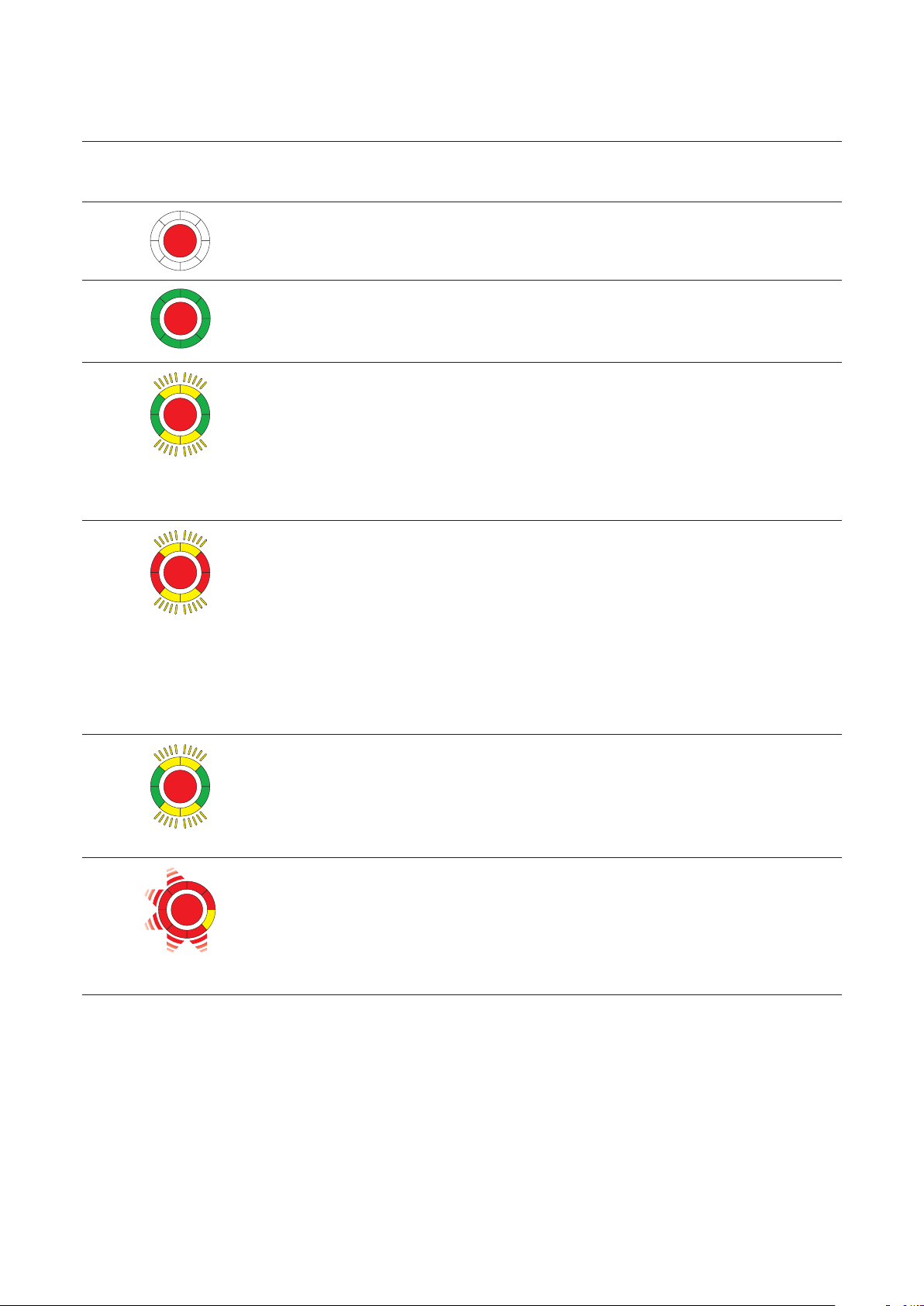

The status display is indicated by the illuminated ring.

The LED segments are assigned to the DCW® security

components and light up or flash depending on the

status of the connected DCW® component.

