Dorner Mfg. Corp. 2 851-738 Rev. A

Brushless DC Motor Control

Table of Contents

Introduction ......................................................................... 2

Warnings -General Safety ................................................. 3

Product Description ............................................................. 4

Brushless DC Motor Control ........................................... 4

Specifications ...................................................................... 5

2200 Light Load Gearmotors........................................... 5

2200 and 3200 Standard Load Gearmotors ..................... 5

2200 Standard Load 90° Gearmotors............................... 5

Controllers ....................................................................... 5

Installation ........................................................................... 6

Required Tools................................................................. 6

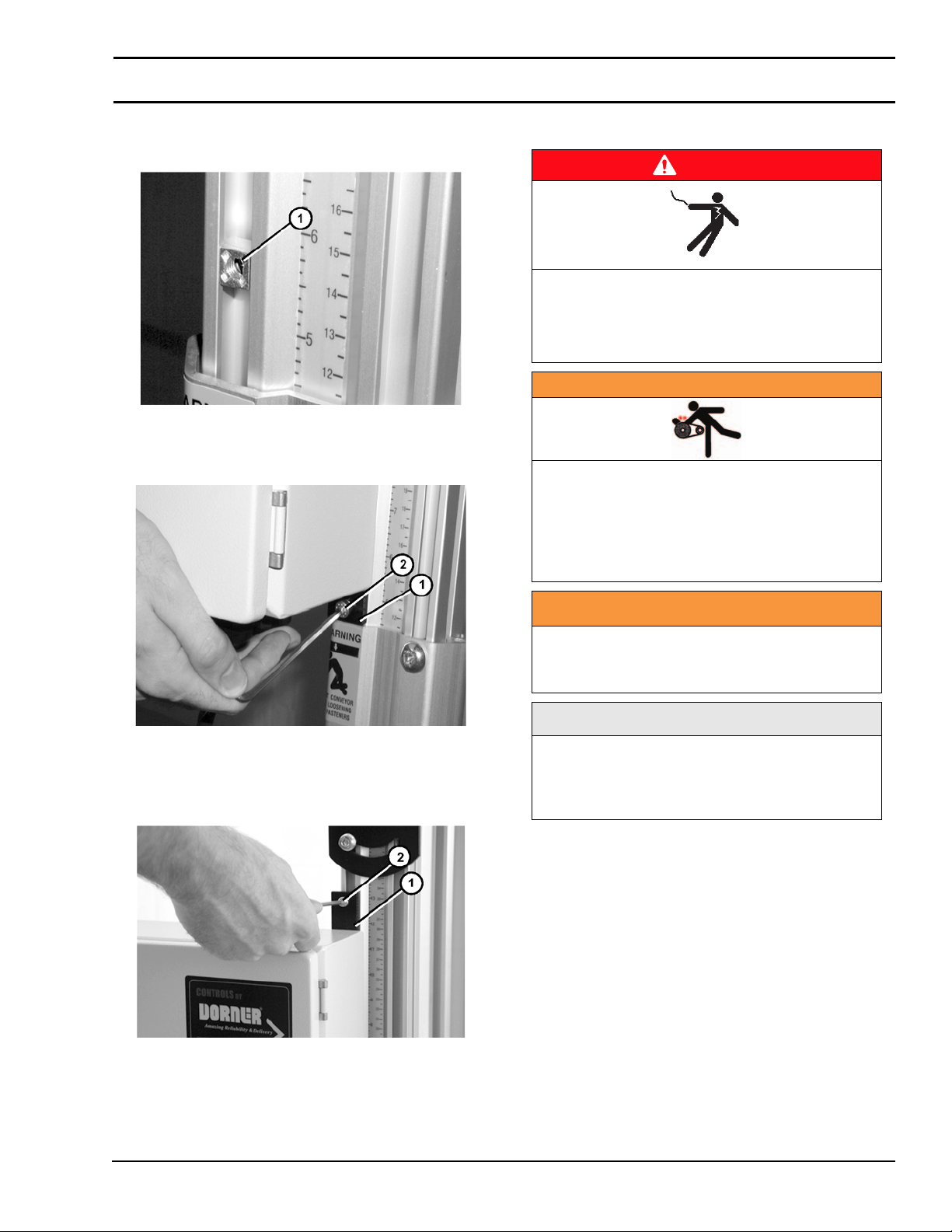

Conveyor Mounting ......................................................... 6

Stand Mounting................................................................ 7

