D+H CPS-M1-MSE-020 Series User manual

CPS-M1-MSE

D+H Downloads

99.828.70 1.2/07/22

en Original instructions..............................................Page ............................................................2

2/36 CPS-M1-MSE English 99.828.70 1.2/07/22

Introduction

Your D+H service and sales partner

Safety in the building is not only provided by the product. Safety is cre-

ated above all by competence. All D+H service and sales partners are

certied and regularly trained SHEV specialist companies. They work

closely with D+H Mechatronic AG as the manufacturer to implement

comprehensive system solutions for SHEV and natural building venti-

lation. With holistic support and continuous quality assurance in every

phase of the project: from consulting, planning and project conguration

to installation, commissioning, maintenance and service. This means

that the highest national and international quality standards are reliably

fullled.

Installation and commissioning

The comprehensive network of D+H service and sales partners is avail-

able to you for proper installation and commissioning. Our partner sys-

tem guarantees that D+H products are installed exclusively by trained

and experienced technicians in compliance with the technical directives

and regulations. Personal transfer and instruction of the operators are

included.

Maintenance and repairs

Building operators are responsible for the functional reliability of safety

devices in their own buildings.

Regular and proper maintenance ensures that your system will always

be operational. As SHEV specialist companies, the D+H service and

sales partners are optimally qualied for the maintenance. Owners/

operators can demonstrate at any time that they have fullled their

obligation by means of a service contract.

Quality with a warranty

You receive extended warranty benets for all D+H SHEV systems that

were installed by a D+H service and sales partner and are regularly

maintained. Ask your local D+H service and sales partner about this.

Always in your neighbourhood

We are represented around the globe with our network of subsidiaries

and exclusive partners.

Looking for a local D+H partner?

Simply visit our website:

www.dh-partner.com

WARNING

Read all the safety information, instructions, images and technical data

provided with this product.

Failure to observe the following instructions can result in electric shock,

re and/or serious injury.

Keep all the safety information and instructions in a safe place for future

reference.

Safety information

230 V AC operating voltage!

Risk of injury from electric shock!

• Only an authorised, electrically skilled person is allowed to connect

the power

• Keep children away from the controller

• Only use in dry spaces

• Only intended for installation indoors

• Only use unaltered D+H original parts

Content................................................................................................... 2

Introduction............................................................................................. 2

Safety information................................................................................... 2

Intended use........................................................................................... 3

MSE functional principle......................................................................... 3

Important regulations.............................................................................. 3

Example of application ........................................................................... 3

Performance features............................................................................. 3

Pictogram explanation............................................................................ 3

Overview of components........................................................................ 4

Control module – CM-BT1-D4-P2 .......................................................... 5

Actuator module – AM-1-2-10-24-D6-D2................................................ 5

Digital I/O module - IOM-D1-1212.......................................................... 5

Supply module – PSM-1-24-40 .............................................................. 5

Trigger module – TMA-1-D4-D12 ........................................................... 5

Bistable relay module - BRM-1-COC-0006 ............................................ 5

Actuator module - AM-1-1-08-230-D4-D2............................................... 6

Power packs PS-S1-24-20 and PS-S1-24-40 ........................................ 6

Analog/Digital I/O-Module - ADM-AD1-1212-4....................................... 6

Technical data......................................................................................... 7

24 V emergency supply.......................................................................... 7

Declaration of conformity........................................................................ 7

Arrangement of the modules .................................................................. 8

Installation of the module sockets .......................................................... 8

Removal of the module sockets ............................................................. 8

General instructions for connection........................................................ 9

Wiring diagram (sample) ........................................................................ 9

Connection – PSM................................................................................ 10

Connection – Mains switching...............................................................11

Connection – CM.................................................................................. 12

Connection – Digital inputs and outputs............................................... 13

Further top hat rail levels for additional CPS-M modules ..................... 13

Battery for the clock of the event memory............................................ 13

Connection – soft starter ...................................................................... 14

Connection – BRM ............................................................................... 15

Connection – Frequency converter ...................................................... 16

Connection – IOM................................................................................. 17

Connection – Star-delta circuit ............................................................. 18

Connection – ADM................................................................................ 19

Connection – ADM................................................................................ 20

Connection – AM 24 ............................................................................. 21

Connection – Vent buttons to AM 24 .................................................... 21

Connection – AM 24 with ACB drives................................................... 22

Connection – AM 24 with ACB drives................................................... 22

Connection – AM 24 with pole-changing drives.................................... 22

Connection – AM 24 with pole-changing drives.................................... 22

Connection – Spring return motor ........................................................ 23

Connection – AM 230 ........................................................................... 24

Connection – NSV 401 control and vent button to AM 230 .................. 24

Connection – NSV 401 power supply and D+H ACB drives................. 25

Connection – NSV 401 power supply and D+H drives......................... 25

Connection – NSV 401 power supply and third-party drives................ 26

Connection – TMA................................................................................ 27

Connection – TMA (2 lines) .................................................................. 28

Connection – TMA parallel connection RT ........................................... 29

Connection – TMA to re alarm system (FAS) ..................................... 29

Description of the inputs and outputs ................................................... 30

Commissioning and conguration with the SCS software.................... 31

Standard congurations........................................................................ 31

Description of the software functions.................................................... 32

Operation - Touch panel (optional) ....................................................... 33

Operation - Daily ventilation ................................................................. 34

Operation - Weather automation .......................................................... 34

Operation - SHEV................................................................................. 34

Operation - Trigger on alarm ................................................................ 35

Operation - Closing after alarm ............................................................ 35

Warranty ............................................................................................... 36

Inspection ............................................................................................. 36

Disposal................................................................................................ 36

Maintenance and cleaning.................................................................... 36

