Dorner Mfg. Corp. 6 851-717 Rev. A

2200 and 2300 Series Center Mount Drive Package for SEW 60 Hz Gearmotors

Specifications

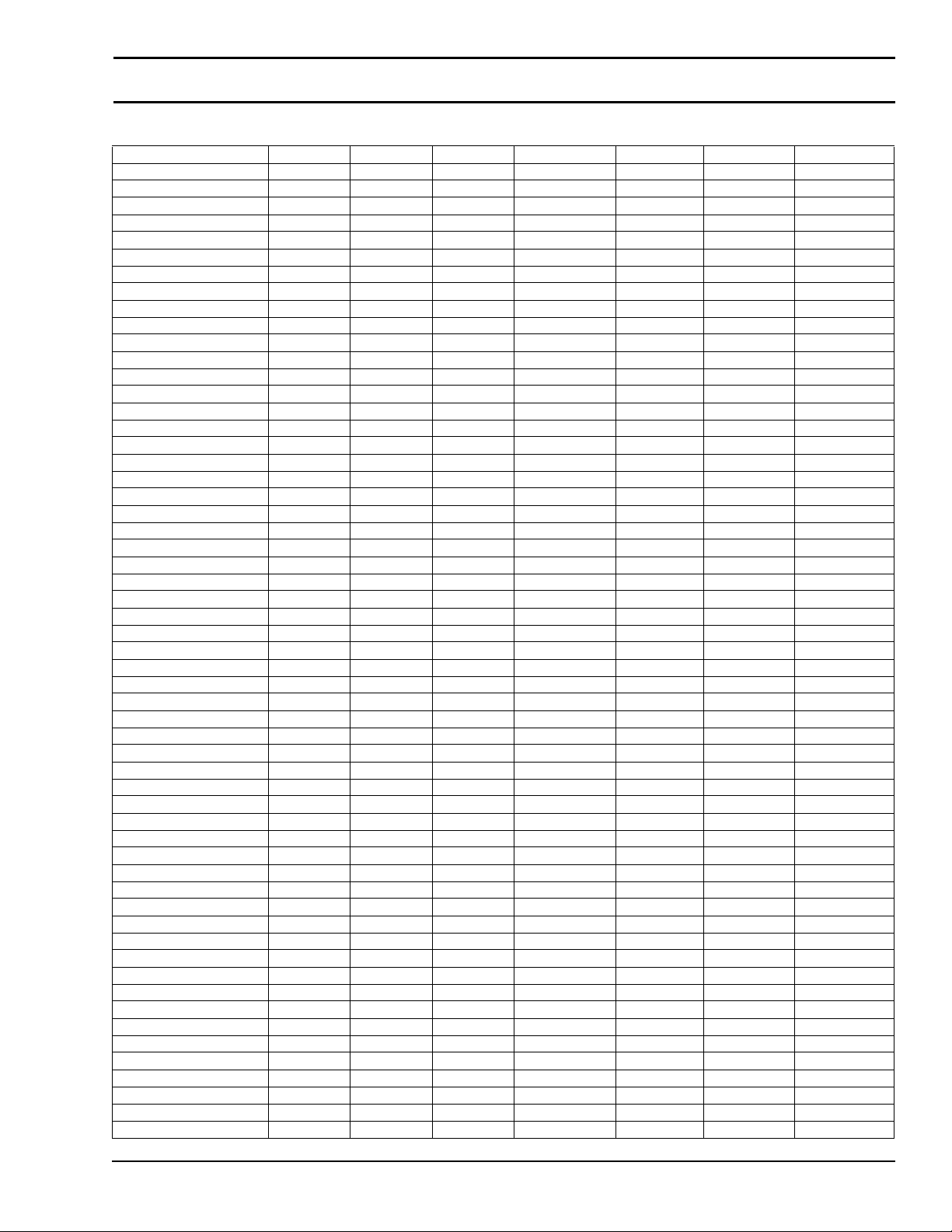

Table 3: Belt Speeds for Variable Speed SEW Gearmotors

Part Number RPM In-lb N-m Ft/min (max) Ft/min (min) M/min (max) M/min (min) Drive