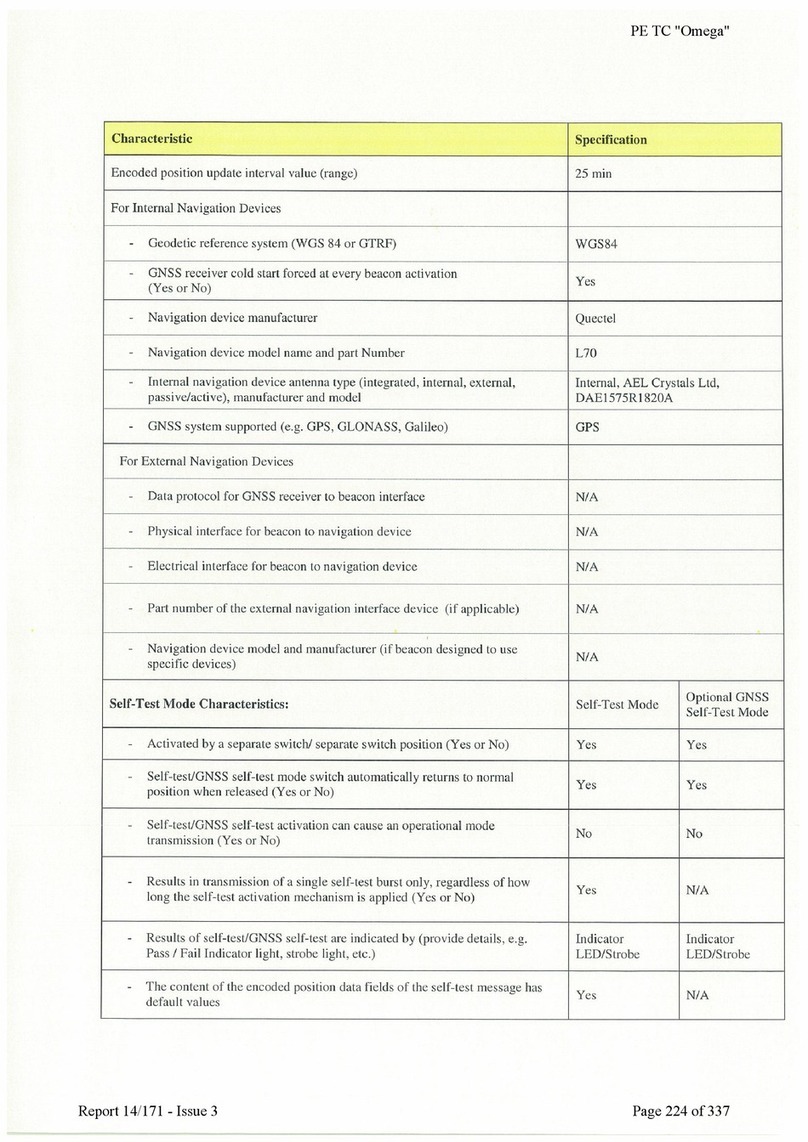

STV 1 (Adr. 1)SCU 1 (Adr. 1)

STV 2

(Adr. 2)

SCU 2

(Adr. 2)

STV 3

(Adr. 3)

SCU 3

(Adr. 3)

STV 4 (Adr.4)SCU 4 (Adr. 4)

Fig. 2 Assignment of the LED segments in the illuminated

ring

5.1.1.1 Configure an SCU-UP/SCU-TL

1. Connect the power supply.

‣ The illuminated ring on the SCU’s emergency

button flashes briefly (for initialization views

see chapter 6.1) and changes to the rainbow

view.

2. Press the S4 service button on the SCU and keep

it pressed for 12 s.

‣ After 8 s, a signal sounds.

‣ After 12 s, another signal sounds and the

illuminated ring lights up blue.

‣ The connected components are detected and

displayed on the illuminated ring (flashing

green/blue alternately).

3. Check if the connected components are displayed

with the correct address.