Content

3/36CPS-M1-MSEEnglish

99.828.70 1.2/07/22

Intended use

• Modular MSE controller for complex control tasks

• Can be used in the AdComNet SHEV bus system

• Combine lines and groups however you want

• Convenience functions for daily ventilation

• Only intended for installation indoors

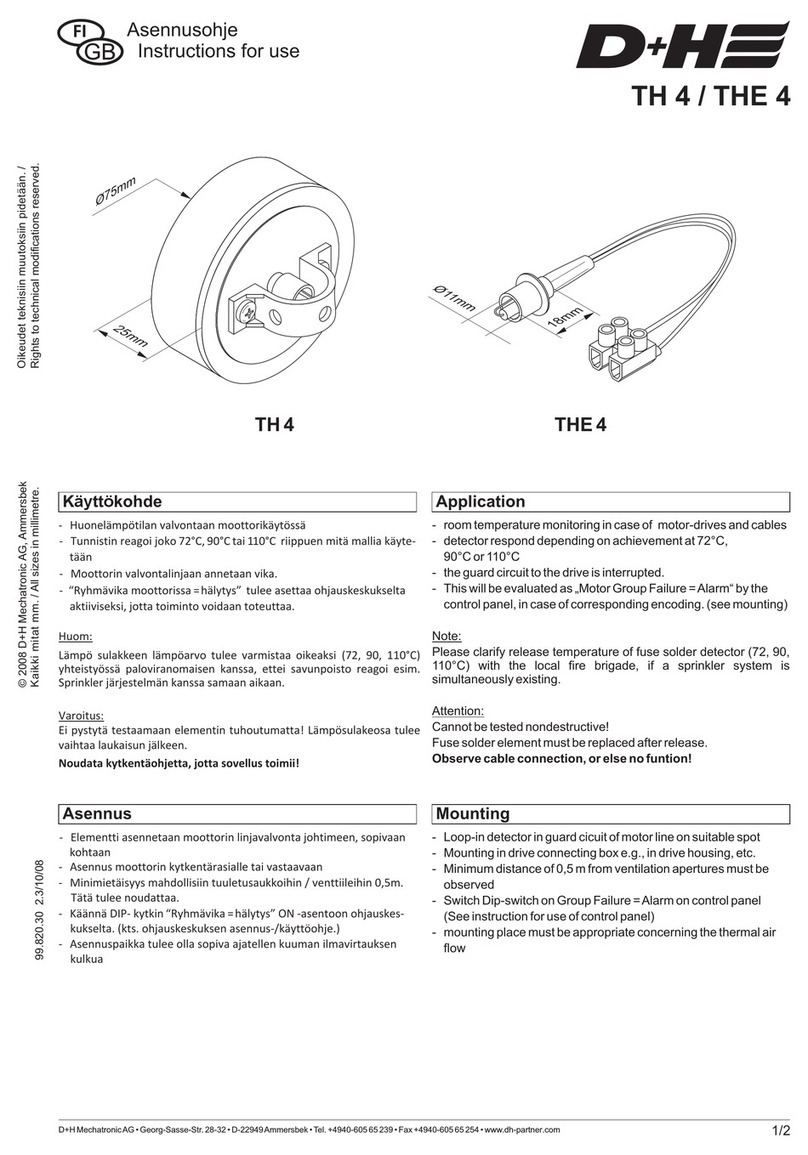

Example of application

Pictogram explanation

Control panel O.K.

Fault

SHEV alarm

MSE functional principle

The following functions run simultaneously in the event of smoke detection

and subsequent triggering of the MSE. 1:

1. supply and discharge After successful feedback, the smoke extraction

fans are switched on. 2.

2. the smoke is removed via temperature-resistant smoke extraction fans.

These fans can be installed either on the roof, in the wall of the respective

utilisation units or centrally. In the case of interior rooms, the smoke is led

out of the building via an appropriate duct system. In doing so, it must be

ensured that the smoke does not re-enter adjacent utilisation units. To

avoid this undesirable eect, appropriate re dampers can be installed

within the duct system. 3.

3. postow openings near the oor are opened so that supply air can ow

in at the required ow velocity within the low-smoke layer accordingly. If a

free afterow is not possible, fresh air is supplied mechanically. The smoke

layer must not be destroyed.

Practical tip: For the implementation of complex smoke extraction sce-

narios, a combination of mechanical and natural supply air tracking is

possible.

Important regulations

It is necessary to observe VDE 0833 for danger alarm systems, VdS

2221, VDE 0100 for electrical systems, DIN 18232 for SHEV systems,

the provisions of the local re brigade and of the energy supply compa-

ny for the mains connection.

EN 12101-10 Energy supply

EN 12101-7 Smoke extraction ducts

EN 12101-8 Smoke dampers

EN 12101-3 Fire gas fans

EN 12101-1 Smoke curtains

Performance features

General

Variable module technology for complex control requirements

Flexible system structure through mounting rail system for all modules

and extensions

Connection of supply and communication through integrated plug

connectors

Retrottable modules in case of building modications

Parameterisable MRA and ventilation functions via D+H Software SCS

Inputs and outputs monitored for line breakage and short circuit

Connection of max. 30 re detectors or 10 MRA control points per

monitored line input

AdComNet bus system for seamless networking of modules within the

CPS-M and other D+H AdComNet components

Flexible use of parameterisable, digital inputs and outputs

24 V DC

2x max. 10 A drive current per actuator module

Stabilised output voltage due to switching power supply technology

No signal loss in case of mains failure due to integrated emergency

power supply (72 hours)

230 V AC

Emergency power supply (72 hours)

Up to 45, 230 V AC drives can be connected per drive group (1840VA)

400 V AC

Fans can be controlled either via frequency converter, soft starter or

directly.

Power supply via main switch and with automatic mains switchover if

required.

OK

External control

CO, NO, LPG sensors

MSE operation panel

Smoke detector

Drives for intake

air opening

Fire damper

Smoke extraction

fan

Jetfan

CCS / BMS

Line

Group

CPS-M

CPS-M

KNX, Modbus gateway

AdComNet enable

D+H control panel

AdComNet

400V AC

4/36 CPS-M1-MSE English 99.828.70 1.2/07/22

Overview of components

Supply module socket

MS-S1-RD-TS

Basic module socket

MS-D1-RR-TS

Expansion module socket

MS-S1-DD-TS

Bus termination module

BTM-1-1

Is plugged into the last

module socket.

Bus connection

Connection for the

power supply

Temperature control sensor unit

TCSU1-RJ12

RJ12 connecting cable (2x)

CC-TP/TCSU-1000 (1 m)

CC-TP/TCSU-2000 (2 m)

Touch panel with bracket (optional)

TP-C1-35-RJ12

RJ12 socket

Control module

CM-BT1-D4-P2

Control module

CM-B-1-D4-P2

Mains supply module

PSM-1-24-040

24 V DC actuator module

AM-1-2-10-24-D6-D2

24 V DC actuator module

AM-B-1-2-10-24-D4-D2

230 V AC actuator module

AM-1-1-08-230-D4-D2

Analogue / Digital

I/O module

ADM-AD1-1212-4

Analogue trigger module

TMA-1-D4-D12

Digital I/O module

IOM-D1-1212

Bistable relay module

BRM-1-COC-0006

5/36CPS-M1-MSEEnglish

99.828.70 1.2/07/22

Control module – CM-BT1-D4-P2 Control module – CM-B-1-D4-P2

• Central control element of the control panel (segment coupler)

• One CM controller module is required for each CPS-M

• Each CM controller module can manage up to 29 addition-

al modules (PSM, AM, TMA)

• AdComNet interfaces for implementing decentralised sys-

tems in combination with other AdComNet control panels

• 1000 SCS links and 100 connectors possible

• USB interface for conguring the system and the con-

nected drives (only ACB), and for rmware updates of the

control panel

• Integrated LEDs to indicate operation (green), fault

(yellow), alarm (red) and AdComNet operation

• Status displays for all modules of the respective CPS-M

as well as emergency operation of the individual lines and

groups using the 3.5" TFT touch panel

• Three user-programmable digital inputs for connecting

buttons, switches, external controls etc.

• Two user-programmable, isolated change-over contacts,

for example, for fault and alarm notications

• Integrated event memory for system analysis and traceability

• Connection using removable spring-type terminals

• Conductor cross-sections max. 1.5 mm² exible

• Dimensions WxHxD: 26x130x125 mm

• Installation on a 35 mm top hat rail in combination with a

basic module socket

• Central control element of the control panel (segment coupler)

• One CM controller module is required for each CPS-M

• Each CM controller module can manage up to 29 addition-

al modules (PSM, AM, TMA)

• 30 SCS links and 10 connectors possible

• USB interface for conguring the system and the con-

nected drives (only ACB), and for rmware updates of the

control panel

• Integrated LEDs to indicate operation (green), fault

(yellow), alarm (red) and AdComNet operation

• Status displays for all modules of the respective CPS-M

as well as emergency operation of the individual lines and

groups using the 3.5" TFT touch panel

• Three user-programmable digital inputs for connecting

buttons, switches, external controls etc.

• Two user-programmable, isolated change-over contacts,

for example, for fault and alarm notications

• Integrated event memory for system analysis and traceability

• Connection using removable spring-type terminals

• Conductor cross-sections max. 1.5 mm² exible

• Dimensions WxHxD: 26x130x125 mm

• Installation on a 35 mm top hat rail in combination with a

basic module socket

Supply module – PSM-1-24-040

• Power supply of the control panel system

• Max. 40 A load current for each supply module

depending on the power supply unit

• If a load current of more than 40 A is required, another

PSM (including supply module socket) can be used.

