Draper DH50 User manual

12498

EN

Original Instructions

Version 1 – May 2023

50L

DEHUMIDIFIER

1.1 Product Reference

User Manual for: Industrial Dehumidier, 50L

Stock No: 12498

Part No: DH50

1.2 Revisions

Version 1: May 2023

First release

As our manuals are continually updated, always ensure

that the latest version is used.

Please visit drapertools.com/manuals for the latest

version of this manual and the associated parts list, if

applicable.

1.3 Understanding the Safety Content of

This Manual

WARNING!

– Situations or actions that may result

in personal injury or death.

CAUTION! – Situations or actions that may result

in damage to the product or surroundings.

Important: – Information or instructions of particular

importance.

1.4 Copyright © Notice

Copyright © Draper Tools Limited.

Permission is granted to reproduce this manual for

personal and educational use ONLY. Commercial

copying, redistribution, hiring or lending is strictly

prohibited.

No part of this manual may be stored in a retrieval system

or transmitted in any other form or means without written

permission from Draper Tools Limited.

In all cases, this copyright notice must remain intact.

1. Preface

– 2 –

These are the original product instructions. This

document is part of the product; retain it for the life

of the product, passing it on to subsequent holders.

Read this manual in full before attempting to

assemble, operate or maintain this product.

This Draper Tools manual describes the purpose

of the product and contains all the necessary

information to ensure its correct and safe use.

Following all the instructions and guidance in

this manual will ensure the safety of both the

product and the operator and increase the

lifespan of the product.

All photographs and drawings within this manual are

supplied by Draper Tools to help illustrate correct

operation of the product.

Every eort has been made to ensure the

information contained in this manual is accurate.

However, Draper Tools reserves the right to amend

this document without prior warning. Always use the

latest version of the product manual.

2. Contents

– 3 –

EN

1. Preface 2

1.1 Product Reference 2

1.2 Revisions 2

1.3 Understanding the Safety Content of This

Manual 2

1.4 Copyright © Notice 2

2. Contents 3

3. Product Introduction 4

3.1 Intended Use 4

3.2 Specication 4

4. Health and Safety Information 5

4.1 Health and Safety Information for this

Dehumidier 5

4.2 Additional Safety Information for Flammable

Refrigerants 6

4.3 Connection to the Power Supply 7

4.4 Residual Risk 7

5. Identication and Unpacking 8

5.1 Product Overview 8

5.2 What’s in the Box? 9

5.3 Packaging 9

6. Preparation Instructions 10

6.1 Assembling the Dehumidier 10

6.2 Selecting a Drainage Mode 10

6.3 Positioning the Dehumidier 11

7. Operating Instructions 12

7.1 The Control Panel 12

7.2 Switching the Dehumidier

On and O 12

7.3 Emptying the Water Tank (Manual Drainage

Mode) 12

7.4 Setting the Target Humidity 13

7.5 Using the Timer 13

7.6 Auto-Defrost Functionality 13

7.7 Overheating Protection 14

8. Maintenance and Troubleshooting 14

8.1 General Maintenance and Storage 14

8.2 Air Filter Care 14

8.3 Air Inlet Care 15

8.4 Water Tank Care 15

8.5 Troubleshooting 15

9. Spares, Returns and Disposal 17

10. Warranty 18

11. Explanation of Symbols 19

3. Product Introduction

– 4 –

3.1 Intended Use

This product is designed to extract moisture from damp

or humid industrial environments to prevent the build-up

of mould and other hazards. Any other application

beyond the conditions established for use will be

considered misuse. Draper Tools accepts no

responsibility for improper use of this product.

Part of our ore range, this product is suitable for regular

use by enthusiasts and tradespersons alike.

Important: This product is not a water pump and is not

designed to transfer water from one location to another.

WARNING! This product is not a toy and must be

respected.

Read this manual in full before attempting to assemble,

operate or maintain the product, and retain it for later

use.

