PL31--15LS2

02/00

Page 2

SAFETY FIRST!

ALWAYS COMPLY WITH:

1. General Industry Safety & Health Regulations, Part

1910, OSHA 2206, available from: Sup’t of Documents;

Government Printing Office; Washington DC 20402

2. Safety Code for Portable Air Tools, ANSI B186.1

available from: American National Standards Institute,

Inc.; 1430 Broadway; New York, NY 10018

3. State and Local regulations.

Portions of the above codes and regulations are listed below

for quick reference.

THESE EXCERPTS ARE NOT INTENDED TO BE ALL

INCLUSIVE -- STUDY AND COMPLY WITH ALL

REGULATIONS!

WARNING FAILURE TO COMPLY WITH ALL SAFETY

REGULATIONS MAY RESULT IN SERIOUS INJURY.

1. TOOL INTENT — Tools shall be used only for purposes

intended in their design (refer to product catalog).

2. AIR SUPPLY — Test and operate tools at 90 PSIG

maximum unless tool is marked otherwise. Use

recommended airline filters—regulators—lubricators.

3. UNUSUAL SOUND or VIBRATION — If tool vibrates or

produces an unusual sound, repair immediately for

correction.

4. OPERATOR PROTECTIVE EQUIPMENT — Wear

goggles or face shield at all times tool is in operation.

Other protective clothing shall be worn, if necessary.

SEE REGULATIONS.

5. SAFETY MAINTENANCE PROGRAM — Employ a

safety program to provide inspection and maintenance

of all phases of tool operation and air supply equipment

in accordance with “Safety Code for Portable Air Tools.”

Safe Work Practices Symbol

WARNING The signal word “Warning” identifies all notes on safe

work practices in this operating instruction, alerting to hazards for life

and health of people. Observe these notes and proceed with special

care in the cases described. Pass all safety instructions on to other

operators. In addition to the safety instructions in this operating

instruction, the general local safety and accident prevention rules must

be observed.

Important Notes

CAUTION The signal word “caution!” identifies all portions of this

operating instruction meriting special attention to ensure that

guidelines, rules, hints and the correct work procedures are observed;

and, to prevent damage to and destruction of the machine and/or parts.