• The PSM always provides power to the actuator and

trigger modules used to the right of it

• Automatic toggling between mains supply and battery

supply in case of a mains outage

• Max. battery capacity 26 Ah (battery type 6)

• 72 hours of emergency supply time

• Integrated protection against excessive discharge

• Temperature-controlled charging voltage with external

temperature sensor

• Integrated LED to indicate a fault (yellow)

• Two connections for peripherals that are and are not

supplied with emergency power

• Connection using removable spring-type terminals

• Conductor cross-sections max. 2.5 mm² exible or for

supply and battery 6 mm² exible

• Dimensions WxHxD: 26x130x125 mm

• Installation on a 35 mm top hat rail in combination with

a basic module socket or for more than one power

supply unit with a supply module socket

Actuator module – AM-1-2-10-24-D6-D2 Actuator module – AM-B-1-2-10-24-D4-D2

• Module for connecting 24 V DC actuators

• 2 independent groups for connecting drives, each with

a total maximum current of 10 A

• The cable is monitored for breaks and short circuits

via the terminal module EM-47K

• Each group is electronically protected against

overload

• 4 user-programmable digital inputs (e.g. ventilation

button)

• 2 user-programmable digital outputs (e.g. NOT

CLOSED signal)

• 2 integrated ACB interfaces for reading out and

conguring the connected ACB drives

• Can be used with 24 V DC pole-changing drives, ACB

drives, spring-return motors and magnets

• Virtual groups in connection with ACB drives possible

• Adjustable ventilation time and opening width for

everyday ventilation

• Integrated LEDs to indicate a fault (yellow) and alarm

(red)

• Connection using removable spring-type terminals

• Conductor cross-sections max. 2.5 mm² Flexible

• Dimensions WxHxD: 26x130x125 mm

• Installation on a 35 mm top hat rail in combination with

an expansion module socket

• Module for connecting 24 V DC actuators

• 2 independent groups for connecting drives, each with

a total maximum current of 10 A

• The cable is monitored for breaks and short circuits

via the terminal module EM-47K

• Each group is electronically protected against

overload

• 4 user-programmable digital inputs (e.g. ventilation

button)

• 2 user-programmable digital outputs (e.g. NOT

CLOSED signal)

• Can be used with 24 V DC pole-changing drives

• Integrated LEDs to indicate a fault (yellow) and alarm

(red)

• Connection using removable spring-type terminals

• Conductor cross-sections max. 2.5 mm² Flexible

• Dimensions WxHxD: 26x130x125 mm

• Installation on a 35 mm top hat rail in combination with

an expansion module socket

Trigger module – TMA-1-D4-D12

• Module for connecting trigger peripheral devices

• Two independent lines for connecting a max. of 10

SHEV buttons and 30 re detectors per line (only

detectors approved by D+H may be used)

• Cables are monitored by the EM-L01 terminal module

• The SCS software can be used to congure the lines

also as user-programmable digital inputs and outputs

• Integrated LEDs to indicate a fault (yellow) and alarm

(red)

• Connection using removable spring-type terminals

• Conductor cross-sections max. 1.5 mm² exible

• Dimensions WxHxD: 26x130x125 mm

• Installation on a 35 mm top hat rail in combination with

an expansion module socket

6/36 CPS-M1-MSE English 99.828.70 1.2/07/22

Power packs PS-S1-24-20 and PS-S1-24-40

Functions:

• Output: 24 V DC, 20 A or 40 A

• Installation on 35 mm top hat rail

• Low ripple

• Reverse-voltage protected and short-circuit resistant

• Multiple power supply units can be combined

• For each power supply unit, one PSM supply module is needed

Technical data:

Type PS-S1-24-20 PS-S1-24-40

Rated input voltage 230 V AC ± 15%

Frequency 45 to 65 Hz

Nominal power 530 VA / 480 W 1040 VA / 960 W

Output voltage 24 V DC ± 1%

Ripple < 50 mVSS

Output current 20 A 40 A

Short-circuit resistant YES

Can be connected in parallel YES

Reverse-voltage protected YES

Input line connection max. 6 mm² star / max. 4 mm² exible

Output line connection max. 6 mm² star / max. 4 mm² exible

max. 16 mm² star / max. 16 mm² exible

Dimensions WxHxD 90x130x150 mm 140x130x150 mm

Bistable relay module - BRM-1-COC-0006

• Six user-programmable, isolated change-over contacts,

for switching signals with 24 V DC or 230 V AC

• change-over contacts as bistable version

• Denition of a switch-o state in the event of a mains and

battery failure possible (failsafe function)

• Integrated LEDs to indicate a fault (yellow) and alarm

(red)

• Connection using removable spring-type terminals

• Conductor cross-sections max. 2.5 mm² exible

• Dimensions WxHxD: 26x130x125 mm

• Installation on a 35 mm top hat rail in combination with

an expansion module socket

Digital I/O module - IOM-D1-1212

• 12

user-programmable digital inputs

• 12

user-programmable digital outputs

• The digital inputs can also be parameterised as LT inputs

• Integrated LEDs to indicate a fault (yellow) and alarm

(red)

• Connection using removable spring-type terminals

• Conductor cross-sections max. 1.5 mm² exible

• Dimensions WxHxD: 26x130x125 mm

• Installation on a 35 mm top hat rail in combination with

an expansion module socket

Actuator module - AM-1-1-08-230-D4-D2

• Module for connecting 230 V AC actuators

• 1 group for connecting drives with a total maximum

current of 8 A

• Up to 45 drives per AM 230 connectable

• D+H 230 V AC drives with SHEV fast mode (HS) are

supported

• The cable is monitored for breaks and short circuits

via the terminal module EM 230

• 2 user-programmable digital inputs (e.g. ventilation

button)

• 1 user-programmable digital output (e.g. NOT

CLOSED signal)

• Can be used with 230 V AC standard drives

• Adjustable ventilation time and opening width for

everyday ventilation

• Integrated LEDs to indicate a fault (yellow) and alarm (red)

• Connection using removable spring-type terminals

• Conductor cross-sections max. 2.5 mm² exible

(230 V AC) or 1.5 mm² exible (24 V DC)

• Dimensions WxHxD: 26x130x125 mm

• Installation on a 35 mm top hat rail in combination with

an expansion module socket

AD I/O module - ADM-AD1-1212-4

• 4

user-programmable multifunctional inputs

(digital or

analog)

• 8

user-programmable digital inputs

• 12

user-programmable digital outputs

• 4 virtual adjustable threshold switches per analog input

from which a virtual user-congurable digital input is set

or reset

• The digital inputs can also be parameterised as LT inputs

• Integrated LEDs to indicate a fault (yellow) and alarm

(red)

• Connection using removable spring-type terminals

• Conductor cross-sections max. 1.5 mm² exible

• Dimensions WxHxD: 26x130x125 mm

• Installation on a 35 mm top hat rail in combination with

an expansion module socket

7/36CPS-M1-MSEEnglish

99.828.70 1.2/07/22

Type CPS-M1-MSE-020-xxxx CPS-M1-MSE-040-xxxx CPS-M1-MSE-060-xxxx CPS-M1-MSE-080-xxxx

Supply 230 V AC, ± 15%, 45 to 60 Hz

Performance*

Performance in standby*

530 VA / 480 W

ca. 7.5 W

1040 VA / 960 W

ca. 8.5 W

1570 VA / 1440 W

ca. 16 W

2080 VA / 1920 W

ca. 17 W

Output voltage

Ripple

24 V DC ± 1%

< 50 mVSS

Nominal output current 20 A 40 A 60 A 80 A

Mode of operation

- Monitoring

- Alarm state / ventilation

Continuous duty

Short-time duty (30 % duty cycle)

Housing Sheet steel

Colour RAL 7035, light grey

Type of protection IP 54 (VdS IP 30)

Protection class I

Temperature range -5 to +40 °C

Air humidity 5% to 95% RH

Installation acc. to ICE 61439 up to 2000 m/üMN

Dimensions W x H x D 500 × 500 × 210 mm 600 × 800 × 250 mm 600 × 800 × 250 mm 800 × 1000 × 300 mm

* For 230 V AC systems plus the power of the NSV 401 and the connected 230 V AC drives

Technical data

• Emergency supply time: 72 hours

• Only use VdS-approved batteries.

