ER136 & ER236

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

DANGER

TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, CAREFULLY FOLLOW

THESE INSTRUCTIONS.

TABLE OF CONTENTS

SECTION « A » DESCRIPTION PAGE

Installation and maintenance manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A1

Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A2

Shipping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A2

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A3

Distances to respect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A4

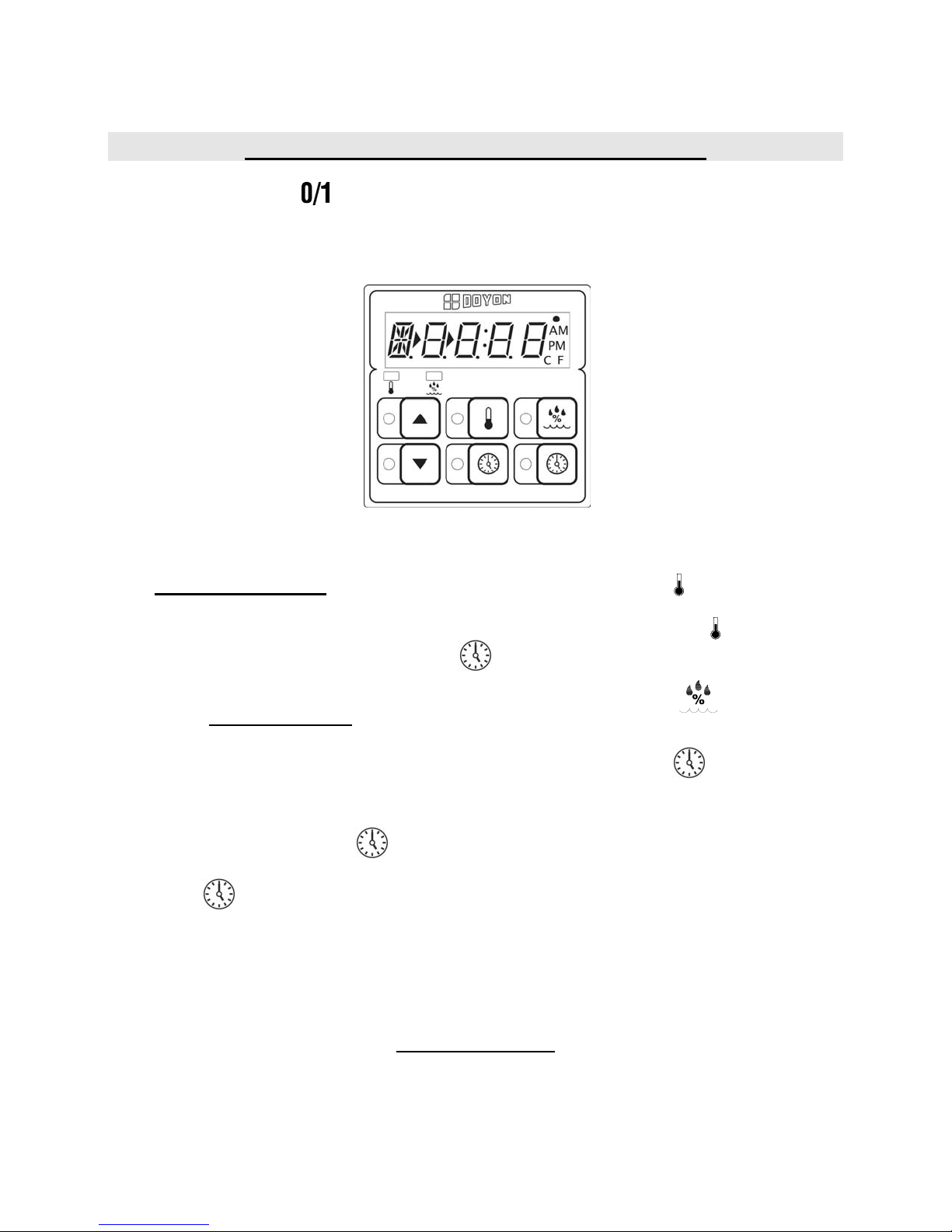

Retarder/proofer operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A5

Timer programming instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A6

Example of timer adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A7

Humidity control instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A8

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A9

Maintenance and cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A10

For more information, please contact our office: . . . . . . . . . . . . . . . . . . . . A12

SECTION « B » DIMENSIONS

ER136 FRONT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B1

ER136 SIDE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B2

ER136 TOP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B3

ER236 FRONT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B4

ER236 SIDE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B5

ER236 TOP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B6

SECTION « E » COMPONENT PARTS

ER136 & ER236 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ER136 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ER236 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E1

E3

E5

SECTION « F » CONTROL PANELS

ER136 120V/208V/1PH & 120V/240V/1PH . . . . . . . . . . . . . . . . . . . . . F1

ER136 220V/1PH/50 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F3

ER236 120V/208V/1PH & 120V/240V/1PH. . . . . . . . . . . . . . . . . . . . . F5

ER236 220V/1PH/50HZ. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F7