ACG Saws & Tools of Canada Inc.

EMDS110V | EMDS220V 3 |P a g e

Safety and Operation

WARNING! In order to safely work with our products, you have to follow all the safety

recommendations from the manufacturer and all the competent safety organisations

governing your territory and area.

It is mandatory and imperative that you read and comprehend the following instructions

to prevent any injury or even death to the operator or any one else in your surrounding

work area and property.

Only trained personnel or experienced operators shall use the cutting tool or saw. Any

repairs must be done by a trained or knowledgeable mechanic.

DO NOT DISCARD the safety instructions; give them to the operator

Safety regulations and obligations vary from local, regional and countries. It is your

responsibility to be informed and to follow all your local, regional, territory or country

safety authorities’ instructions and conform with all their safety recommendations and

obligations.

The saw is designed to safely cut only concrete, masonry and stone.

Only a trained person who has read and understands the operating instruction, has

experience with the use and operation of saws, the related usage of the tool and

completely understands the instruction manual in conjunction with his experience and

knowledge in the safe operation of saws should operate the saw.

General Safety Rules

•For multiple reasons, read and understand the safety instruction before installing,

operating, repairing and maintaining the saws.

•Only qualified and trained operators should use the saws.

•Do not modify the saws. This can reduce effectiveness and safety of saws.

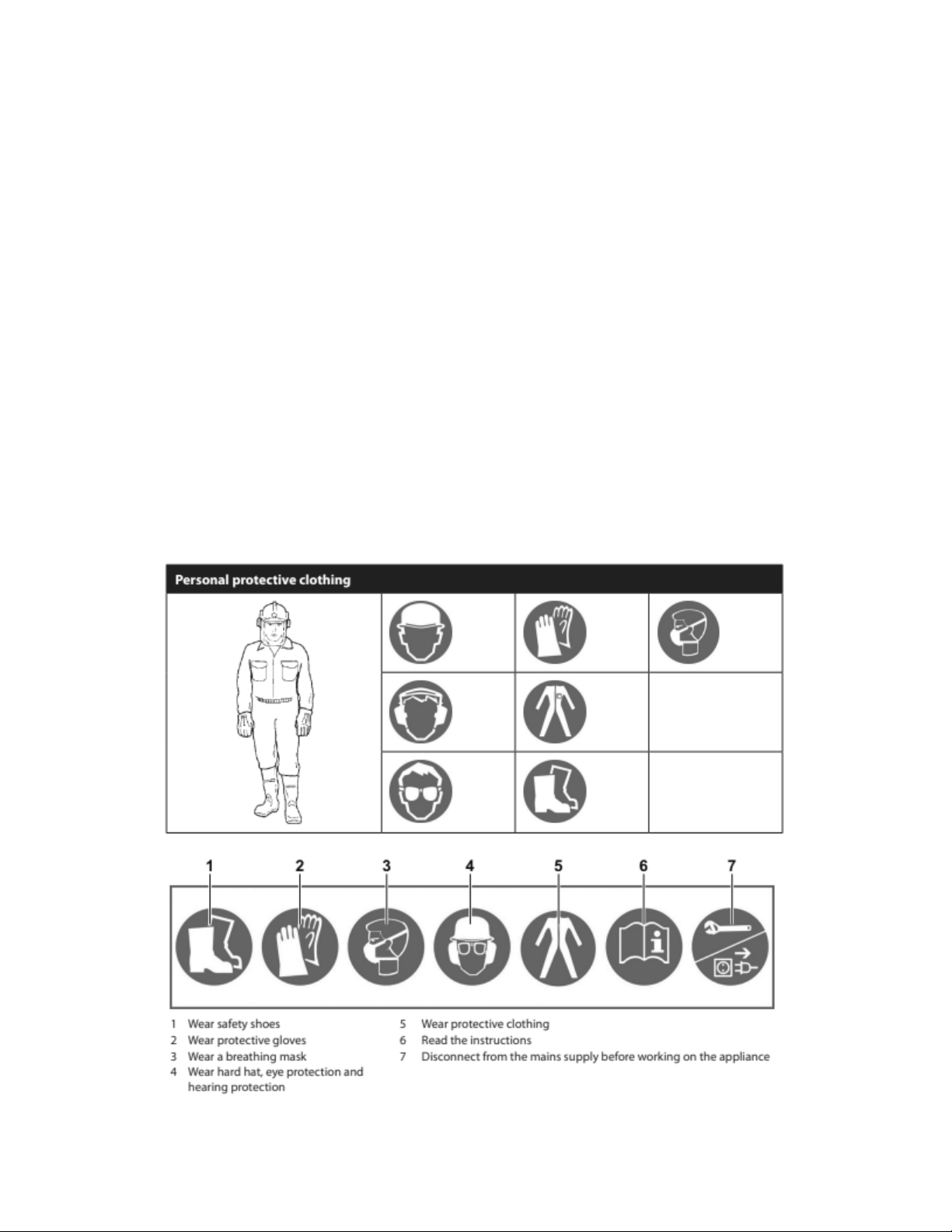

•Wear appropriate safety equipment.