Stock No. 12498

Part No. DH50

Rated frequency 50Hz

Rated power 900W

Rated current 4.0A

Extraction rate 50L per day (at 30°C, 80% relative humidity)

Target humidity range 10–95%

Condensate capacity 7L

Condensate tank outlet Ø12mm

Refrigerant: R290 (propane) 200g

Max. suction pressure 1.0Mpa

Max. discharge pressure 2.5Mpa

Minimum room size 10m2

Ambient operation environment 5–35°C

Global warming potential 3

Ingress protection IP22

Dimensions W 450 × H 655 × D 480mm

Net weight 30kg

3.2 Specication

4. Health and Safety Information

Important: Read all the Health and Safety instructions

before attempting to assemble, adjust, operate or

maintain this product. Non-compliance with these

instructions may result in injury or damage to the user or

the product.

4.1 Health and Safety Information for this

Dehumidier

General Safety Instructions

• Only authorised personnel that have been trained in

the use of this product and are familiar with the

instructions in this manual may operate this machine.

Important: This product is not suitable for use by

children.

• Inspect the product before every use for cracked,

corroded or broken parts and leakages.

WARNING! DO NOT use this product if it is

damaged or leaking in any way. Contact

Draper Tools for repair and replacement

options.

• Use this product only for its intended purpose and do

not modify it in any way.

• DO NOT operate this product while tired or under the

inuence or alcohol, drugs or other medication.

• Keep your hands and other body parts away from

moving parts at all times and keep loose hair, clothing

and jewellery tied back.

• ONLY use spare parts supplied by Draper Tools.

Installation

• DO NOT use or store this product in unventilated

areas that are smaller than the minimum required

space for this product.

• DO NOT use this product in environments containing

high concentrations of dust; ammable, volatile, toxic

or otherwise dangerous gases, vapours and liquids; or

where the air composition is ammable.

• DO NOT use this product in locations in which ames

or sources of ignition are present.

• This product is suitable for indoor use ONLY; DO NOT

immerse it in water or expose it to wet conditions.

• DO NOT use this product in the vicinity of water tanks.

• Keep all air vents and grilles free from obstructions.

• Use this product ONLY on sturdy, at and level

surfaces capable of bearing the weight of the product

and a full water tank.

Important: DO NOT use this product on tilted

surfaces as it may cause damage to the internal

components or cause the unit to tip over.

• Ensure that the product is positioned with no less than

the minimum clearance required around all sides of

the unit during use.

• DO NOT place the product directly beneath wet

materials; allow at least one metre between the unit

and the items to be dried.

Correct Use and Operational Safety

• NEVER connect this product to a power supply if the

air lter is not installed.

• NEVER cover the air vents and grilles or place any

object on the product during use.

• DO NOT insert foreign objects through the air vents or

grilles.

• NEVER open or place your hands inside the product

during use.

• NEVER modify or remove the oat switch from the

water tank.

• ALWAYS switch o the product using the power

button before disconnecting the power supply.

Electrical Safety

• Keep the power cord away from sources of heat,

liquids, oil and hot or sharp surfaces.

• NEVER handle the plug or operate the product with

wet hands.

• NEVER pull the product along using the power cable

or plug and DO NOT pull on the cable to disconnect

the plug from a power supply.

• Position the power cable tidily and safely so that it

does not create a trip hazard.

– 5 –

EN

4. Health and Safety Information

Handling and Storage

WARNING! This product is heavy and requires

two people to lift and transport it. Use

appropriate equipment where necessary. Failure

to transport the product safely may result in

serious injury.

• Switch o the product, disconnect it from the power

supply and wait for all moving parts to stop before

attempting to maintain or move the unit.

• Store and transport the product in an upright

position.

• DO NOT use or store this product in the presence of

ammable liquids or vapours.

• Empty the water tank before transporting the product.

• Discard any liquid accumulated in the water tank; DO

NOT use it for any other purpose.

Servicing

• Any maintenance beyond the procedures detailed in

this manual MUST be performed by an authorised

and suitably qualied technician.

4.2 Additional Safety Information for

Flammable Refrigerants

WARNING! This product contains approximately

200g of pressurised R290 (propane) refrigerant.

This substance is highly ammable and must

NOT be exposed to sources of ignition.

• DO NOT use this product in spaces that are smaller

than the minimum room size rated for the unit.

• By means of ventilation or construction, the space in

which the unit is installed must NOT cause or allow

the refrigerant to stagnate and create a re or

explosion hazard in the event of a leak.

