2

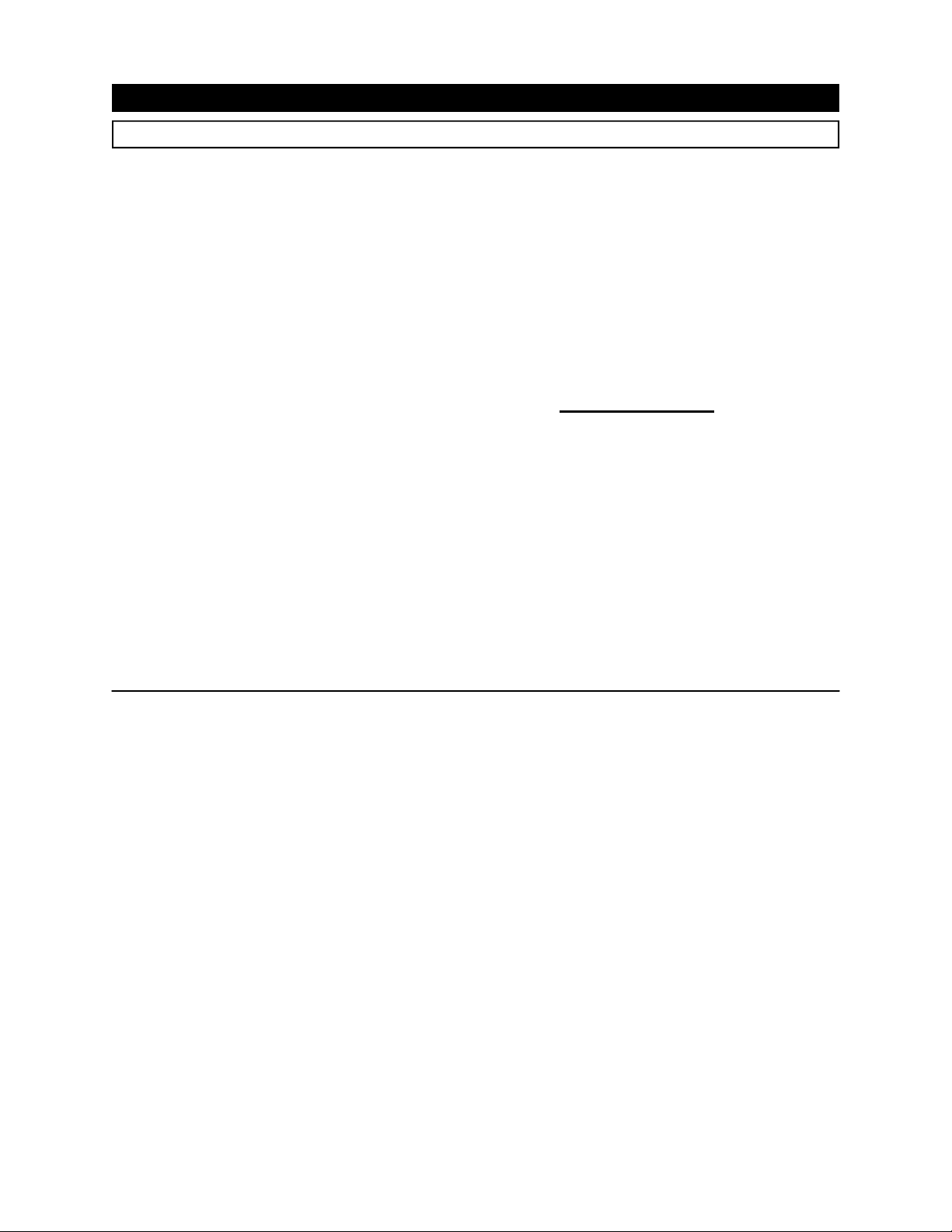

Tabl of Cont nts

Introduction .............................................................................................................. 3