TIPPS UND EMPFEHLUNGEN

Duplicated DCW® addresses are indicated

with yellow flashing.

4. Press and hold the service button for 3 s.

‣ The illuminated ring changes to the operation

indicator.

→The SCU-UP/SCU-TL is configured.

6SafeRoute® System 2019-03

WN 059722 45532

dormakaba CommissioningSystem manual

If the illuminated ring does not change to the

operation indicator (permanently lit red):

1. Use the key switch to push right to left.

‣ The illuminated ring on the emergency button

lights up red permanently.

‣ The STVxxx locks.

→The SCU-UP/SCU-TL is configured.

If the alarm signal "The emergency button is pressed"

is pending (see Chap. 7 on page 8), reset the

alarm signal:

1. Turn and hold the key to the right on the key

switch.

2. Press the emergency button for 1s and then

release.

3. Push the key over the middle to the left and bring

it back to the middle position.

4. Remove the key.

‣ The electric locking device is active.

→The SCU-UP/SCU-TL is configured.

5.1.2 SCU-DR as SafeRoute® Control Unit

(from Basic license)

The status display during the configuration takes

place via LEDs on the board. The LEDs light up or

flash depending on the status of the connected

DCW® component.

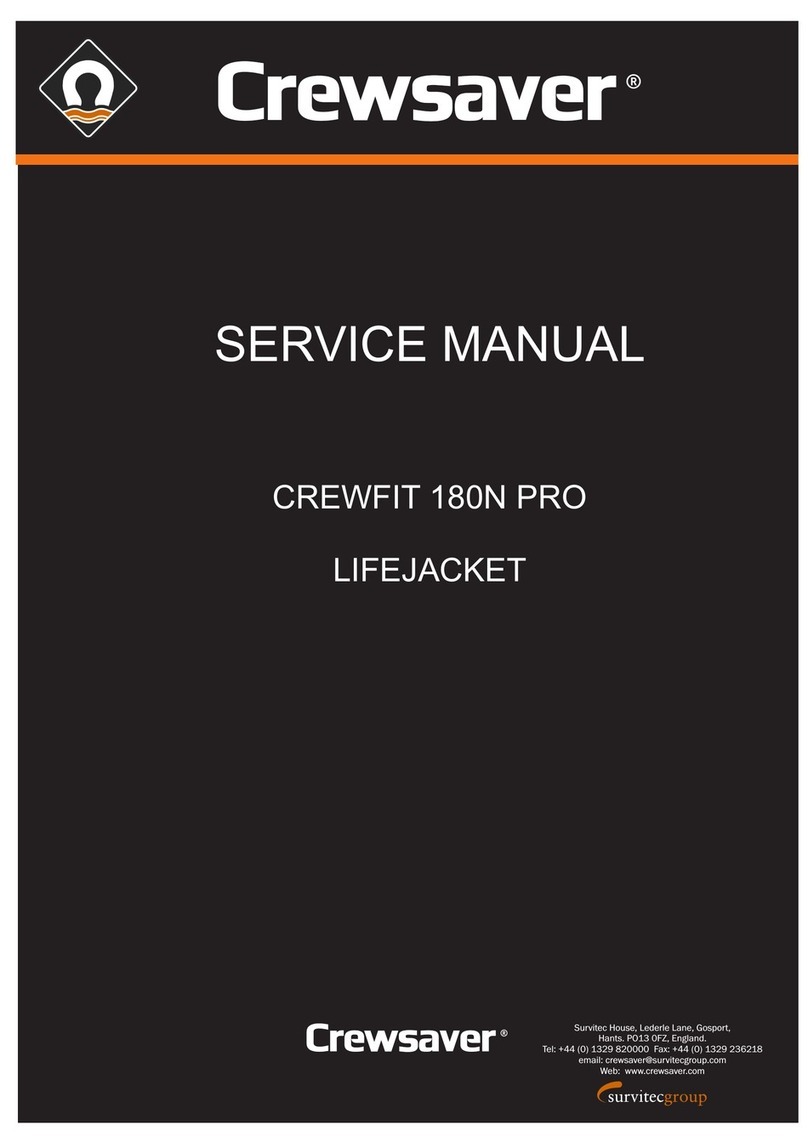

In 1In2 In 3In4

BTRDCW

CPU2

CPU1

SLI

Out2Out1 Out3 Out4

Fig. 3 Arrangement of the LEDs on the SCU-DR board

5.1.2.1 Configure an SCU-DR

1. Connect the power supply.

‣ The DCW® LED lights up red when correctly

connected.