• The unit MUST be stored in a well-ventilated room no

smaller than the minimum room size required for

operation in which no continuously operating open

ames (e.g. an operating gas appliance) and no

sources of ignition (e.g. an operating electric heater)

are present.

• Keep all air vents and grilles in the location and on the

product free from obstructions.

• DO NOT attempt to undertake any maintenance

procedures not covered in this manual; additional

servicing and handling of the refrigerant MUST be

conducted by an authorised and suitably qualied

service agent who is competent in the use and

handling of ammable refrigerants.

• DO NOT puncture, burn or attempt to modify the

refrigerant system or its components in any way.

• DO NOT use any means to accelerate the defrosting

process or to clean other than those identied in this

manual.

WARNING! Refrigerant gases may be odourless

and can explode in the presence of sources of

heat and ignition.

– 6 –

4. Health and Safety Information

4.3 Connection to the Power Supply

WARNING! Risk of electric shock. DO NOT open

this product.

This appliance is supplied with an approved plug and

cable for your safety. The product must be installed

according to national wiring regulations.

If the power supply cord is damaged, it must be replaced

by Draper Tools, an authorised service agent or similarly

qualied personnel in order to avoid a hazard.

The damaged or incomplete plug, when cut from the

cable, must be disabled to prevent connection to a live

electrical outlet.

This product is Class I* and is designed for connection

ONLY to a power supply matching that detailed on the

rating label and compatible with the plug tted.

The value of the fuse tted is marked on the pin face of

the plug. Should the fuse need replacing, ensure the

substitute is of the correct rating, approved to BS 1363/A

and ASTA or BS Kite marked. This should only be

performed by suitably qualied personnel.

ASTA

BSI

The fuse can be replaced by removing the cover using a

small plain slot screwdriver and removing the broken

fuse from its holder. This should only be performed by

suitably qualied personnel.

If an extension lead is required, use an approved and

compatible lead rated for this appliance. Where use of an

extension lead is unavoidable, Draper Tools recommends

using a 2.5mm cable. Follow all the instructions supplied

with the extension lead.

Important: Always follow the extension lead instructions

regarding maximum load while the cable is wound. If in

doubt, unwind the entire cable. A coiled extension lead

generates heat which could melt the lead and cause a

re.

*Earthed: This product requires an earth connection to

protect against electric shock from accessible

conductive parts in the event of a failure of the basic

insulation.

4.4 Residual Risk

The safety instructions in this manual cannot account for

all possible conditions and situations that may occur.

Exercise common sense and caution when using this

product and protect against any additional conceivable

risks.

