Draper GTP33 User manual

These instructions accompanying the product are the original instructions. This document is part of the product, keep

it for the life of the product passing it on to any subsequent holder of the product. Read all these instructions before

assembling, operating or maintaining this product.

This manual has been compiled by Draper Tools describing the purpose for which the product has been designed,

and contains all the necessary information to ensure its correct and safe use. By following all the general safety

instructions contained in this manual, it will ensure both product and operator safety, together with longer life of the

product itself.

AlI photographs and drawings in this manual are supplied by Draper Tools to help illustrate the operation of the

product.

Whilst every effort has been made to ensure the accuracy of information contained in this manual, the Draper Tools

policy of continuous improvement determines the right to make modifications without prior warning.

84706

PETROL

4-IN-1

GARDEN TOOL

ATTENTION!:

2 stroke engines MUST be filled with

unleaded fuel, MIXED with 2-stroke oil.

Failure to add oil or incorrectly mixing the oil

WILL result in running problems or

ENGINE FAILURE!

1. TITLE PAGE

1.1 INTRODUCTION:

USER MANUAL FOR: Petrol 4-in-1 Garden Tool

Stock No: 84706

Part No: GTP33

As our user manuals are continually updated, users should make sure that they use

the very latest version.

Downloads are available from: http://drapertools.com/manuals

Draper Tools Limited

Hursley Road

Chandler’s Ford

Eastleigh

Hampshire

SO53 1YF

UK

Website: drapertools.com

Product Helpline: +44 (0) 23 8049 4344

General Fax: +44 (0) 23 8026 0784

1.3 UNDERSTANDING THIS MANUALS SAFETY CONTENT:

WARNING! – Information that draws attention to the risk of injury or death.

CAUTION! – Information that draws attention to the risk of damage to the product or

surroundings.

1.4 COPYRIGHT © NOTICE:

Copyright © Draper Tools Limited.

Permission is granted to reproduce this publication for personal and educational use

only. Commercial copying, redistribution, hiring or lending is prohibited.

No part of this publication may be stored in a retrieval system or transmitted in any

other form or means without written permission from Draper Tools Limited.

In all cases this copyright notice must remain intact.

1.2 REVISIONS:

Date first published August 2018.

2.1 CONTENTS

Page content Page

1. TITLE PAGE

1.1 INTRODUCTION ............................. 2

1.2 REVISION HISTORY ....................... 2

1.3 UNDERSTANDING THIS MANUAL. 2

1.4 COPYRIGHT NOTICE ..................... 2

2. CONTENTS

2.1 CONTENTS ..................................... 3

3. WARRANTY

3.1 WARRANTY..................................... 4

4. INTRODUCTION

4.1 SCOPE ............................................ 5

4.2 SPECIFICATION.............................. 5

4.3 HANDLING & STORAGE................. 6

5. HEALTH & SAFETY INFORMATION

5.1 GENERAL SAFETY INSTRUCTIONS

FOR POWER TOOL USE................ 7

6. TECHNICAL DESCRIPTION

6.1 IDENTIFICATION........................... 11

– Tree pruning attachment............. 12

– Hedge trimming attachment........ 12

– Grass trimmer/brush cutter ......... 13

7. UNPACKING & CHECKING

7.1 PACKAGING.................................. 14

7.2 WHAT’S IN THE BOX .................... 14

8. PREPARING THE 2-STROKE MOTOR UNIT

8.1 FUELLING...................................... 15

8.2 HARNESS ATTACHMENT ............ 15

9. PREPARING THE ATTACHMENTS

9.1 FITTING AND REMOVING

THE CHAIN AND GUIDE BAR ...... 16

9.2 TENSIONING THE CHAIN ............ 16

9.3 CHAIN OIL ..................................... 17

9.4 FITTING THE BRUSH

CUTTER/GRASS ..............................................

TRIMMER GUARD ........................ 17

9.5 FITTING THE COMPLETE SPOOL ..

ASSEMBLY.................................... 18

9.6 FITTING THE BRUSH

CUTTING BLADE .......................... 18

10. STARTING THE 2-STROKE MOTOR UNIT

10.1 STARTING THE ENGINE .............. 19

11.