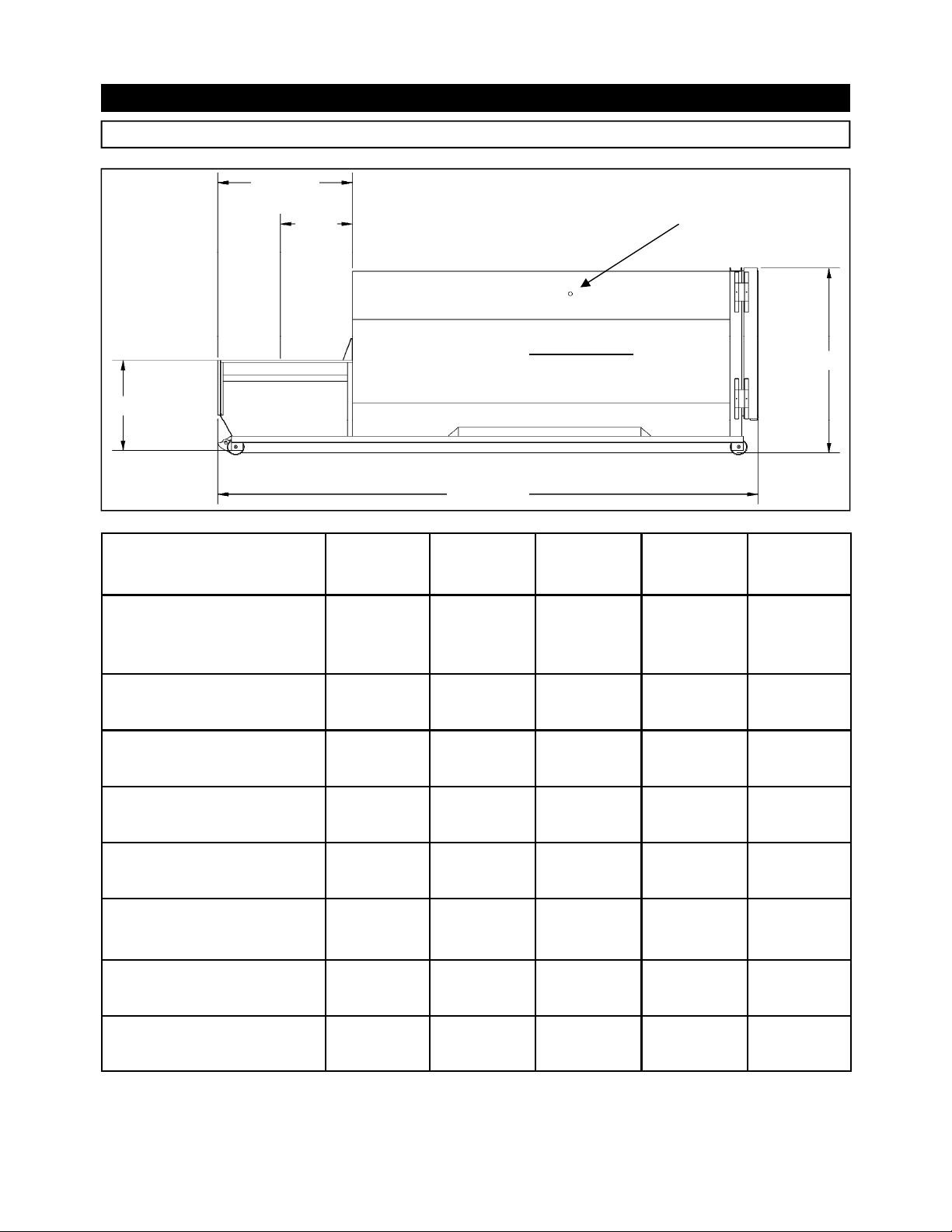

Specifications ............................................................................................................ 4