‣ The SLI LED lights up yellow when the license

is inserted.

‣ The LEDs from In 1 to In 4 change to the

initialization view and display the license.

In 1 - 4 off no/defective license card

In 4 on SLI Basic

In 3 on SLI Standard

‣ The illuminated ring on the emergency button

flashes briefly and changes to the rainbow

view.

2. Press and hold the S4 service button on the SCU-

DR for 12s.

‣ After 12 s, the illuminated ring on the

emergency button lights up blue.

‣ The BTR LED flashes green.

‣ The connected components are detected and

displayed on the illuminated ring (flashing

green/blue alternately).

3. Press and hold the S4 service button for 3s.

‣ The BTR LED lights up green.

‣ The DCW® LED lights up red.

‣ The CPU1 and CPU2 LEDs light up red (CPU1)

and yellow (CPU2).

‣ The illuminated ring on the emergency button

lights up red permanently.

4. Use the key switch to push right to left.

‣ The illuminated ring on the emergency button

lights up red permanently.

‣ The STVxxx locks.

→The SCU-DR is configured.

5.2 Parameterization with TMS Soft®

(from Basic license)

With TMS Soft® and the SafeRoute® configuration

software, the functions of the components and

the SafeRoute® system can be adapted. For more

information, see the TMS Soft® handbook.

The settings made with the SafeRoute® configuration

software must be entered in the respective door unit’s

inspection log.

5.3 Handover of the documentation to the

facility operator

All documents relevant for proper operation are

handed over to the facility operator after initial

commissioning:

• The installed individual components’ assembly

instructions and documents

• The operation manual

• The door unit’s inspection log

• This system manual

7SafeRoute® System 2019-03WN 059722 45532

dormakaba System manual Status query of a configured unit

6 Status query of a configured

unit

After a power failure, the license used and the status

of all connected components are displayed in several

initialization steps on the SafeRoute® Control Unit

emergency button’s illuminated ring.

6.1 Querying the status of an SCU-UP/

SCU-TL

1. Disconnect the power supply.

2. Reconnect the power supply.

‣ The illuminated ring on the emergency button

changes to Initialization view 1:

White (lit up) = SLI license card

SLI Premium

without SLI

SLI Mini

SLI Basic

SLI Standard

‣ The illuminated ring changes to Initialization

view 2:

STV 1

SCU 1

STV 2

SCU 2

STV 3

SCU 3

STV 4

SCU 4

Red = STV-xxx available.

The display flashes red (2.5 Hz) if there is no

configuration and the STV is not assigned to

any SCU.

Green = SCU emergency button available.

The indicator flashes green (2.5 Hz) if the

emergency button is not yet configured.

Yellow = Malfunction: STV/SCU is missing/

defective.

‣ The illuminated ring changes to Initialization

view 3:

ST DCW® 1

I/O DCW® 1

ST DCW® 2

I/O DCW® 2

ST DCW® 3

I/O DCW® 3

ST DCW® 4

I/O DCW® 4

Blue = ST DCW® address X available.

Magenta = I/O DCW® available.

Yellow = Malfunction: STV/SCU is missing/

defective.

‣ The SCU switches to the operating state and

the illuminated ring lights up red permanently.

→The door is locked.

6.2 Querying the status of an SCU-DR

1. Disconnect the power supply.

2. Reconnect the power supply.

‣ The LEDs from In 1 to In 4 change to the

initialization view and display the license.

In 1 - 4 off no/defective license card

In 4 on SLI Basic

In 3 on SLI Standard

‣ The illuminated ring lights up/flashes green/

yellow briefly.

