Draper ER User manual

MANUAL

CONTROL BOX

-ER-

©Draper 190418, 15:20

Draper Control Box Enhanced Radio

190418, 15:20

2

Svenska

English

VARNING: Installationen måste

utföras av behörig elektriker!

CAUTION: The installation must

be wired and connected by a certified

electrician!

Tack för att ni valt en produkt från Draper Europe AB. Vi hoppas

den kan ge er lång tids nytta. Läs igenom hela manualen innan

installation och användning. Behåll detta dokument för framtida

bruk.

Thank you for choosing a product from Draper Europe AB. We

hope it will bring you grat usage for long time. Please read through

the manual completely before installation and usage. Keep this

document for future reference.

3

Egenskaper

Strömförsörjning AC 230V/50Hz

Uteekt 300W

Arbetstemperatur -10 C - +65 Cvv

Kan kontrolleras av: - RS232

- IR (internt och externt IR-öga) För IR-fjärrkontroll

- RF 433,92 MHz +/- 100 kHz 35-50 meter räckvidd

- 12VDC trigger

- Dry contact / Contact closure (ex. reläslutningar)

EGENSKAPER

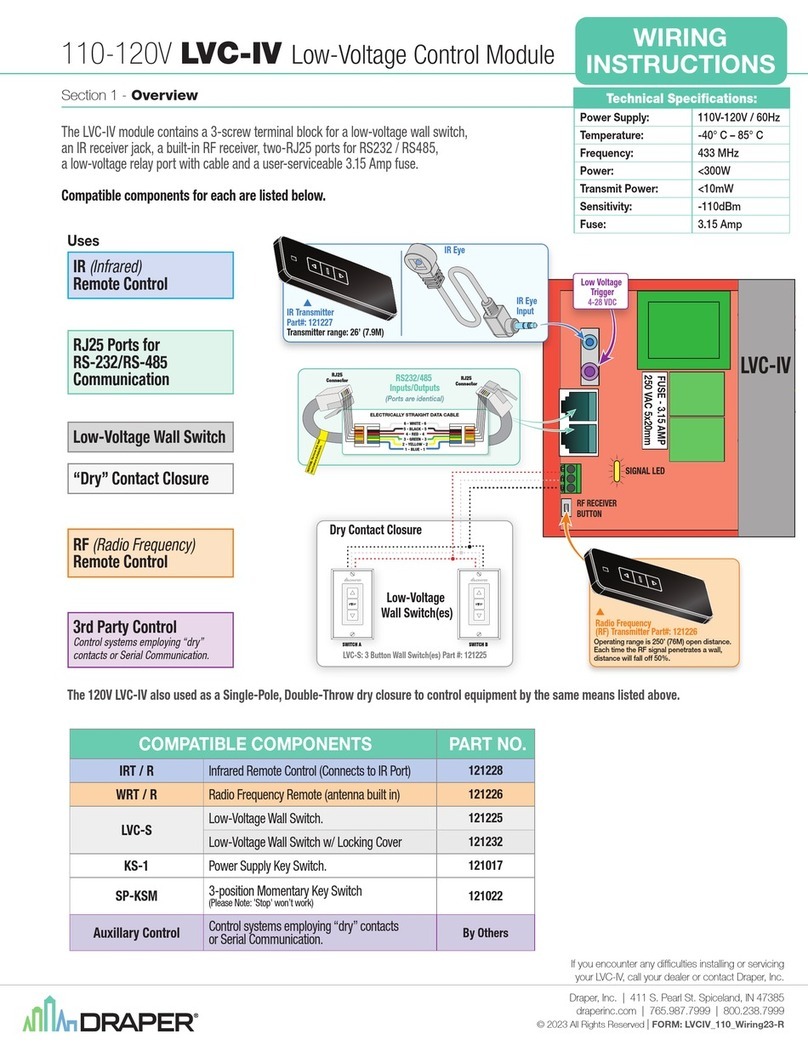

CHARACTERISTICS

Features

Input voltage AC 230V/50Hz

Rated Power 300W

Working temperature -10 C - +65 Cvv

Can be controled by: - RS232

- IR (internal and external IR-eye) For IR-remote control

- RF 433,92 MHz +/- 100 kHz 35-50 meters range

- 12VDC trigger

- Dry contact / Contact closure

12 Trigger

(2,5mm)

Extern IR

(3,5mm)

RS232

Dry contact

(RJ45)

Ner

Stopp

Upp

12V Trigger

(2,5mm)

Extern IR

(3,5mm)

RS232

Dry contact

(RJ45)

Ner

Stopp

Upp

4

INSTALLATION

Motorkabel / Motor cable

E (Earth/Jord):

N (Neutral):

L (Fas/Phase):

Grön-gul/Green-yellow

Blå/Blue

Brun/Brown

E (Earth/Jord):

N (Neutral):

D (Down):

U (Up):

Grön-gul/Green-yellow

Blå/Blue

Brun/Brown

Svart/Black

Srömförsörjning / Power connection

RJ45

1. Reserve

2. RS232 TX

3. Dry contact DOWN

4. Dry contact UP

5. Dry contact STOP

6. GND

7. RS232 RX

8. Reserve

RS232 COMMUNICATION

UP: 55 FE FE 03 01 B9 24

STOP: 55 FE FE 03 03 38 E5

DOWN: 55 FE FE 03 02 F9 25

5

OBS!!! MAX 10 SEKUNDER MELLAN TVÅ KOMMANDON FÖR ATT DET SKA BLI BEKRÄFTAT.

!