OPERATING THE TREE PRUNING

ATTACHMENT

11.1 ADJUSTING THE OIL FLOW ........ 20

11.2 WORKING TECHNIQUES........... 20

– Delimbing .................................. 20

11.3 HAZARDS.................................... 21

– Kickback.................................... 21

– Pull in ........................................ 21

12. USING THE EXTENSION POLE

12.1 USING THE 700mm

EXTENSION POLE........................ 22

13. OPERATING THE HEDGE TRIMMING

ATTACHMENT

13.1 ADJUSTING THE BLADE ANGLE. 23

13.2 WORKING TECHNIQUES ............. 23

– Ground clearance........................ 23

– Vertical cutting (along side)......... 24

– Vertical cutting (at a distance)..... 24

– Hedge topping

(above head height) .................... 24

– Horizontal cutting ........................ 24

14. OPERATING THE BRUSH CUTTER/GRASS ..

TRIMMER

14.1 USING THE GRASS TRIMMER .... 25

14.2 USING THE BRUSH CUTTER ...... 25

15. MAINTENANCE – 2-STROKE MOTOR UNIT

15.1 CLEANING THE AIR FILTER ........ 26

15.2 SPARK PLUG MAINTENANCE ..... 26

15.3 ENGINE SPEED IDLE

ADJUSTMENT ............................... 27

15.4 REPLACING THE FUEL FILTER... 27

16. MAINTENANCE – ATTACHMENTS

16.1 CHAIN MAINTENANCE................. 28

16.2 FITTING AND REMOVING

THE CHAIN AND GUIDE BAR

.................(see section 9.1, page 16).

16.3 TENSIONING THE CHAIN

.................(see section 9.2, page 16).

16.4 CHAIN OIL

.................(see section 9.3, page 17).

16.5 GEARBOX LUBRICATION ............ 28

16.6 BLADE CLEANING ........................ 28

16.7 MAINTAINING THE SPOOL .......... 28

16.8 REMOVING THE COMPLETE

SPOOL ASSEMBLY ...................... 29

16.9 FITTING THE COMPLETE SPOOL ..

ASSEMBLY

.................(see section 9.5, page 18).

17. TROUBLESHOOTING

17.1 TROUBLESHOOTING –

2-STROKE MOTOR UNIT ............. 30

17.2 TROUBLESHOOTING –

TREE PRUNING ATTACHMENT .. 32

17.3 TROUBLESHOOTING – HEDGE .....

TRIMMING ATTACHMENT ........... 32

18. ACCESSORIES

18.1 ACCESSORIES GUIDE................. 33

19. DISPOSAL

19.1 DISPOSAL ..................................... 34

20. EXPLANATION OF SYMBOLS

20.1 EXPLANATION OF SYMBOLS...... 35

DECLARATION OF CONFORMITY ........ Enclosed

Page content Page

2. CONTENTS

2. CONTENTS

- 3-

3. WARRANTY

3. WARRANTY

3.1 WARRANTY

Draper tools have been carefully tested and inspected before shipment and are guaranteed to be

free from defective materials and workmanship.

Should the tool develop a fault, please return the complete tool to your nearest distributor or

contact:

Draper Tools Limited, Chandler's Ford, Eastleigh, Hampshire, SO53 1YF. England.

Telephone Sales Desk: (023) 8049 4333 or:

Product Helpline (023) 8049 4344.

A proof of purchase must be provided.

If upon inspection it is found that the fault occurring is due to defective materials or workmanship,

repairs will be carried out free of charge. This warranty period covering labour is 12 months from

the date of purchase except where tools are hired out when the warranty period is 90 days from

the date of purchase. The warranty is extended to 24 months for parts only. This warranty does

not apply to any consumable parts, any type of battery or normal wear and tear, nor does it cover

any damage caused by misuse, careless or unsafe handling, alterations, accidents, or repairs

attempted or made by any personnel other than the authorised Draper warranty repair agent.

Note: If the tool is found not to be within the terms of warranty, repairs and carriage charges will

be quoted and made accordingly.

This warranty applies in lieu of any other warranty expressed or implied and variations of its

terms are not authorised.

Your Draper warranty is not effective unless you can produce upon request a dated receipt or

invoice to verify your proof of purchase within the warranty period.

Please note that this warranty is an additional benefit and does not affect your statutory rights.

Draper Tools Limited.

- 4-

4. INTRODUCTION

4.1 SCOPE

This 2 stroke 4-in-1 garden tool is designed exclusively for connection to a range of Draper Tools'

accessories [detailed in this documentation] enabling the operator to perform a range of

maintenance tasks in and around the garden.