‣ The LED segment 1 on the SCU emergency

button’s illuminated ring lights up white.

‣ The illuminated ring on the emergency button

lights up red.

→The door is locked.

8SafeRoute® System 2019-03

WN 059722 45532

dormakaba TroubleshootingSystem manual

7 Troubleshooting

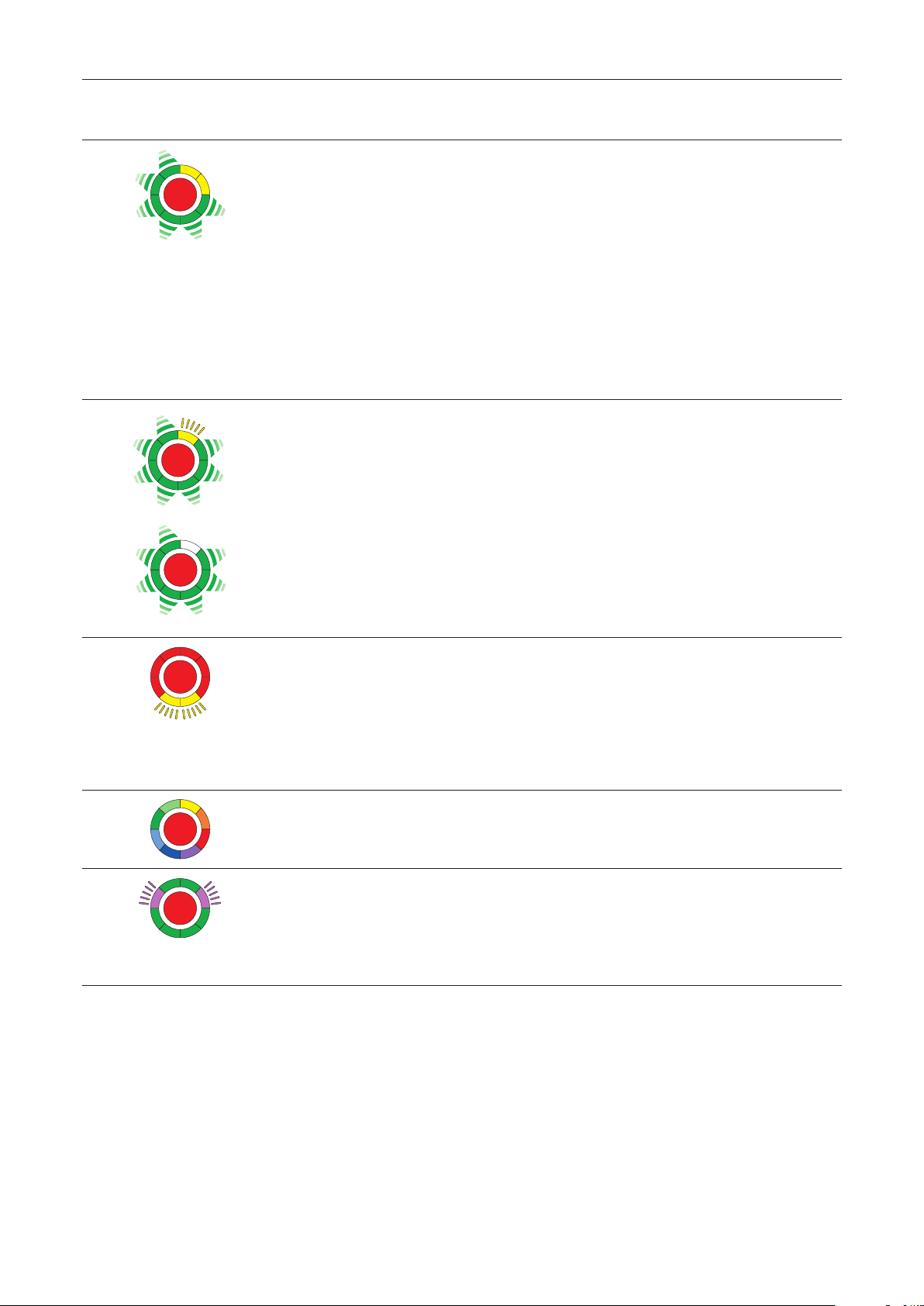

7.1 Illuminated ring display in case of alarm and malfunction

Signal

Cause Procedure

No visual or audible indicator

230 V AC- or 24 V DC power supply

missing.

