a) Before performing maintenance activities, visually check the condition of the bag and shoulder

strap. During this phase, if there are signs of damage or irregularities in the components, contact

DPI or otherwise an authorised service centre. The bag should be presented as in figure 1.

b) Keep a stopwatch at hand and open the zip of the bag containing the appliance, to automatically

activate the air flow as shown in figure 2:

o Check the duration of operation of the appliance and the speed of the air flow supplied,

from the moment of activation of the air flow, when the zip is opened, by timing the duration

of the air emission until the pressure gauge indicates complete emptying and compare it

with the nominal duration shown on the bag (10 minutes for Sekur Navy Cap 10 and 15

minutes for Sekur Navy Cap 15 respectively). If the duration is shorter or longer than

indicated on the bag by more than 2 minutes, contact an authorised service centre.

o Verify that the acoustic signal starts to operate at least one minute before the air in the

cylinder tube runs out. Also verify that the sound is audible and regular. In case of

malfunction of the acoustic signal, contact an authorised service centre.

c) The device successfully passes the functional check above, proceed with the following checks:

o Remove the device from the bag by opening the two Velcro straps holding the bottle in

place as shown in figure 3.

o Remove the tube side of the pressure reducer by pushing the blue ring downwards and

at the same time pushing the tube in the same direction and then pull in the direction of

the arrow, as shown in figure 4 and figure 5. o Check the condition of the pressure gauge.

In case of damage or irregularities in the components, contact DPI or an authorised service

centre.

o Check the condition of the pressure reducer, the flexibility of the cap, the absence of

visible breakage or cracking in the hood, sufficient visibility, the condition, integrity and

elasticity offered by the screen of the black collar of the cap and the state of conservation

of the tube as shown in figure 6 and figure 7.

o In any case, replace the O-ring with the pin and the plastic clamp with the ones in the

maintenance kit.

o Check the exhalation valve on the half mask of the hood by inserting a finger inside as

shown in figure 8. Check that it can move smoothly without blockages and that it is free of

dirt or salt deposits. In such a case and in any case every 6 years contact the D.P.I. or an

authorised service centre.

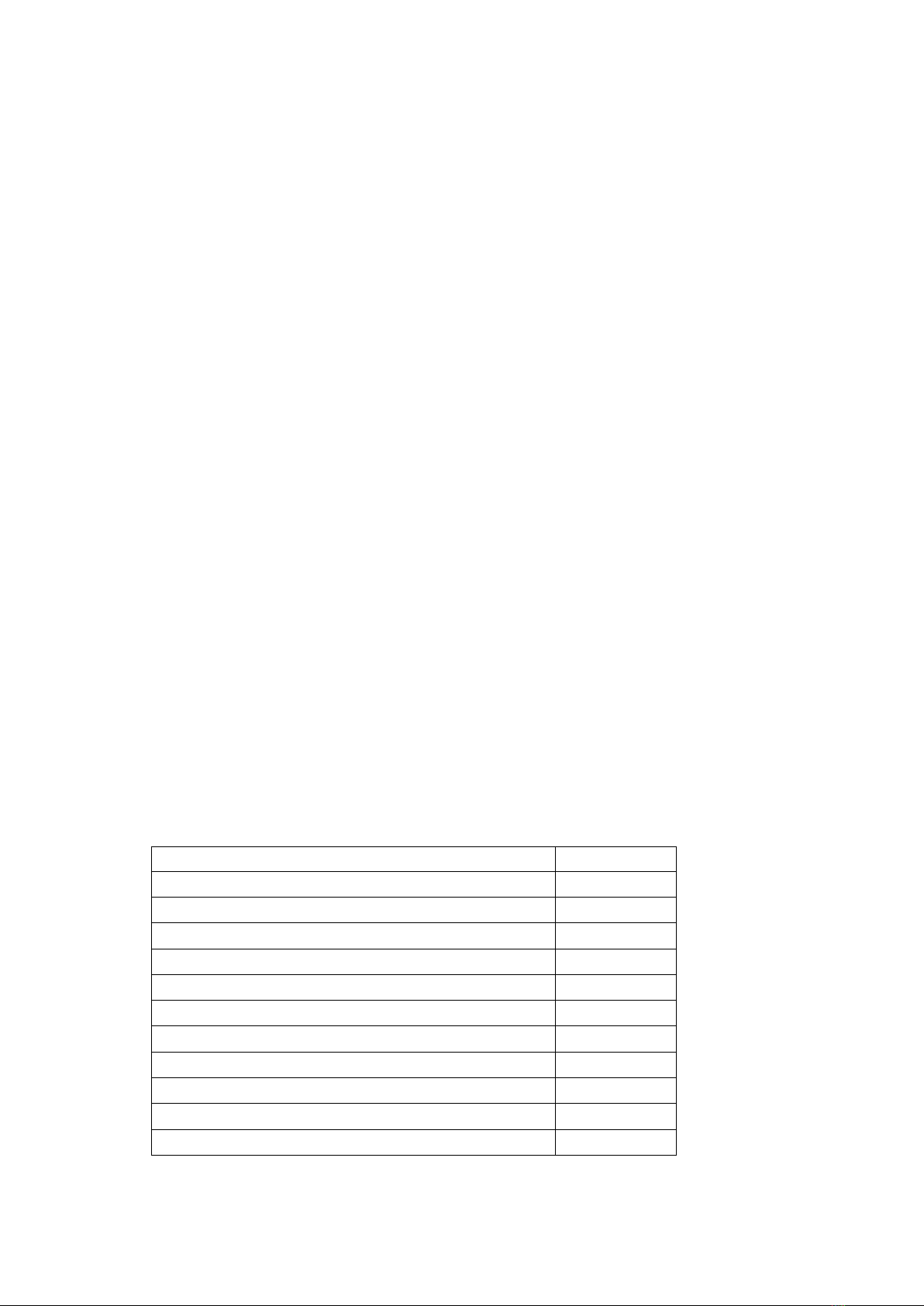

d) Devices that have passed the visual inspection and functional tests can be recharged and

restored to "ready for use" status. To recharge, the device must be returned to the stand-by

position by putting the pin in place as follows:

o Remove the plastic clamp by cutting and discarding to replace it later with a new one

from the kit (fig. 9). Remove the activation pin complete with O-ring from the maintenance

kit and replace it as follows on the pressure reducer to restore the stand-by condition.

o Push the black plastic plate, then the small piston connected to it, until the cross bore of

the body is aligned with that of the shaft. If necessary, rotate the shaft until the alignment

of the hole is visible.