Dr.Thiedig Digox 6 User manual

Operating Manual

Oxygen Analyser

2

Dr. Thiedig + Co

Prinzenallee 78-79

D-13357 Berlin

Phone: +49 30 49 77 69-0

Fax: +49 30 49 77 69-25

www.thiedig.com

Service hotline: (+49) 30 49 77 69-42

File: O2-EC6-E-060301.doc

Edition O2-EC-D-01/03/06

Subject to changes

3

Table of contents

1Introduction ........................................................................................................8

1.1 Conventional use 8

1.2 Unit description 8

1.3 Measuring principle 8

1.4 Processing measuring data 8

1.5 Connections 10

1.6 Operating elements 12

2Menu overview................................................................................................. 13

2.1 The "Measuring" screen 14

2.2 Calibration menu 14

2.3 Main menu 15

2.4 Menu level 2 15

3Taking the unit into service............................................................................ 16

3.1 Filling the reference electrode with KCl solution 16

3.2 Connections 17

3.3 Taking the unit into service 17

4Calibration of the Digox 6............................................................................... 18

4.1 Introduction 18

4.2 Variables influencing calibration 20

4.2.1 Flow 20

4.2.2 Pressure 20

4.2.3 Temperature 20

4.3 Calibrating of the flowmeter 20

4.3.1 Preparation 20

4.3.2 Carrying out the calibration 21

4.3.3 Check Kf factor 21

4.4 Thiedig active calibration 22

4.4.1 Preparation 22

4.4.2 Carrying out the Thiedig active calibration 22

4.4.3 Check Ks factor 24

4.5 Short calibration 24

4.6 Reference calibration 26

4.6.1 Ref min calibration 26

4.6.2 Ref max calibration 27

4

5Measuring ........................................................................................................ 28

5.1 Conditions of the sample and practical hints 28

5.2 The Digox 6 data logger 29

5.2.1 How to operate the continuous Data logger 29

5.2.1.1 Selection of the interval 29

5.2.1.2 Recording and saving measuring values 30

5.2.2 How to operate the measuring point data logger (optional) 30

5.2.3 Output of measuring values 30

5.2.4 Deleting measure values 31

5.3 How to operate DigoxWin 32

5.3.1 Introduction 32

5.3.2 Installing DigoxWin 32

5.3.2.1 Windows operating system 32

5.3.2.2 Checking the data transmission settings 32

5.3.3 Starting DigoxWin 33

5.3.4 Processing measuring data on the PC 34

5.3.4.1 The online data logger 34

5.3.4.2 Reading out the data storage in the Digox 6 35

5.3.4.3 Evaluate measuring data 36

5.3.5 Further DigoxWin functions 37

6Maintenance..................................................................................................... 38

6.1 Cleaning the electrodes 38

6.1.1 General hints 38

6.1.2 Steps to be performed 38

6.2 Exchanging diaphragm and sealing rings 39

6.2.1 General hints 39

6.2.2 Means required 39

6.2.3 Works to be carried out 40

6.3 Hints regarding the moisture indicator 41

6.4 Hints regarding the battery operation 41

7Fault messages and troubleshooting .......................................................... 42

8Special functions............................................................................................. 46

8.1 Status display 46

8.2 Selecting recorder measuring ranges and output currents 46

8.3 Menu level 2 functions 47

8.3.1 Make system settings 48

8.3.2 Setting the interface 48

8.3.3 Setting the clock 49

8.3.4 Polling the identification number 49

8.3.5 Enabling options 49

5

8.3.6 System check 50

8.3.7 Generating a code 50

8.3.8 Flowmeter 50

9Technical data Digox 6 ................................................................................... 51

10 Appendix.......................................................................................................... 52

10.1 Definition of terms 52

10.2 Scope of supply with accessories kit 53

10.3 Spare parts 54

10.3.1 Analyser block Digox 6 54

10.3.2 Further spare parts 56

10.4 Digox 6 EC unit extension and accessories 56

10.5 Terminal assignment 57

11 Index................................................................................................................. 59

6

The instructions at hand are intended to make you

familiar with the functions of the Digox 6 analyser

and to properly operate the device.