– 7 –

EN

– 8 –

5. Identication and Unpacking

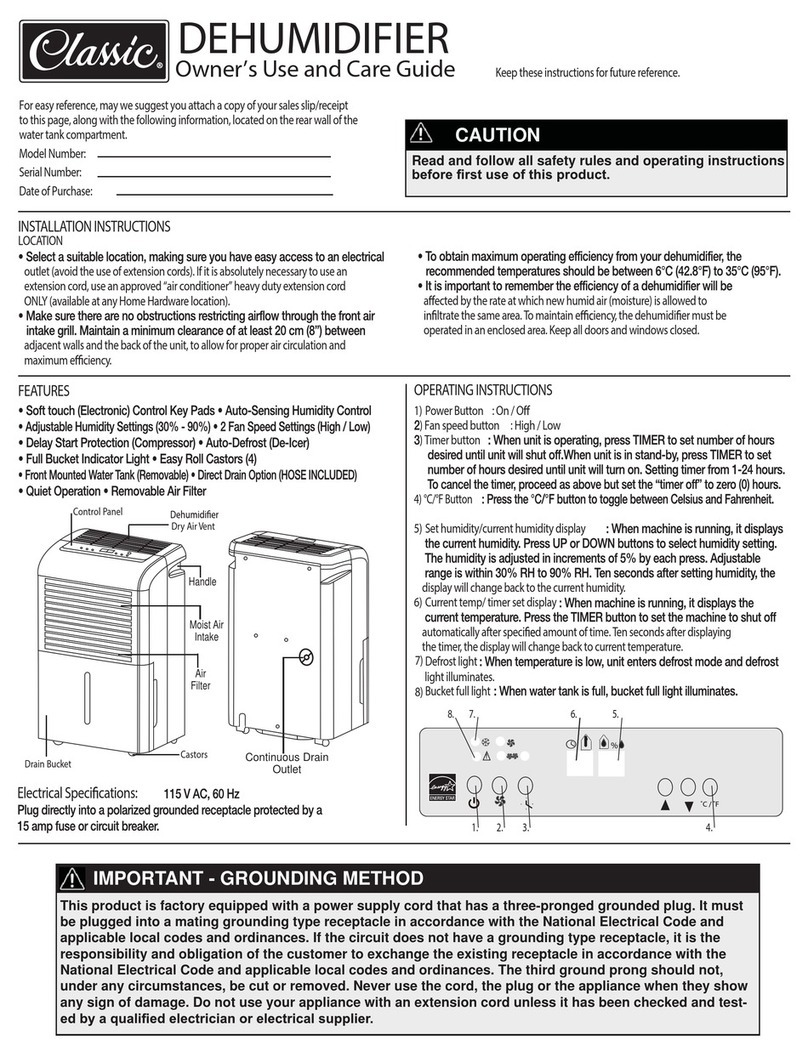

5.1 Product Overview

(1) Air lter

(2) Air inlet

(3) Control panel

(4) Front feet

(5) Power cable and plug

(6) Transport handle

(7) Water tank

(8) Water tank access panel

(9) Water tank hose port

(10) Wheels

(3) (1)

(6)

(8)

(4)

(7)

(10)

(9)

(5)

(2)

(C)

(I)

(H)

(B)

(F)

(D)

(E)

(D)

– 9 –

5. Identication and Unpacking

5.3 Packaging

Keep the product packaging for the duration of the

warranty period for reference should the product need to

be returned for repair.

WARNING! Keep packaging materials out of

reach of children. Dispose of packaging

correctly and responsibly and in accordance

with local regulations.

†Some or all of these parts may be tted to the dehumidier unit before shipment.

(A) 1 × Dehumidier unit (Not shown)

(B) 1 × Axle

(C) 2 × Wheels

(D) 2 × M6 × 35mm bolts†

(E) 4 × M6 × 28mm bolts

(F) 2 × M12 washers

(G) 2 × M12 nuts

(H) 4 × M6 nuts†

(I) 1 × Ø12mm discharge hose

Please visit drapertools.com for our full range of accessories and consumables.

– 9 –

EN

5.2 What’s in the Box?

Carefully remove the product from the packaging and

examine it for any signs of damage that may have

occurred during shipment.

Before assembling the product, lay the contents out and

check them against the parts shown below. If any part is

damaged or missing, do not attempt to use the product.

Please contact the Draper Helpline; contact details can

be found at the back of this manual.

6. Preparation Instructions

Important: Before assembling and installing this

product, read and understand all the safety instructions

listed in this manual.

6.1 Assembling the Dehumidier

WARNING! This product is heavy. For your

safety, Draper Tools recommends that this

product is assembled by two people.

1. Unfold the transport handle (6) and secure it in place

using the four M6 × 35mm bolts (D) and two M6 nuts

(H).

1 Fig.

(6)

(D)

(H)

2. Carefully tip the dehumidier unit onto its front face.

3. Align the axle (B) with the base of the unit and secure

it in place using the four M6 × 28mm bolts (E).

2 Fig.

(B) (E)

4. Place a wheel (C) onto each end of the axle and secure

them in place using the M12 washers (F) and M12

nuts (G).

3 Fig.

(G) (F)

(C)

(B)

5. Carefully tip the unit into its upright position.

CAUTION! After assembly or tipping the

dehumidier for any reason, allow it to rest in an

upright position for at least 2 HOURS before

connecting it to mains power.

6.2 Selecting a Drainage Mode

The dehumidier features two drainage modes:

• Manual (internal water tank)

• Continuous

Manual Drainage Mode

The dehumidier is supplied with a removable internal

water tank (7) and will automatically operate in manual

drainage mode. When the water tank is full, the unit

switches o automatically until the tank is emptied.

Important: Ensure that the water tank outlet is securely

sealed when operating in manual drainage mode.

– 10 –

6. Preparation Instructions

Continuous Drainage Mode

For operations requiring larger amounts of moisture to

be extracted, a Ø12mm discharge hose (supplied) can be

tted to the water tank outlet through the water tank

hose port (9). When operating in this mode, the

dehumidier will run continuously until it is manually

switched o.