4.2 SPECIFICATION

Stock no .............................................................................................................................84706

Part no.............................................................................................................................. GTP33

Motor unit:

Maximum engine performance.......................................................................................... 1,0kW

Engine type .....................................................................................................................2-stroke

Fuel tank capacity ...........................................................................................................900cm³

Engine displacement ......................................................................................................32.5cm³

Fuel/2-stroke oil mix .............................................................................................................25:1

Maximum engine performance...................................................................................... 1.000kW

Engine speed at idle...................................................................................................... 3000rpm

Engine speed (rotational frequency)2.........................................................................7,500min-1

Engine speed (rotational frequency)3.........................................................................3,000min-1

Fuel consumption at maximum engine performance .................................................. 503g/kWh

Sound pressure level (A-weighted LpAav)1................................................................. 93.7dB(A)

Sound power level (A-weighted LWAav)1...................................................................110.5dB(A)

Single value noise level2................................................................................................114dB(A)

Vibration level3................................................................................................................7.29m/s²

Weight (motor & grass trimmer attachment only - no fuel).....................................................6kg

Tree pruning attachment:

Chain speed ................................................................................................................... 15m/sec

Cutting length ...................................................................................................................235mm

Chain type ...................................................................................................... Oregon 91PJ039X

Toothing .......................................................................................................................7T – 0.375

Oil tank capacity.................................................................................................................150ml

Noise level.............................................................................................93.7dB(A) [K=3,0 dB(A)]

Vibration – full throttle................................................................................ 9.23m/s² [K=1,5 m/s²]

Vibration – idling speed ........................................................................... 6.954m/s² [K=1,5 m/s²]

Brush cutter/grass trimmer attachment:

Cutting diameter (blade)...................................................................................................255mm

Cutting diameter (nylon line) ............................................................................................440mm

Cord diameter....................................................................................................................2.5mm

Overall cord length ..............................................................................................................

2.5M

Cord extension ............................................................................................................... Tap’n go

Noise level.............................................................................................94.5dB(A) [K=3,0 dB(A)]

Vibration – full throttle................................................................................ 9.23m/s² [K=1,5 m/s²]

Vibration – idling speed ............................................................................... 3.2m/s² [K=1,5 m/s²]

Hedge trimmer attachment

Max. branch size ................................................................................................................22mm

Blade length .....................................................................................................................440mm

Cutting length ...................................................................................................................380mm

Noise level.............................................................................................94.5dB(A) [K=3,0 dB(A)]

Vibration – full throttle................................................................................ 9.23m/s² [K=1,5 m/s²]

Vibration – idling speed ............................................................................... 3.2m/s² [K=1,5 m/s²]

1 In accordance to BS EN ISO 22868.

2 A-weighted sound pressure level in accordance to 2000/14/EC.

3 In accordance to BS EN ISO 22867.

4. INTRODUCTION

- 5-

4.3 HANDLING & STORAGE

– Care must be taken when handling this product.

●Dropping this power tool could have an effect on its accuracy and could also result in personal

injury. This product is not a toy and must be respected.

– Environmental conditions can have a detrimental effect on this product if neglected.

●Exposure to damp air can gradually corrode components.

●If the product is unprotected from dust and debris, components will become clogged.

●If not cleaned and maintained correctly or regularly, the machine will not perform at its best.

* Continuous A-Weighted Sound Pressure Level at the workstation in accordance to prEN ISO 15744:1999

and declared according to EN ISO 4871.

** A-Weighted Sound Power Level in accordance to prEN ISO 15744:1999 and declared according to EN ISO 4871.

4. INTRODUCTION

- 6-

When using any type of power tool there are steps that should be taken to make sure that you, as

the user, remain safe.

Common sense and a respect for the tool will help reduce the risk of injury.

5.1 GENERAL SAFETY INSTRUCTIONS FOR POWER TOOL USE

5. HEALTH AND SAFETY INFORMATION

Most important: You must know how to safely start and stop this machine, especially in an

emergency.

Keep the work area tidy and clean. Attempting to clear clutter from around the machine during use

will reduce your concentration. Mess on the floor creates a trip hazard. Any liquid spilled on the floor

could result in you slipping.