The unit should be operated by trained personnel

only.

The operating manual contains the following

additional information:

WARNING!

This indicates a warning note to avoid improper

operating states of the unit.

NOTE:

Here you get further information and details.

You should always place this operating manual

within reach of the location of the Digox.

Due to technical improvements, some descriptions

and figures in this operating manual may slightly

differ from the functions of your Digox unit.

Therefore, no claims can be made on the grounds

of data, figures and descriptions included in this

manual.

Copyright

All rights for this operating manual are reserved by

Dr. Thiedig + Co.

No part of this operating manual may be

reproduced or distributed or used for competitive

purposes or disclosed to third parties.

In case of questions regarding the Digox 6

analyser, please contact:

Dr. Thiedig + Co.

Service phone: (+49)30 49 77 69-42

7

8

1 Introduction

1.1 Conventional use

The oxygen analyser Digox 6 measures reliably,

precisely and quickly the oxygen content in beer,

soft drinks and water in the trace range between

0.001 and 20 mg/l.

The precise measuring principle, the built-in

calibration device, the solid assembly and the

easy handling of the Digox 6 are ideal conditions

for an analyser for quality control in breweries and

filling machines.

1.2 Unit description

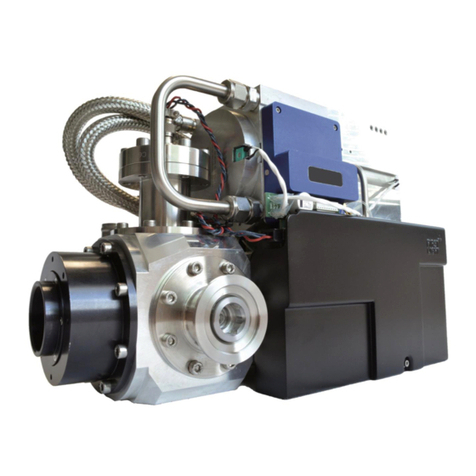

The Digox 6 consists of the analyser block and

the splash-proof display and user field.

The analyser block contains the calibration device,

the measuring cell system as well as the sensors

for temperature and flow measurement. It is

mounted on the back of the housing and is

protected by a cover.

The Digox 6 has connections for power supply,

recorder outputs and PC interface.

The unit has a built-in battery charger for

approximately 8 hours operation independent of

the mains.

The unit can also be operated via the power

supply, however, for a steady state we

recommend using the stationary measuring unit

Digox 5S.

The Digox 6 has a data logger and in connection

with the Touch-Memory-System (optional) has an

additional data memory. The data communication

is carried out via the PC interface.

1.3 Measuring principle

The Thiedig measuring principle for the analysis of

oxygen traces operates according to the

potentiostatic 3 electrodes measuring system

developed by Prof. Tödt and Dr. Teske.

The principle is based on an electrochemical

reduction of dissolved oxygen at the measuring

electrode. For this, the measuring electrode is

polarized.

The measurement takes place directly in the

medium. The sample is the electrolyte for the

electrochemical reaction. This enables the

measurement without using membranes. The

membrane-free sensor measures quickly, drift-free

and reliably in the temperature range between -5

and +50 °C.

The reduction of oxygen causes a measuring

current between both electrodes.

This measuring current is a direct measure for the

oxygen concentration in the sample. The Thiedig

sensor uses this measuring principle in a

potentiostatic regulated grouping of 3 electrodes.

The measuring current depends on the

temperature and flow of the sample. The built-in

flow and temperature sensors measure these

variables. The Digox 6 software corrects the

measuring values. Corrections are carried out

automatically via the medium.

