Operation from a gas cylinder

Screw pressure reducer to cylinder.

Check 2-6 bar delivery-pressure set-

ting. Screw connecting hose (1.5 m or 3

m, see Order List) to device and to

pressure reducer. Fully open cylinder

valves.

Use with

DrSger

OxatoP

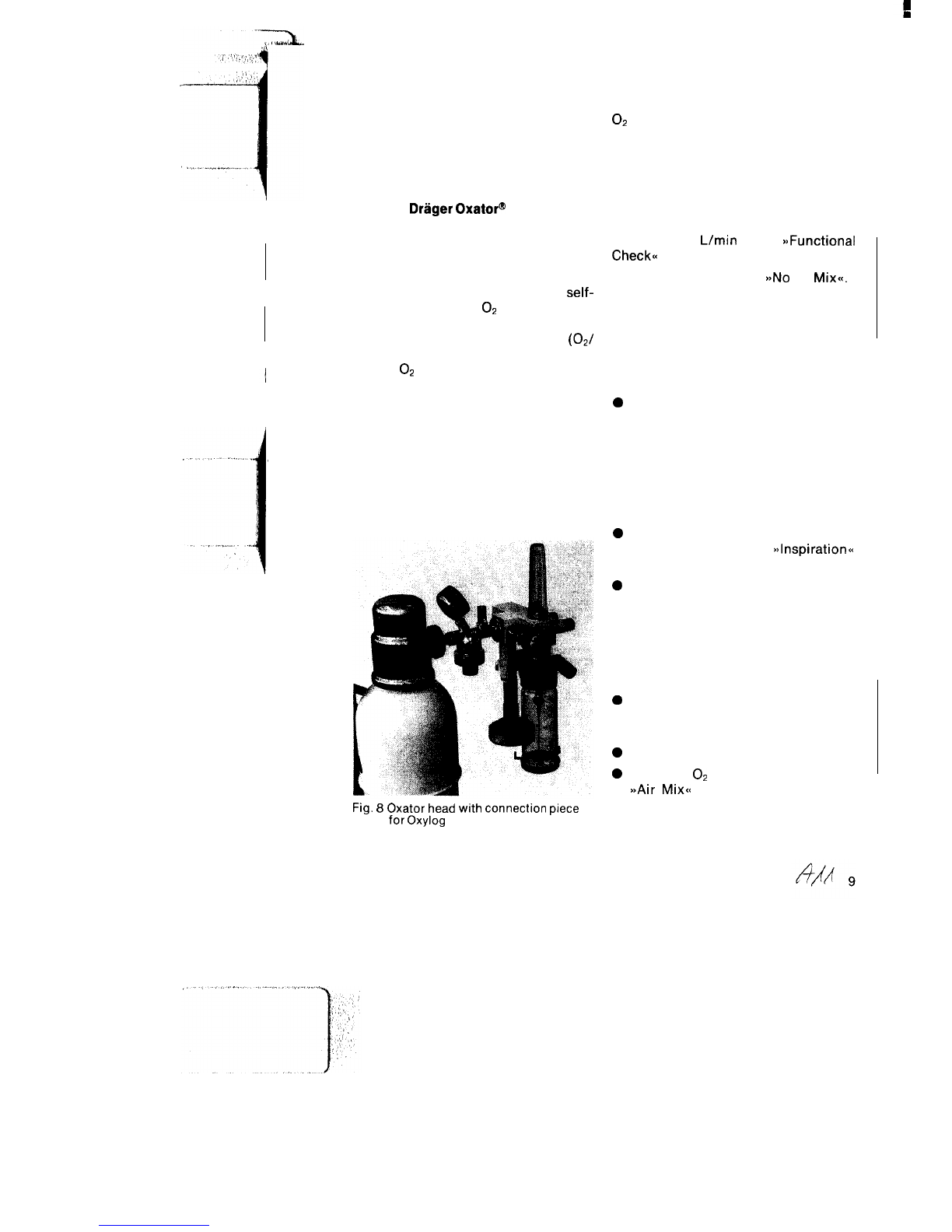

The connection piece 2M 19051 is

exclusively designed for use of the

Oxylog on the Oxator head (Fig. 8). This

connection piece is screwed to the

Oxator head and consists of a

self-

closing, standard

O2

coupling for

connection of the Oxylog using the

standard, gas-specific connector

(02/

air). A self-closing inlet screw connec-

tion for

O2

makes it possible (in addition

to the use of cylinders) to supply the

Oxylog and the other components

connected to the Oxator head (e. g.

humidifier/nebulizer or aspiration ejec-

tor) from a central gas supply unit (see

Oxator Operating Manual).