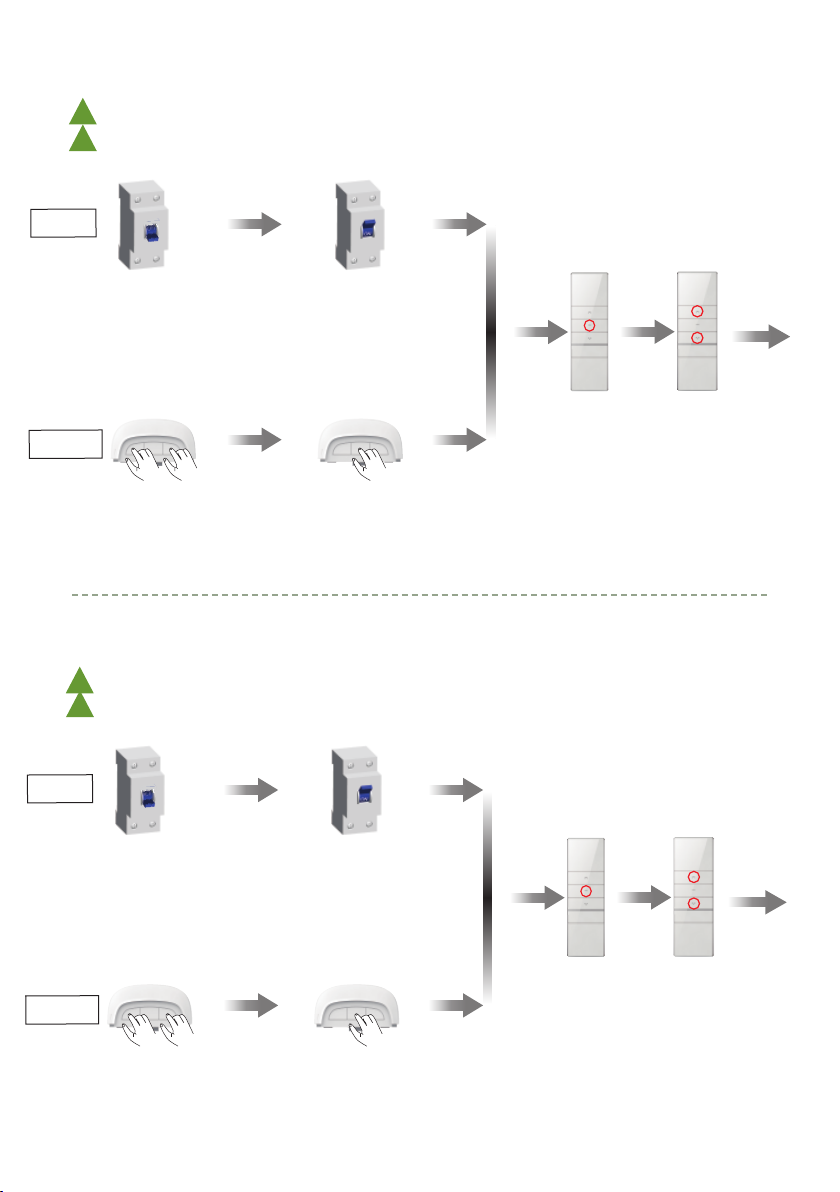

PROGRAMMERING

LÄGGA TILL FJÄRRKONTROLL OCH VÄLJA ROTOATIONSRIKTNING

PROGRAMMING

ADD REMOTE CONTROL AND CHOOSE DIRECTION OF ROTATION

Blue LED

flashes×1

Blue LED

flashes×1

Blue LED

flashes×2

Power on

P2×1 P2×1 P2×1

OK

New emitter is paired to the motor

DD1620A External Switch Signal And Serial Port 485 Control

Note: ①During the setting status, every operation should be less then 10S, or else, it will exit the setting and back to original

status; ②Repeat same procedure will delete additional emitter.

Method one

Method two

Pairing / Delete Additional Emitter

Note: ①During the setting status, every operation should be less then 10S, or else, it will exit the setting and back to original

status; ②as existing emitter, as new emitter to pair or delete;

③

Repeat same procedure will delete additional emitter.

A. Infrared receiving function: ①infrared emission port registry with the middle area of healing, can control motor; ②The external infrared interface can be

connected with 1 Infrared joints, which can be controlled by the infrared emission port. ③The infrared control distance is within 10 meters.

B. External trigger function (projection screen function): ①The external trigger interface can be connected to the 12V signal. ②When the 12V signal is connected,

trigger motor running downward. ③When the 12V signal is disconnected, Trigger motor running upward.

C. External serial port: DD1620 is 232 serial port; DD1620A is 485 serial port.

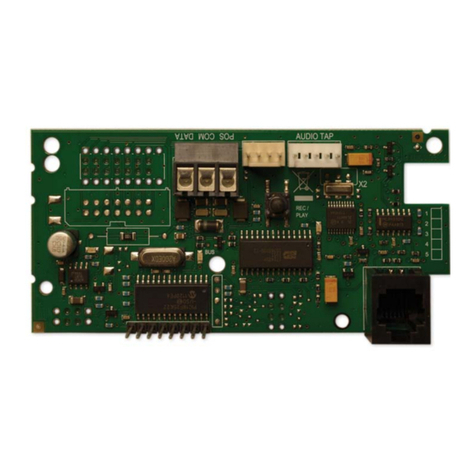

Wiring

DD1620 External Switch Signal And Serial Port 232 Control

DOWN

STOP

UP

External switch

and serial port

External

infrared interface

External

trigger interface

Blue line = power neutral line

Brown line = power live line

Green/yellow line = power earth wire

Power

connection

Signal

line

Motor

interface

Power

interface

Signal indicator light (blue)

Infrared receiving head

Control indicator light (red)

Brown line = motor forward line

Black line = motor reversing line

Blue line = common line

Yellow/green line =motor earth wire

Motor

connection

UP

STOP

DOWN

External

trigger interface

External

infrared interface

External

switch and

serial port

Power neutral line

Power live line

Power grounding

wire

Motor reversing line

Motor common line

Motor motor

forward line

Motor grounding wire

External pulse switch:

①The green line (UP) and the black line (COM) touch to

control motor running upward.

②The red line (STOP) and the black line (COM) touch to

control the motor stop.

③The yellow line (DOWN) and the black line (COM) touch

to control motor running downward.

Serial port control needs to be connected to the computer for operation

The white line (RX) and the blue line (TX) are connected to the RS232

serial port (DD1620)

①When the white line (RX) receives 55 FE FE 03 01 B9 24,

can controlled the motor running upward.

②When the white line (RX) receives 55 FE FE 03 03 38 E5,

can controlled the motor stop;

③When the white line (RX) receives 55 FE FE 03 02 F9 25,

can controlled the motor running downward.

①Reserve

②White line(RX)→Connect

the TX side of the RS232

③Black line(COM)→Connect

the GND side of the RS232

④Red line(STOP)

⑤Green line(UP)

⑥Yellow line(DOWN)

⑦Blue line(TX)→Connect

the RX side of the RS232

⑧Reserve

①Reserve

②White line(A)→Connect

the A side of the RS485

③Black line(COM)→Connect

the GND side of the RS485

④Red line(STOP)

⑤Green line(UP)

⑥Yellow line(DOWN)

⑦Blue line(B)→Connect

the B side of the RS485

⑧Reserve

External pulse switch:

①The green line (UP) and the black line (COM) touch to

control motor running upward.

②The red line (STOP) and the black line (COM) touch to

control the motor stop.

③The yellow line (DOWN) and the black line (COM) touch

to control motor running downward.

Serial port control needs to be connected to the computer for operation

The white line (A) and the blue line (B) are connected to the RS485 serial

port (DD1620A)

①When the white line (A) receives 55 FE FE 03 01 B9 24,

can controlled the motor running upward.

②When the white line (A) receives 55 FE FE 03 03 38 E5,

can controlled the motor stop;

③When the white line (A) receives 55 FE FE 03 02 F9 25,

can controlled the motor running downward.

AC 220V/50Hz

AC 220V/50Hz

Blue LED

flashes×1

Power onPower off

OFF

OFF

Blue LED

flashes×2

STOP×2s

OK

Emitter is paired to the motor

STOP×2s

Release button

after blue LED

flashes

(UP+DOWN)

×2S

Håll 3 sek:

UPP + NER

BLÅ LED

blinkar

Håll 3 sek:

STOPP

Släpp när BLÅ

LED blinkat

1 gång.

RÖD LED lyser

nu konstant

Bryt ström Anslut ström

Vänta 10 sek

ALT. 1:

ALT. 2:

BLÅ LED

blinkar 1 gång

Håll 3 sek:

STOPP

Blue LED

flashes×1

Blue LED

flashes×1

Blue LED

flashes×2

Power on

P2×1 P2×1 P2×1

OK

New emitter is paired to the motor

DD1620A External Switch Signal And Serial Port 485 Control

Note: ①During the setting status, every operation should be less then 10S, or else, it will exit the setting and back to original

status; ②Repeat same procedure will delete additional emitter.

Method one

Method two

Pairing / Delete Additional Emitter

Note: ①During the setting status, every operation should be less then 10S, or else, it will exit the setting and back to original

status; ②as existing emitter, as new emitter to pair or delete;

③

Repeat same procedure will delete additional emitter.

A. Infrared receiving function: ①infrared emission port registry with the middle area of healing, can control motor; ②The external infrared interface can be

connected with 1 Infrared joints, which can be controlled by the infrared emission port. ③The infrared control distance is within 10 meters.

B. External trigger function (projection screen function): ①The external trigger interface can be connected to the 12V signal. ②When the 12V signal is connected,

trigger motor running downward. ③When the 12V signal is disconnected, Trigger motor running upward.

C. External serial port: DD1620 is 232 serial port; DD1620A is 485 serial port.

Wiring

DD1620 External Switch Signal And Serial Port 232 Control

DOWN

STOP

UP

External switch

and serial port

External

infrared interface

External

trigger interface

Blue line = power neutral line

Brown line = power live line

Green/yellow line = power earth wire

Power

connection

Signal

line

Motor

interface

Power

interface

Signal indicator light (blue)

Infrared receiving head

Control indicator light (red)

Brown line = motor forward line

Black line = motor reversing line

Blue line = common line

Yellow/green line =motor earth wire

Motor

connection

UP

STOP

DOWN

External

trigger interface

External

infrared interface

External

switch and

serial port

Power neutral line

Power live line

Power grounding

wire

Motor reversing line

Motor common line

Motor motor

forward line

Motor grounding wire

External pulse switch:

①The green line (UP) and the black line (COM) touch to

control motor running upward.

