OM-HY/6G(CE) 7

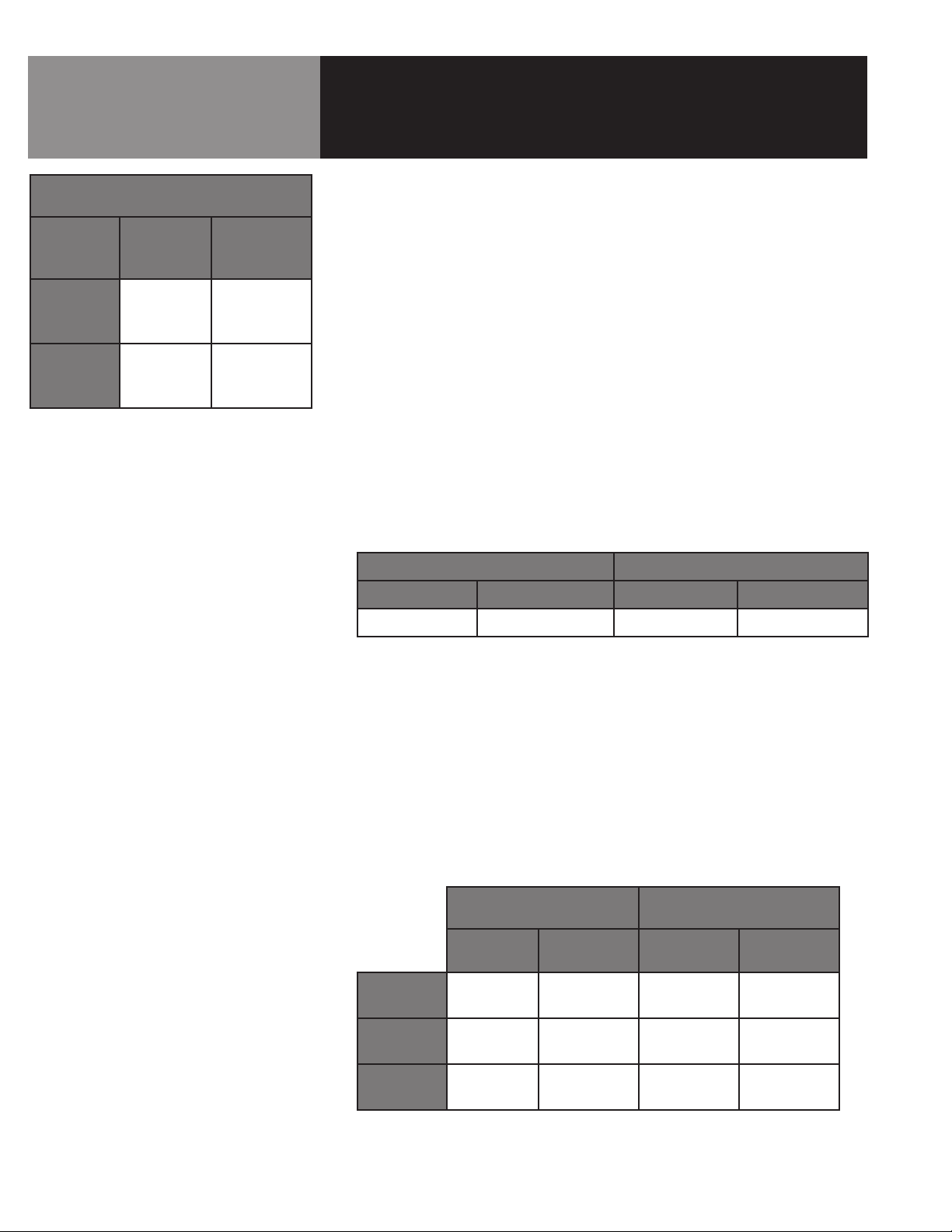

The HY-6G(CE) steamer is suitable for installation in combustible and noncombustible

locations. Minimum clearances for installation are:

Right Side 300 mm (12 inches)

Left Side 0 mm (0 inches)

Rear of Flue 150 mm (6 inches)

However, for easy service at least 300 mm (12 inches) clearance is required for the

right side of the unit, and it may not be installed within 300 mm (12 inches) of a heat

source, as stated in the Caution above.

The unit must be installed in a well-ventilated room with an adequate air supply. The

steamer must be installed beneath a ventilation hood, since gas combustion products

exit the appliance.

Any item which might obstruct or restrict the flow of air for combustion and ventilation

must be removed. Do not obstruct the flue cover or any front, side, rear, or top vents

after installation.

The area directly around the appliance must be cleared of all combustible material.

The installation must conform with local codes or, in the absence of local codes, with

the National Fuel Gas Code, ANSI Z223.1, latest edition, including the following:

The unit and its individual shutoff valve must be disconnected from the gas supply

system during any pressure testing of that system at test pressures in excess of ½

PSI (3.45 kPa). It must be isolated from the gas supply piping system by closing its

individual manual shutoff valve during any pressure testing of the gas supply piping

system at test pressures equal to or less than ½ PSI (3.45 kPa).

1. Electrical Supply Connection

The unit is designed for connection to fixed wiring. A suitably rated isolating

switch with contact separation of at least 3 mm on both poles must be fitted

to the installation. Wiring must be executed in accordance with the regulations

listed on page 2 of this manual.

Cable entry is at the bottom rear right side of the appliance. To gain access the

panel must be removed. Open the lower front panel by removing its screws. Lift

the panel and swing its bottom toward you. Set the panel aside.

Provide 230 Volt, 50 Hz, Single Phase, 15 Ampere service. Maximum load is 2½

amps. The electrical schematic is located in the service compartment. A copy is

also printed at the rear of this manual.

2. Gas Supply Connection

Incoming service must be of sufficient size to supply full rate without excessive

pressure drop. A gas meter is connected to the service pipe by the Gas Supplier.

Any existing meter should be checked out by the Gas Supplier to ensure that

it has adequate capacity to provide the required rate of gas to the steamer, in

addition to any other equipment.

WARNING

THE UNIT MUST BE INSTALLED BY

PERSONNEL WHO ARE QUALIFIED TO

WORK WITH ELECTRICITY AND PLUMBING.

IMPROPER INSTALLATION CAN CAUSE

INJURY TO PERSONNEL AND/OR DAMAGE

TO THE EQUIPMENT. THE UNIT MUST

BE INSTALLED IN ACCORDANCE WITH

APPLICABLE CODES.

CAUTION

DO NOT INSTALL THE UNIT WITH THE

RIGHT SIDE VENTS BLOCKED OR WITHIN

30 CENTIMETERS OF A HEAT SOURCE

(SUCH AS A BRAISING PAN, DEEP FRYER,

CHAR BROILER, OR KETTLE). TO AVOID

DRAINAGE PROBLEMS, LEVEL THE UNIT

FRONT TO BACK, OR PITCH IT SLIGHTLY

TO THE REAR.

Installation

CAUTION

THE UNIT MUST HAVE A SEPARATE

EARTHING WIRE FOR SAFE OPERATION.

MODEL WIDTH

mm (in)

DEPTH

mm (in)

HEIGHT

mm (in)

WEIGHT

Kg (lbs)

HY-6G(CE) 549 (21.6) 894 (35.2) 1464 (57.6) 193 (425)