Find a suitable location. If the machine is bench mounted, the location should provide good natural

light or artificial lighting as a replacement. Avoid damp and dusty locations as it will have a negative

effect on the machine’s performance. If the machine is portable do not expose the tool to rain. In all

cases do not operate power tools near any flammable materials.

Keep bystanders away. Children, onlookers and passers by must be restricted from entering the

work area for their own protection. The barrier must extend a suitable distance from the tool user.

Unplug and house all power tools that are not in use. A power tool should never be left unattended

while connected to the power supply. They must be housed in a suitable location, away locked up

and from children.

Do not overload or misuse the tool. All tools are designed for a purpose and are limited to what

they are capable of doing. Do not attempt to use a power tool (or adapt it in any way) for an

application it is not designed for. Select a tool appropriate for the size of the job. Overloading a tool

will result in tool failure and user injury. This covers the use of accessories.

Dress properly. Loose clothing, long hair and jewellery are all dangerous because they can become

entangled in moving machinery. This can also result in parts of body being pulled into the machine.

Clothing should be close fitted, with any long hair tired back and jewellery and neck ties removed.

Footwear must be fully enclosed and have a non-slip sole.

Wear personal protective equipment (PPE). Dust, noise, vibration and swarf can all be dangerous

if not suitably protected against. If the work involving the power tool creates dust or fumes wear a

dust mask. Vibration to the hand, caused by operating some tools for longer periods must be

protected against. Wear vibration reducing gloves and allow long breaks between uses. Protect

against dust and swarf by wearing approved safety goggles or a face shield. These are some of the

more common hazards and preventions, however, always find out what hazards are associated with

the machine/work process and wear the most suitable protective equipment available.

Do not breathe contaminated air. If the work creates dust or fumes connect the machine (if

possible) to an extraction system either locally or remotely. Working outdoors can also help if

possible.

Move the machine as instructed. If the machine is hand held, do not carry it by the power supply

cable. If the product is heavy, employ a second or third person to help move it safely or use a

mechanical device. Always refer to the instructions for the correct method.

Do not overreach. Extending your body too far can result in a loss of balance and you falling. This

could be from a height or onto a machine and will result in injury.

Maintain your tools correctly. A well maintained tool will do the job safely. Replace any damaged

or missing parts immediately with original parts from the manufacturer. As applicable keep blades

sharp, moving parts clean, oiled or greased, handles clean and emergency devices working.

Warning!

●Read all safety warnings and all instructions. Failure to follow the warnings and instructions

may result in electric shock, fire and/or serious injury.

●The term "power tool" in the warnings refers to your mains operated (corded) power tool or

battery-operated (cordless) power tool.

- 7-

5. HEALTH AND SAFETY INFORMATION

Wait for the machine to stop. Unless the machine is fitted with a safety brake, some parts may

continue to move due to momentum. Wait for all parts to stop, then unplug it from the power supply

before making any adjustments, carrying out maintenance operations or just finishing using the tool.

Remove and check setting tools. Some machinery requires the use of additional tools or keys to

set, load or adjust the power tool. Before starting the power tool always check to make certain they

have been removed and are safely away from the machine.

Prevent unintentional starting. Before plugging any machine in to the power supply, make sure the

switch is in the OFF position. If the machine is portable, do not hold the machine near the switch and

take care when putting the machine down, that nothing can operate the switch.

Carefully select an extension lead. Some machines are not suitable for use with extension leads. If

the tool is designed for use outdoors, use an extension lead also suitable for that environment. When

using an extended lead, select one capable of handling the current (amps) drawn by the machine in

use. Fully extend the lead regardless of the distance between the power supply and the tool. Excess

current (amps) and a coiled extension lead will both cause the cable to heat up and can result in fire.

Concentrate and stay alert. Distractions are likely to cause an accident. Never operate a power tool

if you are under the influence of drugs (prescription or otherwise), including alcohol or if you are

feeling tired. Being disorientated will result in an accident.

Have this tool repaired by a qualified person. This tool is designed to conform to the relevant

international and local standards and as such should be maintained and repaired by someone

qualified, using only original parts supplied by the manufacturer. This will ensure the tool remains safe

to use.

5.2 ADDITIONAL SAFETY INSTRUCTIONS FOR 4-IN-1 PETROL

GARDEN TOOL USE

WARNING! For your safety, please read and understand these instructions before assembling,

operating or maintaining this machine.