②The red line (STOP) and the black line (COM) touch to

control the motor stop.

③The yellow line (DOWN) and the black line (COM) touch

to control motor running downward.

Serial port control needs to be connected to the computer for operation

The white line (RX) and the blue line (TX) are connected to the RS232

serial port (DD1620)

①When the white line (RX) receives 55 FE FE 03 01 B9 24,

can controlled the motor running upward.

②When the white line (RX) receives 55 FE FE 03 03 38 E5,

can controlled the motor stop;

③When the white line (RX) receives 55 FE FE 03 02 F9 25,

can controlled the motor running downward.

①Reserve

②White line(RX)→Connect

the TX side of the RS232

③Black line(COM)→Connect

the GND side of the RS232

④Red line(STOP)

⑤Green line(UP)

⑥Yellow line(DOWN)

⑦Blue line(TX)→Connect

the RX side of the RS232

⑧Reserve

①Reserve

②White line(A)→Connect

the A side of the RS485

③Black line(COM)→Connect

the GND side of the RS485

④Red line(STOP)

⑤Green line(UP)

⑥Yellow line(DOWN)

⑦Blue line(B)→Connect

the B side of the RS485

⑧Reserve

External pulse switch:

①The green line (UP) and the black line (COM) touch to

control motor running upward.

②The red line (STOP) and the black line (COM) touch to

control the motor stop.

③The yellow line (DOWN) and the black line (COM) touch

to control motor running downward.

Serial port control needs to be connected to the computer for operation

The white line (A) and the blue line (B) are connected to the RS485 serial

port (DD1620A)

①When the white line (A) receives 55 FE FE 03 01 B9 24,

can controlled the motor running upward.

②When the white line (A) receives 55 FE FE 03 03 38 E5,

can controlled the motor stop;

③When the white line (A) receives 55 FE FE 03 02 F9 25,

can controlled the motor running downward.

AC 220V/50Hz

AC 220V/50Hz

Blue LED

flashes×1

Power onPower off

OFF

OFF

Blue LED

flashes×2

STOP×2s

OK

Emitter is paired to the motor

STOP×2s

Release button

after blue LED

flashes

(UP+DOWN)

×2S

DD1620(A)

Projection screen

L1

Power on

P2×1 STOP×1 P2×1

OK

All emitters are deleted

Note: ①During the setting status, every operation should be less then 10S, or else, it will exit the setting and back to original

status.

Note: after the controller enters radio lock status, press any button to exit this mode.

Delete All Emitters

Controller Button Operation

Switch Rotating Direction

Blue LED

flashes×1

Blue LED

flashes×1

Blue LED

flashes×

1

Blue LED

flashes×2

Blue LED

flashes×1

Blue LED

flashes×1

Blue LED

flashes×2

Power on

P2×1

Power on

P2×1 STOP×2s

OK

OK

Within 30S after

adding the Emitter

successfully

Method three

Note: ①During the setting status, every operation should be less then 10S, or else, it will exit the setting and back to original

status; ②Press UP and motor runs downwards, try below to switch direction.

(UP+DOWN)×2S

New emitter is paired to the motor

The direction has been switched successfully

DD1802H

15-channel

LCD Emitter

DD1600H

Single-channel

Emitter

DD1800H

Single-channel

Emitter

DD1602H

15-channel

LCD Emitter

DD1620(A) controller

DD1620(A)

Controller Instruction

Version: A/01

Note: ①The maximum run time is 4 minutes; ②When emitter is under group control, match code will be invalid.

DD1620 is a RS232 protocol, and DD1620A is a RS485 protocol

Infrared reception function(Equipped with DC95 infrared emitter)

Input voltage: AC 220V/50Hz

Rated power: 300W

Working temperature: -10℃~ +65℃

One DD1620(A) controller can store maximum 10 emitter channels.

If there are already 10 channels, it will take turns to cover the last channel.

DD1620(A)

Projection screen

L2

0.3m 0.2m

0.3m

1.5m

Matchable Emitter

DM35S

DM45S

DD1600H

Single-channel

Emitter

DD1600H

Back

Setting

button

(P2)

Product Features

Matchable Motor &

Button Instructions

The Best Installation

Distance

UP

STOP

DOWN

UP

STOP

DOWN

DC95

infrared emitter

Note: Effective transmitting distancemay have deviation due to actual environment.

Control Range

L1 open L2 partition Reception frequency

AC 220V/50Hz 200m 35m 433.92MHz±100KHz

The shortest distance between controller

and ground ≥1.5m

The shortest distance between controller

and roof ≥0.3m

The shortest distance between controller

and receive ≥0.2m

Note: ①During the setting status, every operation should be less then 10S, or else, it will exit the setting and back to original

status; ②as existing emitter, as new emitter to pair.

Release button

after blue LED

flashes The controller

enters the

setting state.

(UP+DOWN)×2S

Release button

after blue LED

flashes once

The controller enters the

pairing / delete emitter state.

STOP×2s

Release button

after blue LED

flashes 2 times

The controller enters

radio lock state.

Release button

after blue LED

flashes 3 times

The direction has been

switched successfully.

Release button

after blue LED

flashes 4 times

The motor has been reset to

factory mode.

STOP×6s

STOP×10s

STOP×14s

BLÅ LED

blinkar

2 gånger

Fel rotations-

riktning?

Håll 3 sek:

UPP+NER.

RÖD LED

släcks

1 sek

Blue LED

flashes×1

Blue LED

flashes×1

Blue LED

flashes×2

Power on

P2×1 P2×1 P2×1

OK

New emitter is paired to the motor

DD1620A External Switch Signal And Serial Port 485 Control

Note: ①During the setting status, every operation should be less then 10S, or else, it will exit the setting and back to original

status; ②Repeat same procedure will delete additional emitter.

Method one

Method two

Pairing / Delete Additional Emitter

Note: ①During the setting status, every operation should be less then 10S, or else, it will exit the setting and back to original

status; ②as existing emitter, as new emitter to pair or delete;

③

Repeat same procedure will delete additional emitter.

A. Infrared receiving function: ①infrared emission port registry with the middle area of healing, can control motor; ②The external infrared interface can be

connected with 1 Infrared joints, which can be controlled by the infrared emission port. ③The infrared control distance is within 10 meters.

B. External trigger function (projection screen function): ①The external trigger interface can be connected to the 12V signal. ②When the 12V signal is connected,

trigger motor running downward. ③When the 12V signal is disconnected, Trigger motor running upward.

C. External serial port: DD1620 is 232 serial port; DD1620A is 485 serial port.

Wiring

DD1620 External Switch Signal And Serial Port 232 Control

DOWN

STOP

UP

External switch

and serial port

External

infrared interface

External

trigger interface

Blue line = power neutral line

Brown line = power live line

Green/yellow line = power earth wire

Power

connection

Signal

line

Motor

interface

Power

interface

Signal indicator light (blue)

Infrared receiving head

Control indicator light (red)

Brown line = motor forward line

Black line = motor reversing line

Blue line = common line

Yellow/green line =motor earth wire

Motor

connection

UP

STOP

DOWN

External

trigger interface

External

infrared interface

External

switch and

serial port

Power neutral line

Power live line

Power grounding

wire

Motor reversing line

Motor common line

Motor motor

forward line

Motor grounding wire

External pulse switch:

①The green line (UP) and the black line (COM) touch to

control motor running upward.

②The red line (STOP) and the black line (COM) touch to

control the motor stop.

③The yellow line (DOWN) and the black line (COM) touch

to control motor running downward.

Serial port control needs to be connected to the computer for operation

The white line (RX) and the blue line (TX) are connected to the RS232

serial port (DD1620)

①When the white line (RX) receives 55 FE FE 03 01 B9 24,

can controlled the motor running upward.

②When the white line (RX) receives 55 FE FE 03 03 38 E5,

can controlled the motor stop;

③When the white line (RX) receives 55 FE FE 03 02 F9 25,

can controlled the motor running downward.