1. Check the power supply.

2. Connect the power supply.

The door lock does not become active

Permanent unlocking is still active.

1. Close the door.

2. Turn the key in the key switch to the

left.

Tampering message:

The STV is unlocked

Tamper alarm was triggered.

All door locks on the door are

unlocked. The tamper alarm occurs

after unlocking the door.

The door can be opened.

1. Make sure all housings and covers

are intact and sealed.

2. Turn and hold the key switch to the

right.

‣ The alarm is acknowledged.

→The door remains unlocked.

Tampering message:

The STV is locked

Tamper alarm has been triggered, all

door locks on the door are locked.

1. Make sure all housings and covers

are intact and sealed.

2. Turn and hold the key switch to the

right.

‣ The alarm is acknowledged.

‣ The door unlocks.

3. Turn the key switch to the left.

→The door locks.

high flashing frequency

License error

The locks are disabled, the license

card has been removed from the

SCU control center for more than 2

minutes

1. Reinsert the license card assigned

to the door.

→The door locks.

Partially locked (where a door has

several locks)

Here: Locks 1 and 2 are locked, lock 3

is not.

1. Check if all door leaves are locked

or can lock (mechanically).

2. Turn the key switch to the right.

3. Push the key switch to the left.

→The door locks.

9SafeRoute® System 2019-03WN 059722 45532

dormakaba System manual Troubleshooting

Signal

Cause Procedure

The alarm system reports an alarm

Alarm system has triggered via fire

detector or smoke switch or there is

an open circuit/short circuit to fire

detector or smoke switch.

1. Reset to fire detector or smoke

switch.

‣ The alarm is automatically*

acknowledged.

→The door lock locks.

The emergency button is pressed

The locking device does not lock.

1. Push and hold the key to the right

on the key switch.

2. Press the emergency button for 1s

and then release.

3. Push the key over the middle to the

left and bring it back to the middle

position.

4. Remove the key.

→The electric locking device is

active.

The emergency button is faulty

Internal emergency button error.

1. Push and hold the key to the right

on the key switch.

2. Press the emergency button for 1s

and then release.

3. Push the key over the middle to the

left and bring it back to the middle

position.

4. Remove the key.

→The electric locking device is

active.

If the error occurs again, replace the

device.

When locked

When permanent open

The connection via DCW® bus to a

standard DCW® node is interrupted

A standard DCW® component** is

missing/defective or SCU emergency

buttons signal that the SCU control

center is missing or defective.

1. Check the DCW® connection to the

DCW® component.

2. Reset the components table with

the TMS Soft or perform new

configuration.

Attention: Parameter settings

changed by TMS Soft® are lost!

If the error persists: Replacement of the

non-safety-related DCW® component.

*Depending on the parameterization, manual acknowledgment may also be required.

**I/O module DCW®, key switch STxx DCW®, SVP lock SVP 2xxx DCW®, smoke switch RS DCW®

10 SafeRoute® System 2019-03

WN 059722 45532

dormakaba TroubleshootingSystem manual

Signal

Cause Procedure

in addition, an alarm

signal sounds

The connection to an SCU emergency

button is interrupted

The electrical lock is deactivated.

or

The door is not closed.

or

The door contacts on the STV are not

connected.

1. Check the line to the SCU

emergency button.

2. Acknowledge the error after

removal.

3. Press the key switch to the right

and then to the left.

→The STVxxx locks.

or

4. Replace the defective SCU

emergency button

Missing or defective STV-xxx

STV-xxx is missing or the connection is

broken, e.g. plug disconnected

(Fig. shows Address 1 as an example)

The communication between SCU

and STV-xxx was interrupted (e.g. due

to a loose connection).