The Oxylog may not be fed via the flow

control valves at the Oxator head!

Fig.

8

Oxator

head

with

connection

piece

for

Oxylog

Use of gas blenders

.

In the case of lengthy ventilation, e. g.

during repatriation flights, low, defined

O2

concentrations may be required.

For this purpose a compressed-gas

blender can be connected upstream of

the Oxylog (see Order List).

Caution!

The inlet pressure at the Oxylog must

however be at least 2 bar at a flow rate of

approx. 60

L/min

(see

BjFunctional

Check<<

on page 11).

The switch is to be set to

a>No

Air

Mix<<.

Equipping

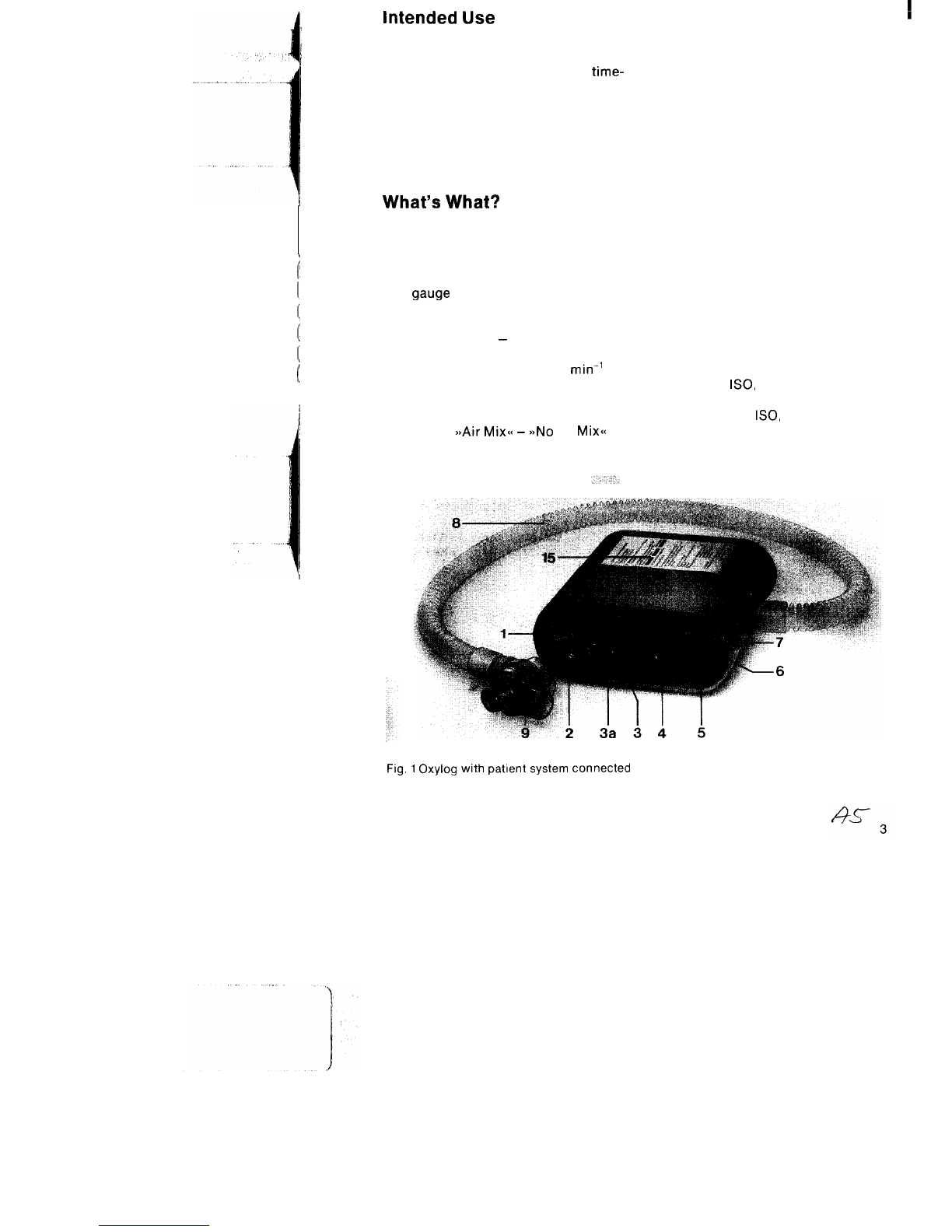

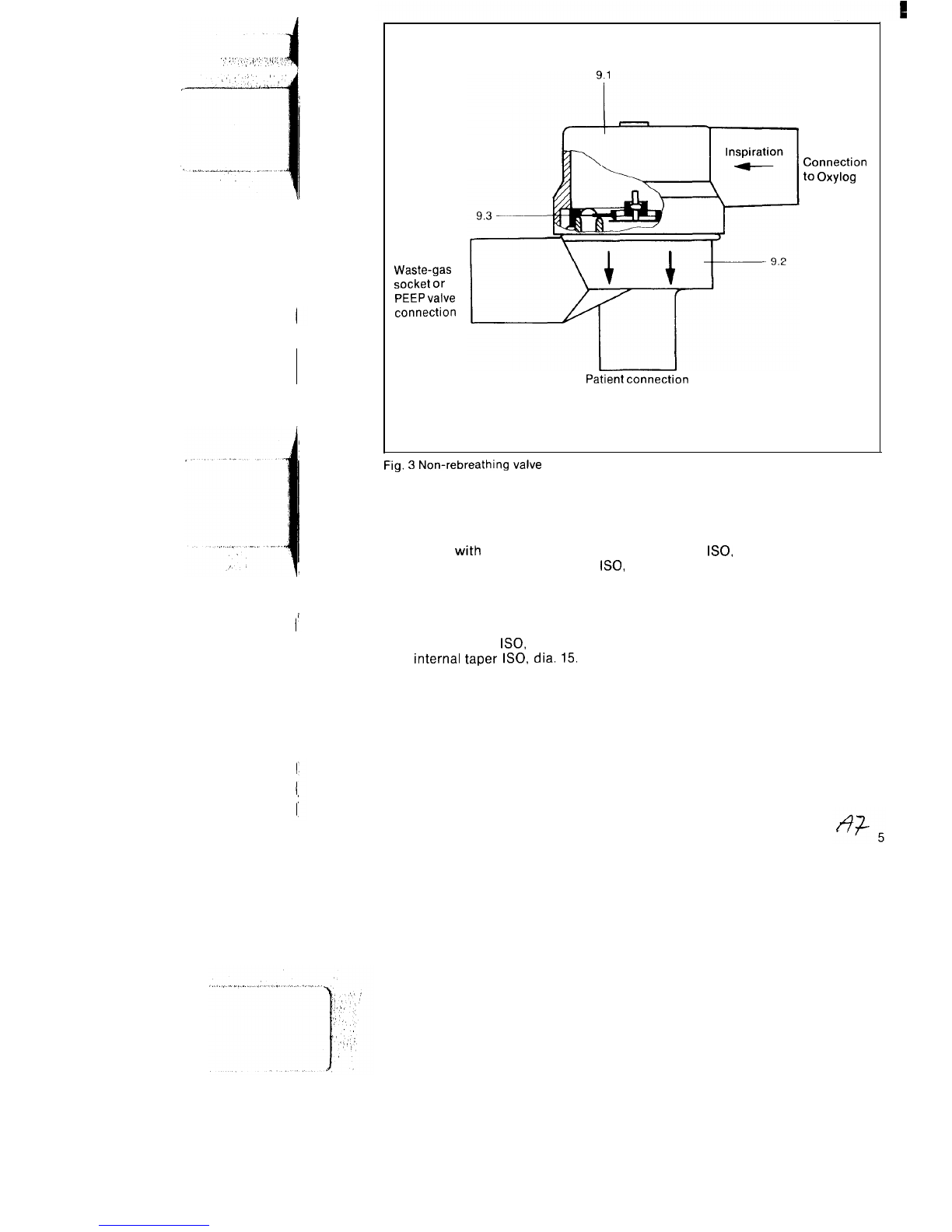

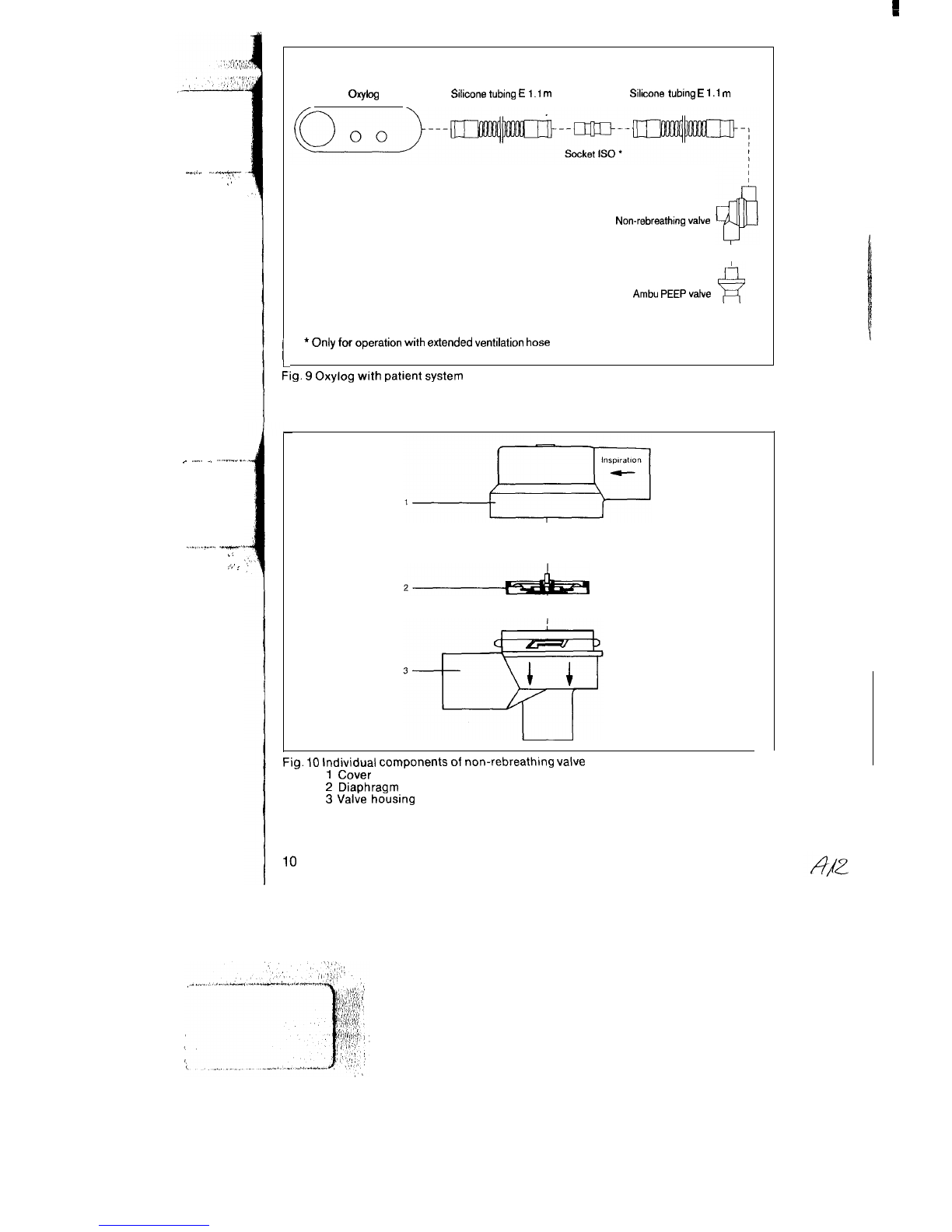

(Fig. 9)

0

Assemble non-rebreathing valve as

per Fig. 10. Ensure that entire

diaphragm is correctly positioned

and take particular care to ensure

that red check valve is present and

not out of shape. Screw cover to

valve housing (turn 45” in clockwise

direction).

0

Attach ventilation tubing to socket at

Oxylog as well as to

~~lnspiration~~

socket on non-rebreathing valve.

0

If use is made of an (optional)

externally adjustable pressure limit-

ing valve (see Order List), attach this

valve first to the socket at the Oxylog

and then connect the ventilation

tubing to the socket of the pressure

limiting valve.

0

If PEEP is being applied, insert PEEP

valve (see Order List) into waste-gas

socket of non-rebreathing valve.

0

Set airway pressure gauge to zero.

0

Preselect

O2

concentration

a>Air

Mix<<

setting reduces drive-gas

consumption by roughly 50% as

ambient air is sucked in.