Test Procedure:

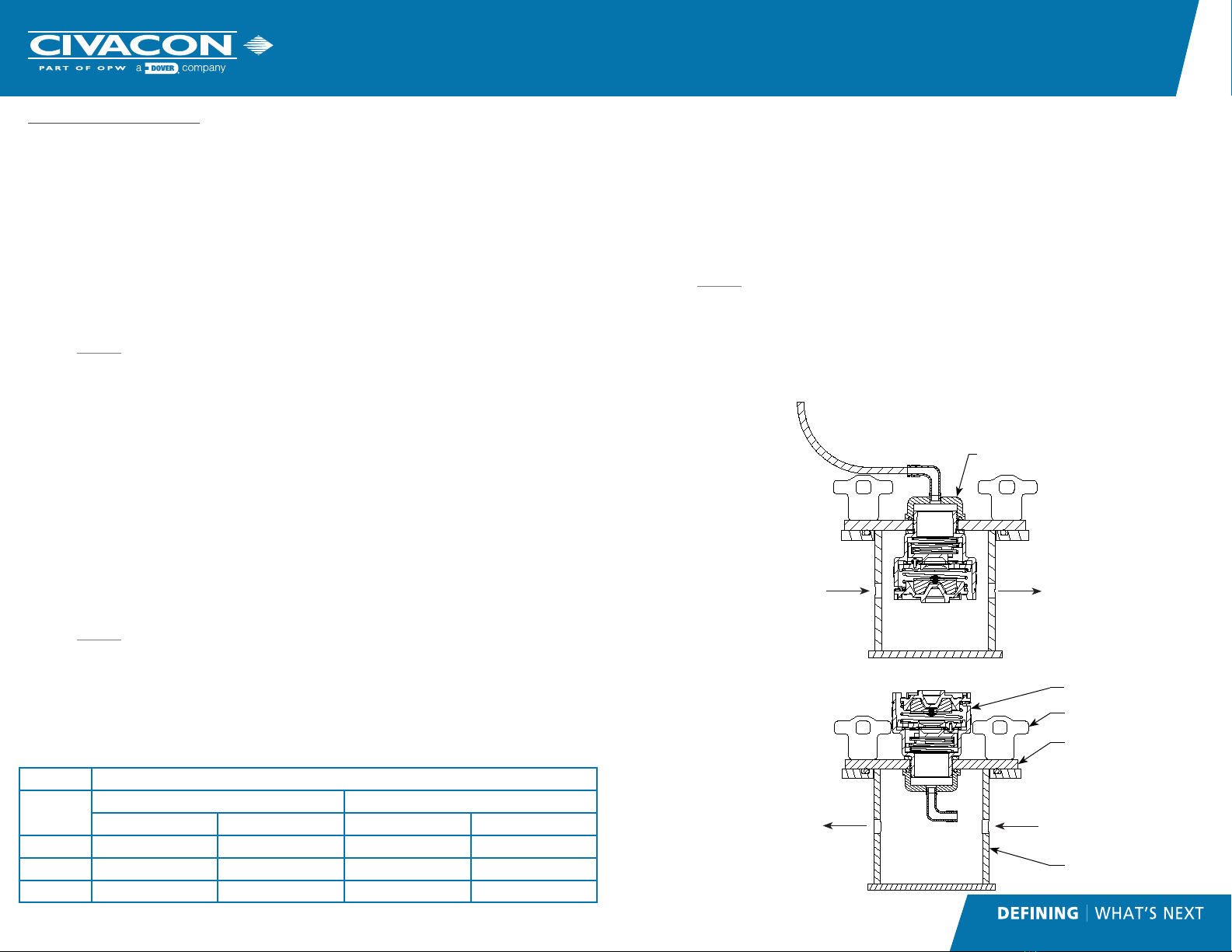

Pressure Test (See Illustration “A”)

1. Intall vent (Item# 5) in the hole in the cover plate (Item# 3) of the vent

test tank (Item# 2). Screw vacuum test cap (Item# 1) on to the threaded

portion of the vent (Item# 5).

2. Install cover plate (Item# 3) and vent (Item#5) onto test tank (Item# 2),

with vent (Item# 5) pointing downward as shown in the illustration. Use

wing nuts (Item# 4) to fasten the cover plate (Item# 3) to the test tank

(Item#2).

3. Attach a short length of hose to the vacuum test cap (Item#1) and run it

to a small container of water. Keep the end of the hose 1/4” below the

surface of the water.

4. Slowly apply pressure, and take note at what pressure the bubbles start

coming out of the hose. Note the pressure reading on the gauge or the

manometer.

5. The measured pressure level should fall in the range found in Table 1 for

the specific vent model being tested. If the vent does not pass the test, it

must be cleaned, repaired or replaced.

