TERMS AND CONDITIONS

You must immediately remove all packaging, inspect the goods and notify us of any damage to the goods within 3 days of delivery. We shall have no obligation to

replace or repair damaged goods in the event of failure by the Buyer to comply with this provision. Radiators which are off an unacceptable standard or are

damaged must not be installed. If any items is installed it will be treated as being as accepted as received.

Damaged goods being returned will only be collected from your delivery address, unless otherwise agreed in writing. Any other goods, which we accept back, are

to be returned by you to our place of business at your expense.

Items will be accepted as a return which have not been installed or damaged after delivery. We do not accept liability for any damages sustained after delivery.

Goods should be returned in their original packaging, provided such packaging and goods are undamaged.

We may issue a credit note for goods which we accept as returned.

We may agree to provide you with replacement goods prior to collecting or receiving back the goods to be returned (whether faulty, damaged or otherwise) but

only on the condition that: the replacement goods are paid for in full and we reserve the right to re-invoice you in the event that the returned goods are found to

be in a worse condition than when they were originally received by you or where such goods have not been received back to us within 3 months of the replacement

goods being received by yourselves. A re-stocking charge of 30% will be applied to all non-faulty stock items that wish to be returned. Special order and non-

stock products cannot be canceled. Where cancellation or alteration of orders is accepted by us, you may be required to pay a restocking charge, to cover

administrative costs and collection costs (if applicable); such charges to be determined by us. If the goods we deliver are faulty or damaged, we will meet the

cost of the return, as long as the fault is reported to us within 3 working days.

The goods will be deemed to have been accepted when they have been delivered and we may not accept claims for any visible defects found after installation.

We accept no liability for any cost incurred relating to the cost of installation.

We shall not be liable for any plumber’s costs, decorator’s costs, transport costs, late penalties, or any other costs, as a direct or indirect result of (i) any defect in

the goods (including but not limited to any manufacturing faults, such as leaks, that become apparent on or after installation) or (ii) late delivery of the goods.

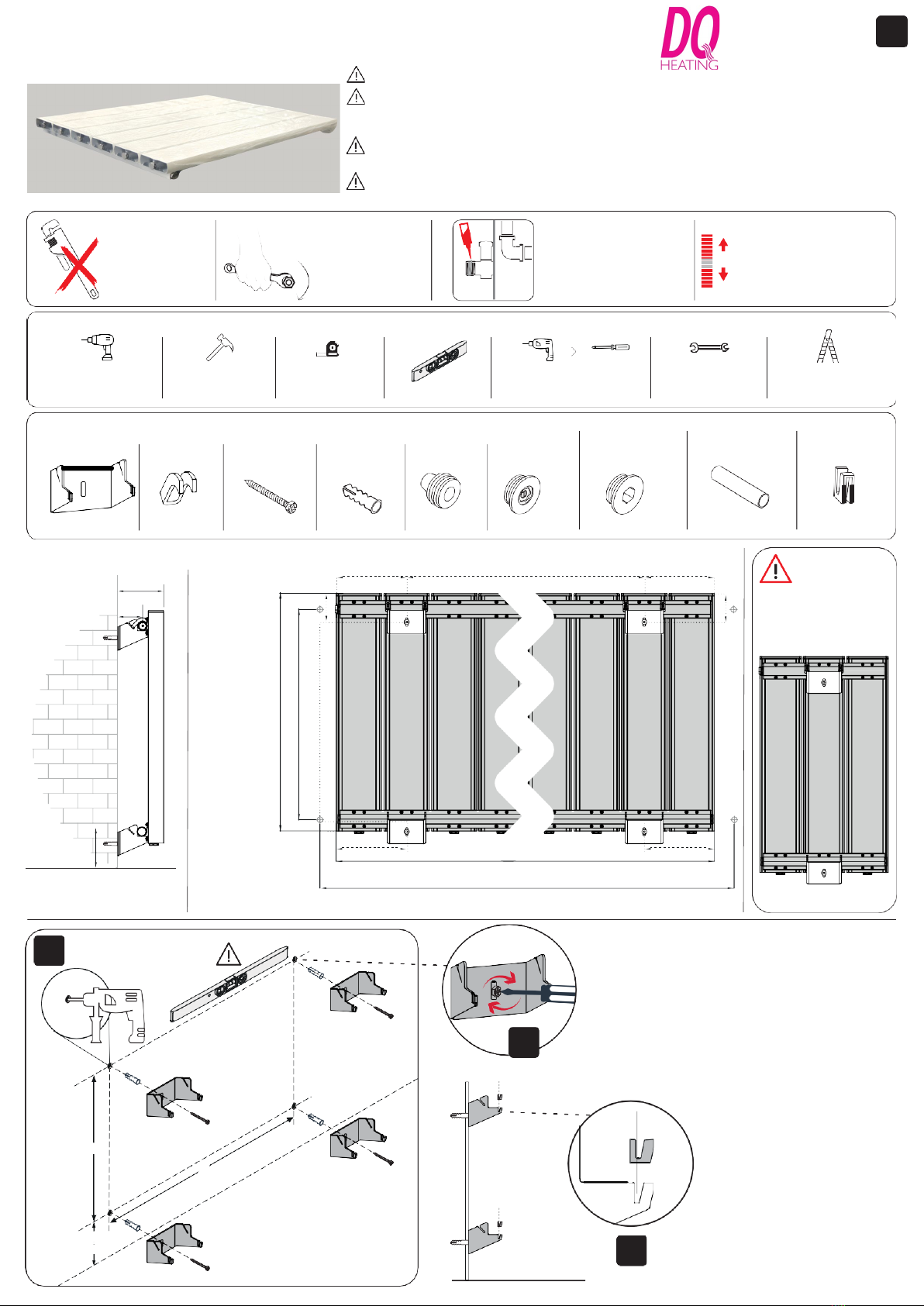

GUARANTEES AND LIABILITIES – we are not the manufacturer of this product we will take all reasonable endeavors to make over to you the benefit of any

warranty or guarantee given by the manufacturers. The item must have been fitted in accordance with British and or European standards as well as these fitting

instructions.