To calibrate the oxygen analyser, different

procedures can be used. Some operate fully

automatically. Here the calibration is carried out

without interrupting the measuring process.

1.4 Processing measuring data

The supplied software DigoxWin runs under the

operating system Windows 98/ 2000/ XP. The

measuring data can be displayed, saved as well

as evaluated in tables or graphically online on the

PC. The measured data can be processed with

Microsoft Excel ™.

9

The optional Touch-Memory-System can be

combined with the data storage. Touch-Memories

are individually programmed data storage

(TouchKeys), which are attached to measuring

points. They automatically enable a safe allocation

of measurement and measuring points.

In addition, when using the special user

TouchKeys, a clear allocation of user and

measurement is ensured.

In the created data file, the measuring values, the

measuring point and the user are filed.

If you have further questions regarding the use

and the advantages of this system, please do not

hesitate to contact us.

10

1.5 Connections

Figure: 1.1

1 Regulating valve sample flow

2 Moisture indicator for housing interior

3 Socket for RS-232 interface or

Touch-Memory Stick (optional)

4 Sample out flow Out

5 Socket for recorder output/

measuring range identification

6 Socket for plug-in power supply unit

Figure: 1.2

1

2

3

4

5

6

11

Figure: 1.3

1 Display

2 Sample supply In

Figure: 1.4

1.6

1

2

12

Operating elements

Figure:1.5

1 Display,

"Measuring" is displayed, the measuring

mode is active

2

To switch the Digox 6 on

– shortly press this key

To switch the Digox 6 off

– press and hold the key for 5 seconds

3 to switch the measuring mode on

4 to open the calibration menu

5 to confirm your input

6 Press this key once –

to switch the display lighting on,

after the set lighting period has passed,

the light goes out independently

7 To open the main menu

8 Cursor keys

To make your selection and to enter

numbers.

13

Notes:

14

2 Menu overview

2.1 The "Measuring" screen

The "Measuring" screen appears automatically

after switching the Digox 6 on or after pressing

.

Figure: 2.1

1 Faulty parameter

2 Measuring value

3 Sample temperature in [°C]

4 Flow in [l/h]

5 Date and time

2.2 Calibration menu

To enter press .

Figure: 2.2

Selection of the calibration mode:

•Thiedig active calibration, section 4.4

•Short calibration, section 4.6

•Reference calibration, section 4.7

•Calibration of the flowmeter, section 4.3

Use scroll down.

15

2.3 Main menu

To enter the main menu press .

Figure: 2.3

Mark the desired function with or and

confirm with .

•select the medium

•data logger,

see section 5.2

•poll status (e.g. Ks factor),

see section 8.1

•set measuring range,

see section 8.2

•battery status,

see section ???

•Code for entering menu level 2,

see section 8.3

NOTE:

A four-digit code can be used to protect menu

level 2 functions against unauthorised use. The

default setting is 9999.

2.4 Menu level 2

Confirm the last entry in the main menu with .

Figure: 2.4

Select numbers with or , mark the next

digit with .

Press to confirm the code.

Menu level 2 is opened. Here the following

functions are available:

•System settings,

see section 8.3.1

•Select interface,

see section 8.3.4

•Set clock,

see section 8.3.5

•Identification,

see section 8.3.6

•Enable options,

see section 8.3.7

•System check,

see section 8.3.8

•Flowmeter,

see section 8.3.9

•Generate code,

see section 8.3.10

NOTE:

Please also take into account the menu overview

in the appendix and the enclosed quick reference.

16

3 Taking the unit into service

Before you can use the Digox 6 to do

measurements, you must carry out some

preliminary steps.

3.1 Filling the reference electrode

with KCl solution

The measuring system is equipped with a

reference electrode for a precise setting of the

measuring potential. During operation, this

electrode immerses into a 15% KCl solution.

NOTE:

This solution is included in the service pack.

Before taking the unit into service, you have to fill

the analyser block with the solution.