1. Check the line to STV address1.

2. Acknowledge the error after

removal.

3. Press the key switch to the right

and then to the left.

→The STVxxx locks.

Maintenance is required

The maintenance interval has been

exceeded.

1. Conduct maintenance (or order it)

according to specifications.

2. Reset the maintenance alarm. To

do this, press the key switch to the

left for 15 seconds or set a new

maintenance interval with TMS

Soft (as of license standard).

The unit is not configured 1. Check the components.

2. Carry out a new configuration.

The unit is supplied with over/

undervoltage.

The power supply does not meet the

requirements or specifications.

1. Check the power supply.

2. If the voltage drop on the supply

cable is too high, select a larger

cable cross-section or place an

additional power supply.

*Depending on the parameterization, manual acknowledgment may also be required.

11SafeRoute® System 2019-03WN 059722 45532

dormakaba System manual Replacement and removal of components

8 Replacement and removal of

components

The replacement and removal of components

connected to the SCU is performed in accordance

with the relevant assembly instructions. For safety-

related components, such as e.g. electrical door

locks STV xxx or SCU control units, the replacement

must be documented in the door unit’s inspection

log. The SafeRoute® system must then also be re-

commissioned.

Replacing DCW® components

When exchanging standard DCW® components, the

DCW® address and thus the set parameters can be

adopted. For a permanent removal from the bus

system, additional steps must be taken.

Replacing license cards

The replacement of the license card must be done

within 2 minutes. Any loaded applications are

permanently stored on the SLI license card. After

replacement, any necessary applications must be

reloaded.

8.1 Replace non-safety related DCW®

components

TIPS AND RECOMMENDATIONS

If the replaced component’s DCW® address

is retained, the set parameters are adopted.

1. Disconnect the wiring to the component.

2. Replace the defective component.

3. Take over the defective component’s DCW®

address (DIP switch).

4. Reconnect the wiring to the component.

→The component is incorporated in the system.

8.2 Remove non-safety related DCW®

components completely

1. Disconnect the wiring to the component.

2. Remove the component.

3. Delete the component from the system. To do

this, update the internal DCW® table (see chap.

8.4).

→The component is completely removed from

the system.

8.3 Replace/remove safety-related DCW®

components

1. Use TMS Soft®to read the current parameters (if

parameterized).

2. Disconnect the wiring to the component.

3. Replace/remove the component.

4. Take over the replaced component’s DCW®

address (DIP switch).

5. Reconnect the wiring to the component.

6. Carry out a new configuration.

7. Transfer parameter settings changed by TMS

S o f t ®.

→The component is incorporated in the system.

8.4 Update internal DCW® table

TIPS AND RECOMMENDATIONS

Attention: Parameter settings changed by

TMS Soft® are lost during configuration!

Before configuring with TMS Soft, read out

the current parameters (if parameterized)

and transfer again after configuration.

1. Reset the components table with TMS Soft®.

→The internal DCW® table is updated.

or

2. Carry out a new configuration.

→The internal DCW® table is updated.

8.4 Reset configuration to factory settings

TIPS AND RECOMMENDATIONS

Alternatively, the configuration can also be

done with the configuration software.

1. Press the S4 service button for 8 s.

‣ All default values are loaded.

2. Carry out a new configuration.

→All parameters are reset to the factory

settings.

12 SafeRoute® System 2019-03

WN 059722 45532

dormakaba MaintenanceSystem manual

9 Maintenance

The facility operator commissions the maintenance.

Maintenance is periodic and is performed by service

technicians authorized by dormakaba.

Customer service

dormakaba Service can be reached at the toll-free

number.

E-mail: [email protected]om

Fax: +49 2333 793-3777

dormakaba

SERVICE

24 h HOTLINE

0800 - 5240246

Other contact options:

• dormakaba - Technical Competence Center

Tel.: +49 2333 7932900

• Online repair order: www.dormakaba.com

dormakaba Service App for smartphone/tablet: Apple

iOS Appstore or Google Android Playstore

10 Disassembly, recycling and

disposal

Disassembly is carried out in the reverse order of

mounting and must be carried out by qualified

personnel.