4 Fig.

(9)

Important: Ensure that the receptacle is large enough to

accommodate the amount of moisture that will be

extracted during the operating time. The product will

NOT stop operating if the receptacle is lled.

Important: Remove the outlet bung before connecting a

discharge hose. The discharge point of the hose MUST

be lower than the water tank outlet in order for water to

be continually discharged from the unit. Ensure that the

hose is not bent or kinked and does not contain any

upward stretches.

Draper Tools recommends locating the discharge point

in a permanent drain or closed-top container to prevent

the moisture from being recycled through the

dehumidier once it has been discharged.

This product may be used with an external uplift pump

(not supplied) for low-level applications.

Important: Ensure that the water discharged from the

hose does not create a slipping hazard.

6.3 Positioning the Dehumidier

Failure to position the dehumidier correctly will

adversely impact on its performance.

Important: DO NOT move the dehumidier if the internal

tank contains water as it may tip over and cause a

spillage. ALWAYS drain the water tank before moving the

unit.

• Allow at least 50cm of clear space around the sides

and rear of the unit.

• Allow at least 1m of clear space at the front of the unit.

• Position the unit in a clear and central location.

• For maximum eciency, create an enclosed

environment by closing all doors and windows.

Important: The enclosed area MUST be larger than

the minimum room size rated for the unit.

• When used in a home, ensure that all external

openings are closed and open all appropriate interior

doors, with the unit located in a central location.

• If moisture or dampness is particularly prolic in one

specic area, position the unit closer to that location

before moving to a more central spot.

5 Fig.

≥ 50cm

≥ 50cm

≥ 1m

≥ 50cm

WARNING! Position the unit on sturdy at and

level surfaces ONLY. NEVER position the unit on

sloped surfaces as it may tip over and cause

injury or damage.

CAUTION! DO NOT position the unit in close

proximity to radiators or other heat sources.

CAUTION! When using the dehumidier to dry

wet materials, position the unit at least one

meter from the items to be dried. This prevents

water from falling onto the unit and damaging

internal components.

– 11 –

EN

Important: Ensure that the product is correctly prepared

and positioned before operation.

CAUTION! After assembly or tipping the

dehumidier for any reason, allow it to rest in an

upright position for at least 2 HOURS before

connecting it to mains power and switching it on.

7.1 The Control Panel

POWER TIMER

DEHUMIDIFIER

T ON

T OFF

H°C

PRES

PHASE

LACK

SET

CURRENT

DEHUM

FULL

%

PIPE TEMP

ROOM TEMP

88 88 88

FROST

6 Fig.

(23) (16)(21) (20) (17)

(12) (24) (13)

(14)

(18) (11)

(15)

(22)(19)

(11) Decrease value button

(12) Defrost indicator

(13) Dehumidication indicator

(14) Fan indicator

(15) Full tank indicator

(16) Humidity status indicator

(17) Humidity value indicator

(18) Increase value button

(19) Power button

(20) Temperature mode indicator

(21) Temperature value indicator

(22) Timer button

(23) Timer status indicators

(24) Timer value indicator

7.2 Switching the Dehumidier

On and O

Important: ALWAYS ensure that the air lter (1) is

installed before switching on the product.

Important: When using Continuous Drainage mode,

ensure that the discharge hose is positioned correctly

before switching on the product.

To switch the dehumidier on, ensure that it is positioned

correctly with suitable clear space around each side of

the unit, then connect the plug (5) to a power supply.

While the dehumidier is connected to mains power but

not switched on, it remains in standby mode. To switch

on the unit, press the power button (19) once. Press the

power button again to return the unit to standby mode.

To completely shut down the unit, disconnect the plug

from mains power.

Important: The fan continues to operate for a few

seconds after the unit is switched o.

Important: ALWAYS switch o the unit using the power

button BEFORE disconnecting the plug from the power

supply.

7.3 Emptying the Water Tank (Manual

Drainage Mode)

When a discharge hose is not installed on the water tank

(7) and the tank outlet is sealed, the dehumidier will

automatically stop operating when the water tank is full

and the full tank indicator (15) illuminates on the control

panel.