WARNING!

Before the analyser block is filled with sample, the

reference block must have been filled with the KCl

solution.

In order to fill the reference cell, the analyser block

has to be dismantled.

Removal of analyser block

1. Lie the analyser flat on a table with the

reverse side showing upwards.

2. Loosen the knurled screws on the cover of the

analyser block and remove the sealing plug.

3. Loosen the knurled nuts and remove the plug

connector from the electrodes.

4. Now you can take off the analyser block from

the holders and in order to fill, place vertically.

Filling

1. Unscrew the reference electrode (1) from the

analyser block (Figure3.1).

2. Fill the KCl solution into the hollow place as

far as to the tip of the V.

3. If required, remove air bubbles from the

diaphragm bridge (2) by slightly tilting the

analyser block (Figure3.2).

4. Screw in the reference electrode and re-attach

the analyser block.

Figure:3.1

17

Figure:3.2

NOTE:

When screwing in the reference electrode, excess

KCl solution will leave the bore (3) (Figure 3.2).

Please collect the liquid with absorbent paper.

WARNING!

The analyser block should now rest for about 15

minutes so that the diaphragm can take up the

KCl solution.

3.2 Connections

A flexible hose and two hose clips are included in

the scope of supply to connect the Digox 6.

NOTE:

Keep the feed line from the samplings point to the

analyser as short as possible.

If reductions, clutches or other hose adapters are

used, air bubbles could settle on it. Because of

this, the running-in time of the analyser is

prolonged in order to reach low concentrations.

WARNING!

Only use oxygen-proof hoses. Silicon hoses will

lead to higher oxygen values.

3.3 Taking the unit into service

Shortly press to switch the Digox 6 on.

The starting screen is displayed.

The Digox 6 will at first perform a system check.

Then the message

"The current user of this unit is" ************

Version X.X“.

Then the "Measuring" screen appears (see section

2.1).

NOTE:

The message "Version X.X“ indicates the current

firmware version of the Digox 6.

To switch the Digox 6 off, press and hold it for

at least 5 seconds.

18

4 Calibration of the Digox 6

4.1 Introduction

During measurement in the liquid samples, the

electrochemically active surface of the electrode

system may change. By this, the sensitivity of the

measuring electrode will change as well.

Therefore, the electrode system needs to be

calibrated from time to time.

The Digox 6 has a built-in process regulated

calibration system, which can carry out a

calibration without interrupting the measuring

series.

For the Thiedig active calibration and the short

calibration, a defined increase of the oxygen

concentration is produced. This is done by

electrolysis of the sample. The resulting increase

of the measuring current is used to determine the

calibration function. With the essential requirement

"no oxygen – no measuring current“ the processor

places this function through the zero point (Figure:

4.1.)

The Thiedig active calibration lasts about 120

seconds. During the actual calibration, the

measuring conditions are also being monitored.

The short calibration operates similar to the

Thiedig active calibration, however, it does not

compare the values of measuring current, flow

and temperature with those of the beginning.

It lasts about 60 seconds.

Cross-sensibilities can be eliminated with the

reference calibration. For this, two defined

oxygen concentrations Ref min and Ref max must

be set. The calibration line is crossing those two

points.

The reference calibration takes into account all

conditions deviating from the ideal case (the

function crosses the zero point) (Figure: 4.1).

Figure: 4.1

19

Individual cases and recommended

calibration

Measurement in beer

•For the measurement in beer, we recommend

using the Thiedig active calibration for most

cases.

Trimming of an offset (cross-sensibility)

•If an offset occurs during the measurement,

which means the indicated measuring value is

increased by the same value in the total

measuring range, this offset can be corrected.

•For this, the Ref min calibration determines a

zero current Izero. A combination with the other

calibrations is possible.

