INDEX

1. PRESENTATION .............................................................................4

2. HOW TO USE THIS MANUAL.........................................................5

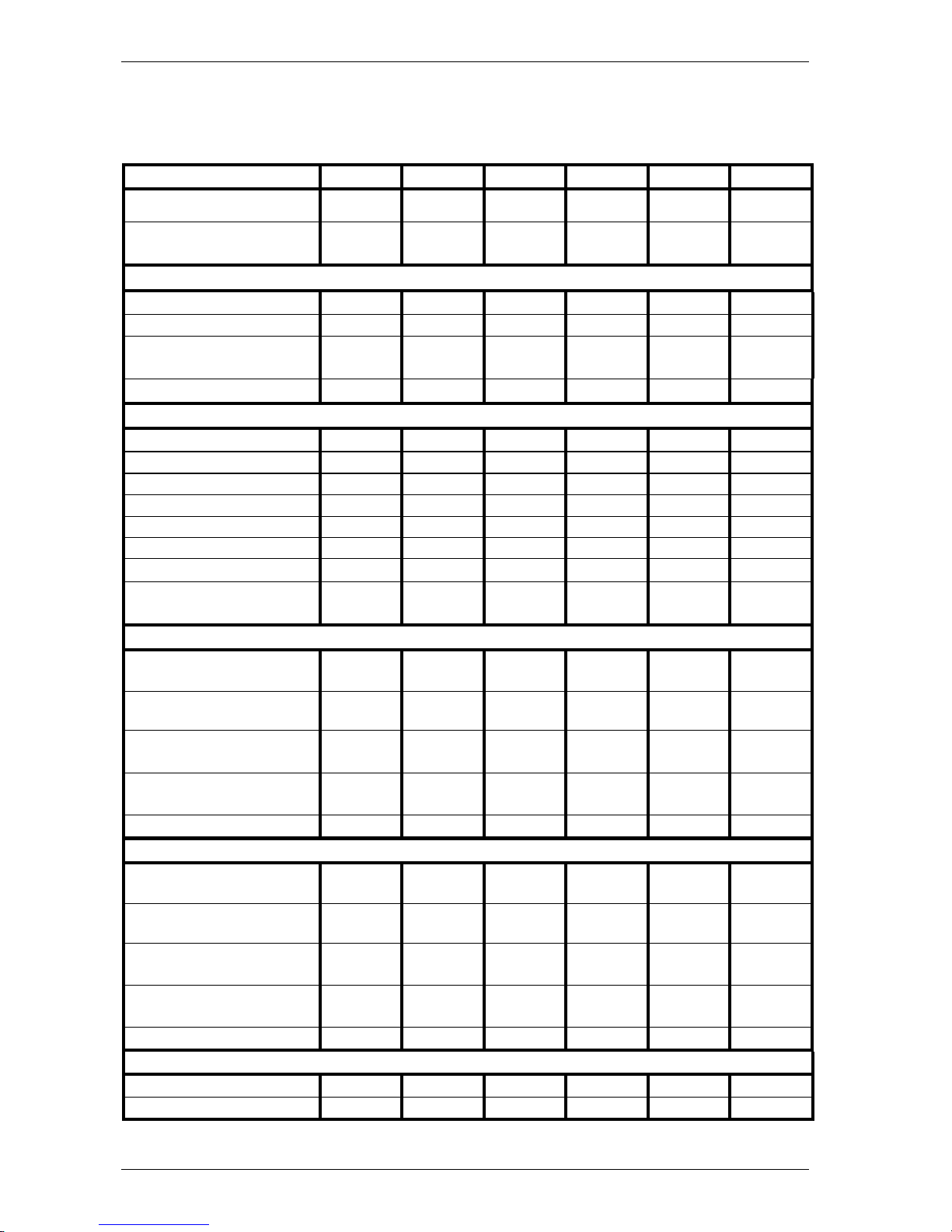

3. TECHNICAL SPECIFICATIONS......................................................7

3.1 Identifying the product...................................................................7

3.2 Conformity to European directives................................................7

3.3 Use intended for the product.........................................................7

3.4 Technical specifications................................................................8

4. INSTALLATION ...............................................................................9

4.1 Checking on delivery.....................................................................9

4.1.1 List of disassembled parts supplied.....................................10

4.2 Choice of the place of installation the rotisserie..........................10

4.2.1 Specifications for areas housing gas ovens.........................12

4.3 Moving the unit ...........................................................................12

4.4 Electrical connection...................................................................13

4.5 Connecting the gas.....................................................................15

4.6 Emissions from Cooking Appliances...........................................15

4.7 Checking before starting work ....................................................16

5. FUNCTIONING AND USE..............................................................17

5.1 Preparing the rotisserie for use...................................................17

5.2 Turning on the spits and rotisserie..............................................17

5.3 Opening and closing the glass doors..........................................17

5.4 Loading and inserting the spits ...................................................18

5.5 Removing the spits .....................................................................18

6. SAFETY WARNINGS.....................................................................19

6.1 Avoiding danger and taking responsibility for safety ...................19

7. CLEANING.....................................................................................20

5.2 Cleaning the protection between the burners..............................21

8. MAINTENANCE.............................................................................22

8.1 Removing the fixed side protection.............................................22

8.2 Adjusting the chain .....................................................................22

8.3 Changing the type of gas supply.................................................23

8.3.1 Regulating the......................................................................24

8.4 Exploded Diagrams.....................................................................26

8.5 Wiring diagram............................................................................29

9. DECOMISSIONING AND DEMOLITION........................................30