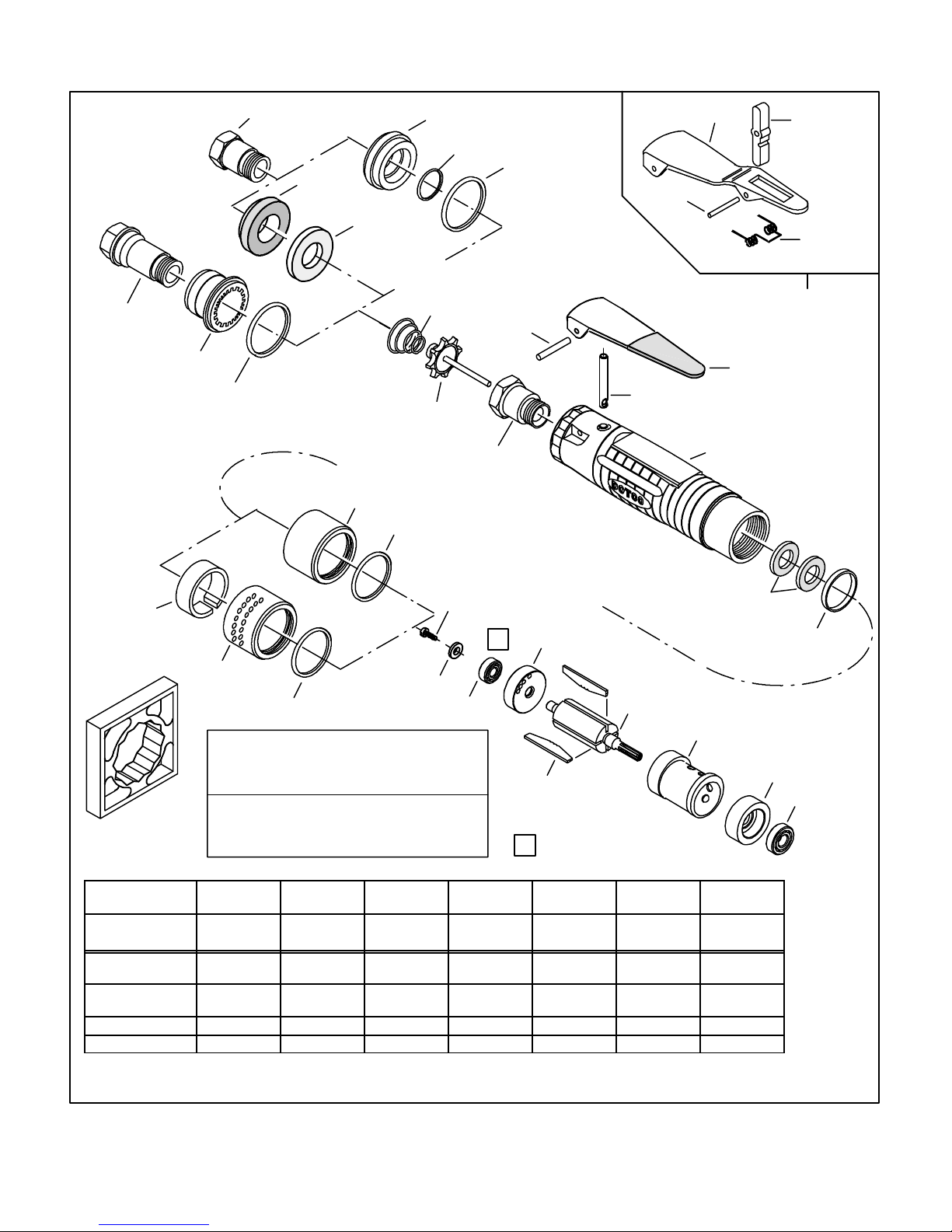

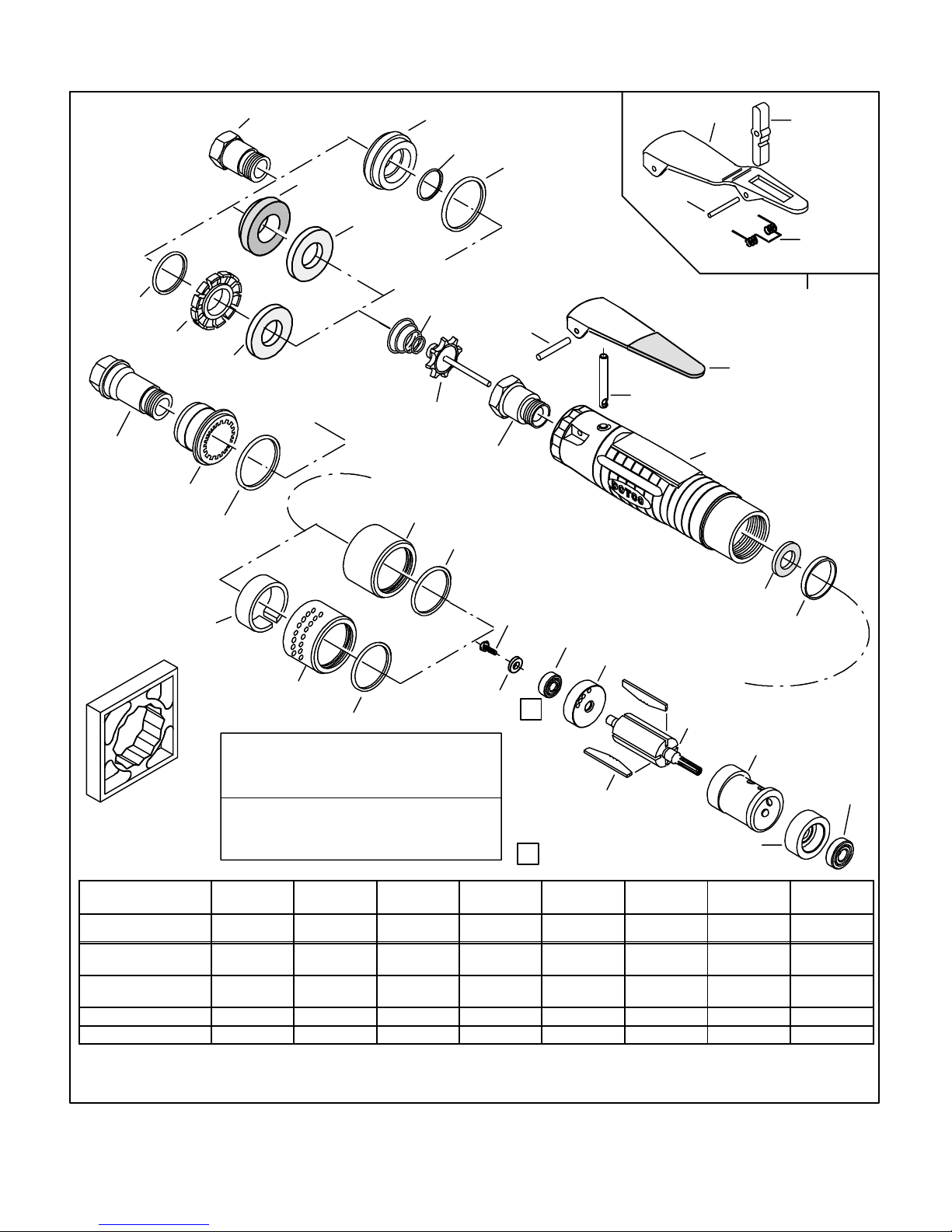

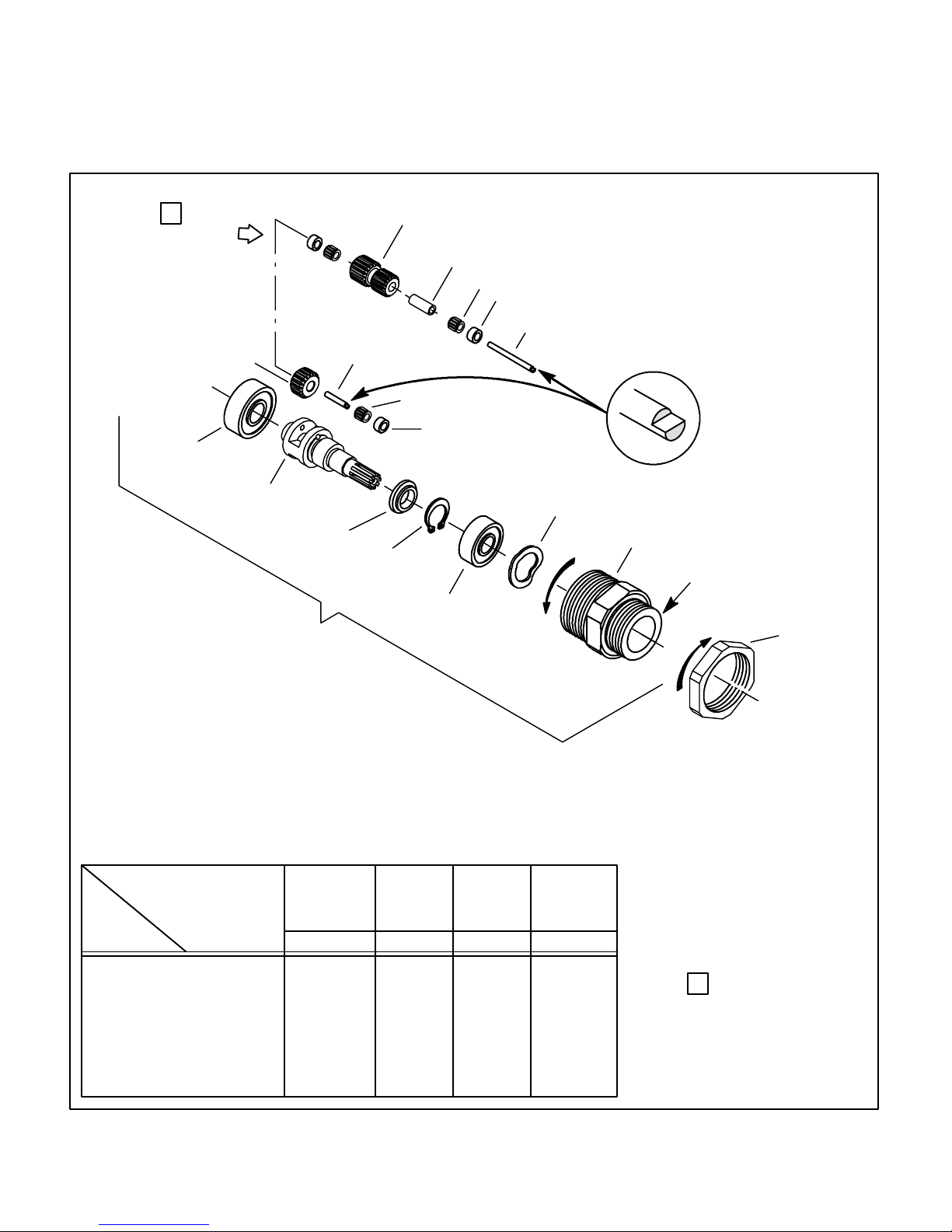