Pulley

Driven

Pulley

22M039WS423EN 46 203 22.9 9.6 1.6 2.9 0.5 19 32

22M039WS423EN 46 203 22.9 11.0 1.8 3.4 0.6 19 28

22M039WS423EN 46 203 22.9 11.1 1.9 3.4 0.6 22 32

22M039WS423EN 46 203 22.9 12.7 2.1 3.9 0.6 22 28

22M039WS423EN 46 203 22.9 14.2 2.4 4.3 0.7 28 32

22M039WS423EN 46 203 22.9 16.2 2.7 4.9 0.8 32 32

22M039WS423EN 46 203 22.9 18.5 3.1 5.6 0.9 32 28

22M039WS423EN 46 203 22.9 20.6 3.4 6.3 1.0 28 22

22M039WS423EN 46 203 22.9 22.3 3.7 6.8 1.1 44 32

22M017WS423EN 109 159 18.0 22.7 3.8 6.9 1.2 19 32

22M039WS423EN 46 203 22.9 23.6 3.9 7.2 1.2 32 22

22M039WS423EN 46 203 22.9 23.9 4.0 7.3 1.2 28 19

22M039WS423EN 46 203 22.9 24.3 4.1 7.4 1.2 48 32

22M039WS423EN 46 203 22.9 25.5 4.2 7.8 1.3 44 28

22M017WS423EN 109 159 18.0 25.9 4.3 7.9 1.3 19 28

22M017WS423EN 109 159 18.0 26.3 4.4 8.0 1.3 22 32

22M039WS423EN 46 203 22.9 27.3 4.5 8.3 1.4 32 19

22M039WS423EN 46 203 22.9 27.8 4.6 8.5 1.4 48 28

22M017WS423EN 109 159 18.0 30.0 5.0 9.2 1.5 22 28

22M039WS423EN 46 203 22.9 32.4 5.4 9.9 1.6 44 22

22M017WS423EN 109 159 18.0 33.4 5.6 10.2 1.7 28 32

22M039WS423EN 46 203 22.9 35.4 5.9 10.8 1.8 48 22

22M039WS423EN 46 203 22.9 37.5 6.3 11.4 1.9 44 19

22M017WS423EN 109 159 18.0 38.2 6.4 11.6 1.9 32 32

22M039WS423EN 46 203 22.9 40.9 6.8 12.5 2.1 48 19

22M017WS423EN 109 159 18.0 43.7 7.3 13.3 2.2 32 28

22M008WS423EN 219 132 14.9 45.6 7.6 13.9 2.3 19 32

22M017WS423EN 109 159 18.0 48.6 8.1 14.8 2.5 28 22

22M008WS423EN 219 132 14.9 52.1 8.7 15.9 2.6 19 28

22M017WS423EN 109 159 18.0 52.5 8.8 16.0 2.7 44 32

22M008WS423EN 219 132 14.9 52.8 8.8 16.1 2.7 22 32

22M017WS423EN 109 159 18.0 55.6 9.3 16.9 2.8 32 22

22M017WS423EN 109 159 18.0 56.3 9.4 17.2 2.9 28 19

22M017WS423EN 109 159 18.0 57.3 9.6 17.5 2.9 48 32

22M017WS423EN 109 159 18.0 60.0 10.0 18.3 3.1 44 28

22M008WS423EN 219 132 14.9 60.3 10.1 18.4 3.1 22 28

22M017WS423EN 109 159 18.0 64.4 10.7 19.6 3.3 32 19

22M017WS423EN 109 159 18.0 65.5 10.9 20.0 3.3 48 28

22M008WS423EN 219 132 14.9 67.2 11.2 20.5 3.4 28 32

22M017WS423EN 109 159 18.0 76.4 12.7 23.3 3.9 44 22

22M008WS423EN 219 132 14.9 76.8 12.8 23.4 3.9 32 32

22M017WS423EN 109 159 18.0 83.4 13.9 25.4 4.2 48 22

22M008WS423EN 219 132 14.9 87.8 14.6 26.8 4.5 32 28

22M017WS423EN 109 159 18.0 88.5 14.7 27.0 4.5 44 19

22M017WS423EN 109 159 18.0 96.5 16.1 29.4 4.9 48 19

22M008WS423EN 219 132 14.9 97.7 16.3 29.8 5.0 28 22

22M008WS423EN 219 132 14.9 105.6 17.6 32.2 5.4 44 32

22M008WS423EN 219 132 14.9 111.7 18.6 34.1 5.7 32 22

22M008WS423EN 219 132 14.9 113.2 18.9 34.5 5.7 28 19

22M008WS423EN 219 132 14.9 115.2 19.2 35.1 5.9 48 32

22M008WS423EN 219 132 14.9 120.7 20.1 36.8 6.1 44 28

22M008WS423EN 219 132 14.9 129.4 21.6 39.4 6.6 32 19

22M008WS423EN 219 132 14.9 131.7 21.9 40.1 6.7 48 28

22M008WS423EN 219 132 14.9 153.6 25.6 46.8 7.8 44 22

22M008WS423EN 219 132 14.9 167.6 27.9 51.1 8.5 48 22

22M008WS423EN 219 132 14.9 177.9 29.6 54.2 9.0 44 19

22M008WS423EN 219 132 14.9 194.0 32.3 59.1 9.9 48 19

NOTE

For belt speed other than those listed, contact

factory for details.