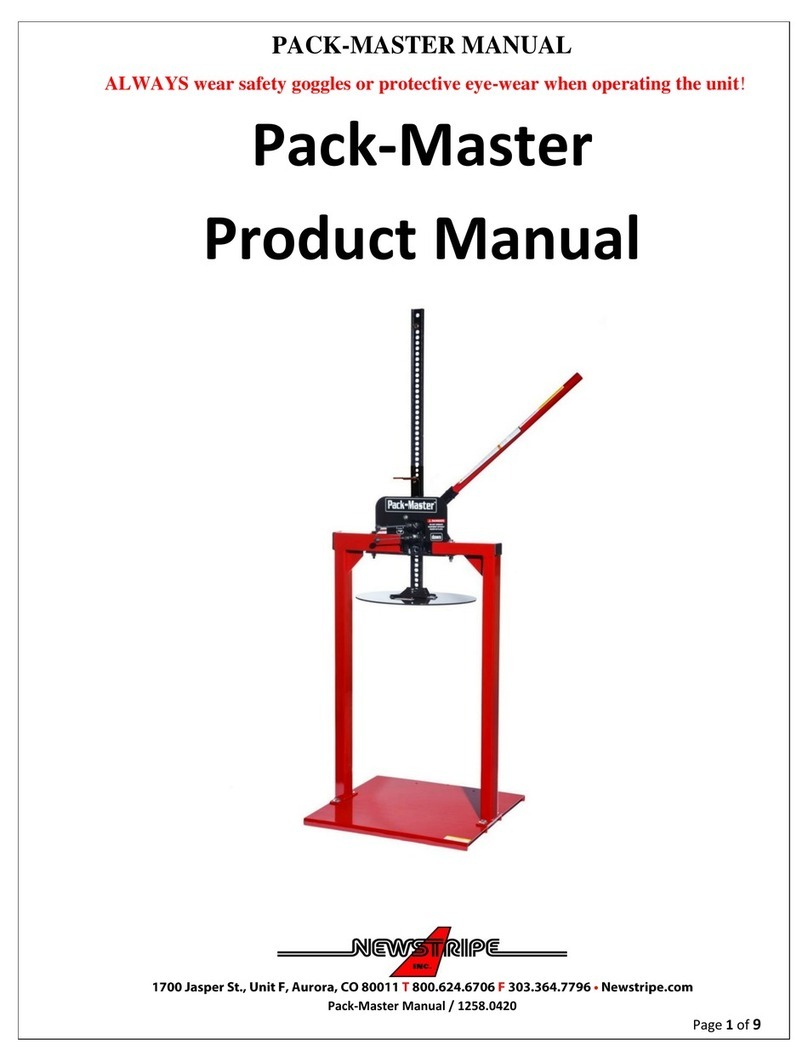

Pre-Operating Instructions .......................................................................................... 5

Control Panel ............................................................................................................. 6

Operating Instructions - Standard Models .................................................................... 7

Operating Instructions - Models ith Photoelectric Cycle Control .................................... 8

Optional Controls ....................................................................................................... 9