WARNING! Read the instructions carefully.

Never attempt to modify or operate a modified machine. Fully assemble this machine, including all

relevant guards, before operating.

Do not operate this machine without being completely familiar with the safety features and how to

operate them.

Never operate this machine if the stop switch is faulty or not functioning.

Never operate this machine while tired, ill or under the influence of drugs.

DANGER! Keep out of the reach of children.

Refer to the instructions supplied with the attachment. Fully read and understand before

attempting to assemble, operate or maintain the attachment.

Never allow people unfamiliar with these instructions to operate this machine. Local regulations

may restrict the age of the operator.

Prior to each use, inspect the machine for signs of damage. Make sure the safety features are

present and functioning and that all visible nuts, bolts and screws remain tight. Vibration from

normal use can cause them to loosen over time.

Never operate this machine with defective or missing guards.

WARNING! Use of this product can pose a danger to wildlife. Before

attempting to use this machine, check the area, particularly long grass and

under bushes for signs of life: if necessary relocate.

NOTE: Not all animals will be deterred by the noise of the product alone.

Do not operate this machine near animals or bystanders.

Check the attachment is correctly fitted to the machine before attempting to start the engine.

- 8-

5. HEALTH AND SAFETY INFORMATION

CAUTION! As the user you are responsible for any injury to people or damage to property.

Never leave this machine running when not in use or leave the it unattended during use.

WARNING! During use the engine gets very hot. Do not touch it, especially the exhaust.

Always be aware of your surroundings, staying alert for possible hazards that you may not hear

over the noise of the engine.

Always wear appropriate PPE [Personal Protective Equipment].

– Always wear suitable eye/face protection.

– Ear defenders must be worn to prevent damage to your hearing.

– Gloves to help reduce vibration fatigue.

– Always wear safety footwear.

5.3 HEALTH AND SAFETY INFORMATION CONCERNING THE USE OF

FUELS

Fuels are inflammable and explosive. Reduce the risk of explosion and fire by:

– Turning off and cooling the motor down before filling the tank with fuel.

– Refraining from smoking and starting open fires when handling fuels.

– Storing and mixing fuels in approved and correspondingly labelled canisters.

– Storing fuels in closed containers. Keeping in mind that fuels may evaporate at room

temperature and collect on the floor of closed rooms (risk of explosion).

– Start the device at least nine metres away from the machine.

Fuels are toxic, they contain substances that have an immediate toxic effect and may cause

permanent damage to your health.Take all precautionary measures to prevent your body

from absorbing any of these substances:

– Tank and siphon fuels only outdoors or in well-ventilated rooms.

– Do not inhale fuel fumes.

– Avoid contact with eyes and skin.

– Wear gloves when transferring fuel.

– When fuel has come into contact with your clothes, change them immediately. Clean your

clothes before putting them back on.

– Store fuels out of the reach of children.

When handled inappropriately, fuels may cause damage to the environment:

– Transfer fuel carefully. Fuel must never trickle into the ground or the sewage system.

– Dispose of any remaining fuel in an appropriate manner. Never dispose of fuel with regular

household waste.

– Fuels may be stored only for a limited time. Purchase only such quantities that can be used up

within a few months.

