www.mc-techgroup.com PMA 50 EX | 1.01.04 3

List of Contents

1General information ............................................................................................................................. 5

2Declaration of conformity.................................................................................................................... 5

3Electrical standards............................................................................................................................... 6

4Safety instructions ................................................................................................................................ 6

4.1 Proper Use ....................................................................................................................................................................................7

5Information and safety instructions for using the Analyzer in hazardous areas ......................... 7

5.1 Analyzing gases from Ex zone II 1G Ex IIC T4.....................................................................................................7

6Warranty ................................................................................................................................................. 8

7Used terms and signal indications...................................................................................................... 8

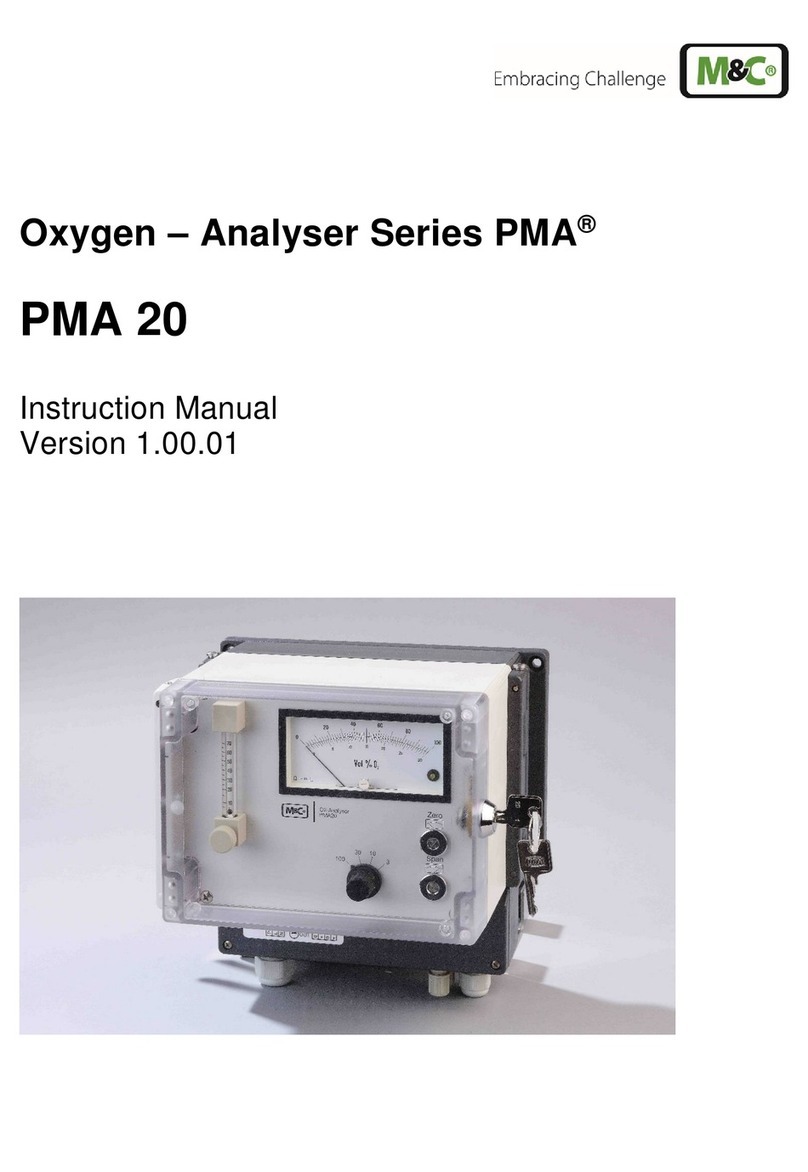

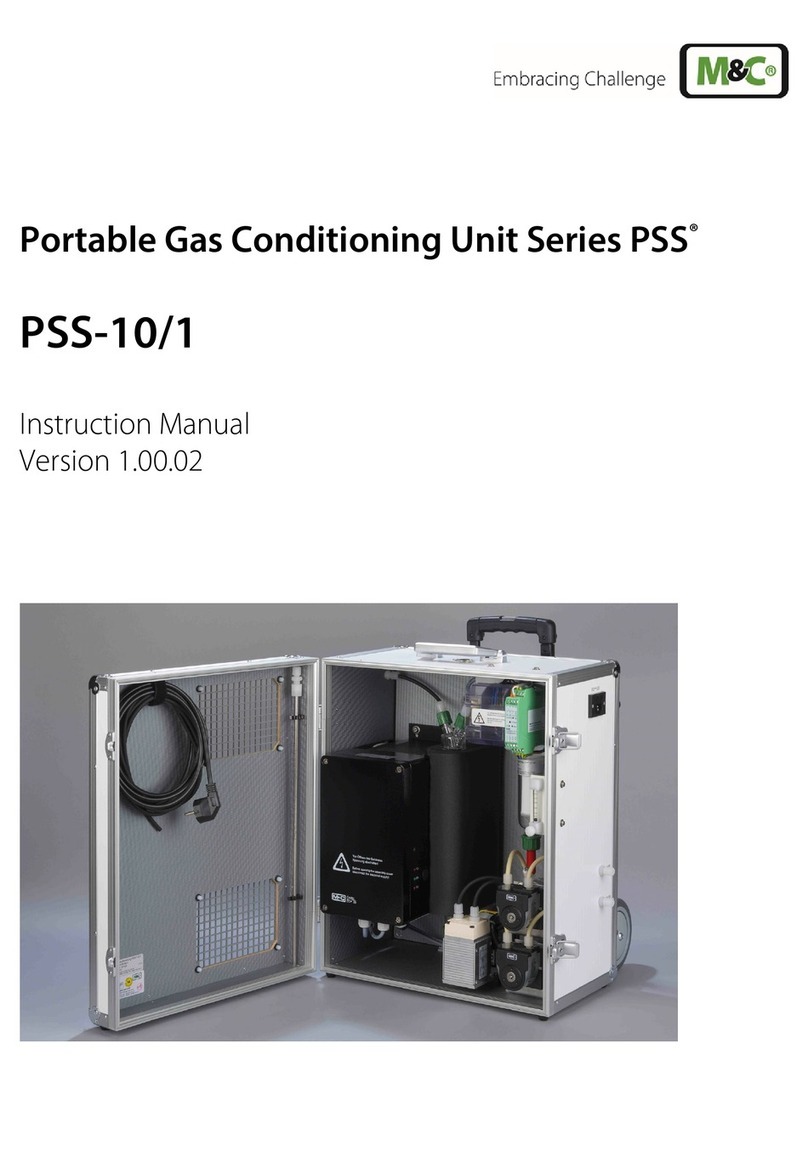

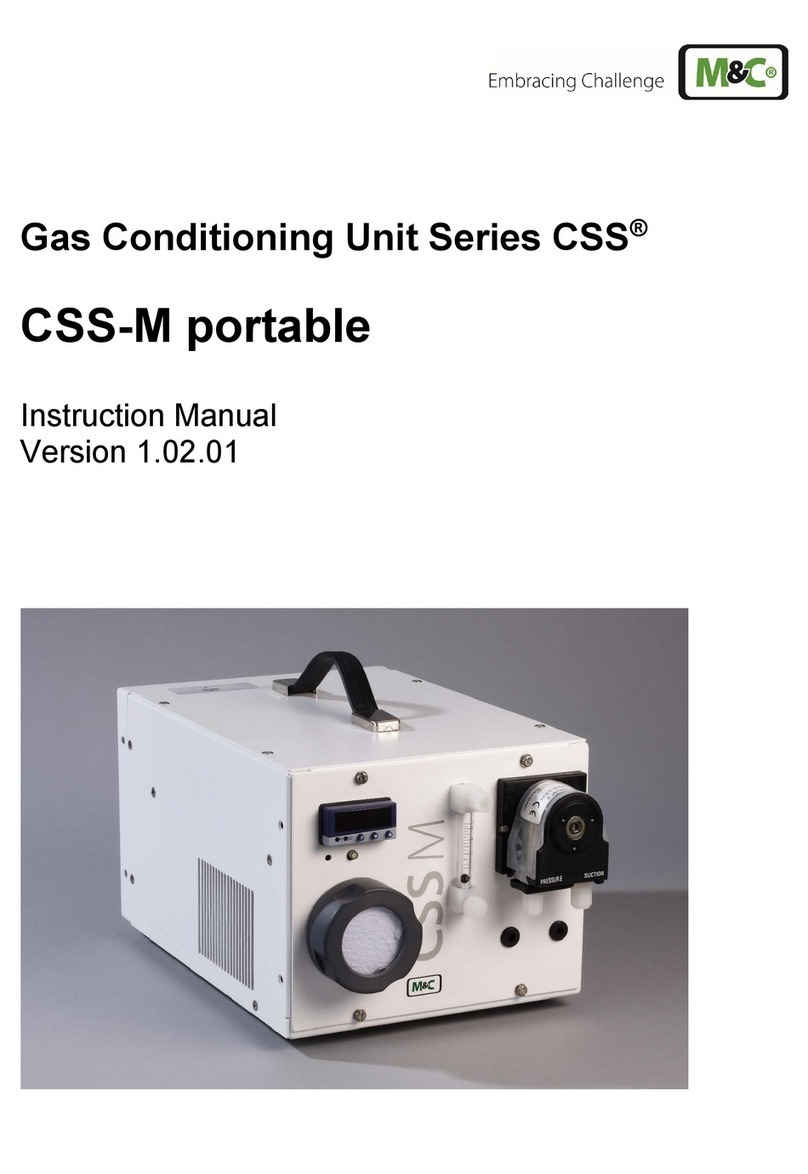

8Introduction ......................................................................................................................................... 10

8.1 Serial number...........................................................................................................................................................................10

8.2 Power supply............................................................................................................................................................................10

9Application........................................................................................................................................... 10

10 Technical Data ..................................................................................................................................... 11

