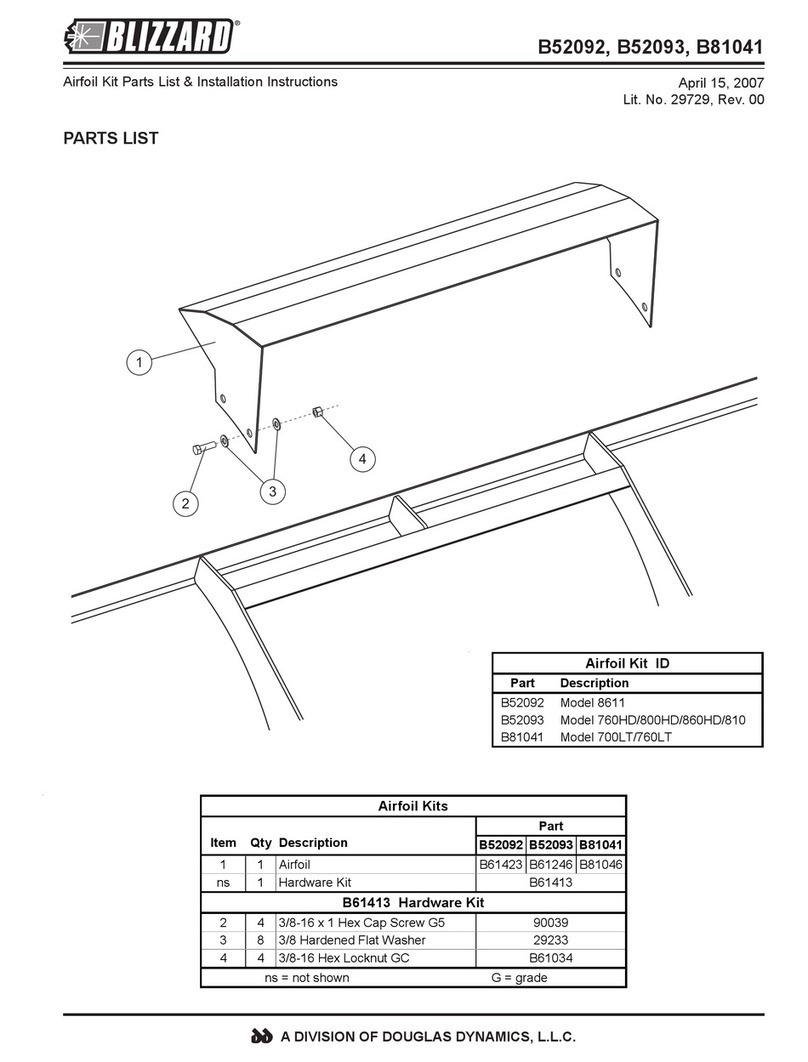

Lit. No. B64093, Rev. 09 8 April 15, 2011

OPERATION

Your SPEEDWING™ snowplow is the newest

multi-position snowplow on the market. The

easy-to-use controls allow you to automatically adjust

the snowplow blade into a variety of plowing positions.

Review the illustrations below for instruction on

maneuvering your snowplow.

A. Lowered or Float Position

Pushing the joystick forward, toward the

"Lower/Float" designation on the label, or pushing

the D button on the touchpad will lower your blade

to the ground. Pushing and momentarily holding

the control in this position will allow the snowplow

to "float," or follow the contour of the ground when

moving forward or backward.

B. Raised Position

Pulling the joystick back, toward the "Raise"

designation on the label, or pushing the U button

on the touchpad will lift your blade off the ground.

To stop raising the snowplow, simply return the

joystick to its neutral (center) position or release the

touchpad button. The snowplow has reached its

maximum raised height when the blade stops lifting.

C. BUCKET BLADE™ Position

(7'-7" or 8'-7" Blade Width)

Automatic position when blade is not angled;

creates a scoop and eliminates trails.

• Primary position for transporting snow

• For use in initial clearing with decent visibility,

transporting large volumes of snow, final clean-up

• Ideal application: residential driveways, small

roads, roadway intersections

D. Angled Width with Trailing Wing

(6'-7" or 7'-10" Blade Width)

To angle your blade, position the joystick toward

the "R" or "L" on the label or push the R or L

button on the touchpad. An angled blade will

automatically extend the trailing wing. To stop

angling the blade, return the joystick to its neutral

(center) position or release the touchpad button.

The blade has reached its maximum angled

position when it

stops moving to the side.

• Primary position for accelerated angled plowing

• For use in directional plowing, cornering, diverting

snow away from objects or buildings

• Ideal application: plowing adjacent to buildings,

driveway/road intersections

E. Back Blade Position

(8'-7" or 9'-9" Blade Width)

Lock the wings into place to create the largest

clearing path and get the most out of your wings.

• Primary position for clearing large surfaces

• For use in light snow conditions with good

visibility, final clearing and clean-up

• Ideal application: large parking lots, widening

roadways

NOTE: To prevent premature failure of the power

contactor (solenoid), return the joystick to its

neutral (center) position, or release the touchpad

button, immediately after the blade reaches

the limit of any position. Continuing to hold the

control after the blade has reached the limit of

movement in any position will reduce the life of

the solenoid.

C.

D.

E.