Lift the stair assembly into the pool being careful not to

contact and/or damage the pool liner with the handrail ends

if they are already installed (see NOTE above). Turn the

assembly upright as shown and position it near the selected

installation location.

Filled Pools: Tilt the stairs so that trapped air can escape

through the small predrilled vent holes.

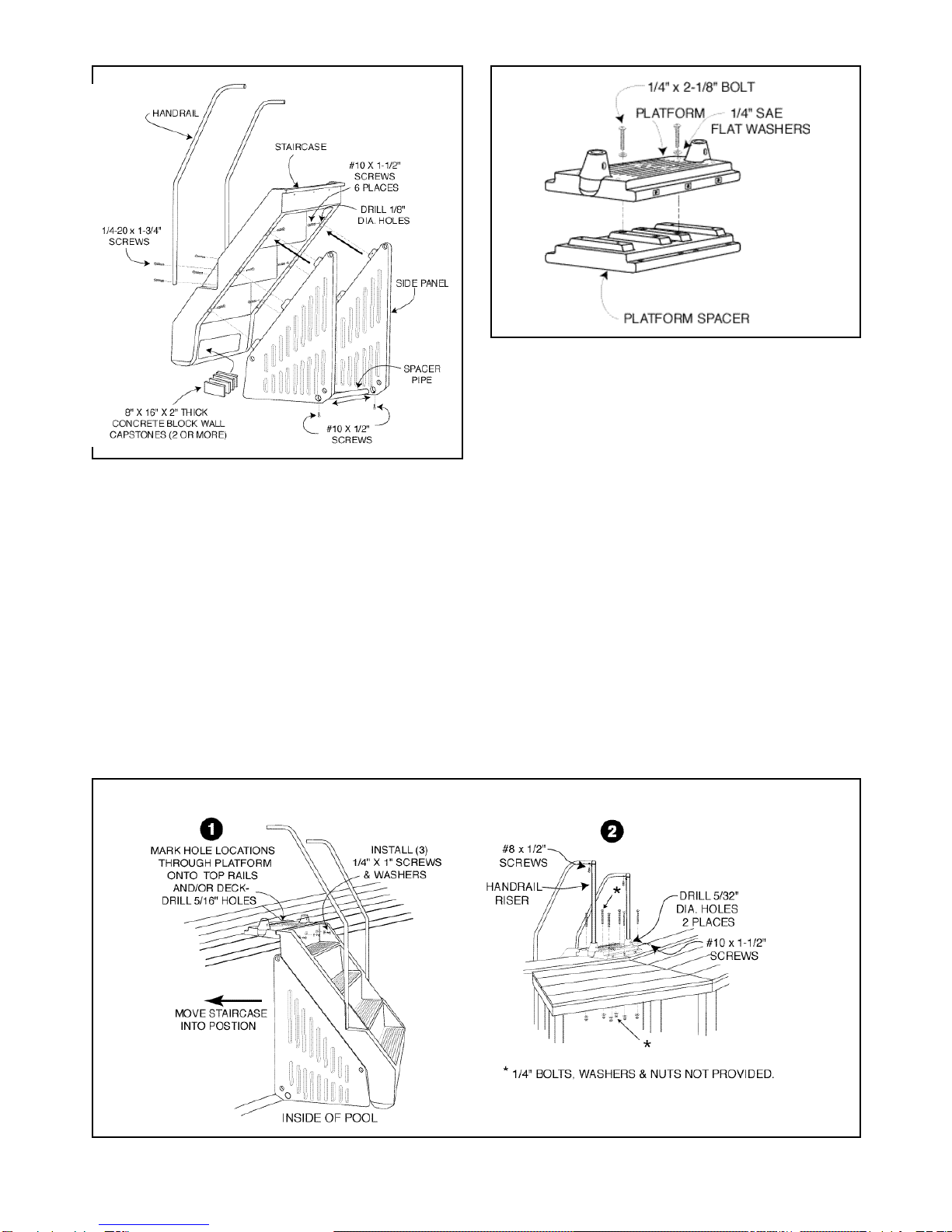

Install Concrete Blocks

See Fig. 3

You must insert two (2) or more 8” x 16” x 2” thick concrete

block wallcapstones into the stair cavity as shown in Fig. 3.

The blocks counteract the stairs natural buoyancy and will

helptostabilizethecompletedassembly. CAUTION: Don’t

install the blocks until the stair assembly is in the pool.

Theblockscouldfalloutcausingdamagetothepooland/

or deck or cause personal injury. When installing blocks

when the pool is filled, be sure that you have someone to

assist you.

Remove Top Connector (If required)

Iftheplatformistobelocatedovera verticalsupport,remove

the pool’s top connector from the area selected for platform

installationsotheplatformcan layflat on thepool’stoprails.

DO NOT REMOVE SCREWS THAT ATTACH THE TOP

RAILS TO THE VERTICAL END CAP.

Locate and Drill Mounting Holes

See Fig. 5A for 52” Tall Pools

See Fig. 5B for 48” Tall Pools

Move the inside stair assembly to the selected installation

location and position it completely against the pool wall at

its final location.

Lay the platform (52” Pools) or platform with spacer (48”

Pools)attached ontothe top rails andalign itsthreaded brass

holes with the holes intop edge of the staircase. Install three

(3) 1/4” x 1” long screws with 1/4” flat washers through

staircase holes into the platform. Tighten securely.

Recheck the staircase and platform position in relation to

the pool wall andmake any final adjustmentsto its location

Be sure that both side panels are as tight as possible

against the pool wall.

IMPORTANT: Foradditional strength,it isrecommended

that you install at least two #14 sheet metal screws into the

vertical endcap when the platform is locatedovera vertical

support. If possible, locate hole positions where bolts and

nuts will be on the outside of the pool wall. Avoid hole

locations where the drill bit could contact and damage

the pool wall or liner.

52” Pools Only (See Fig. 5A): When satisfied with the

platform’sposition,selecttheholesyouwilluseforfastening

the platform to the pool’s frame. For maximum stability,

youshouldconnectthe platformtothe poolframe in at least

four places. Use a pencil to mark hole locations through

the platform onto the top rails and vertical end cap.

After marking holes, move the staircase/platform assembly

aside anddrill 5/16” diameterholes at the marked locations

on the top rails. Drill 7/32” diameter holes for connection

to vertical end caps with #14 x 3-1/2” screws.

48” Pools Only (See Fig. 5B): When satisfied with the

platform’s position, use a pencil to mark the platform

spacer’slocationonto thetoprails. Movethestaircaseaside

and disassemble the spacer from the platform. Return the

spacer totheposition previouslymarked andselectthe holes

you will use for fastening the platform spacer to the pool’s

frame. For maximum stability, you should connect the

platform spacer to the pool frame in at least four places.

Use a pencil to mark hole locationsthrough the spacer onto

the top rails and vertical end cap.

After marking holes, move the platform spacer aside and

drill 5/16” diameter holes at the marked locations on the

toprails. Drill7/32”diameterholesforconnectiontovertical

end caps with #14 x 3-1/2” screws.

FIG. 5B - 48” TALL POOLS

4