①Reserve

②White line(RX)→Connect

the TX side of the RS232

③Black line(COM)→Connect

the GND side of the RS232

④Red line(STOP)

⑤Green line(UP)

⑥Yellow line(DOWN)

⑦Blue line(TX)→Connect

the RX side of the RS232

⑧Reserve

①Reserve

②White line(A)→Connect

the A side of the RS485

③Black line(COM)→Connect

the GND side of the RS485

④Red line(STOP)

⑤Green line(UP)

⑥Yellow line(DOWN)

⑦Blue line(B)→Connect

the B side of the RS485

⑧Reserve

External pulse switch:

①The green line (UP) and the black line (COM) touch to

control motor running upward.

②The red line (STOP) and the black line (COM) touch to

control the motor stop.

③The yellow line (DOWN) and the black line (COM) touch

to control motor running downward.

Serial port control needs to be connected to the computer for operation

The white line (A) and the blue line (B) are connected to the RS485 serial

port (DD1620A)

①When the white line (A) receives 55 FE FE 03 01 B9 24,

can controlled the motor running upward.

②When the white line (A) receives 55 FE FE 03 03 38 E5,

can controlled the motor stop;

③When the white line (A) receives 55 FE FE 03 02 F9 25,

can controlled the motor running downward.

AC 220V/50Hz

AC 220V/50Hz

Blue LED

flashes×1

Power onPower off

OFF

OFF

Blue LED

flashes×2

STOP×2s

OK

Emitter is paired to the motor

STOP×2s

Release button

after blue LED

flashes

(UP+DOWN)

×2S

Hold 3 sec:

UP+DOWN

BLUE LED

flashes

Hold 3 sec:

STOP

Release after

BLUE LED flas-

hes once.

RED LED

constant light

Power off Power on

Wait 10 sec.

ALT. 1:

ALT. 2:

BLUE LED

flashes once

Hold 3 sec:

STOP

Blue LED

flashes×1

Blue LED

flashes×1

Blue LED

flashes×2

Power on

P2×1 P2×1 P2×1

OK

New emitter is paired to the motor

DD1620A External Switch Signal And Serial Port 485 Control

Note: ①During the setting status, every operation should be less then 10S, or else, it will exit the setting and back to original

status; ②Repeat same procedure will delete additional emitter.

Method one

Method two

Pairing / Delete Additional Emitter

Note: ①During the setting status, every operation should be less then 10S, or else, it will exit the setting and back to original

status; ②as existing emitter, as new emitter to pair or delete;

③

Repeat same procedure will delete additional emitter.

A. Infrared receiving function: ①infrared emission port registry with the middle area of healing, can control motor; ②The external infrared interface can be

connected with 1 Infrared joints, which can be controlled by the infrared emission port. ③The infrared control distance is within 10 meters.

B. External trigger function (projection screen function): ①The external trigger interface can be connected to the 12V signal. ②When the 12V signal is connected,

trigger motor running downward. ③When the 12V signal is disconnected, Trigger motor running upward.

C. External serial port: DD1620 is 232 serial port; DD1620A is 485 serial port.

Wiring

DD1620 External Switch Signal And Serial Port 232 Control

DOWN

STOP

UP

External switch

and serial port

External

infrared interface

External

trigger interface

Blue line = power neutral line

Brown line = power live line

Green/yellow line = power earth wire

Power

connection

Signal

line

Motor

interface

Power

interface

Signal indicator light (blue)

Infrared receiving head

Control indicator light (red)

Brown line = motor forward line

Black line = motor reversing line

Blue line = common line

Yellow/green line =motor earth wire

Motor

connection

UP

STOP

DOWN

External

trigger interface

External

infrared interface

External

switch and

serial port

Power neutral line

Power live line

Power grounding

wire

Motor reversing line

Motor common line

Motor motor

forward line

Motor grounding wire

External pulse switch:

①The green line (UP) and the black line (COM) touch to

control motor running upward.

②The red line (STOP) and the black line (COM) touch to

control the motor stop.

③The yellow line (DOWN) and the black line (COM) touch

to control motor running downward.

Serial port control needs to be connected to the computer for operation

The white line (RX) and the blue line (TX) are connected to the RS232

serial port (DD1620)

①When the white line (RX) receives 55 FE FE 03 01 B9 24,

can controlled the motor running upward.

②When the white line (RX) receives 55 FE FE 03 03 38 E5,

can controlled the motor stop;

③When the white line (RX) receives 55 FE FE 03 02 F9 25,

can controlled the motor running downward.

①Reserve

②White line(RX)→Connect

the TX side of the RS232

③Black line(COM)→Connect

the GND side of the RS232

④Red line(STOP)

⑤Green line(UP)

⑥Yellow line(DOWN)

⑦Blue line(TX)→Connect

the RX side of the RS232

⑧Reserve

①Reserve

②White line(A)→Connect

the A side of the RS485

③Black line(COM)→Connect

the GND side of the RS485

④Red line(STOP)

⑤Green line(UP)

⑥Yellow line(DOWN)

⑦Blue line(B)→Connect

the B side of the RS485

⑧Reserve

External pulse switch:

①The green line (UP) and the black line (COM) touch to

control motor running upward.

②The red line (STOP) and the black line (COM) touch to

control the motor stop.

③The yellow line (DOWN) and the black line (COM) touch

to control motor running downward.

Serial port control needs to be connected to the computer for operation

The white line (A) and the blue line (B) are connected to the RS485 serial

port (DD1620A)

①When the white line (A) receives 55 FE FE 03 01 B9 24,

can controlled the motor running upward.

②When the white line (A) receives 55 FE FE 03 03 38 E5,

can controlled the motor stop;

③When the white line (A) receives 55 FE FE 03 02 F9 25,

can controlled the motor running downward.

AC 220V/50Hz

AC 220V/50Hz

Blue LED

flashes×1

Power onPower off

OFF

OFF

Blue LED

flashes×2

STOP×2s

OK

Emitter is paired to the motor

STOP×2s

Release button

after blue LED

flashes

(UP+DOWN)

×2S

DD1620(A)

Projection screen

L1

Power on

P2×1 STOP×1 P2×1

OK

All emitters are deleted

Note: ①During the setting status, every operation should be less then 10S, or else, it will exit the setting and back to original

status.

Note: after the controller enters radio lock status, press any button to exit this mode.

Delete All Emitters

Controller Button Operation

Switch Rotating Direction

Blue LED

flashes×1

Blue LED

flashes×1

Blue LED

flashes×1

Blue LED

flashes×2

Blue LED

flashes×1

Blue LED

flashes×1

Blue LED

flashes×2

Power on

P2×1

Power on

P2×1 STOP×2s

OK

OK

Within 30S after

adding the Emitter

successfully

Method three

Note: ①During the setting status, every operation should be less then 10S, or else, it will exit the setting and back to original

status; ②Press UP and motor runs downwards, try below to switch direction.

(UP+DOWN)×2S

New emitter is paired to the motor

The direction has been switched successfully

DD1802H

15-channel

LCD Emitter

DD1600H

Single-channel

Emitter

DD1800H

Single-channel

Emitter

DD1602H

15-channel

LCD Emitter

DD1620(A) controller

DD1620(A)

Controller Instruction

Version: A/01

Note: ①The maximum run time is 4 minutes; ②When emitter is under group control, match code will be invalid.

DD1620 is a RS232 protocol, and DD1620A is a RS485 protocol

Infrared reception function(Equipped with DC95 infrared emitter)

Input voltage: AC 220V/50Hz

Rated power: 300W

Working temperature: -10℃~ +65℃

One DD1620(A) controller can store maximum 10 emitter channels.

If there are already 10 channels, it will take turns to cover the last channel.

DD1620(A)

Projection screen

L2

0.3m 0.2m

0.3m

1.5m

Matchable Emitter

DM35S

DM45S

DD1600H

Single-channel

Emitter

DD1600H

Back

Setting

button

(P2)

Product Features

Matchable Motor &

Button Instructions

The Best Installation

Distance

UP

STOP

DOWN

UP

STOP

DOWN

DC95

infrared emitter

Note: Effective transmitting distancemay have deviation due to actual environment.