- 9-

6. TECHNICAL DESCRIPTION

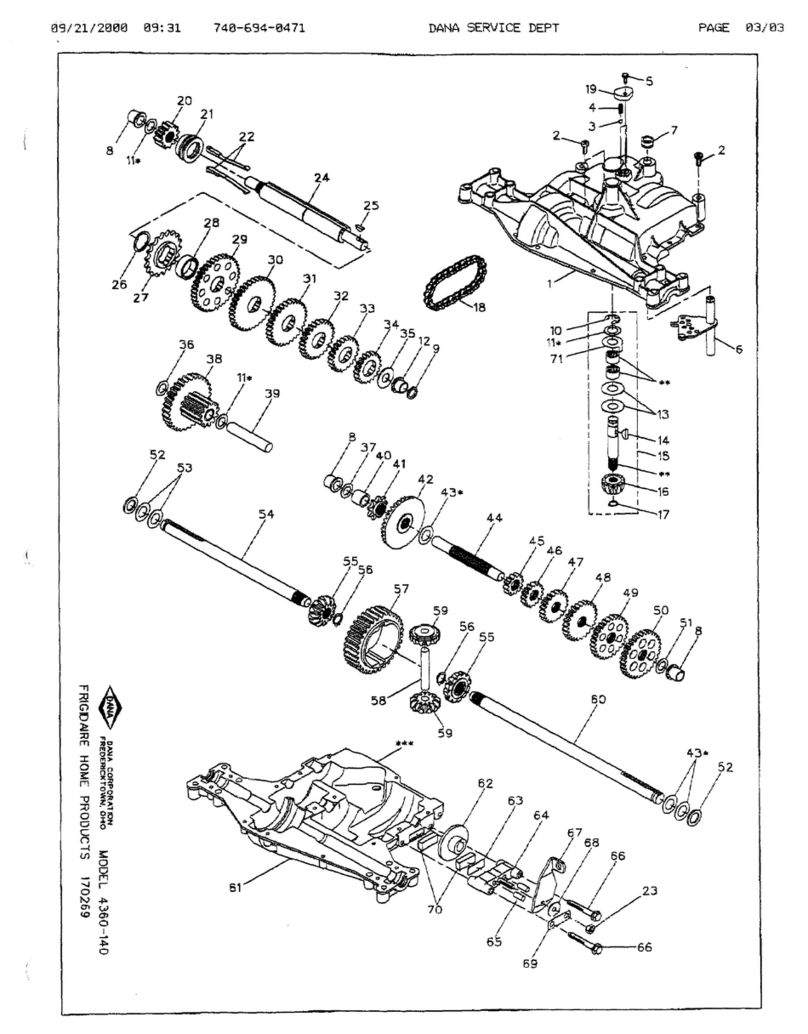

6.1 IDENTIFICATION

2-Stoke motor unit:

Air filter housing.

Fuel primer.

Carburettor.

Choke lever.

Fuel tank.

Spark plug cover (H.T lead).

Pull start assembly.

Exhaust.

Throttle lever.

Throttle release lever.

Throttle lock (start position).

Engine stop switch.

Harness attachment point.

Harness strap.

Front (auxiliary) handle.

Reaction bar.

Power take off.

Power take off locking handle.

Power take off release button.

- 10-

6. TECHNICAL DESCRIPTION

Power take off connection point.

Shaft.

Grease nipple.

Oil reservoir cap.

Oil reservoir.

Bar guard.

Chain tension adjustment screw.

Chain.

Guide bar.

Drive sprocket cover.

Oil flow adjustment screw.

Shaft.

Angle adjustment locking lever.

Angle adjustment lever.

Adjustment handle.

Gearbox.

Grease nipple.

Blade.

Blade guards.

Tree pruning attachment:

Hedge trimmer attachment:

- 11-

6. TECHNICAL DESCRIPTION

Power take off connection point.

Shaft.

Cutting attachment guard.

Cutting attachment guard fittings.

Brush cutting blade.

Spool assembly.

Spool housing.

Spool insert.

Nylon cutting line.

Spool cover.

Cutting filament

trimming blade.

Brush cutter attachment:

Grass trimmer attachment:

- 12-

7.1 PACKAGING

Carefully remove the products from the packaging and examine them for any sign of damage that

may have happened during shipping. Lay the contents out and check them against the parts shown

below. If any part is damaged or missing; please contact the Draper Helpline (the telephone number

appears on the Title page) and do not attempt to use the product.

The packaging material should be retained at least during the guarantee period: in case the

machine needs to be returned for repair.

Warning! Some of the packaging materials used may be harmful to children. Do not leave any of

these materials in the reach of children.

If any of the packaging is to be thrown away, make sure they are disposed of correctly; according

to local regulations.

7.2 WHAT´S IN THE BOX?

As well as the 4-in-1 garden tool, there are several parts not fitted or attached to it.

Harness strap.

Saw chain.

Guide bar.

Cutting attachment guard and fittings.

Brush cutting blade.

Cutting filament line spool.

Extension pole.

2-stroke mixing bottle.

Spark plug spanner.

Combination spanner.

2 × hex keys.

Screwdriver.

Outer flange.

Flange cover.

Blade retaining nut.

Saw chain sharpening file.

7. UNPACKING & CHECKING

- 13-

8.1 FUELLING – FIG.1

This Draper petrol product is powered by a engine

which MUST be filled with unleaded fuel MIXED with

2-stroke oil. Failure to add oil or incorrectly mixing the

oil and fuel can result in running problems or engine

failure. Any machine returned under warranty which is

found to have failed due to a lack of lubrication will be

considered a chargeable repair.