• The sum of the nominal currents of the drives and actuators that are

triggered when there is an alarm must not exceed the max. permitted

load of the respective battery type

• The required battery capacity has to be determined for each PSM.

• The sum of the required ampere-hours (Ah) of all components,

including a 30% reserve, must be smaller than the capacity of the

battery

Standard batteries:

For each PS-S1-24-20 (+PSM): 2 x battery type 5 (12 V, 18 Ah ± 15%)

For each PS-S1-24-40 (+PSM): 2 x battery type 6 (12 V, 26 Ah ± 15%)

A special battery calculator is available for the exact determination

of the required battery capacity.

24 V emergency supply

Components Approx. Ah required for 72 hours

Intrinsic consumption by CM 0.52 Ah

CM supply of the modules 0.018 Ah per module

PSM 0.29 Ah

IOM 0,26 Ah

BRM 0,21 Ah

TMA 0.58 Ah

AM 0.43 Ah

AM 230 0,3 Ah

Fire detector 0.005 Ah

Smoke vent button 0.014 Ah

24 V DC Drives / actuators for

180 sec.

0.18 Ah (for each 1 A nominal

current)

Alarm devices 250 mA for 180

sec.

0.045 Ah

Devices and digital outputs with

an emergency supply (can be

adjusted using SCS)

7.2 Ah (for each 100 mA output

current)

Digital outputs with an emer-

gency supply (can be adjusted

using SCS)

3.6 Ah (for each 50 mA output

current)

Touch panel 0.4 Ah

Required capacity = Sum of the required Ah plus a 30% reserve

Battery type Max. permitted

load through

drives / actuators

Connector

Battery type 4 (12 Ah ± 15%) 24 A Flat plug

6,35 mm

Battery type 5 (18 Ah ± 15%) 36 A hole cable

lug Ø 5 mm

Battery type 6 (26 Ah ± 15%) 52 A

Declaration of conformity

We declare under our sole responsibility that the product described

under "Technical Data" complies with the following directives:

2014/30/EU, 2014/35/EU, 2011/65/EU

S.I. 2016/1091, S.I. 2016/1011, S.I. 2012/3032

Technical documents stored at:

D+H Mechatronic AG, D-22949 Ammersbek

Dirk Dingfelder Maik Schmees

CEO CTO

06.07.2022

ACB interface

ACB is used for secure communication between the drive and com-

patible D+H control systems. It enables activation, diagnostics and

conguration with perfect position, directly from the control panel. In this

process, all status messages, such as the OPEN and CLOSED signals,

opening stroke and drive errors are transmitted to the control panel.

The ACB bus is based on an open Modbus RTU protocol via which the

actuator can be directly controlled and queried.

Further information can be found in the D+H ACB Planning Manual.

Max. Number of drives per ACB connection:

AM 24 = max. 20 ACB drives

AM 230 = max. 20 ACB drives (CDC-5-ACB = max. 15)

In conjunction with locking drives (VLD, FRA),

a maximum of 10 drives (incl. locking drives) can be

connected.

Topology of the ACB bus line:

• Stub lines max. 15m

• Total length incl. stubs max. 200m.

• To avoid interference, the cables from the drive to the AM module

must be laid close together.

8/36 CPS-M1-MSE

1

1

2

2

3

3

CM PSM AM AM TMA TMA PSM AM AM TMA TMA

2x Akku Type 6

PS-S1-24-40

2x Akku Type 6

PS-S1-24-40

English 99.828.70 1.2/07/22

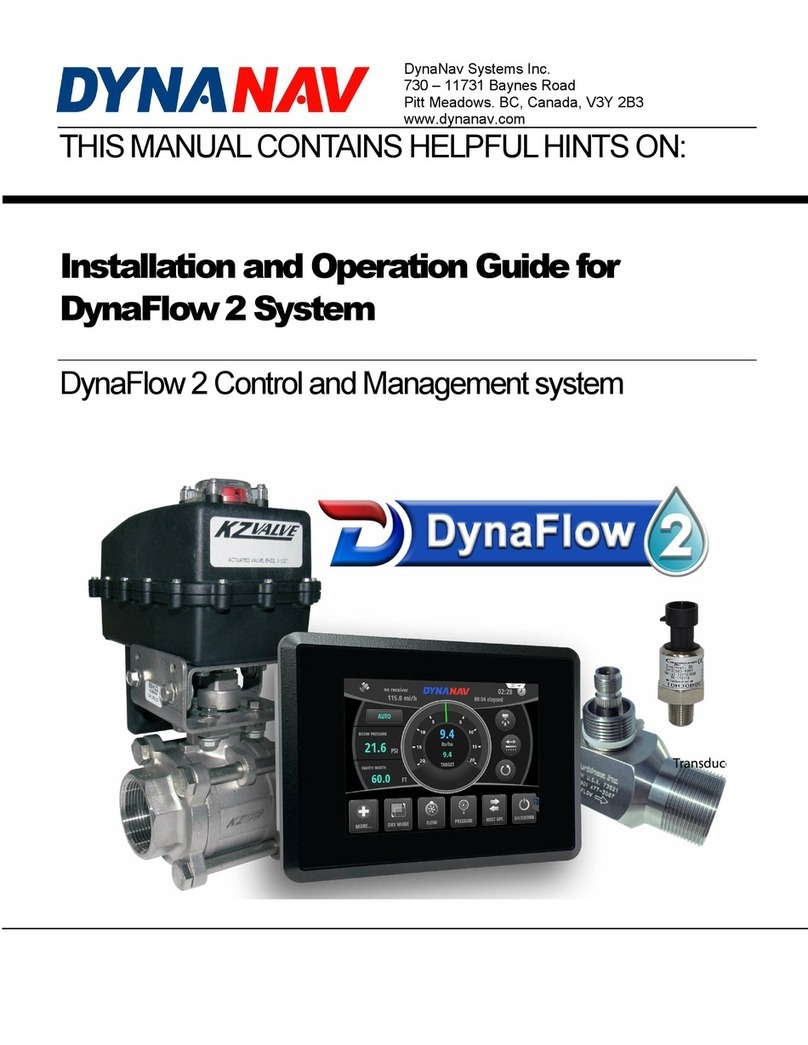

Arrangement of the modules

• Each CM controller module can manage up

to 29 additional modules (PSM, AM, TMA)

• The rst PSM provides power to the CM

module as well as to the AM and TMA

modules to the right of it

• Each additional PSM always provides power

only to the modules to the right of it

• This applies also to the emergency battery

power. Therefore, the modules are to be

distributed evenly across the PSM modules

• Due to the higher current consumption and

shorter cable paths, the AM 24 modules

are each to be used rst next to the PSM

module

• The total current of the drives respectively

connected to the PSM must not exceed

the output current of the respective power

supply unit.