Control Range

L1 open L2 partition Reception frequency

AC 220V/50Hz 200m 35m 433.92MHz±100KHz

The shortest distance between controller

and ground ≥1.5m

The shortest distance between controller

and roof ≥0.3m

The shortest distance between controller

and receive ≥0.2m

Note: ①During the setting status, every operation should be less then 10S, or else, it will exit the setting and back to original

status; ②as existing emitter, as new emitter to pair.

Release button

after blue LED

flashes The controller

enters the

setting state.

(UP+DOWN)×2S

Release button

after blue LED

flashes once

The controller enters the

pairing / delete emitter state.

STOP×2s

Release button

after blue LED

flashes 2 times

The controller enters

radio lock state.

Release button

after blue LED

flashes 3 times

The direction has been

switched successfully.

Release button

after blue LED

flashes 4 times

The motor has been reset to

factory mode.

STOP×6s

STOP×10s

STOP×14s

BLUE LED

flashes

twice

Wrong

direction of

rotation?

Hold 3 sek:

UP+DOWN

RED LED

gœs out

1 sec.

OBS!!! MAX 10 SECONDS BETWEEN TWO COMMANDS TO CONFIRM PROGRAMMING.

!

NOTERA: UPPREPA SAMMA PROCEDUR FÖR ATT TA BORT FJÄRRKONTROLL.

!

NOTE: REPEAT SAME PROCEDURE TO DELETE REMOTE CONTROL.

!

6

RADERA ALLA SÄNDARE

LÄGGA TILL/TA BORT SÄNDARE

ADD/DELETE TRANSMITTER

OBSERVERA: FJÄRRKONTROLL AMÅSTE REDAN VARA INPROGRAMMERAD I KONTROLLBOXEN!

NOTERA: EXTRA SÄNDARE KAN VARA FJÄRRKONTROLL, SENSOR ELLER ”AUTOLINK TRIGGER”.

OBS!!! REMOTE CONTROL AMUST ALREADY BE PROGRAMMED INTO THE BOX!

NOTE: EXTRA TRANSMITTER CAN BE A REMOTE CONTROL, SENSOR OR ”AUTOLINK TRIGGER”.

NOTERA: UPPREPA SAMMA PROCEDUR FÖR ATT TA BORT FJÄRRKONTROLL B.

NOTE: NOTE: REPEAT SAME PROCEDURE TO DELETE REMOTE CONTROL B.

Blue LED

flashes×1

Blue LED

flashes×1

Blue LED

flashes×2

Power on

P2×1 P2×1 P2×1

OK

New emitter is paired to the motor

DD1620A External Switch Signal And Serial Port 485 Control

Note: ①During the setting status, every operation should be less then 10S, or else, it will exit the setting and back to original

status; ②Repeat same procedure will delete additional emitter.

Method one

Method two

Pairing / Delete Additional Emitter

Note: ①During the setting status, every operation should be less then 10S, or else, it will exit the setting and back to original

status; ②as existing emitter, as new emitter to pair or delete;

③

Repeat same procedure will delete additional emitter.

A. Infrared receiving function: ①infrared emission port registry with the middle area of healing, can control motor; ②The external infrared interface can be

connected with 1 Infrared joints, which can be controlled by the infrared emission port. ③The infrared control distance is within 10 meters.

B. External trigger function (projection screen function): ①The external trigger interface can be connected to the 12V signal. ②When the 12V signal is connected,

trigger motor running downward. ③When the 12V signal is disconnected, Trigger motor running upward.

C. External serial port: DD1620 is 232 serial port; DD1620A is 485 serial port.

Wiring

DD1620 External Switch Signal And Serial Port 232 Control

DOWN

STOP

UP

External switch

and serial port

External

infrared interface

External

trigger interface

Blue line = power neutral line

Brown line = power live line

Green/yellow line = power earth wire

Power

connection

Signal

line

Motor

interface

Power

interface

Signal indicator light (blue)

Infrared receiving head

Control indicator light (red)

Brown line = motor forward line

Black line = motor reversing line

Blue line = common line

Yellow/green line =motor earth wire

Motor

connection

UP

STOP

DOWN

External

trigger interface

External

infrared interface

External

switch and

serial port

Power neutral line

Power live line

Power grounding

wire

Motor reversing line

Motor common line

Motor motor

forward line

Motor grounding wire

External pulse switch:

①The green line (UP) and the black line (COM) touch to

control motor running upward.

②The red line (STOP) and the black line (COM) touch to

control the motor stop.

③The yellow line (DOWN) and the black line (COM) touch

to control motor running downward.

Serial port control needs to be connected to the computer for operation

The white line (RX) and the blue line (TX) are connected to the RS232

serial port (DD1620)

①When the white line (RX) receives 55 FE FE 03 01 B9 24,

can controlled the motor running upward.

②When the white line (RX) receives 55 FE FE 03 03 38 E5,

can controlled the motor stop;

③When the white line (RX) receives 55 FE FE 03 02 F9 25,

can controlled the motor running downward.

①Reserve

②White line(RX)→Connect

the TX side of the RS232

③Black line(COM)→Connect

the GND side of the RS232

④Red line(STOP)

⑤Green line(UP)

⑥Yellow line(DOWN)

⑦Blue line(TX)→Connect

the RX side of the RS232

⑧Reserve

①Reserve

②White line(A)→Connect

the A side of the RS485

③Black line(COM)→Connect

the GND side of the RS485

④Red line(STOP)

⑤Green line(UP)

⑥Yellow line(DOWN)

⑦Blue line(B)→Connect

the B side of the RS485

⑧Reserve

External pulse switch:

①The green line (UP) and the black line (COM) touch to

control motor running upward.

②The red line (STOP) and the black line (COM) touch to

control the motor stop.

③The yellow line (DOWN) and the black line (COM) touch

to control motor running downward.

Serial port control needs to be connected to the computer for operation

The white line (A) and the blue line (B) are connected to the RS485 serial

port (DD1620A)

①When the white line (A) receives 55 FE FE 03 01 B9 24,

can controlled the motor running upward.

②When the white line (A) receives 55 FE FE 03 03 38 E5,

can controlled the motor stop;

③When the white line (A) receives 55 FE FE 03 02 F9 25,

can controlled the motor running downward.

AC 220V/50Hz

AC 220V/50Hz

Blue LED

flashes×1

Power onPower off

OFF

OFF

Blue LED

flashes×2

STOP×2s

OK

Emitter is paired to the motor

STOP×2s

Release button

after blue LED

flashes

(UP+DOWN)

×2S

Ström är ansluten

till boxen sedan

minst 10 sek. Tryck ”P2”

sändrare A

Tryck ”P2”

sändrare A

Tryck ”P2”

sändrare B

BLÅ LED

blinkar

BLÅ LED

blinkar

BLÅ LED

blinkar 3

gånger

DD1620(A)

Projection screen

L1

Power on

P2×1 STOP×1 P2×1

OK

All emitters are deleted

Note: ①During the setting status, every operation should be less then 10S, or else, it will exit the setting and back to original

status.

Note: after the controller enters radio lock status, press any button to exit this mode.

Delete All Emitters

Controller Button Operation

Switch Rotating Direction

Blue LED

flashes×1

Blue LED

flashes×1

Blue LED

flashes×1

Blue LED

flashes×2

Blue LED

flashes×1

Blue LED

flashes×1

Blue LED

flashes×

2

Power on

P2×1

Power on

P2×1 STOP×2s

OK

OK

Within 30S after

adding the Emitter

successfully

Method three

Note: ①During the setting status, every operation should be less then 10S, or else, it will exit the setting and back to original

status; ②Press UP and motor runs downwards, try below to switch direction.