Only use fresh, clean, and good quality unleaded fuel

mixed with synthetic 2-stroke oil in a ratio of 25:1.

Before attempting to fuel this machine, make sure you

have completely read and understood the safety

instructions.

Danger! Fuel is highly flammable.

– Open the fuel cap by turning it anticlockwise. Hang it to one side so that it does not block

the opening.

– Combine fuel and 2-stroke oil to create a 25:1 mixture.

Example: Add 40ml of synthetic 2-stroke oil in to 1,000ml (1 litre) unleaded fuel and shake

well to produce a 25:1 mix.

Fuel quality degrades rapidly: Avoid storing fuel by mixing only what you require.

Using fuel that has degraded will cause starting/running problems.

– Carefully pour the mixture into the fuel tank filling it while taking care not to spill or waste

any. Have a rag to hand to clean away any residue or spilt fuel.

– Replace the fuel cap making sure it is seated

properly before tightening clockwise. If the threads

become crossed it will damage the tank. It may also

result in fuel leaking out during use and potentially

causing a fire risk.

8.2 HARNESS ATTACHMENT - FIGS.2 - 3

The harness is supplied to help reduce user

fatigue.

– Pass your head and right arm through the

harness and position the attachment point

by your right hip.

– Make sure the Dring is clipped on to the

attachment point .

– Pass the harness bracket through the D

ring and push the flat pin in place to

lock.

FIG. 1

FIG. 3

FIG. 2

8. PREPARING THE 2-STROKE MOTOR UNIT

- 14-

9.1 FITTING AND REMOVING THE CHAIN

AND GUIDE BAR - FIGS.4 - 6

Caution! Take care when handling the chain as it is

sharp.

– With the engine stopped, remove the 10mm nut

anticlockwise, followed by the drive sprocket

cover .

– Adjust the chain tension adjustment screw

until the tensioning pin is approximately in the

midway position.

– Hold the guide bar up and beginning at the

nose [tip] lay the saw chain in to the groove.

Make sure the nose sprocket teeth sit correctly

between the chain links (Fig.6).

– Fit the guide bar with the saw chain on to

the locating stud . The chain links on the top of

the guide bar must have the arrow pointing away

from the housing. If there is no arrow marking visible

on the chain, mount it as shown in (Fig.7).

– Replace the drive sprocket cover and the

10mm nut and tighten securely.

When the chain begins to wear, the cutting

performance will reduce. Have the chain sharpened or

replace it with an identical one.

To remove the chain and guide bar:

– With the engine stopped, loosen the 10mm nut

anticlockwise.

– Turn the chain tension adjustment screw

anticlockwise to loosen the strain on the bar.

– Remove the 10mm nut anticlockwise,

followed by the drive sprocket cover .

– Lift the guide bar with the saw chain off

the locating stud and tension pin and

away from the drive sprocket .

9.2 TENSIONING THE CHAIN - FIGS.7 - 9

When fitting a new chain, check and adjust it regularly

until the initial stretch has been taken out [this is

normal].

– With the engine stopped and the 10mm nut

(Fig.4) finger tight, hold the tip of the bar up.

– Turn the chain tension adjustment screw (Fig.5)

clockwise until the chain pulls tight on the bottom of

the bar.

FIG. 6

FIG. 5

FIG. 7

FIG. 4

9. PREPARING THE ATTACHMENTS

- 15-

9. PREPARING THE ATTACHMENTS

– When correctly adjusted it should be possible

manually run the chain around the bar and pull one

complete chain link clear of the groove.

9.3 CHAIN OIL - FIG.10

– A continuous flow of oil on to the guide bar and

chain must be provided at all times. This oil

lubricates the chain around the bar preventing it

from over heating and seizing up.

– Turn the oil reservoir cap anticlockwise to

remove it.

– Fill the reservoir with chain oil. Do not use any

other type of new or used oil. Chain oil is

specifically designed for the job and is not harmful to

the environment.

– Replace the oil reservoir cap tightly, turning it

clockwise.

9.4 FITTING THE BRUSH CUTTER/GRASS

TRIMMER GUARD - FIG.11

All guards must be fitted and fully operational before

using this machine.