7 Fig.

(7)

(8)

Important: Switch o the dehumidier using the power

button (19) BEFORE removing the water tank.

1. To access the water tank, open the water tank access

panel (8) on the front of the unit.

– 12 –

7. Operating Instructions

7. Operating Instructions

2. Grip the tank handle and carefully pull the tank

outward from the dehumidier.

Important: It may help to gently lift the clasp that

grips the water tank outlet as you pull the tank from

the unit. Take care not to trap or pinch your ngers

when doing so.

3. After emptying the water tank, push it back into place

inside the unit.

Apply gentle force to ensure that the outlet clasp

passes over the outlet and grips it in place.

Important: Dispose of the water from the water tank;

DO NOT use it for any other purpose.

4. Close the access panel and press the power button to

start up the dehumidier.

Important: The water tank does not require emptying

when using Continuous Drainage mode.

Important: The full tank indicator may also illuminate if

the water tank has been incorrectly installed inside the

unit.

7.4 Setting the Target Humidity

The target humidity of the room to be treated can be set

from 10–95%. To set the target humidity level, press the

increase (18) and decrease (11) value buttons as

appropriate while the device is switched on. The

humidity value indicator (17) displays the chosen

percentage. When the desired level is reached, allow the

humidity value indicator to stop ashing to save the

target value.

Once a target humidity value has been set, the

dehumidier will run until that level has been reached. If

the humidity level rises by 3% above the set level, the

unit will automatically resume operation until the

congured level is reached again.

The recommended target humidity for a typical room is

50–70%.

Important: If the target humidity level is set at a value

lower than is achievable in the climate in which it is used,

the dehumidier will operate continuously.

7.5 Using the Timer

The dehumidier can be programmed to switch either on

or o after a dened number of hours. If a value is set for

both on and o timers, the unit will cycle between on and

o according to the congured intervals.

To enable the timer, press the timer button (22) and use

the increase (18) and decrease (11) value buttons to set

the number of hours until the unit switches on or o. The

chosen value is shown on the timer value indicator (24).

When the desired number of hours is reached, allow the

timer value indicator to stop ashing to save the target

value.

If the timer is set while the unit is in standby mode, the

timer will determine the number of hours until the

dehumidier automatically switches on. The T ON timer

status indicator is illuminated.

If the timer is set while the unit is switched on, the timer

will determine the number of hours until the dehumidier

automatically switches o (unless the water tank is lled

before this period expires). The T OFF timer status

indicator is illuminated.

7.6 Auto-Defrost Functionality

When used for extended periods or in lower ambient

temperatures, frost may accumulate on the evaporator

coils, reducing the airow within the unit. When this

occurs, the dehumidier will automatically enter Defrost

mode.

When Defrost mode is enabled, the defrost indicator (12)

illuminates on the control panel and the compressor

switches o. The fan, however, continues to run.

When the dehumidier has completed the defrosting

process, it will automatically resume operation with the

previously congured settings.

Important: DO NOT switch o the machine or

disconnect it from mains power during defrosting.

– 13 –

EN

7. Operating Instructions

7.7 Overheating Protection

The dehumidier is tted with overload and overheating

protection functions

If sudden power loss to the unit occurs during operation,

the unit will shut down for three minutes to protect the

compressor and will not run during this period. If power

is reconnected, the dehumidier will resume operation

once this time has elapsed.

If the temperature of the coolant circuit coil rises

abnormally and does not drop within 10 minutes, the

unit will enter standby mode and the PRES indicator will

illuminate on the control panel. The dehumidier will not

operate until the circuit has cooled.

Important: ALWAYS switch o and disconnect the

dehumidier from the power supply, allow moving parts

to stop and empty the water tank before performing any

product care or maintenance.

– 14 –

8. Maintenance and Troubleshooting

8.1 General Maintenance and Storage

• Clean the outer surface of the unit with a soft, damp

cloth and mild detergent.

− DO NOT spray the device with liquid or submerge

it in water.

− Once clean, wipe the unit dry to prevent corrosion.

CAUTION! DO NOT use solvents or

aggressive chemicals to clean the unit as

they may cause corrosion or damage

insulated parts.

• Clean other parts of the unit in accordance with their

dedicated instructions.