10.1 Options........................................................................................................................................................................................12

11 Description........................................................................................................................................... 13

11.1 PMA 50 Ex/P/PD-1-50 with pressure compensation and enclosure purging (without SIL-

certification)..............................................................................................................................................................................14

11.2 PMA 50 Ex/P/PD with pressure compensation (without SIL-certification) ................................................15

11.3 Option zero suppression (without SIL-certification).............................................................................................15

11.4 Option enclosure purging or enclosure ventilation .............................................................................................15

12 Measuring principle ............................................................................................................................ 15

13 Gas flow diagram................................................................................................................................. 17

14 Receipt of goods.................................................................................................................................. 19

15 Installation ........................................................................................................................................... 19

16 Supply connections............................................................................................................................. 20

16.1 Sample gas inlet and sample gas outlet.....................................................................................................................20

16.2 Option purging enclosure or enclosure ventilation .............................................................................................21

16.3 Electrical connection............................................................................................................................................................22

17 Starting up ........................................................................................................................................... 23

18 Calibration............................................................................................................................................ 23

18.1 Zero calibration.......................................................................................................................................................................24

18.2 Full scale value calibration.................................................................................................................................................25

19 Measuring............................................................................................................................................. 27

20 Cross sensitivities................................................................................................................................ 28

21 Closing down ....................................................................................................................................... 31

22 Storage and Transport........................................................................................................................ 31

23 Maintenance ........................................................................................................................................ 31

23.1 Removal of the measuring cell........................................................................................................................................33

23.2 Mechanical zero point adjustment................................................................................................................................36

24 Proper disposal of the device ............................................................................................................ 37

25 Spare parts list ..................................................................................................................................... 37

26 Appendix .............................................................................................................................................. 38