Lit. No. 74125/74126, Rev. 00 3 July 1, 2020

TABLE OF CONTENTS

PREFACE................................................................... 4

Owner's Information Form .................................... 4

SAFETY ..................................................................... 5

Safety Denitions.................................................. 5

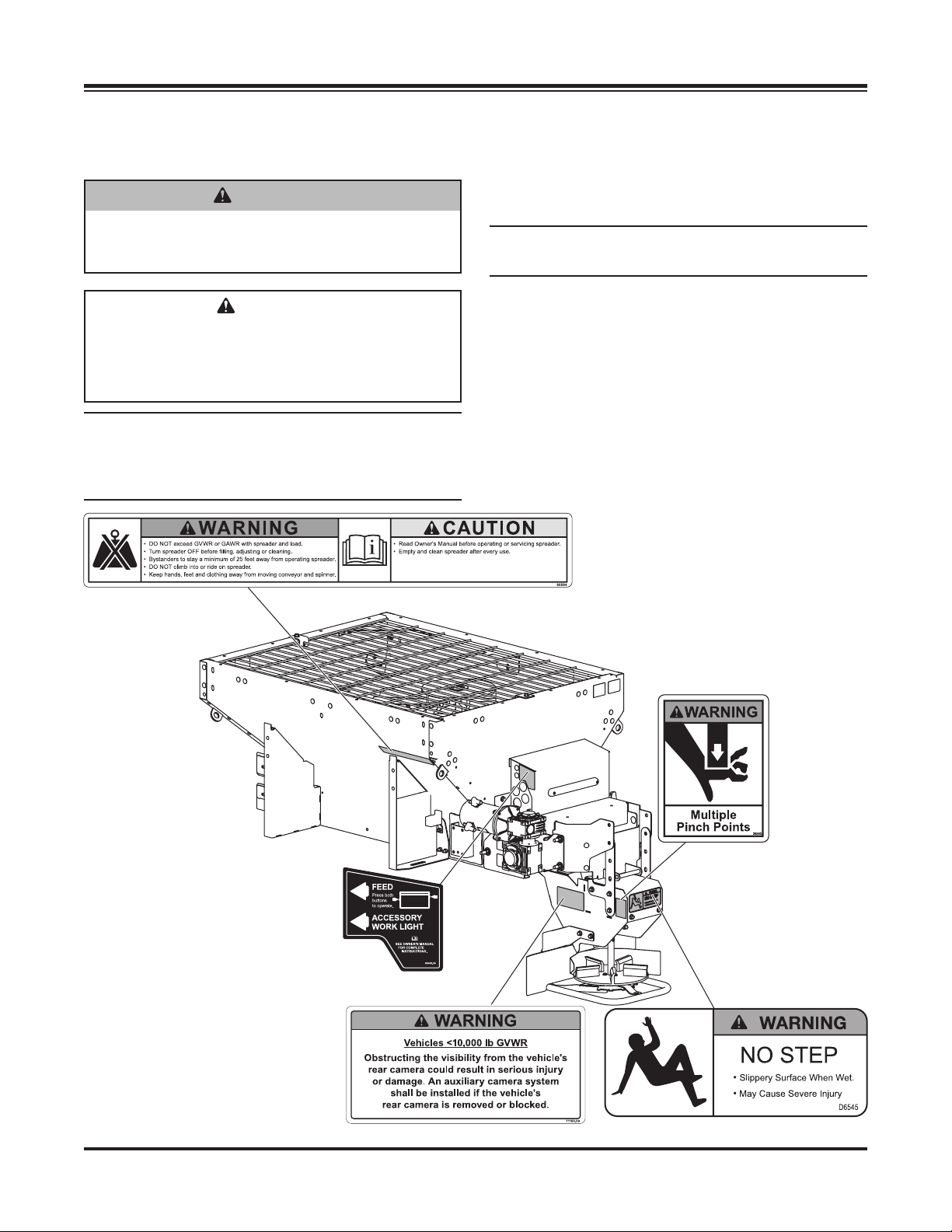

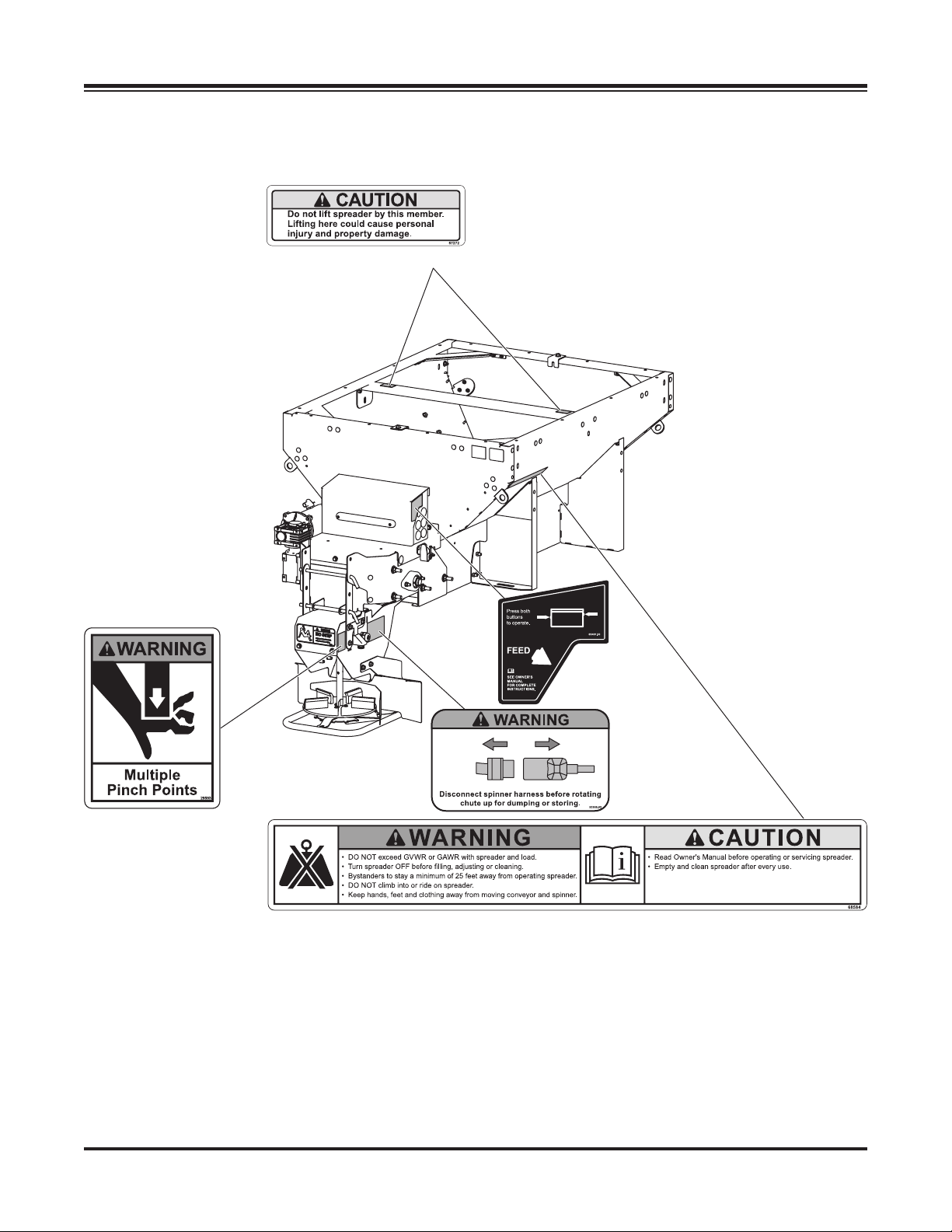

Warning/Caution Labels ....................................... 5

Serial Number Label ............................................. 7

Safety Precautions................................................ 7

Fuses .................................................................... 8

Personal Safety..................................................... 8

Fire and Explosion ................................................ 8

Cell Phones........................................................... 8

Ventilation ............................................................. 9

Battery Safety ....................................................... 9

Noise..................................................................... 9

Vibration................................................................ 9

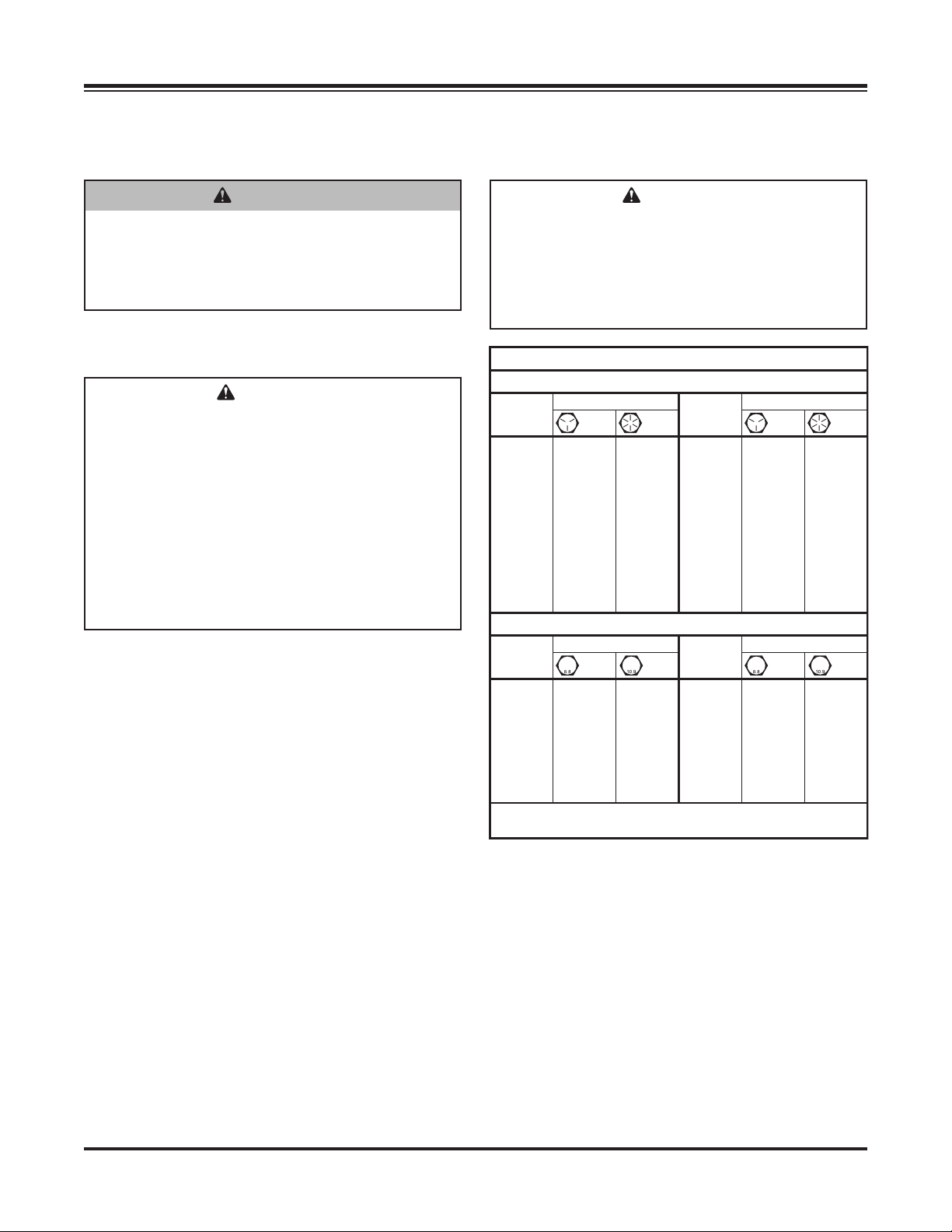

Torque Chart ......................................................... 9

LOADING ................................................................. 10

Certication......................................................... 10

Spreader Specications...................................... 10