Installation of the module sockets

Removal of the module sockets

9/36CPS-M1-MSE

4x 0,8 Ø

6x 0,8 Ø (RT 45)

10x 0,8 Ø (RT 45-LT)

6x 0,8 Ø (RT 45)

10x 0,8 Ø (RT 45-LT)

2x 0,8 Ø

2x 0,8 Ø

OK

OK

4x 0,8 Ø

English99.828.70 1.2/07/22

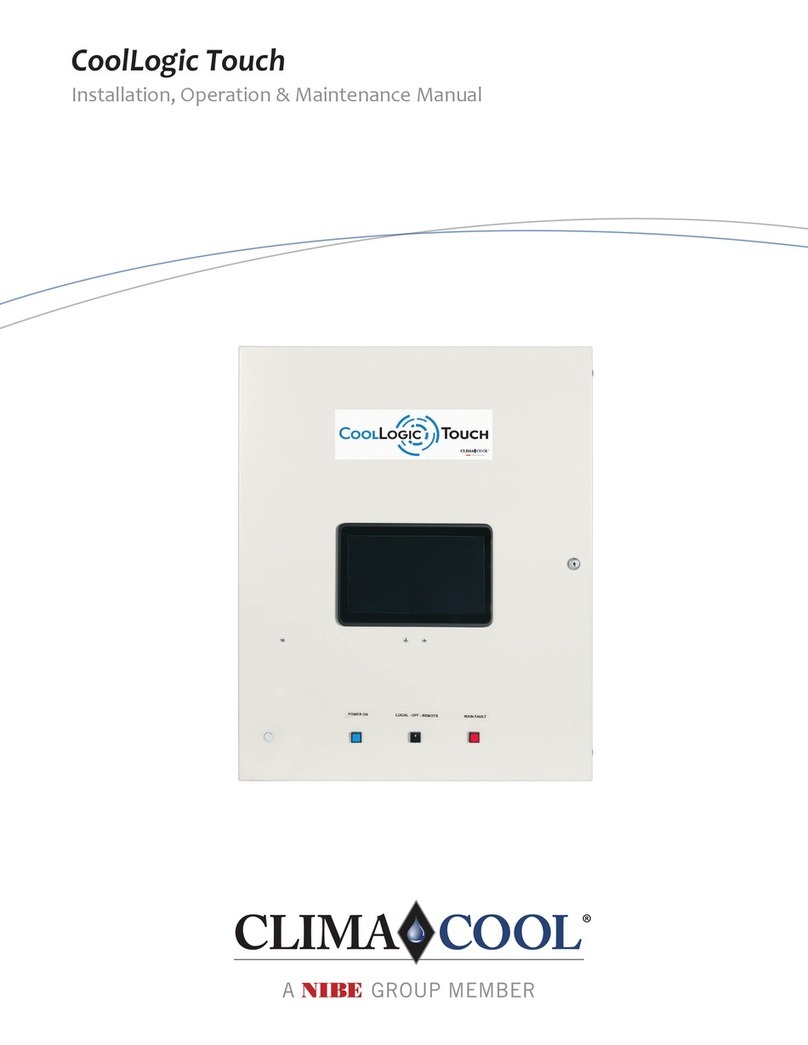

General instructions for connection

• The connections, particularly the earth connections, may be connected to the respective associated PSM supply module and components only.

No cross-ow of current may occur.

• System voltage 24 V DC and/or 230 V AC!

• If 24 V DC and 230 V AC cables are laid in the same cable duct in the control panel,

it must be ensured that the insulation of each conductor must be designed for the highest nominal voltage (≤ 250 V).

• A green-yellow core may only be used as protective earth conductor.

Wiring diagram (sample)

When selecting and routing cables, regional

installation requirements pertaining to electric

cable systems and necessary safety devices,

and/or directives pertaining to maintaining the

function of electrical cables must be observed

(e.g. MLAR guidelines for the re protection

requirements to be met by cable systems in

Germany).

Note:

Due to the variety available on the market,

no type designations are specied for these

cables. Please contact your D+H Partner for

this information.

Cable line (control panel - detector)

The cables are monitored for short circuits and

line breaks.

Cables for D+H SHEV systems

Cable group (control panel - drive)

At least three-wire design:

• 2 wires for supplying the drive (Mot.a/

Mot.b)

• For pole-changing drives, 1 additional

wire for cable monitoring, through which

the SHEV high-speed (HS) signal is also

transmitted to the drive.

• For ACB drives, 2 additional wires for the

bus connection.

Cross-section (mm²) = cable length (m) x total current

80

Wind/rain sensor

SHEV control panel

External control

SHEV operation panel

Approx. 1.5 m

above upper edge

of nished oor

Ventilation button

Approx. 1.2 m

above upper edge

of nished oor

Fire detector

SD-O 371 or FD-T 271

Drive on

SHEV opening

See cable lengths and cross sections

230 V AC 50 Hz

Separate power circuit.

Identify the fuse.

to additional

Total current 1 A 2 A 3 A 4 A 5 A 6 A 7 A 8 A 9 A 10 A

2 x 1,5 mm² 120 60 40 30 24 20 17 15 13 12 m

2 x 2,5 mm² 200 100 65 50 40 33 28 25 22 20 m

• max. cable length 500 m

• min. cable cross section 1.5 mm²

• A maximum voltage drop of 6.5% (3% with

third-party drives) on the cables is permitted.

• Max. 45 drives can be connected to a group

• The following two formulas must always be

used to calculate cable cross sections. The

higher value must be used.

Cable lengths and cross sections for Mot.a and Mot.b (AM 24 / 24 V drives)

Cable lengths and cross sections for L ▲, L▼, N and PE (AM 230 / 230 V drives)

Total power consumption 200 VA 500 VA 800 VA 1100 VA 1400 VA 1700 VA 1840 VA

5 x 1,5 mm² 167 167 167 132 104 85 79 m

5 x 2,5 mm² 278 278 278 220 173 142 131 m

5 x 4 mm² 444 444 444 351 276 227 210 m

Formula 1: Cross section (mm²) = Basic cable length (m) x total power of all Drives (VA)

96600

Formula 2: Cross section (mm²) = Basic cable length (m)

111

10/36 CPS-M1-MSE

X2.1 X2.4

4321

PSM-1-24-040

1

1

2

2

SNT–

BATT–

SNT+

BATT+

RJ12

TCSU1

X2

X6 X5 X4

–

+

–

N+

–

+–

+

++–––

LN

Output: 24 V DC

PS-1-24-20/40

Input: 230 V AC, 50 Hz

TCSU1-RJ12

L

N

PE

X4

X5.2

X6.2

X5.1

X6.1

X6

X2

X5

X4

English 99.828.70 1.2/07/22

230 V AC, 50 Hz

Separate power circuit.

Identify the fuse.

Do not reverse L+N!

Connect PE

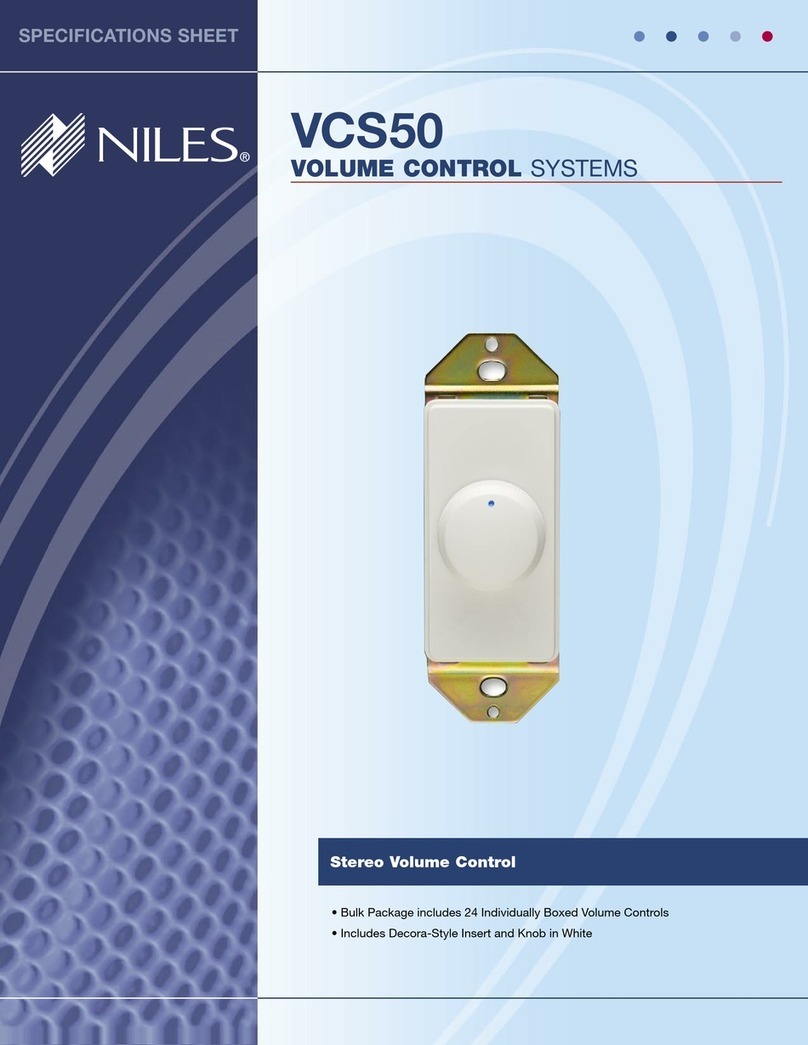

Connection – PSM

RJ12 connecting cable

CC-TP/TCSU

(max. 2 m)