The product must be disposed of in an

environmentally friendly manner. Electro-

technical parts and batteries must not be

disposed of as domestic waste. Dispose of

electrotechnical parts and batteries in the designated

acceptance and collection points. Refer to the

statutory regulations for your country.

11 Manufacturer's declarations

and test certificates

Any required documents, such as e.g. the EC

Declaration of Conformity, the manufacturer's

Declaration of Conformity, and compatibility lists, are

available at www.dormakaba.com .

13SafeRoute® System 2019-03WN 059722 45532

dormakaba System manual Annex

12 Annex

SLI

Mini

SLI

Basic

SLI

Standard

Release Via emergency button (with alarm trigger) ○ ○ ○

Unlock Via key switch(without alarm trigger)

– Temporary unlocking ○ ○ ●

– Long-term unlocking - - ●

– Permanent unlocking ○ ○ ○

– Operating time of the key switch for triggering the

unlocking type long-term permanent unlocking

- - ●

– Combination function short-term, long-term, permanent

unlocking: one of the different unlocking types can be deactivated

- - ●

Automatic unlocking at defined times of day (timer) - - ●

By alarm system (fire, danger, smoke detectors, sprinklers, etc.) ○ ○ ○

Bi-directional escape route - ○ ○

From outside to inside via external analog ST (key switch) ○ ● ●

From outside to inside via external DCW® ST or SVP / M-SVP xx - ● ●

Lock Automatic relocking

– After temporary unlocking ○ ○ ●

– After long-term unlocking - - ●

– If door was not opened after pressing the emergency button 1) - ● ●

– After closing - - ●

Automatic locking at defined times of day (timer) - - ●

Automatic relocking after power cut ○ ○ ○

Resetting the unlocking via key/emergency button ○ ● ●

Direct connection of motor locks

SVP 2xxx DCW®/ M-SVP 22xx DCW®

- ● ●

Vis./Aud. display Status/Warning/Initialization display on the illuminated ring.

– Adjusting the brightness - ● ●

– Adjusting the flashing frequencies - - ●

Pre-alarm/main alarm after temporary unlocking and

long-term unlocking

○ ○ ●

Maintenance alarm ○ ○ ●

Acoustic confirmation when activating

long-term or permanent unlocking

○ ○ ●

Alarm duration limit ○ ● ●

Alarm management (activation/deactivation of alarms) - ● ●

Monitoring Tamper monitoring (can be deactivated for maintenance purposes) ● ● ●

“Door open” monitoring ○ ○ ●

Two different time ranges for

the “door open” monitoring’s pre-alarm and main alarm

- - ●

Entry control Access control via keypad, e.g. STD-UP touchscreen display - - ●

History memory with date and time stamp - - ○

Networking LON - ● ●

LAN - ○ ○

Miscellaneous Automatic reactivation after power cut ○ ○ ○

Parameterization/visualization/control via TMS Soft® - ● ●

Freely programmable inputs/outputs on the SCU - ● ●

Additional programmable inputs/outputs via SIO-DR or I/O DCW® - - ●

Application cards

SLI-A

Multi-door control - ■ ■

Interlock control - ■ ■

Logic functions - - ■

Time-Delayed Release 1) - ■ ■

– one time delay step (parameterizable) - ■ ■

-not available ○available, not parameterizable ●available and parameterizable ■ with app

1) EN 13637 function

14 SafeRoute® System 2019-03

WN 059722 45532

dormakaba MaintenanceSystem manual

15SafeRoute® System 2019-03WN 059722 45532

dormakaba System manual Maintenance

www.dormakaba.com

Translation of the original document, subject to change without notice

dormakaba Deutschland GmbH

DORMA Platz 1

58256 Ennepetal

Germany

T: +49 2333 793-0

F: +49 2333 793-4950

Table of contents

Other Dormakaba Safety Equipment manuals