Material Weights ................................................. 10

Load Volume ....................................................... 11

Determining Vehicle Payload.............................. 11

Determining Vehicle Payload Worksheet............ 12

UNPACKING THE SPREADER............................. 13

Remove Shipping Brackets and Locate

Components .................................................... 13

MOUNTING THE SPREADER............................... 14

Chute Assembly.................................................. 14

Install Hopper in Vehicle Bed.............................. 14

Install Tie-Down Straps ................................ 15

Construct Sill Spacer.................................... 15

Install Spinner Drive Assembly ........................... 16

OPERATING THE SPREADER—CAB CONTROL 17

Powering the Control .......................................... 17

Starting and Stopping Spreader ......................... 17

Controlling Material Application .......................... 18

BLAST/Maximum Application ...................... 18

Cab Control Modes............................................. 18

Standby Mode .............................................. 18

Ready Mode ................................................. 18

ON Mode ...................................................... 18

Error Mode ................................................... 18

Cab Control Codes – Table ............................... 19

Setup Procedures ............................................... 21

Calibrate the Empty Hopper Setting............. 21

Adjust LED Brightness Level........................ 21

OPERATING THE SPREADER ...............................22

Spread Pattern Adjustment.................................22

Material Spread Patterns.............................. 23

Accessory LED Work Light ................................. 24

Dump Function.................................................... 24

Remove Spreader from Vehicle.......................... 25

Store the Spreader ............................................. 25

MAINTENANCE ...................................................... 26

After First Use .....................................................26

After Each Use.................................................... 26

Cab Control......................................................... 26

Storage ...............................................................26

At the End of Each Season or

After Extended Storage ................................... 26

Fuse Replacement.............................................. 26

Recycle ...............................................................26

Grease Fittings ................................................... 27

ELECTRICAL COMPONENTS .............................. 28

Vehicle Harness Diagram ................................... 28

Electrical Control Box .........................................29

FINAL ADJUSTMENTS.......................................... 30

Conveyor Pintle Chain Tension........................... 30

TROUBLESHOOTING GUIDE............................... 31