7

- After start of the machine by the main switch the motor starts and spin the

cutting band.

- Place the cut material on the cutting table, lean it on the cutting ruler and

move gradually towards the cutting zone, first test the cutting on a sample

- Cutted material must be moved fluently to get straight and fluent cut,

otherwise the band saw can be damage (the band can be twisted, it can

lead to its destruction).

- After reaching the end position of the cutting table, band saw turns off

automatically.

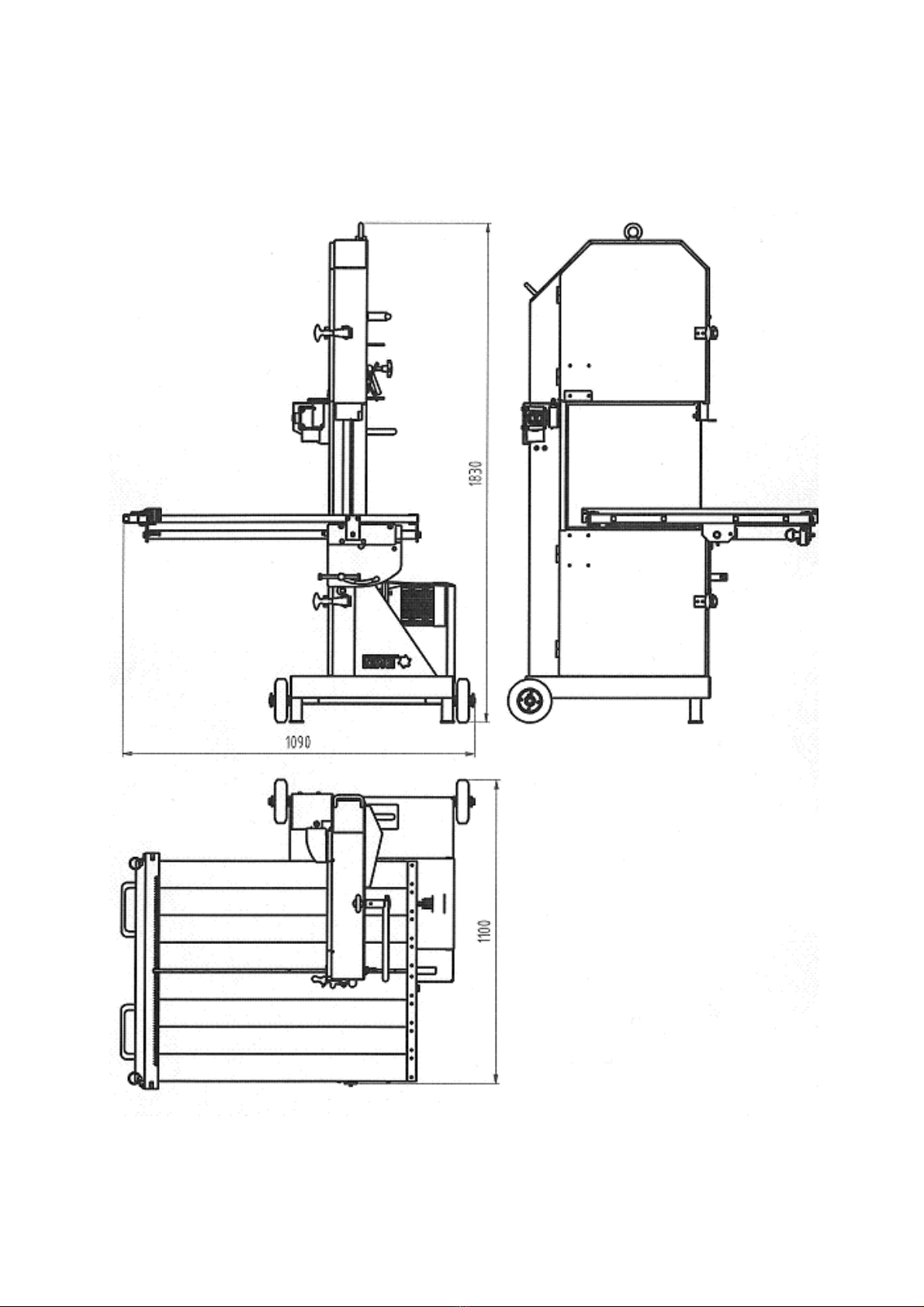

Band saw

Hard metal band saw is specifically designed for cutting of large-scale building

blocks. Cutting siliceous materials is prohibited - will damage the blade. It is

permissible to cut clay bricks or tiles.

Damage of the cutting blade is always caused by improper use.

4. Safety instructions

Installation of the blade

Before the replacement of the band saw, the operator must disconnect the machine

from the electrical system by disconnecting the power cord. Each part of the machine

should be cleaned from the remnants of the cut materials. If you are replacing band

saw after cutting, it is necessary to note with the fact that the band saw may be hot!

Open the top (Pos. 43) and bottom door (Pos. 44) of impellers, release tension lever

(Pos. 6) and lift the stop bar. After removing the cotter pins, remove the retaining bar

handles. Remove the band saw and remove all its potential remains. Insert the new

band in length with corresponding parameters and attach it in the reverse side. Pay

attention to the correct direction of teeth. After attaching the band must be properly

tensioned.

After tension of the band saw is recommended run machine for short time and check

the tension of the band saw and mounting.

Do not operate the machine without a properly fitted covers! Door of impellers

must be properly secured. In the event that the door is opened, the machine

automatically stops!

5. Maintenance, adjusting, liquidation of machine

Maintenance and implementation terms

Check of saw condition daily, continuously

Change of cutting tool wear out, damage tooth

Remove of dust, cleaning daily, continuously

Check of electrical installation daily, continuously

Check of rotating parts daily, continuously

Check wholeness of machine daily, continuously

Check tightening of connection daily, continuously