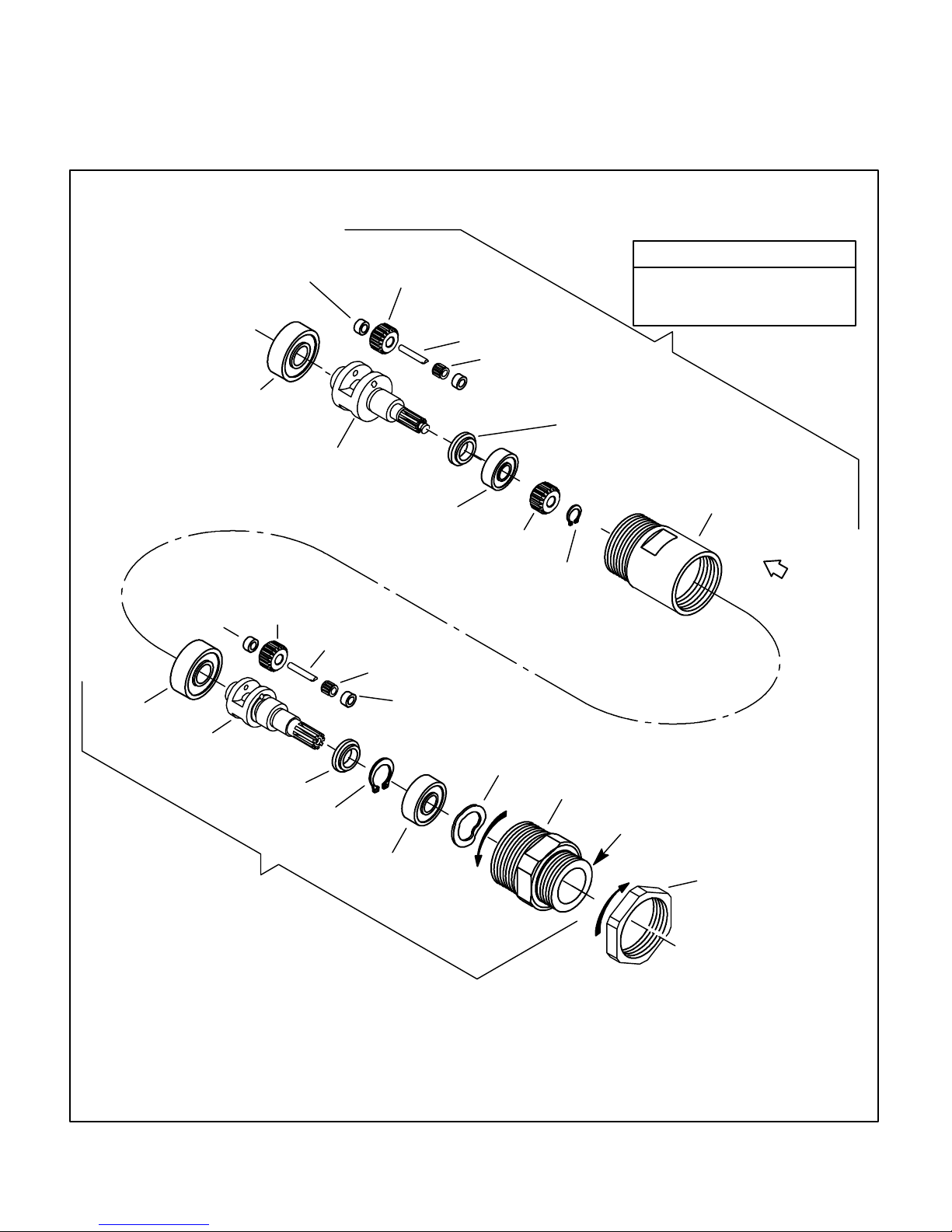

1The number in a square is a “service note” reference indicating

additional information for the correct assembly or disassembly of this

product. See Service Note page at end of this manual.