BatteryBattery

No. Name Description

X2.1 N+ Output potential without an emergency supply for

ventilation functions, max. 500 mA

X2.2 - Reference potential (do not connect to P-)

X2.3 + Output potential with an emergency supply, max.

500 mA

X2.4 - Reference potential (do not connect to P-)

X4 TCSU1 RJ12 connection of external battery temperature

sensor

X5.1 BATT+ Secondary power supply (battery),

max 40 A

X5.2 BATT-

X6.1 SNT+ Primary power supply (power pack),

max 40 A

X6.2 SNT-

11/36CPS-M1-MSE

4321

4321

BRM-1-COC0006

4

4

4

3

3

3

2

2

2

1

1

1

X1 X2 X3

X6 X5 X4

COM 6

NO 6

NC 6

COM 6

COM 5

NO 5

NC 5

COM 5

COM 4

NO 4

NC 4

COM 4

4321

NO 3

COM 3

COM 3

NC 3

COM 2

NO 2

COM 1

COM 1

COM 2

NC 2

NO 1

NC 1

N

X1.1

L1

L2

L3

PE

N

L1

L2

L3 T3

T2

T1

L1

L2

L3 T3

T2

T1

Q1

PE

63A

T2

T3

X1.2

L1

L2

L3

PE

N

Q2.1

8

7

Q3.1

2

1

4

3

6

5

F1

L3L2L1

T1

8

7

2

1

4

3

6

5

F2 B13A

230V~24V=

L N PE

SNT+

SNT–

PS-S1-24-40

T1

4321

PSM-1-24-40

1

1

2

2

SNT–

BATT–

SNT+

BATT+

RJ12

TCSU1

X2

X6 X5 X4

–

+

–

N+

–

+–

+

TCSU1-RJ12

A

A

A1

A2

Q2.1

A1

A2

Q3.1

22

21

Q2.1

22

21

Q3.1

English99.828.70 1.2/07/22

Connection – Mains switching

Main switch

Phase monitoring relay

Power supply

400V~/25A/50Hz

Power supply

400V~/25A/50Hz

Emergency power supply

on site

12/36 CPS-M1-MSE

4

4

3

3

2

2

RJ12

1

1

CM-BT1-D4-P2

TP-C1

NO 1

NO 2

NC 1

NC 2

COM 2

n.c.

n.c.

5

1

1

4

2

2

3

3

3

2 1

DI 1.3

ACN D+

ACN D+

DI 1.2

ACN D-

ACN D-

DI 1.4

–

n.c.

Shield

Shield

X1 X2 X3

X6 X5 X4

COM 1

TP-C1-35-RJ12

X1.1 X1.4

X2.1 X2.4

X3

X4.3

X5.3

X6.5 X6.1

X4.1

X5.1

X1

X6

X2

X5

X4

X3

English 99.828.70 1.2/07/22

No. Name Description

X1.1 n.c. n.c.

X1.2 NO 1 Isolated change-over contact, max. 35 V / 1 A,

collective alarm (factory setting, can be pro-

grammed using SCS)

X1.3 COM 1

X1.3 NC 1

X2.1 n.c. n.c.

X2.2 NO 2 Isolated change-over contact, max. 35 V / 1 A,

general malfunction (factory setting, can be pro-

grammed using SCS)

X2.3 COM 2

X2.4 NC 2

X3 TP-C1 RJ12 connection for touch panel

X4.1 Shield AdComNet master interface

X4.2 ACN D-

X4.3 ACN D+

X5.1 Shield AdComNet slave interface

X5.2 ACN D-

X5.3 ACN D+

X6.5 n.c. n.c.

X6.4 DI 1.2 Freely congurable digital input,

0 to 28 V, active minus or plus,

control panel OPEN (factory setting, can be pro-

grammed using SCS)

X6.3 DI 1.3 Freely congurable digital input,

0 to 28 V, active minus or plus,

control panel CLOSED (factory setting, can be

programmed using SCS)

X6.2 DI 1.4 Freely congurable digital input,

0 to 28 V, active minus or plus

X6.1 - Reference potential (do not connect to P-)

Connection – CM

* Termination:

Every segment must be

terminated with 2 resistors

(110 Ω).

The resistors must be

connected as far apart as

possible.

Connections that are not used

also have to be terminated!

Isolated change-over contacts, max. 35 V / 1 A,

(factory settings, can be programmed using SCS)

Collective alarm General malfunction

Freely congurable

digital inputs

Central OPEN

Central CLOSE

Earth the

shielding

once per segment.

RJ12 connecting cable

CC-TP/TCSU

Relay de-en-

ergizes on

fault

Relay

energizes

on alarm

13/36CPS-M1-MSE

CM / AM / TMA / IOM

DI x.1

–

–

DO x.1

24 V DC

CM PSM AM AM TMA TMA

CM PSM AM AM TMA TMA

CM PSM AM

X4.3

X5.3 X5.3

X4.1

X5.1 X5.1

ACN D+

ACN D-

Shield

ACN D+

ACN D-

Shield

English99.828.70 1.2/07/22

Connection – Digital inputs and outputs

Contact Inverted Signal

Open O 0

Closed O 1

Open On 1

Closed On 0

active minus

˄

either

˅

active plus

Digital inputs

Digital outputs

24 V DC

Each max. 50 mA

(programmable using SCS)

Battery for the clock of the event memory

The CM module has a built-in lithium battery on the underside, which

buers the internal clock of the event memory in the event of a power

failure.

The battery should be replaced at least every 10 years.

Attention! Folgende Reihenfolge beachten:

1. Read out and save existing parameterization

2. Change battery. Battery type: Lithium cell CR1216

3. Read in parameterization again

* Termination:

The AdComNet segment must

be terminated with 2 resistors

(110 Ω).

The resistors must in each case

be connected at the end of the

cable.

Connections that are not used

also have to be terminated! Earth the segment

shielding once.

Further top hat rail levels for additional CPS-M modules

If a top-hat rail is not sucient for the conguration of your system, a further top-hat rails can be integrated in the following way.

Further top-hat rail rows are assembled like the rst row of the CPS-M (see « Arrangement of the modules » page 8 )

Connect the AdComNet master interface X4 on the CM module of the rst row to the AdComNet slave interface X5 on the CM module of the

additional row. If you need additional module rows, proceed in the same way.

You can connect to any CM via USB and use the connected rows as a common control panel.

LT inputs, lines and groups can be freely linked across all rows.