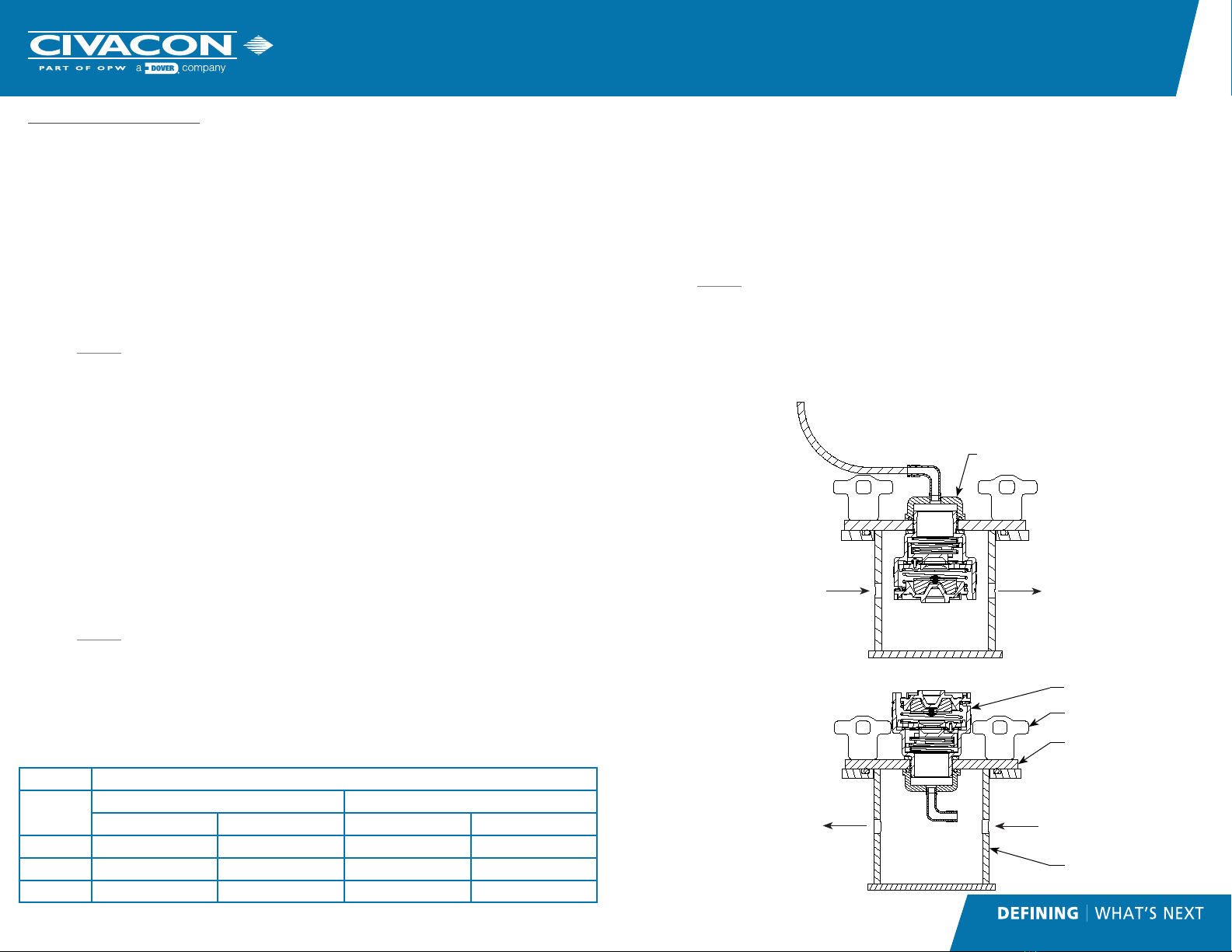

Vacuum Test (See Illustration “B”)

1. Intall vent (Item# 5) in the hole in the cover plate (Item# 3) of the vent

test tank (Item# 2). Screw vacuum test cap (Item# 1) on to the threaded

portion of the vent (Item# 5).

2. Install cover plate (Item# 3) and vent (Item#5) onto test tank (Item# 2),

with cap inside the tank as shown in the illustration. Use wing nuts

(Item# 4) to fasten the cover plate (Item# 3) to the test tank (Item#2).

3. Spray water/soap solution areound the two black poppets on the side of

the vent.

4. Slowly apply pressure, with the vent in the orientation shown in the

illustration. Take note at what pressure the bubbles start being produced

from the sealing surface. Note the pressure reading on the gauge or the

manometer.

5. The measured vacuum level should fall in the range found in Table 1 for

the specific vent model being tested. If the vent does not pass the test, it

must be cleaned, repaired or replaced.

Overturn Test (See Illustration “A”)

1. Intall vent (Item# 5) in the hole in the cover plate (Item# 3) of the vent

test tank (Item# 2). Screw vacuum test cap (Item# 1) on to the threaded

portion of the vent (Item# 5).

2. Install cover plate (Item# 3) and vent (Item#5) onto test tank (Item# 2),

with vent (Item# 5) pointing downward as shown in the illustration. Use

wing nuts (Item# 4) to fasten the cover plate (Item# 3) to the test tank

(Item#2).

3. Set pressure regulator between 4 and 5 psi (27.6 kPa and 34.5 kPa).

Slowly apply pressure until the air is exhausting out the top or the vent.

4. Rotate test fixture 90 degrees and attach a short length of hose to the

vacuum test cap (Item# 3) and run it to a small container of water. Keep

the end of the hose 1/4” below the surface of the water. A steady

stream of bubbles would represent a failure. This overturn test must be

repeated at an angle of 180 degrees and 270 degrees. If the vent fails at

any of the three orientations, it must be cleaned, repaired or replaced.

TABLE 1 REQUIRED SETTINGS

PART

NUMBER

PRESSURE VACUUM

MIN. MAX. MIN. MAX,

NV4000 1.0 PSI (27.7”H20) 1.5 PSI (41.5” H20) .25 PSI (7.0” H20) .375 PSI (10.4” H20)

NV4000C .87 PSI (6 kPa) 1.16 PSI (8 kPa) .29 PSI (2 kPa) .43 PSI (3 kPa)

NV4000E 1.0 PSI (69 mbar) 1.74 PSI (120 mbar) .25 PSI (17 mbar) .29 PSI (25 mbar)

Air out to small container

of water to see bubbles

when valve opens

Air in from regulator

(0-5 PSI)

Air out to manometer or

low pressure gauge

ILLUSTRATION “A”

POSITIVE PRESSURE TEST POSITION

ILLUSTRATION “B”

VACUUM TEST POSITION

Air out to manometer or

low pressure gauge

Air in from regulator

(0-5 PSI)

1

4

3

5

2