(UP+DOWN)×2S

New emitter is paired to the motor

The direction has been switched successfully

DD1802H

15-channel

LCD Emitter

DD1600H

Single-channel

Emitter

DD1800H

Single-channel

Emitter

DD1602H

15-channel

LCD Emitter

DD1620(A) controller

DD1620(A)

Controller Instruction

Version: A/01

Note: ①The maximum run time is 4 minutes; ②When emitter is under group control, match code will be invalid.

DD1620 is a RS232 protocol, and DD1620A is a RS485 protocol

Infrared reception function(Equipped with DC95 infrared emitter)

Input voltage: AC 220V/50Hz

Rated power: 300W

Working temperature: -10℃~ +65℃

One DD1620(A) controller can store maximum 10 emitter channels.

If there are already 10 channels, it will take turns to cover the last channel.

DD1620(A)

Projection screen

L2

0.3m 0.2m

0.3m

1.5m

Matchable Emitter

DM35S

DM45S

DD1600H

Single-channel

Emitter

DD1600H

Back

Setting

button

(P2)

Product Features

Matchable Motor &

Button Instructions

The Best Installation

Distance

UP

STOP

DOWN

UP

STOP

DOWN

DC95

infrared emitter

Note: Effective transmitting distancemay have deviation due to actual environment.

Control Range

L1 open L2 partition Reception frequency

AC 220V/50Hz 200m 35m 433.92MHz±100KHz

The shortest distance between controller

and ground ≥1.5m

The shortest distance between controller

and roof ≥0.3m

The shortest distance between controller

and receive ≥0.2m

Note: ①During the setting status, every operation should be less then 10S, or else, it will exit the setting and back to original

status; ②as existing emitter, as new emitter to pair.

Release button

after blue LED

flashes The controller

enters the

setting state.

(UP+DOWN)×2S

Release button

after blue LED

flashes once

The controller enters the

pairing / delete emitter state.

STOP×2s

Release button

after blue LED

flashes 2 times

The controller enters

radio lock state.

Release button

after blue LED

flashes 3 times

The direction has been

switched successfully.

Release button

after blue LED

flashes 4 times

The motor has been reset to

factory mode.

STOP×6s

STOP×10s

STOP×14s

Ström är ansluten

till boxen sedan

minst 10 sek. Tryck P2 Tryck P2 Tryck P2

BLÅ LED

blinkar

BLÅ LED

blinkar

BLÅ LED

blinkar 3

gånger

OK

OK

DELETE ALL TRANSMITTERS

Blue LED

flashes×1

Blue LED

flashes×1

Blue LED

flashes×2

Power on

P2×1 P2×1 P2×1

OK

New emitter is paired to the motor

DD1620A External Switch Signal And Serial Port 485 Control

Note: ①During the setting status, every operation should be less then 10S, or else, it will exit the setting and back to original

status; ②Repeat same procedure will delete additional emitter.

Method one

Method two

Pairing / Delete Additional Emitter

Note: ①During the setting status, every operation should be less then 10S, or else, it will exit the setting and back to original

status; ②as existing emitter, as new emitter to pair or delete;

③

Repeat same procedure will delete additional emitter.

A. Infrared receiving function: ①infrared emission port registry with the middle area of healing, can control motor; ②The external infrared interface can be

connected with 1 Infrared joints, which can be controlled by the infrared emission port. ③The infrared control distance is within 10 meters.

B. External trigger function (projection screen function): ①The external trigger interface can be connected to the 12V signal. ②When the 12V signal is connected,

trigger motor running downward. ③When the 12V signal is disconnected, Trigger motor running upward.

C. External serial port: DD1620 is 232 serial port; DD1620A is 485 serial port.

Wiring

DD1620 External Switch Signal And Serial Port 232 Control

DOWN

STOP

UP

External switch

and serial port

External

infrared interface

External

trigger interface

Blue line = power neutral line

Brown line = power live line

Green/yellow line = power earth wire

Power

connection

Signal

line

Motor

interface

Power

interface

Signal indicator light (blue)

Infrared receiving head

Control indicator light (red)

Brown line = motor forward line

Black line = motor reversing line

Blue line = common line

Yellow/green line =motor earth wire

Motor

connection

UP

STOP

DOWN

External

trigger interface

External

infrared interface

External

switch and

serial port

Power neutral line

Power live line

Power grounding

wire

Motor reversing line

Motor common line

Motor motor

forward line

Motor grounding wire

External pulse switch:

①The green line (UP) and the black line (COM) touch to

control motor running upward.

②The red line (STOP) and the black line (COM) touch to

control the motor stop.

③The yellow line (DOWN) and the black line (COM) touch

to control motor running downward.

Serial port control needs to be connected to the computer for operation

The white line (RX) and the blue line (TX) are connected to the RS232

serial port (DD1620)

①When the white line (RX) receives 55 FE FE 03 01 B9 24,

can controlled the motor running upward.

②When the white line (RX) receives 55 FE FE 03 03 38 E5,

can controlled the motor stop;

③When the white line (RX) receives 55 FE FE 03 02 F9 25,

can controlled the motor running downward.

①Reserve

②White line(RX)→Connect

the TX side of the RS232

③Black line(COM)→Connect

the GND side of the RS232

④Red line(STOP)

⑤Green line(UP)

⑥Yellow line(DOWN)

⑦Blue line(TX)→Connect

the RX side of the RS232

⑧Reserve

①Reserve

②White line(A)→Connect

the A side of the RS485

③Black line(COM)→Connect

the GND side of the RS485

④Red line(STOP)

⑤Green line(UP)

⑥Yellow line(DOWN)

⑦Blue line(B)→Connect

the B side of the RS485

⑧Reserve

External pulse switch:

①The green line (UP) and the black line (COM) touch to

control motor running upward.

②The red line (STOP) and the black line (COM) touch to

control the motor stop.

③The yellow line (DOWN) and the black line (COM) touch

to control motor running downward.

Serial port control needs to be connected to the computer for operation

The white line (A) and the blue line (B) are connected to the RS485 serial

port (DD1620A)

①When the white line (A) receives 55 FE FE 03 01 B9 24,

can controlled the motor running upward.

②When the white line (A) receives 55 FE FE 03 03 38 E5,

can controlled the motor stop;

③When the white line (A) receives 55 FE FE 03 02 F9 25,

can controlled the motor running downward.

AC 220V/50Hz

AC 220V/50Hz

Blue LED

flashes×1

Power onPower off

OFF

OFF

Blue LED

flashes×2

STOP×2s

OK

Emitter is paired to the motor

STOP×2s

Release button

after blue LED

flashes

(UP+DOWN)

×2S

Power is connec-

ted to the box for

at least 10 sec. Press ”P2”

Remote A

Press ”P2”

Remote A

Press ”P2”

Remote/

transmitter B

BLUE LED

flashes

BLue LED

flashes

3 times

DD1620(A)

Projection screen

L1

Power on

P2×1 STOP×1 P2×1

OK

All emitters are deleted

Note: ①During the setting status, every operation should be less then 10S, or else, it will exit the setting and back to original

status.

Note: after the controller enters radio lock status, press any button to exit this mode.

Delete All Emitters

Controller Button Operation

Switch Rotating Direction

Blue LED

flashes×1

Blue LED

flashes×1

Blue LED

flashes×1

Blue LED

flashes×2

Blue LED

flashes×1

Blue LED

flashes×1

Blue LED

flashes×

2

Power on

P2×1

Power on

P2×1 STOP×2s

OK

OK

Within 30S after

adding the Emitter

successfully

Method three

Note: ①During the setting status, every operation should be less then 10S, or else, it will exit the setting and back to original

status; ②Press UP and motor runs downwards, try below to switch direction.

(UP+DOWN)×2S

New emitter is paired to the motor

The direction has been switched successfully

DD1802H

15-channel

LCD Emitter

DD1600H

Single-channel

Emitter

DD1800H

Single-channel

Emitter

DD1602H

15-channel

LCD Emitter

DD1620(A) controller

DD1620(A)

Controller Instruction

Version: A/01

Note: ①The maximum run time is 4 minutes; ②When emitter is under group control, match code will be invalid.