• Inspection and replenishment of the coolant MUST

be performed by an authorised and qualied service

agent.

• Disconnect the plug from the power supply when the

unit is not used for extended periods.

• Empty the water tank (7) and cover the unit when

storing the dehumidier.

• Store the product upright in a cool, clean and dry

environment, out of direct sunlight and out of reach of

children.

• Store the unit in a well-ventilated room no smaller

than the minimum room size required for operation in

which no continuously operating open ames (e.g. an

operating gas appliance) and no sources of ignition

(e.g. an operating electric heater) are present.

• Observe any additional storage safety instructions

relating to R290 refrigerant; see 4.2 Additional

Safety Information for Flammable Refrigerants.

8.2 Air Filter Care

Over time, the air lter (1) will gather dust and debris

from the air drawn into the dehumidier. Clean the lter

regularly to ensure a consistent ow of air into the unit.

8 Fig.

(1)

1. Pull the air lter up and out of the front of the unit and

tap away any excess dust.

2. Remove light dust using a vacuum cleaner and a soft

brush.

3. For tough dust or clogged lters, wash the lter

element in hot, soapy water and allow it to dry

naturally and thoroughly.

4. Insert the lter back into the unit.

CAUTION! NEVER connect the dehumidier to a

power supply or switch it on without the air

lter installed.

8. Maintenance and Troubleshooting

– 15 –

8.3 Air Inlet Care

The air inlet (2) grille may accumulate dust and other

debris during operation. Clean the inlet grille regularly to

ensure a consistent ow of air into the unit.

To clean the inlet grille, remove the air lter (1) from the

unit and use a vacuum cleaner or compressed air at low

pressure and a soft brush.

8.4 Water Tank Care

The water tank (7) should be cleaned occasionally to

prevent the build-up of mould and bacteria.

1. Partially ll the tank with warm, clean water and add

a mild detergent.

2. Swirl the water around the inside of the tank, then

empty it out.

3. Rinse the tank thoroughly with clean water and allow

it to dry before inserting it back into the dehumidier.

Important: DO NOT clean the water tank in a

dishwasher.

8.5 Troubleshooting

Problem Possible cause Remedy

The unit expels hot or cold air. Normal operation. During normal operation, cold air is

expelled from the machine. Hot air is

produced during the defrost cycle.

The unit does not switch on. The product is not connected to an

active power supply.

Check that the plug is securely

connected and that the power supply

is active.

The water tank is full or incorrectly

installed.

Empty the water tank and reinstall it

securely.

The ambient temperature is beyond

the working range of the unit.

Take steps to bring the ambient

temperature within 5–35°C.

The unit is defrosting. Wait for defrosting to complete

before resuming. Increasing the

ambient temperature may help to

speed up the defrosting process.

The power supply was interrupted. Wait for three minutes for the

overload protection to deactivate.

The unit does not extract much

moisture.

The air lter or air inlet is clogged. Clean the inlet grille and lter

element as appropriate.

The ambient temperature and/or

humidity are already low.

The unit is operating normally.

The target humidity level is greater

than the current ambient humidity

level.

Reduce the target humidity level

until it is lower than the current level.

EN

8. Maintenance and Troubleshooting

8.5 Troubleshooting (continued)

Problem Possible cause Remedy

Water is leaking from the unit. The unit was moved and the water

tank was not empty.

Empty the water tank before moving

the unit. Dry the unit thoroughly

before resuming.

The water tank is not installed

correctly.

Check the positioning of the water

tank.

The water tank outlet is open and no

discharge hose is connected.

Seal the water tank outlet.

The discharge hose is damaged,

obstructed or poorly connected to

the water tank outlet.

Check the hose connection and

inspect it for any damage, cracks,

kinks or blockages.

The device is excessively noisy. The device is not stable or the

surface is not level.

Move the unit to a more appropriate

location. Empty the water tank and

switch o the unit before moving it.

An internal component has become

loose.

Have the unit inspected and repaired

by an authorised service agent.

The noise sounds like water owing. This is normal and is caused by the

coolant circulating.

The control panel displays an error

code.

E1 – Coolant coil sensor fault. Ensure that the environment meets

the requirements for this unit.

Unplug the unit and allow it to rest

for several minutes before retrying. If

the error persists, contact Draper

Tools for support.