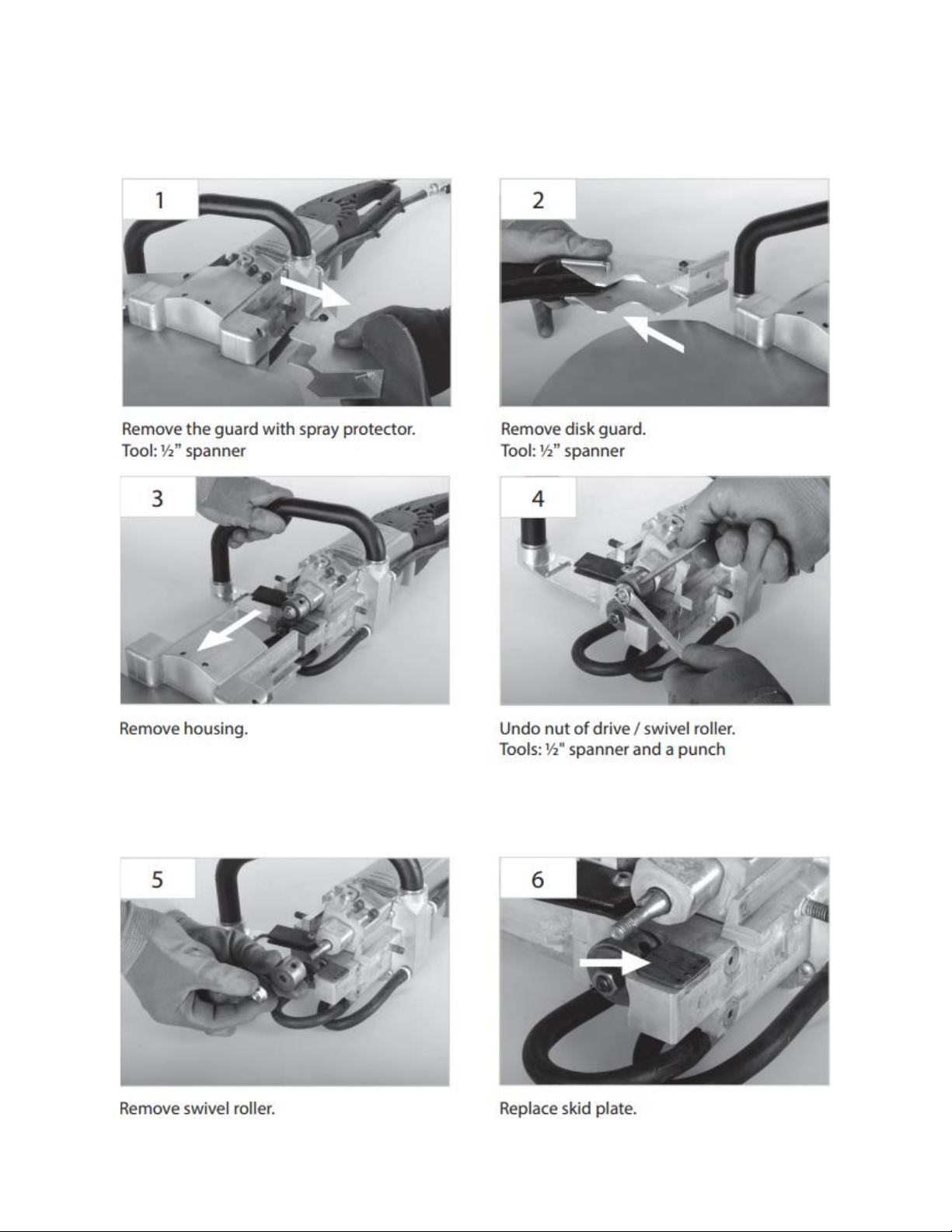

•Tools shall be inspected periodically for damaged parts or missing labels. Only

parts recommended by the manufacturer shall be used.

•Do not discard safety instruction; give them to the operator.

Electrical Safety

•The electric plug of the Electric Dragon Saw must fit into the socket outlet.

•Do not use any adapter plugs or modify the plug in any way

•Protect your electrical equipment from moisture and rain

•Do not use the cable to carry or hang up the saw or pull the plug out of the outlet.

Keep the cable away from heat, oil, sharp and moving objects