NOTE:

Should implausible results occur during the

Thiedig active calibration, please check the zero

current (section 8.1, Status display). It should be

0µA in most cases. In order to delete the zero

current, please refer to section 4.6.1, Ref min

calibration.

Measurements with the sampling device.

•The short calibration is especially suitable for

cases in which constant measuring conditions

for a calibration are only available for a short

time.

Measurement in wort

•If the oxygen concentrations are above 1mg/l

(e.g. in wort), it is no longer possible to carry

out a Thiedig active calibration.

•For this, we recommend carrying out a Ref

max calibration. In the course of this, the

Digox 6 is trimmed with an externally

determined reference value.

NOTE:

Due to a frequently occurring content of

suspended particles, blockages in the analyser

block can happen during the measurement in wort.

Therefore, we recommend the following practical

steps:

- Secure the hose, which is connected at the

sample return, with a hose clamp.

- On this hose, put a hose clip after the

regulating valve and open the regulating valve

as far as it will go.

- Regulate the flow via the hose clip after the

analyser block.

For further uses, please do not hesitate to contact

us.

20

4.2 Variables influencing calibration

4.2.1 Flow

Measurements done at open electrodes are

influenced by the flow volume. Flow volumes

between 3 and 18 litres per hour affect the

measuring value of the medium water and of the

medium beer, which is then compensated by the

Digox 6.

NOTE:

If a flow volume outside this range is found, the

value indicating the flow will flash in the

"Measuring" screen, and an indicating symbol will

appear.

The accuracy of the flow measurement depends

on the viscosity of the medium.

4.2.2 Pressure

The pressure of the sample does not influence the

measured value. The measuring system of the

Digox 6 has been designed for operating

pressures of up to 8 bar, allowing for short

pressure peaks of up to 16 bar.

4.2.3 Temperature

The measured value is influenced by the

temperature with a gradient of 3% per °C.

The Digox 6 has got a temperature compensation

in the range between 0 and +50 °C.

4.3 Calibrating of the flowmeter

The calibration of the flowmeter is done in the

works with water. When taking the unit into

service, the Digox 6 should be calibrated with the

measuring medium.

When calibrating the flowmeter, the Kf factor is

determined. Usual values are between 0.9 and

1.2.

Calibration does not have to be repeated in

regular intervals. We recommend one-year

intervals.

4.3.1 Preparation

Required means

•Measuring cylinder, 250 ml (included in the

supply)

•PVC hose (included in the supply)

1. Connect the sample supply (marker In) to the

sampling point.

2. Connect the PVC hose to the sample return

(marker Out).

3. Switch the Digox 6 on and wait until the

"Measuring“ screen appears.

4. Set the flow at the regulating valve to 10 litres

per hour, check the measured value in the

display.

5. Press .

The calibration menu is opened. Use the

cursor keys to mark the menu item

FLOWMETER.