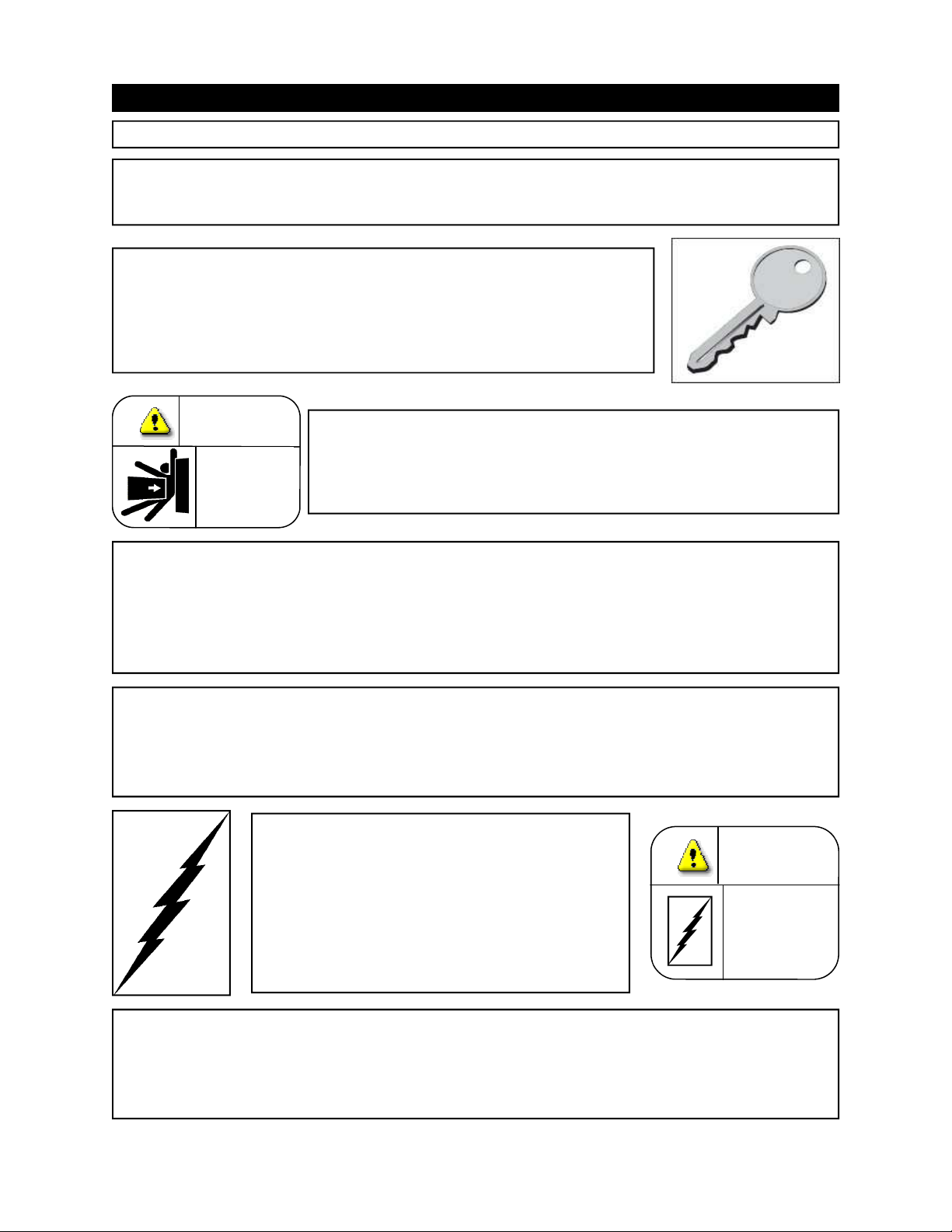

Decals ...................................................................................................................... 10

Decal Placement ........................................................................................................ 11

Decal Images ............................................................................................................ 12

Decal Placement for Optional Loading Configuration ..................................................... 13

Additional Decals for Hydraulic Tailgate (HT) Units ....................................................... 14

Lock-Out & Tag-Out Instructions .......................................................................... 16

Periodic Maintenance ................................................................................................. 17

Procedures - (Hydraulic System Pressure Check) .......................................................... 18

Principles of Operation ............................................................................................... 19

Cylinder Removal ....................................................................................................... 19

Tailgate Seal Replacement .......................................................................................... 20

Fuse & Circuit Breaker ................................................................................................ 21

Wire Sizes/Heater Element ......................................................................................... 22

Typical Panel Box....................................................................................................... 23

PLC - Layout and Description ...................................................................................... 24

PLC - Maintenance and Programming .......................................................................... 25

Po er Unit - Standard 5 HP ....................................................................................... 26

Po er Unit - Standard 5 HP - (Parts List) .................................................................... 27

Po er Unit - Standard 10 HP - (MECO) ........................................................................ 28

Po er Unit - Standard 10 HP - (Parts List) (MECO) ....................................................... 29

Po er Unit - Standard 10 HP - (NON MECO) ................................................................ 30

Po er Unit - Standard 10 HP - (Parts List) (NON MECO) ............................................... 31

Po er Unit - Submerged 10 HP ................................................................................... 32

Po er Unit - Submerged 10 HP - (Parts List) ................................................................ 33

Hydraulic Schematic - Typical ..................................................................................... 34