(•) Indicates recommended spare part (or set) for every five (5)

tools. Small, low cost or easily lost parts should be stocked as 3-4

per 10 tools.

WARNING Disconnect the air supply hose before servicing the tool.

INSTALLATION & OPERATION

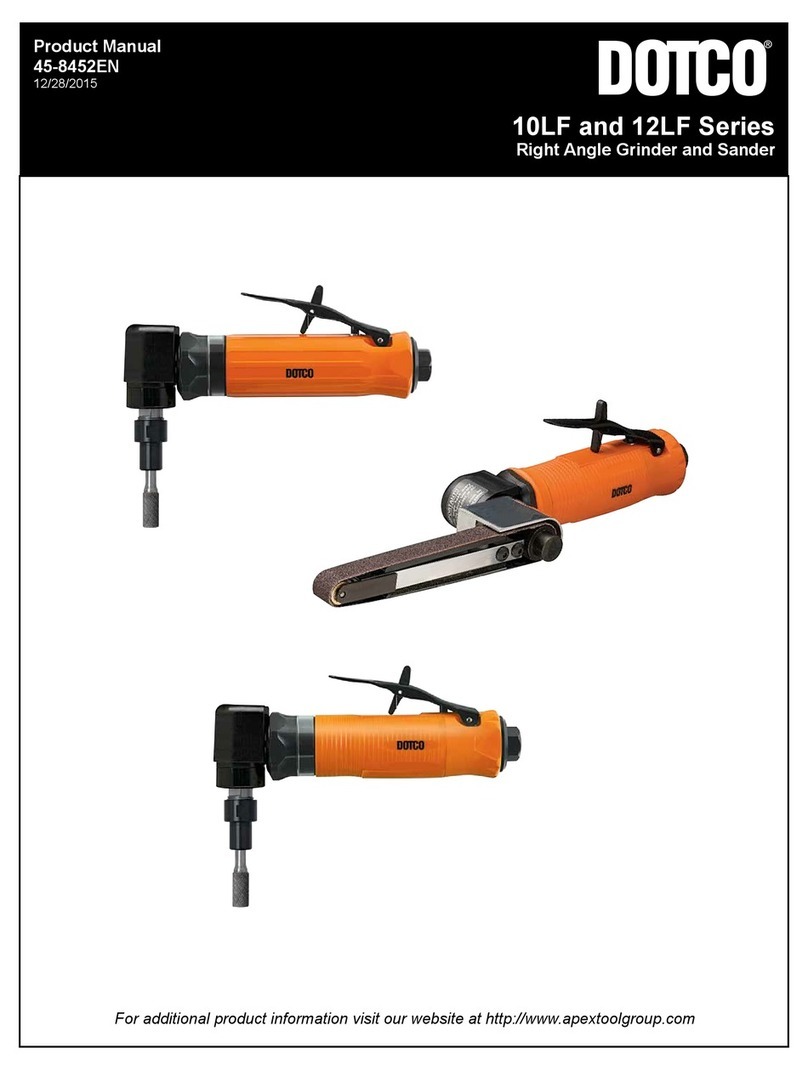

All 15LN2.. & 15LS2.. models covered by this

parts list...

These models are lever operated horizontal--type motors

with angle heads. The operator actuates and releases the

lever which starts and stops the air motor, gearing and

output spindle.

For best tool performance, a working air pressure of 90

pounds per square inch is recommended. Pipings, fit-

tings and hose should be adequate to maintain 90 psig

while the tool is in operation. An air line filter and lubri-

cator, such as Cooper Power Tool’s #F02--M Filter (1/4”

NPT) and #L02--EP Lubricator (1/4” NPT) should be used

(refer to Cooper’s “F--R--L” brochure). Hose should be

blown out before attaching to the tool.

LUBRICATION

Motor

Lubricate the motor with an air line lubricator, using a

light air tool oil. Adjust the lubricator to dispense one drop

per cycle or three drops per minute. This oil is available in

one (1) quart (540397) or one (1) gallon (533485) quanti-

ties. A high film strength oil (536333) is also available;

this oil cannot be used in Atomist type lubricators, use

only with Economist or serv-oil type lubricators.