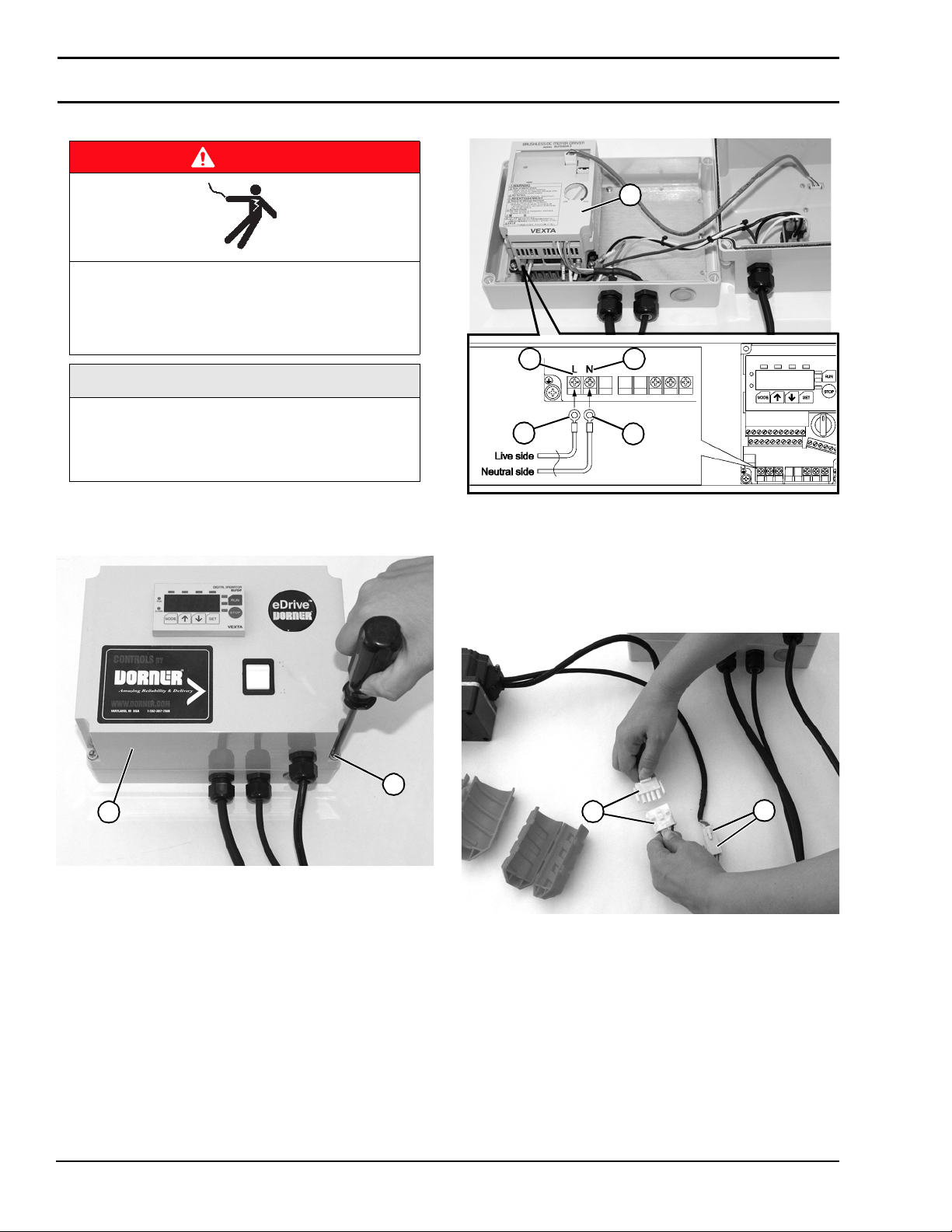

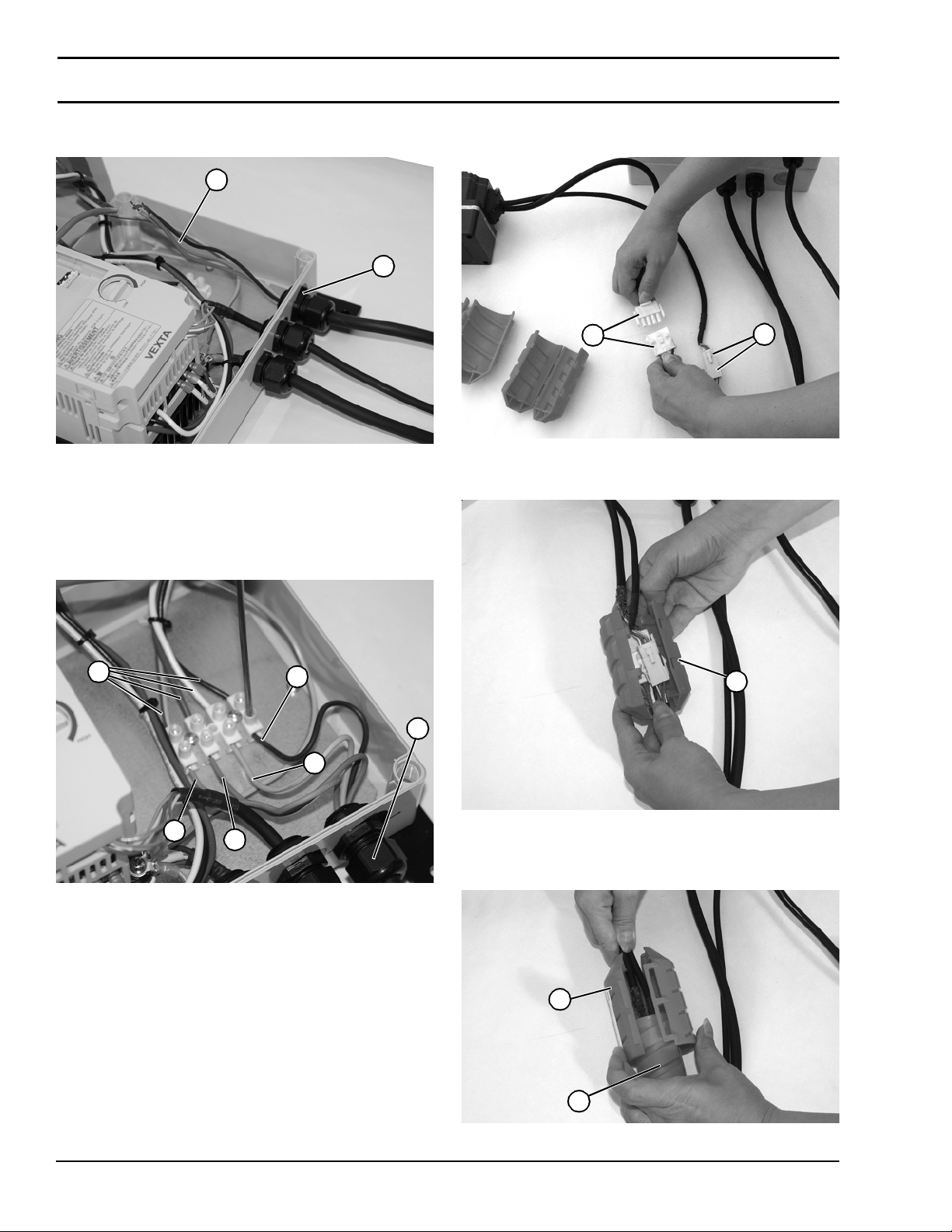

Wiring .............................................................................. 7

For 1 Phase (115 Volt) Controllers: ............................. 8

For 3 Phase (230 Volt) Controllers: ............................. 9

For Remote ON/OFF Signal: ...................................... 11

External Input Signals................................................. 12

Input Signal Connection Terminals ........................ 12

Operation............................................................................ 13

Controller Setup ............................................................ 13

Setting Speed Acceleration and Deceleration............. 13

Set Motor Direction .................................................... 15

Displaying the Conveyor Belt Speed.......................... 15

Setting Speed While Motor is Running ...................... 17

Switching the Signal Method

to Remote Signal (If Required)................................... 17

Notes .................................................................................. 18

Service Parts....................................................................... 19

Brushless DC Motor Control.......................................... 19

Return Policy...................................................................... 20

Introduction

Upon receipt of shipment:

• Compare shipment with packing slip. Contact factory

regarding discrepancies.

• Inspect packages for shipping damage. Contact carrier

regarding damage.

• Accessories may be shipped loose. See accessory instruc-

tions for installation.

The Dorner Limited Warranty applies.

Dorner reserves the right to make changes at any time

without notice or obligation.

Dorner has convenient, pre-configured kits of Key Service

Parts for all conveyor products. These time saving kits are

easy to order, designed for fast installation, and guarantee

you will have what you need when you need it. Key Parts

and Kits are marked in the Service Parts section of this

manual with the Performance Parts Kits logo .

CAUTION

Some illustrations may show guards

removed. DO NOT operate equipment without

guards.