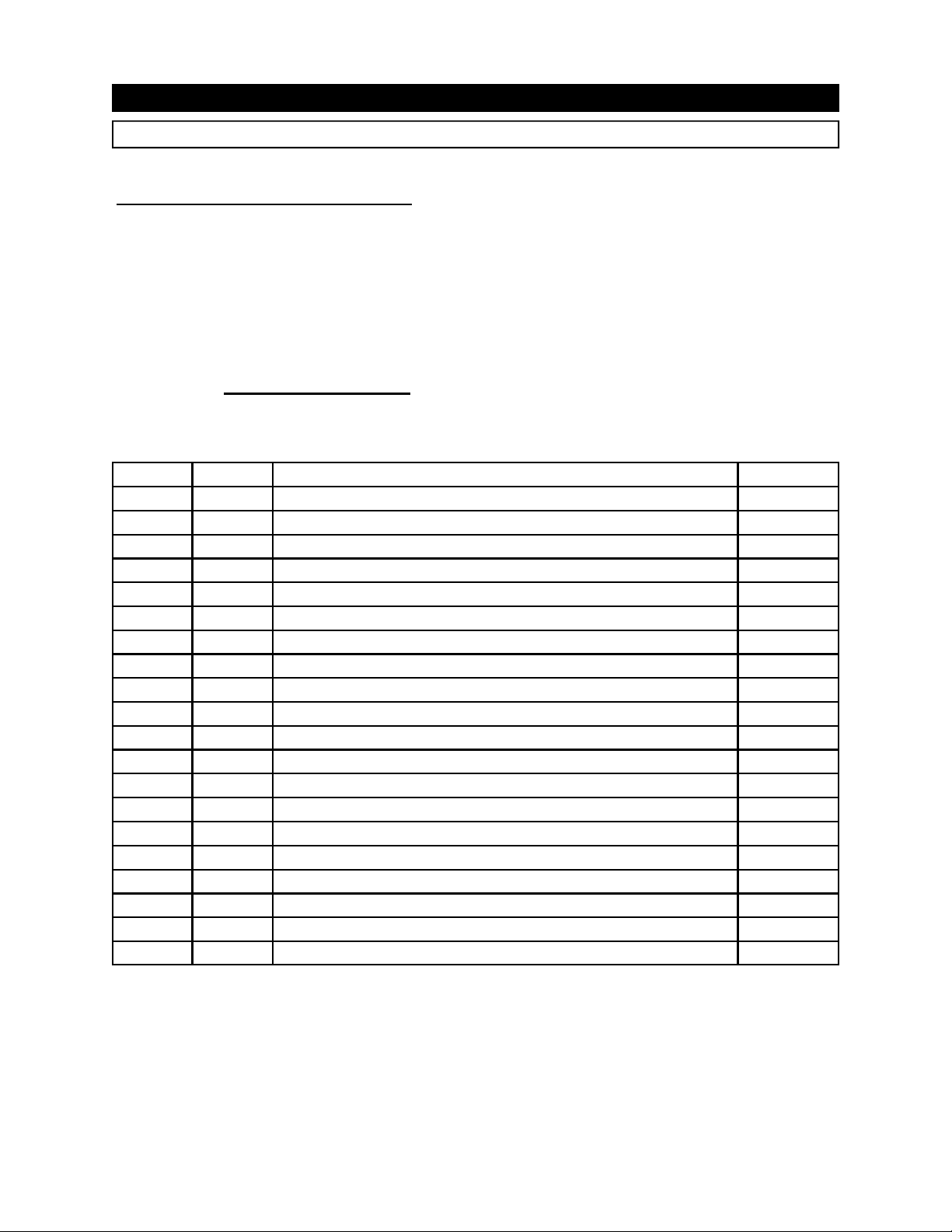

Troubleshooting ....................................................................................................... 35

Concrete Pad Requirements ........................................................................................ 37

Steel Installation Procedures ....................................................................................... 38

Electrical & Hydraulic Installation ................................................................................ 39

Through-The-Wall Po er Unit Installation .................................................................... 40

Hauler Instructions - General ...................................................................................... 42

Hauler Instructions - Door/Latch Operation .................................................................. 43

Hauler Instructions - Hydraulic Tailgate Operation (for optional HT units) ....................... 44

Hauler Instructions - Tailgate Maintenance Bar (for optional HT units) ........................... 45

Hauler Instructions - Liquid Removal (for optional SL units) ........................................... 46

OPERATION

INSTALLATION

MAINTENANCE

HAULER INFORMATION

© 2011 Marathon Equipm nt Company