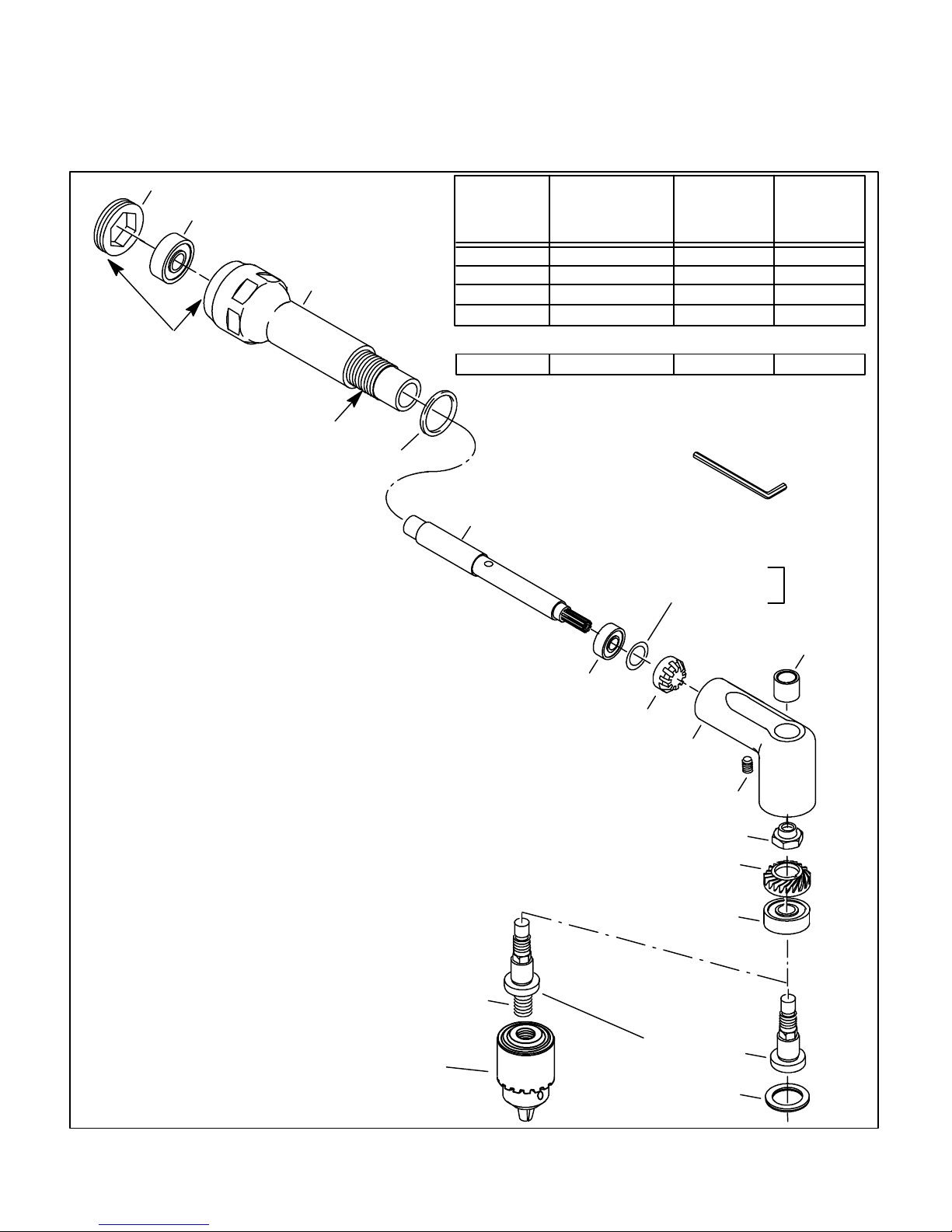

Planetary Gearing

Thoroughly grease all gears with Cooper Power Tools

teflon grease every 100,000 cycles. Whenever the tool is

disassembled, pack the gearing with approximately 1/4

ounce of grease. Teflon grease is available in one (1)

pound cans (513156) or two (2) oz. tube (540395).

Establish a routine inspection and re--lubrication program,

don’t short cut. Re--lubricate planetary by filling 1/3 to

1/2 full. Midget grease fittings are provided on the gear

housings and internal gears for external lubrication. Too

much grease will cause overheating.

CAUTION Do not use substitutes for oil and

grease. This could result in damage to the tool.

Angle Head Gear Lubrication

When angle head gearing is replaced, wipe on a thin coat

of Molykote, grade G; only a small amount is necessary.

An 8 ounce tube is available under part number 540394.

Molykote has been shown to improve the wearing

characteristics of angle gearing.