Dissassembly

1. Loosen two (2) screws (Det. 5) and remove indicator housing

(Det. 4) from adapter (Det. 6). Remove dial indicator (Det. 1)

from indicator housing (Det. 4).

2. Loosen locknut (Det. 19) with wrench (Det. 20) and remove

range extension (Det. 16, 17 or 18) and adapters (Det. 21)

from gaging head (Det. 12).

3. Loosen two (2) screws (Det. 9) and remove spring (Det. 8).

4. Loosen two (2) screws (Det. 10) and disengage housing as-

sembly (Det. 6). Remove plunger rod (Det. 7).

5. Remove centralizer (Det. 11) from gaging head (Det. 12).

6. Remove retainer (Det. 15) from gaging head (Det. 12). Re-

move gaging pin (Det. 14) and gaging transfer (Det. 13).

Setting

1. Insert appropriate range extension (Det. 16, 17 or 18) and

adapters (Det. 21) into gaging head (Det. 12) and adjust

range extension to the approximate desired diameter.

2. Insert gage into reference master (master ring gage, bore

gage setmaster or gage block setup) and adjust range exten-

sion until dial indicator reads zero at rst 12 o’clock position.

Lock range extension in place with locknut (Det. 19).

3. Rock gage forward and back in reference master to insure

zero reading. Adjust indicator bezel to zero if necessary.

4. Repeat Step No. 3

Assembly

1. Insert gaging pin (Det. 14), gaging transfer (Det. 13) and

retainer (Det. 15) into gaging head (Det. 12).

2. Place centralizer (Det. 11) over gaging head (Det. 12).

3. Insert plunger rod (Det. 7) into gaging head (Det. 12). Place

housing assembly (Det. 6) over plunger rod (Det. 7) onto

gaging head (Det. 12) and lock in place with two (2) screws

(Det. 10).

4. Insert spring (Det. 8) and lock in place with two (2)screws

(Det. 9).

5. Insert dial indicator (Det. 1) into indicator housing (Det. 4)

and place onto housing assembly (Det. 6). Lock in place with

two (2) screws (Det. 5) insuring proper contact of indicator

with plunger rod (Det. 7).

6. Thread locknut (Det. 19) onto range extension (Det. 16, 17

or 18) and assemble extension to adapters (Det. 21) and

gaging head (Det. 12).

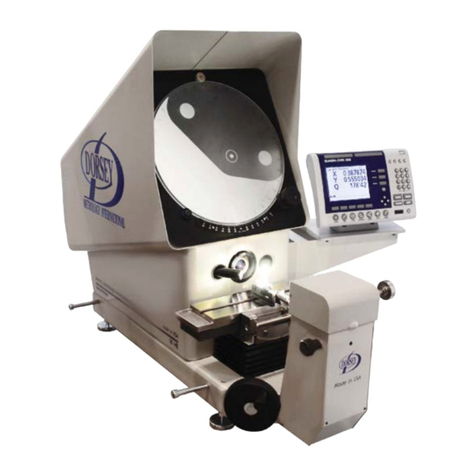

Dorsey Dial Bore Gage

Model DBL-1499

Range 1.50 - 3.00

Item PT. No. Part Name Item PT. No. Part Name Item PT. No. Part Name

1 .0001 Indicator 8 1150 Spring 15 1122 Retainer

2 120 Indicator Spring 9 Screw 16 1114-1 Range Extension

3 110 Indicator Contact 10 Screw 17 1114-2 Range Extension

4 104 Indicator Housing 11 1202 Centralizer 18 1114-3 Range Extension

5 Screw 12 1210 Gaging Head 19 1113 Extension Nut

6 1245 Gaging Body 13 1120 Transfer 20 1160 Wrench

7 1247 Plunger Rod 14 1130 Gaging Pin 21 1217 Adapter

tel: 845-454-3111

www.dorseymetrology.com