DD1620 is a RS232 protocol, and DD1620A is a RS485 protocol

Infrared reception function(Equipped with DC95 infrared emitter)

Input voltage: AC 220V/50Hz

Rated power: 300W

Working temperature: -10℃~ +65℃

One DD1620(A) controller can store maximum 10 emitter channels.

If there are already 10 channels, it will take turns to cover the last channel.

DD1620(A)

Projection screen

L2

0.3m 0.2m

0.3m

1.5m

Matchable Emitter

DM35S

DM45S

DD1600H

Single-channel

Emitter

DD1600H

Back

Setting

button

(P2)

Product Features

Matchable Motor &

Button Instructions

The Best Installation

Distance

UP

STOP

DOWN

UP

STOP

DOWN

DC95

infrared emitter

Note: Effective transmitting distancemay have deviation due to actual environment.

Control Range

L1 open L2 partition Reception frequency

AC 220V/50Hz 200m 35m 433.92MHz±100KHz

The shortest distance between controller

and ground ≥1.5m

The shortest distance between controller

and roof ≥0.3m

The shortest distance between controller

and receive ≥0.2m

Note: ①During the setting status, every operation should be less then 10S, or else, it will exit the setting and back to original

status; ②as existing emitter, as new emitter to pair.

Release button

after blue LED

flashes The controller

enters the

setting state.

(UP+DOWN)×2S

Release button

after blue LED

flashes once

The controller enters the

pairing / delete emitter state.

STOP×2s

Release button

after blue LED

flashes 2 times

The controller enters

radio lock state.

Release button

after blue LED

flashes 3 times

The direction has been

switched successfully.

Release button

after blue LED

flashes 4 times

The motor has been reset to

factory mode.

STOP×6s

STOP×10s

STOP×14s

Press P2 Press P2 Press P2

BLUE LED

flashes

BLUE LED

flashes

BLUE LED

flashes 3

times

OK

OK

Power is connec-

ted to the box for

at least 10 sec.

BLUE LED

flashes

7

ADDITIONAL FUNCTIONS

DD1620(A)

Projection screen

L1

Power on

P2×1 STOP×1 P2×1

OK

All emitters are deleted

Note: ①During the setting status, every operation should be less then 10S, or else, it will exit the setting and back to original

status.

Note: after the controller enters radio lock status, press any button to exit this mode.

Delete All Emitters

Controller Button Operation

Switch Rotating Direction

Blue LED

flashes×1

Blue LED

flashes×1

Blue LED

flashes×1

Blue LED

flashes×2

Blue LED

flashes×1

Blue LED

flashes×1

Blue LED

flashes×2

Power on

P2×1

Power on

P2×1 STOP×2s

OK

OK

Within 30S after

adding the Emitter

successfully

Method three

Note: ①During the setting status, every operation should be less then 10S, or else, it will exit the setting and back to original

status; ②Press UP and motor runs downwards, try below to switch direction.

(UP+DOWN)×2S

New emitter is paired to the motor

The direction has been switched successfully

DD1802H

15-channel

LCD Emitter

DD1600H

Single-channel

Emitter

DD1800H

Single-channel

Emitter

DD1602H

15-channel

LCD Emitter

DD1620(A) controller

DD1620(A)

Controller Instruction

Version: A/01

Note: ①The maximum run time is 4 minutes; ②When emitter is under group control, match code will be invalid.

DD1620 is a RS232 protocol, and DD1620A is a RS485 protocol

Infrared reception function(Equipped with DC95 infrared emitter)

Input voltage: AC 220V/50Hz

Rated power: 300W

Working temperature: -10℃~ +65℃

One DD1620(A) controller can store maximum 10 emitter channels.

If there are already 10 channels, it will take turns to cover the last channel.

DD1620(A)

Projection screen

L2

0.3m 0.2m

0.3m

1.5m

Matchable Emitter

DM35S

DM45S

DD1600H

Single-channel

Emitter

DD1600H

Back

Setting

button

(P2)

Product Features

Matchable Motor &

Button Instructions

The Best Installation

Distance

UP

STOP

DOWN

UP

STOP

DOWN

DC95

infrared emitter

Note: Effective transmitting distancemay have deviation due to actual environment.

Control Range

L1 open L2 partition Reception frequency

AC 220V/50Hz 200m 35m 433.92MHz±100KHz

The shortest distance between controller

and ground ≥1.5m

The shortest distance between controller

and roof ≥0.3m

The shortest distance between controller

and receive ≥0.2m

Note: ①During the setting status, every operation should be less then 10S, or else, it will exit the setting and back to original

status; ②as existing emitter, as new emitter to pair.

Release button

after blue LED

flashes The controller

enters the

setting state.

(UP+DOWN)

×2S

Release button

after blue LED

flashes once

The controller enters the

pairing / delete emitter state.

STOP×2s

Release button

after blue LED

flashes 2 times

The controller enters

radio lock state.

Release button

after blue LED

flashes 3 times

The direction has been

switched successfully.

Release button

after blue LED

flashes 4 times

The motor has been reset to

factory mode.

STOP×6s

STOP×10s

STOP×14s

TILLÄGGSFUNKTIONER

OBS!!! MAX 10 SEKUNDER MELLAN TVÅ KOMMANDON FÖR ATT DET SKA BLI BEKRÄFTAT.

OBS!!! MAX 10 SECONDS BETWEEN TWO COMMANDS TO CONFIRM PROGRAMMING.

Håll 3 sek:

UPP + NER

STOPP 3 sek

Släpp när

BLÅ LED

blinkar

...1 gång:

Boxen öppen för

att lägga till/radera

sändare

...2 gånger:

Boxen är i radio-

sköldläge

STOPP 6 sek

STOPP 10 sek

STOPP 14 sek

...3 gånger:

Ändrar rotations-

riktning

...4 gånger:

Nollställer boxen

till fabriksläge

Släpp när BLÅ LED

blinkat...

Kontrollboxen

är nu i

inställnings-

läge

FÖR ATT KOMMA UR RADIOSKÖLDLÄGET, TRYCK PÅ VALFRI KNAPP PÅ BOXEN

TO EXIT THE RADIO LOCK STATE, PRESS ANY BUTTON ON THE BOX.

DD1620(A)

Projection screen

L1

Power on

P2×1 STOP×1 P2×1

OK

All emitters are deleted

Note: ①During the setting status, every operation should be less then 10S, or else, it will exit the setting and back to original

status.

Note: after the controller enters radio lock status, press any button to exit this mode.

Delete All Emitters

Controller Button Operation

Switch Rotating Direction

Blue LED

flashes×1

Blue LED

flashes×1

Blue LED

flashes×1

Blue LED

flashes×2

Blue LED

flashes×1

Blue LED

flashes×1

Blue LED

flashes×2

Power on

P2×1

Power on

P2×1 STOP×2s

OK

OK

Within 30S after

adding the Emitter

successfully

Method three

Note: ①During the setting status, every operation should be less then 10S, or else, it will exit the setting and back to original

status; ②Press UP and motor runs downwards, try below to switch direction.

(UP+DOWN)×2S

New emitter is paired to the motor

The direction has been switched successfully

DD1802H

15-channel

LCD Emitter

DD1600H

Single-channel

Emitter

DD1800H

Single-channel

Emitter

DD1602H

15-channel

LCD Emitter

DD1620(A) controller

DD1620(A)

Controller Instruction

Version: A/01

Note: ①The maximum run time is 4 minutes; ②When emitter is under group control, match code will be invalid.

DD1620 is a RS232 protocol, and DD1620A is a RS485 protocol

Infrared reception function(Equipped with DC95 infrared emitter)

Input voltage: AC 220V/50Hz

Rated power: 300W

Working temperature: -10℃~ +65℃

One DD1620(A) controller can store maximum 10 emitter channels.

If there are already 10 channels, it will take turns to cover the last channel.