14/36 CPS-M1-MSE

5432

1

5432

1

IOM-D1-1212

5

5

5

4

4

4

3

3

3

2 1

2 1

2 1

X1 X2 X3

X6 X5 X4

5432

1

–

DO 1.1

DO 1.2

DO 1.4

DO 1.3

–

DO 2.4

DO 2.4

DO 2.1

DO 2.3

DO 3.2

–

DO 3.1

DO 3.4

DO 3.3

–

DI 3.2

DI 3.3

DI 3.4

DI 3.1

–

DI 2.2

DI 2.3

DI 2.4

DI 2.1

–

DI 1.2

DI 1.3

DI 1.4

DI 1.1

T1

N

PE

T2

T3

T1

N

PE

T2

T3

2 6

5

4

3

2

1

Q2.1

X2

1

2

3

PE

M

3~

U

V

W

PE

1T1 1T2 1T3

1L3 1L2 1L1

13

14

21

22

HIS HIS HIO HIO PE

C13A

F1

1

L1 3

L2 5

L3

T1

2

T2

4

T3

6

Q2.2

3

L2

1

L1

5

L3

42 6

T2T1 T3

Q2.3

4321

4321

BRM-1-COC0006

4

4

4

3

3

3

2

2

2

1

1

1

X1 X2 X3

X6 X5 X4

COM 6

NO 6

NC 6

COM 6

COM 5

NO 5

NC 5

COM 5

COM 4

NO 4

NC 4

COM 4

4321

NO 3

COM 3

COM 3

NC 3

COM 2

NO 2

COM 1

COM 1

COM 2

NC 2

NO 1

NC 1

A1

A2

Q2.1

+A1

-A2

+U 13

S

Q2.3

13

14

F1

95

98

X2

95

96

Q2.2

English 99.828.70 1.2/07/22

Connection – soft starter

Soft starter

Revision switch

Revision switch

15/36CPS-M1-MSE

X1.1 X1.4

X2.1 X2.4

X3.1 X3.4

BRM

X4.4 X4.1

X5.4 X5.1

X6.4 X6.1

BRM

4321

4321

BRM-1-COC-0006

4

4

4

3

3

3

2

2

2

1

1

1

X1 X2 X3

X6 X5 X4

COM 6

NO 6

NC 6

COM 6

COM 5

NO 5

NC 5

COM 5

COM 4

NO 4

NC 4

COM 4

4321

NO 3

COM 3

COM 3

NC 3

COM 2

NO 2

COM 1

COM 1

COM 2

NC 2

NO 1

NC 1

4321

COM x

COM x

NO x

NC x

BRM

X1

X6

X2

X5

X4

X3

English

99.828.70 1.2/07/22

Connection – BRM

Nr. Name Beschreibung

X1.1 NC 1 Floating output 1 - normally closed *

X1.2 COM 1 Floating output 1 – COM

X1.3 NO 1 Floating output 1 – normally open *

X1.4 COM 1 Floating output 1 – COM

X2.1 NC 2 Floating output 2 – normally closed *

X2.2 COM 2 Floating output 2 – COM

X2.3 NO 2 Floating output 2 – normally open *

X2.4 COM 2 Floating output 2 – COM

X3.1 NC 3 Floating output 3 – normally closed *

X3.2 COM 3 Floating output 3 – COM

X3.3 NO 3 Floating output 3 – normally open *

X3.4 COM 3 Floating output 3 – COM

X4.4 COM 4 Floating output 4 – COM

X4.3 NO 4 Floating output 4 – normally open *

X4.2 COM 4 Floating output 4 – COM

X4.1 NC 4 Floating output 4 – normally closed *

X5.4 COM 5 Floating output 5 – COM

X5.3 NO 5 Floating output 5 – normally open *

X5.2 COM 5 Floating output 5 – COM

X5.1 NC 5 Floating output 5 – normally closed *

X6.4 COM 6 Floating output 6 – COM

X6.3 NO 6 Floating output 6 – normally open *

X6.2 COM 6 Floating output 6 – COM

X6.1 NC 6 Floating output 6 – normally closed *

* 5 ... 30 V DC, 10 mA ... 3 A / 5 ... 265 V AC, 10 mA ... 3 A, cos φ = 1

The "Failsafe power failure" parameter can be used to dene the state

of the potential-free contact to be taken in the event of a failure of the

mains and battery supply. If the "None" conguration is selected, the

last status is retained.

16/36 CPS-M1-MSE

X2

1

2

3

PE

3~

U

V

W

PE

L1

L2/N

L3

U V W PE

T2

C16A

F1

T1

N

PE

T2

T3

T1

N

PE

T2

T3

1T1 1T2 1T3

1L3 1L2 1L1

13

14

21

22

HIS HIS HIO HIO PE

4321

4321

BRM-1-COC0006

4

4

4

3

3

3

2

2

2

1

1

1

X1 X2 X3

X6 X5 X4

COM 6

NO 6

NC 6

COM 6

COM 5

NO 5

NC 5

COM 5

COM 4

NO 4

NC 4

COM 4

4321

NO 3

COM 3

COM 3

NC 3

COM 2

NO 2

COM 1

COM 1

COM 2

NC 2

NO 1

NC 1

T1

English 99.828.70 1.2/07/22

Connection – Frequency converter

Revision switch

Frequency converter

Lüftergeschwindigkeit 1

Lüftergeschwindigkeit 2

FWD

+24 V

17/36CPS-M1-MSE

X1.1 X1.5

X2.1 X2.5

X3.1 X3.5

IOM

X4.5 X4.1

X5.5 X5.1

X6.5 X6.1

IOM

5432

1

5432

1

IOM-D1-1212

5

5

5

4

4

4

3

3

3

2 1

2 1

2 1

X1 X2 X3

X6 X5 X4

5432

1

–

DO 1.1

DO 1.2

DO 1.4

DO 1.3

–

DO 2.4

DO 2.4

DO 2.1

DO 2.3

DO 3.2

–

DO 3.1

DO 3.4

DO 3.3

–

DI 3.2

DI 3.3

DI 3.4

DI 3.1

–

DI 2.2

DI 2.3

DI 2.4

DI 2.1

–

DI 1.2

DI 1.3

DI 1.4

DI 1.1

IOM

DI x.x

–

24 V DC

DO x.x

–

X1

X6

X2

X5

X4

X3

English

99.828.70 1.2/07/22

Connection – IOM

Nr. Name Beschreibung

X1.1 DO 1.4 freely congurable digital output

1.4 *

X1.2 DO 1.3 freely congurable digital output

1.3 *

X1.3 - Reference potential (do not connect to P-)

X1.4 DO 1.2 freely congurable digital output

1.2 *

X1.5 DO 1.1 freely congurable digital output

1.1 *

X2.1 DO 2.4 freely congurable digital output

2.4 *

X2.2 DO 2.3 freely congurable digital output

2.3 *

X2.3 - Reference potential (do not connect to P-)

X2.4 DO 2.2 freely congurable digital output

2.2 *

X2.5 DO 2.1 freely congurable digital output

2.1 *

X3.1 DO 3.4 freely congurable digital output

3.4 *

X3.2 DO 3.3 freely congurable digital output

3.3 *

X3.3 - Reference potential (do not connect to P-)

X3.4 DO 3.2 freely congurable digital output

3.2 *

X3.5 DO 3.1 freely congurable digital output

3.1 *

X4.5 DI 1.1 freely congurable digital input

1.1 **

X4.4 DI 1.2 freely congurable digital input

1.2 **

X4.3 - Reference potential (do not connect to P-)

X4.2 DI 1.3 freely congurable digital input

1.3 **

X4.1 DI 1.4 freely congurable digital input

1.4 **

X5.5 DI 2.1 freely congurable digital input

2.1 **

X5.4 DI 2.2 freely congurable digital input 2.2 **

X5.3 - Reference potential (do not connect to P-)