E2 – Moisture sensor error.

E3 – Temperature sensor error.

EE – Coolant leak. Switch o and unplug the unit and

ensure that the room is well-

ventilated. Allow the unit to rest for at

least three hours before retrying. If

the error persists, contact Draper

Tools for support.

– 17 –

For spare parts, servicing, and repair and replacement

options, please contact the Draper Tools Product

Helpline for details of your nearest authorised agent.

Draper Tools will endeavour to hold any spare parts, if

applicable, for seven years from the date that it sells the

nal matching stock item.

Any servicing or repairs carried out by unauthorised

personnel or installation of spare parts not supplied by

Draper Tools will invalidate your warranty.

Important: For safety, ALWAYS drain and clean the

product of any oil, fuel, chemicals or other substances

before returning it to Draper Tools or its authorised

agent. Store these materials in suitable containers and

dispose of them in accordance with local regulations.

Draper Tools and its agents cannot be responsible for the

disposal of these substances.

At the end of its working life, dispose of the product

responsibly and in line with local regulations. Recycle

where possible.

• DO NOT dispose of this product with domestic waste;

most local authorities provide appropriate recycling

facilities.

• DO NOT burn or incinerate this product.

• DO NOT abandon this product in the environment.

9. Spares, Returns and Disposal

EN

10. Warranty

Draper Tools products are carefully tested and inspected

before shipment and are guaranteed to be free from

defective materials and workmanship.

Should the tool develop a fault, return the complete tool

to your nearest distributor or contact Draper Tools

directly. Contact information can be found at the back of

this manual.

Proof of purchase must be provided.

If, upon inspection, it is found that the fault occurring is

due to defective materials or workmanship, repairs will

be carried out free of charge. This warranty period covers

parts and labour for 12 months from the date of

purchase. Where tools have been hired out, the warranty

period covers 90 days from the date of purchase.

This warranty does not apply to any consumable parts,

batteries or normal wear and tear, nor does it cover any

damage caused by misuse, careless or unsafe handling,

alterations, accidents, or repairs attempted or made by

any personnel other than the authorised Draper Tools

repair agent.

In all cases, to make a claim for faulty workmanship or

materials within the standard warranty period, please

contact or return the product to the place of purchase.

Proof of purchase may be required.

If the place of purchase is no longer trading or if you

experience any diculties with your warranty, please

contact Customer Services with the product details and

your proof of purchase. Contact details can be found at

the back of this manual.

If the tool is not covered by the terms of this warranty,

repairs and carriage charges will be quoted and charged

accordingly.

This warranty supersedes any other guarantees

expressed or implied and variations of its terms are not

authorised.

Your Draper Tools guarantee is not eective until you can

produce, upon request, a dated receipt or invoice to

verify your purchase within the guarantee period.

Please note that this warranty is an additional benet

and does not aect your statutory rights.

Draper Tools Limited

– 18 –

11. Explanation of Symbols

– 19 –

Read the instruction manual

Warning!

Do not abandon in the environment

Do not incinerate or throw onto re

Warning!

Highly ammable refrigerant

Rated input

Rated voltage

Maximum discharge pressure

Maximum suction pressure

Extraction rate per day (at 30°C, 80%

relative humidity)

Extraction rate per day (at 27°C, 80%

relative humidity)

Condensate tank capacity

Refrigerant – R290 (Propane)

Ingress protection rating

Product dimensions

Product weight

European conformity

UK Conformity Assessed

EN

© Published by Draper Tools Limited© Published by Draper Tools Limited

Delta International

Delta International BV

Oude Graaf 8

6002 NL

Weert

Netherlands

Contact Details

Draper Tools

Draper Tools Limited

Hursley Road

Chandler’s Ford

Eastleigh

Hampshire

SO53 1YF

UK

Website: drapertools.com

Email: [email protected]

Product Helpline: +44 (0) 23 8049 4344

Telephone Sales Desk: +44 (0) 23 8049 4333

General Enquiries: +44 (0) 23 8026 6355

General Fax: +44 (0) 23 8026 0784

Please contact the Draper Tools Product Helpline for repair and servicing enquiries.

This manual suits for next models

1

Table of contents

Other Draper Dehumidifier manuals