DD1620(A)

Projection screen

L2

0.3m 0.2m

0.3m

1.5m

Matchable Emitter

DM35S

DM45S

DD1600H

Single-channel

Emitter

DD1600H

Back

Setting

button

(P2)

Product Features

Matchable Motor &

Button Instructions

The Best Installation

Distance

UP

STOP

DOWN

UP

STOP

DOWN

DC95

infrared emitter

Note: Effective transmitting distancemay have deviation due to actual environment.

Control Range

L1 open L2 partition Reception frequency

AC 220V/50Hz 200m 35m 433.92MHz±100KHz

The shortest distance between controller

and ground ≥1.5m

The shortest distance between controller

and roof ≥0.3m

The shortest distance between controller

and receive ≥0.2m

Note: ①During the setting status, every operation should be less then 10S, or else, it will exit the setting and back to original

status; ②as existing emitter, as new emitter to pair.

Release button

after blue LED

flashes The controller

enters the

setting state.

(UP+DOWN)

×2S

Release button

after blue LED

flashes once

The controller enters the

pairing / delete emitter state.

STOP×2s

Release button

after blue LED

flashes 2 times

The controller enters

radio lock state.

Release button

after blue LED

flashes 3 times

The direction has been

switched successfully.

Release button

after blue LED

flashes 4 times

The motor has been reset to

factory mode.

STOP×6s

STOP×10s

STOP×14s

Hold 3 sec:

UP+DOWN

STOP 3 sec

Release when

BLÅ LED

flashes

...1 time:

The box enters

pairing/delete

transmitters mode

...2 times:

The box enters

radio lock mode

STOP 6 sec

STOP 10 sec ...3 times:

Changes direction

of rotation

...4 times:

Set the box to

factory mode

Release after BLÅ

LED falshes...

The box

enters

setting state

STOP 14 sec

WWW.DRAPEREUROPE.SE

INFO@DRAPEREUROPE.SE

Table of contents

Other Draper Control Unit manuals

Popular Control Unit manuals by other brands

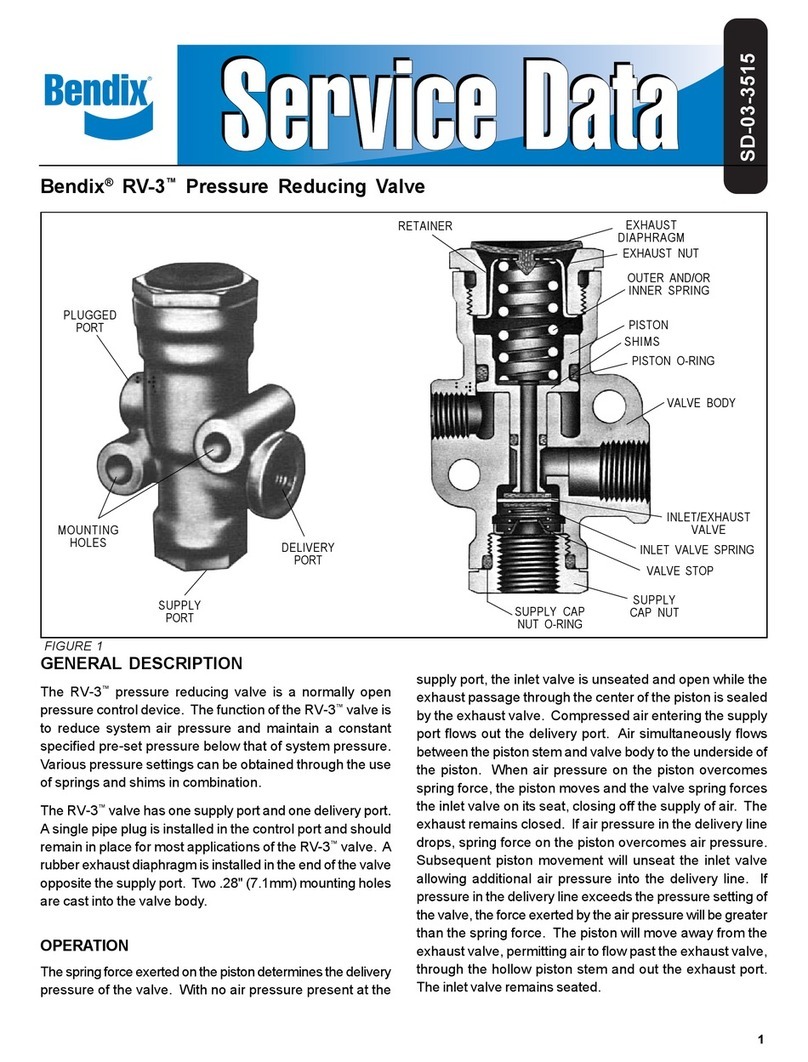

BENDIX

BENDIX RV-3 PRESSURE REDUCING VALVE General description

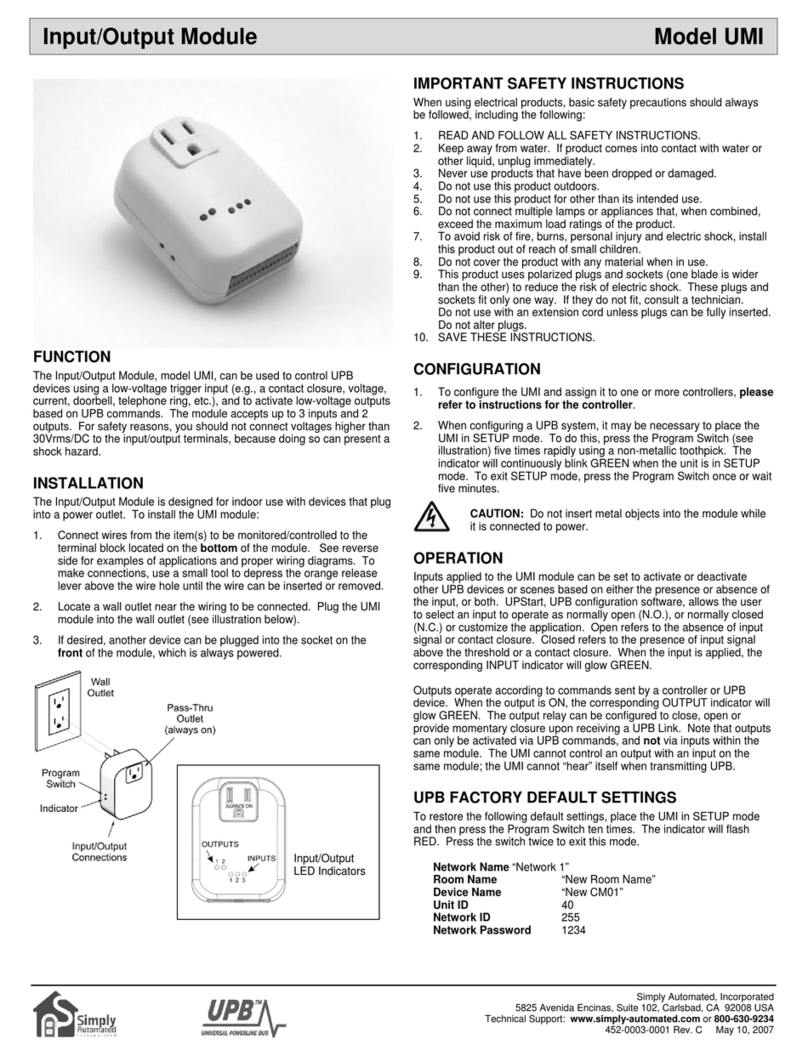

Simply Automated

Simply Automated UMI manual

National Instruments

National Instruments NI 9264 Getting started guide

JYTEK

JYTEK PXI-93518 user manual

Siemens

Siemens SCALANCE W788C-2 operating instructions

GEM

GEM R478 Tugela operating instructions

Siko

Siko MA523/1-S installation instructions

Ebyte

Ebyte E22-400T33S user manual

1Control

1Control Solo quick guide

UTC Fire and Security

UTC Fire and Security Interlogix NX-535N installation manual

Raspberry Pi

Raspberry Pi Compute quick start guide

Honeywell

Honeywell Ex-Or CDW12U5 Installation and commissioning instructions