X5.2 DI 2.3 freely congurable digital input

2.3 **

X5.1 DI 2.4 freely congurable digital input

2.4 **

X6.5 DI 3.1 freely congurable digital input

3.1 **

X6.4 DI 3.2 freely congurable digital input

3.2 **

X6.3 - Reference potential (do not connect to P-)

X6.2 DI 3.3 freely congurable digital input

3.3 **

X6.1 DI 3.4 freely congurable digital input

3.4 **

*

max. 50 mA, short-circuit-proof

**

0 ... 28 V,

active minus or plus

(not galvanically isolated)

< either >

active plus

active minus

Digital inputs

Digital outputs

24 V DC

Each max. 50 mA

(programmable using SCS)

18/36 CPS-M1-MSE

1O 2O 3O

1I 2I 3I

13

14

21

22

HIS HIS HIO HIO PE

4O 5O 6O

4I 5I 6I

S1

3~ W2U1

U2V1

V2W1

PE

3

1

2

6

4

5

T1

N

PE

X2 X2

135

246

135 135

246 246

Q2 Q3 Q4

C16A

F1

1

L1 3

L2 5

L3

T1

2T2

4T3

6

Q5

T1

N

PE

T2

T3

T2

T3

5432

1

5432

1

IOM-D1-1212

5

5

5

4

4

4

3

3

3

2 1

2 1

2 1

X1 X2 X3

X6 X5 X4

5432

1

–

DO 1.1

DO 1.2

DO 1.4

DO 1.3

–

DO 2.4

DO 2.4

DO 2.1

DO 2.3

DO 3.2

–

DO 3.1

DO 3.4

DO 3.3

–

DI 3.2

DI 3.3

DI 3.4

DI 3.1

–

DI 2.2

DI 2.3

DI 2.4

DI 2.1

–

DI 1.2

DI 1.3

DI 1.4

DI 1.1

F1

95

98

95

96

Q5

4321

4321

BRM-1-COC0006

4

4

4

3

3

3

2

2

2

1

1

1

X1 X2 X3

X6 X5 X4

COM 6

NO 6

NC 6

COM 6

COM 5

NO 5

NC 5

COM 5

COM 4

NO 4

NC 4

COM 4

4321

NO 3

COM 3

COM 3

NC 3

COM 2

NO 2

COM 1

COM 1

COM 2

NC 2

NO 1

NC 1

+

-stern

dreieck

Q4 Q3

Q2 Q3 Q4

English 99.828.70 1.2/07/22

Connection – Star-delta circuit

Revision switch

19/36CPS-M1-MSE

X1

X6

X2

X5

X4

X3

English99.828.70 1.2/07/22

Nr. Name Beschreibung

X1.1 DO 1.4 freely congurable digital output

1.4

max. 50 mA, short-circuit-proof

X1.2 DO 1.3 freely congurable digital output

1.3

max. 50 mA, short-circuit-proof

X1.3 - Reference potential (do not connect to P-)

X1.4 DO 1.2 freely congurable digital output

1.2

max. 50 mA, short-circuit-proof

X1.5 DO 1.1 freely congurable digital output

1.1

max. 50 mA, short-circuit-proof

X2.1 DO 2.4 freely congurable digital output

2.4

max. 50 mA, short-circuit-proof

X2.2 DO 2.3 freely congurable digital output

2.3

max. 50 mA, short-circuit-proof

X2.3 - Reference potential (do not connect to P-)

X2.4 DO 2.2 freely congurable digital output

2.2

max. 50 mA, short-circuit-proof

X2.5 DO 2.1 freely congurable digital output

2.1

max. 50 mA, short-circuit-proof

X3.1 DO 3.4 freely congurable digital output

3.4

max. 50 mA, short-circuit-proof

X3.2 DO 3.3 freely congurable digital output

3.3

max. 50 mA, short-circuit-proof

X3.3 - Reference potential (do not connect to P-)

X3.4 DO 3.2 freely congurable digital output

3.2

max. 50 mA, short-circuit-proof

X3.5 DO 3.1 freely congurable digital output

3.1

max. 50 mA, short-circuit-proof

X4.5 DI/AI 1.1 freely congurable multifunctional input

1.1 *

digital

0 ... 28 V,

active minus or plus

analog 0 ... 10 V

X4.4 DI/AI 1.2 freely congurable multifunctional input

1.2 *

digital

0 ... 28 V,

active minus or plus

analog 0 ... 10 V

X4.3 - Reference potential (do not connect to P-)

X4.2 DI/AI 1.3 freely congurable multifunctional input

1.3 *

digital

0 ... 28 V,

active minus or plus

analog 0 ... 10 V

X4.1 DI/AI 1.4 freely congurable multifunctional input

1.4 *

digital

0 ... 28 V,

active minus or plus

analog 0 ... 10 V

X5.5 DI 2.1 freely congurable digital input

2.1 *

digital

0 ... 28 V,

active minus or plus

X5.4 DI 2.2 freely congurable digital input 2.2 *

digital

0 ... 28 V,

active minus or plus

X5.3 - Reference potential (do not connect to P-)

X5.2 DI 2.3 freely congurable digital input

2.3 *

digital

0 ... 28 V,

active minus or plus

X5.1 DI 2.4 freely congurable digital input

2.4 *

digital

0 ... 28 V,

active minus or plus

X6.5 DI 3.1 freely congurable digital input

3.1 *

digital

0 ... 28 V,

active minus or plus

X6.4 DI 3.2 freely congurable digital input

3.2 *

digital

0 ... 28 V,

active minus or plus

X6.3 - Reference potential (do not connect to P-)

X6.2 DI 3.3 freely congurable digital input

3.3 *

digital

0 ... 28 V,

active minus or plus

X6.1 DI 3.4 freely congurable digital input

3.4 *

digital

0 ... 28 V,

active minus or plus

* not galvanically isolated

Connection – ADM

20/36 CPS-M1-MSE

X1.1 X1.5

X2.1 X2.5

X3.1 X3.5

ADM

X4.5 X4.1

X5.5 X5.1

X6.5 X6.1

ADM

5432

1

5432

1

ADM-A1-1212-4

5

5

5

4

4

4

3

3

3

2 1

2 1

2 1

X1 X2 X3

X6 X5 X4

5432

1

–

DO 1.1

DO 1.2

DO 1.4

DO 1.3

–

DO 2.4

DO 2.4

DO 2.1

DO 2.3

DO 3.2

–

DO 3.1

DO 3.4

DO 3.3

–

DI 3.2

DI 3.3

DI 3.4

DI 3.1

–

DI 2.2

DI 2.3

DI 2.4

DI 2.1

–

DI/AI 1.2

DI/AI 1.3

DI/AI 1.4

DI/AI 1.1

ADM

DO x.x

–

X1 / X2 / X3

ADM

DI x.x

–

24 V DC

X6 / X5

ADM

DI/AI x.x

–

24 V DC

X4

ADM

DI/AI x.x

–

0 ... 10 V DC

X4

24 V DC

N+ –

in out

English 99.828.70 1.2/07/22

Connection – ADM

< either >

< either >

active plus

Separate signal conditioner *

active plus

active minus

active minus

Digital inputs

Multifunctional inputs

(programmable using SCS)

Digital:

Analog:

Digital outputs 24 V DC each max. 50 mA

(programmable using SCS)

* Without a separate signal conditioner there is no galvanic isolation.

Sensors supplied by the CPS-M do not require an signal conditioner.

This manual suits for next models

4

Table of contents

Other D+H Control System manuals

Popular Control System manuals by other brands

Nice

Nice WIDES User, installation and safety instructions

Precision Engineering

Precision Engineering Bimba PCS user manual

Roberts Gorden

Roberts Gorden CORAYVAC installation manual

Lennox

Lennox Harmony III Homeowner's manual

Yetter

Yetter AIR ADJUST 2940 Operator's manual

Siemens

Siemens tiastar MCC installation instructions