6. Press . The following display appears.

Figure 4.2

Table of contents

Popular Analytical Instrument manuals by other brands

SCIEX

SCIEX PA 800 Plus System overview guide

Rothenberger

Rothenberger ROSCOPE mini Instructions for use

LIGHTEL Technologies

LIGHTEL Technologies ViewConn Pro VC-8200 manual

Troglotech

Troglotech T804 WiFi System operating instructions

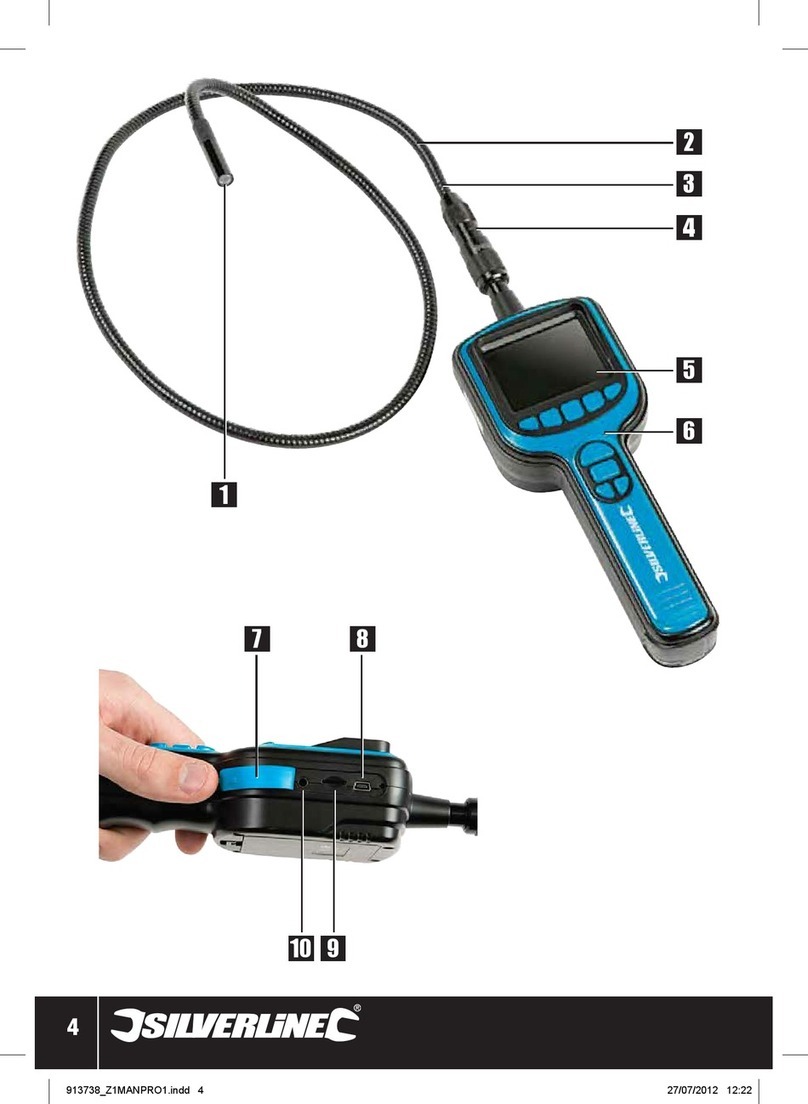

Silverline

Silverline 913738 manual

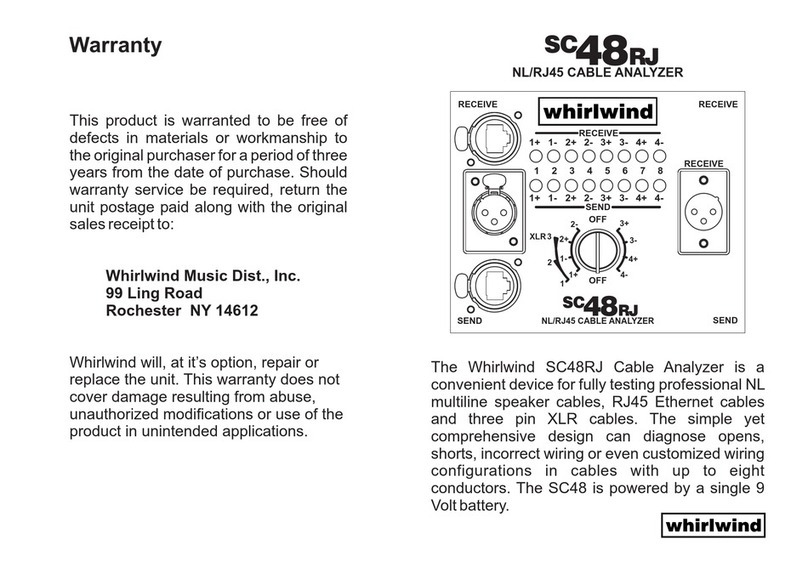

Whirlwind

Whirlwind Cable Analyzer SC48RJ owner's manual