CONTENTS

SETTINGUPTHESYSTEM 4

SoftwareInstallation.................................................................................................................. 4

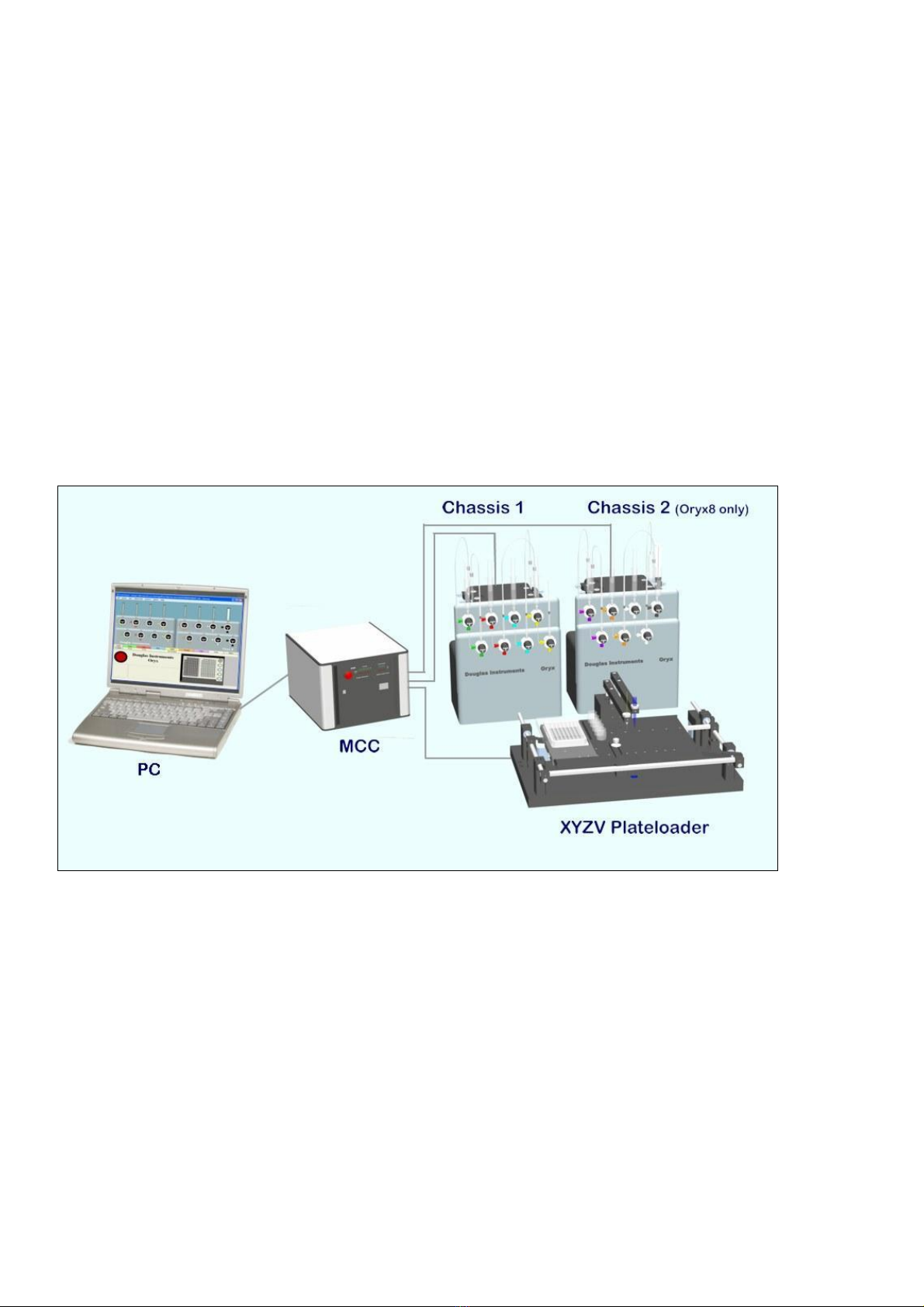

Layout ofthe Hardware.............................................................................................................4

Recordingthe Positionsof Motors............................................................................................ 5

Unpacking.................................................................................................................................5

ElectricalConnection ................................................................................................................ 5

Installing theZandVArms....................................................................................................... 5

RezeroingMotorizedSyringeDrivers.......................................................................................6

Mounting 100 mlGas-Tight SyringesonMotorizedSyringeDrivers,and

Fillingthem withWater.............................................................................................................. 6

Installing 2.5 mlsyringe.............................................................................................................8

Testing the Performanceof the Plateloader.............................................................................. 9

RealigningthePlateloader........................................................................................................9

Rezeroing all Motorsofthe Plate Loader.................................................................................. 10

FRONTPANELMENU ITEMS 11

USEANDMAINTENANCEOFTHEHARDWARE 15

Installing Microtips.....................................................................................................................15

Use ofLiquidHandling SystemIncluding ValvePositions........................................................15

Refilling100mlGas-TightSyringeswith Water....................................................................... 15

Debubbling ............................................................................................................................. 15

FlushingTubing betweenValves............................................................................................ 16

FillingMicrotipwith Solution................................................................................................... 16

Dispensing Experiments.........................................................................................................16

Attachthe EvaporationshieldforVaporDiffusion Experiments................................................ 17

FlushingMicrotipafterUse....................................................................................................... 18

Alwayswearprotective goggleswhenhandling causticmaterials............................................18

Protein Coatingsof Microtip...................................................................................................... 18

Blockages.................................................................................................................................. 18

ChemicalInertness................................................................................................................... 18

TubingConnections.................................................................................................................. 18

Lubrication of SyringeDrivers andPlateLoader....................................................................... 20

Lubrication of Shafts............................................................................................................... 20

Lead-screws........................................................................................................................... 20

Spillages.................................................................................................................................20

XYZVPlate Loader................................................................................................................... 20

Adjustmentof XYZVPlate Loader.......................................................................................... 20

HARDWARECONFIGURATIONAND CONTROL 21

UsingDifferent Syringeswith the System................................................................................. 21

ChangingPlates........................................................................................................................21

WASPandASPRUN.............................................................................................................. 21

PickAndMix........................................................................................................................... 21

XSTEP– ChangingPlates..................................................................................................... 21

AddingFurtherPlatesto PLATES.DAT.................................................................................... 21

HardwareConfiguration Files.................................................................................................... 22

HARDWARE.CFG.................................................................................................................. 22

HARDWARE.FTH .................................................................................................................. 22

Specifications............................................................................................................................ 24

INDEXOFMANUAL 25