– Snap the guard over the output shaft

collar .

– Drop the spring washer followed by the flat washer

over the end of the 5mm hex. socket bolt.

– One side of the guard has a hexagon

shaped recess in which the 10mm nut sits.

– Pass the bolt through the guard from the other side

[guiding it under the curved end of bracket and turn

it clockwise to engage it with the nut.

– When the attachment is fitted the guard should be

position directly between the spool and your legs.

Using a 5mm hex. key tighten the guard so that it

does not move freely.

FIG. 9

FIG. 11

FIG. 8

FIG. 10

- 16-

9. PREPARING THE ATTACHMENTS

9.5 FITTING THE COMPLETE SPOOL

ASSEMBLY - FIG.12

– With the engine stopped, locate the spindle locking

point .

– Using the hex. key supplied , lock the spindle to

stop it from turning. It may be necessary to turn the

spool assembly before the hex. key fully engages all

the way.

– Screw the spool assembly clockwise on to the

spindle making sure the threads are not crossed.

– Tighten the spool before removing the hex. key from

the spindle lock.

9.6 FITTING THE BRUSH CUTTING

BLADE: - FIG.13 - 14

– With the engine stopped, locate the spindle locking

point (Fig 12).

– Using the hex. key supplied , lock the spindle to

stop it from turning. It may be necessary to turn the

spool assembly before the hex key fully engages all

the way (Fig 12).

Before fitting, match the direction of rotation arrow

on the blade with the one on the guard.

– Sit the blade on the spindle making sure the

inner flange is the right way round.

– Replace the outer flange and flange cover

.

– Start the blade nut anticlockwise before

tightening it

– Remove the hex. key from the spindle lock.

9.7 CONNECTING THE ATTACHMENTS

- FIG.15

– Before attempting to start the engine, this

attachment must be correctly assembled to the

engine output shaft's, power take off.

– Make sure the locking handle is loose by

turning it anticlockwise a few turns.

– Pull back on the positioning pin and move it to

one side, clear of the hole.

– Slide the attachment shaft inside the power

take off collar of the engine unit.

– Line up the holes in both shafts before locating

pin .

– Tighten the locking handle clockwise to secure

the two sections together.

FIG. 12

FIG. 14

FIG. 15

FIG. 13

- 17-

10. STARTING THE 2-STROKE MOTOR UNIT

Do not attempt to start this machine until you have

read and understood all the safety instructions.

10.1 STARTING THE ENGINE

- FIGS.16 - 18

Warning! In an emergency, slide the engine stop

switch forward to kill the engine.

– Slide the engine stop switch backward.

– Grip the front handle and squeeze and hold the

throttle lock button whilst at the same time

depressing the throttle safety lever and throttle

. When slowly released, the throttle should

be held in its start position by throttle lock button

.

Cold starts – close the choke to restrict the amount of

air entering the engine. Slide the choke lever

to

the OFF position.

Warm starts – open the choke to increase the amount

of air entering the engine. Slide the choke

lever

to the ON position.

– Prime the engine with fuel. Press the fuel primer

3 or 4 times. The primerand fuel line from the tank

should have fuel present.

Attention! Over priming will cause the engine to

flood with too much fuel. This will engulf the spark

plug and stop the engine from starting. There will

be a stronger smell of fuel when this occurs.

– Grip the neck of the motor unit with your left hand

holding the machine firmly on the ground. Crouch

over the machine while maintaining firm footing.

Attention! Do not stand or apply any pressure on to

the output shaft.

– With your right hand hold the pull start handle .

– Make 2 or 3 short, sharp pulls of the starter or until

the engine starts. If the engine does not start by the

fifth crank, move the choke setting.

Warning! Do not pull the starter rope out fully as it may

break. Do not release the starter rope and allow it to recoil unaided.

– When the engine starts, pull throttle lever

to release the 'start' position.

– When the engine has been running for a few minutes open the choke fully.

Attention! The majority of engines have an initial period in which the internal components bed

themselves in. This engine is no different. During this the first 5 or 6 tank fulls [bedding in period],

running the engine in the very high rev. range must be avoided as the stresses involved can cause

damage to the engine.

FIG. 16

FIG. 17

FIG. 18

- 18-

FIG. 19

FIG. 20

11. OPERATING THE TREE PRUNING ATTACHMENT

11.1 ADJUSTING THE OIL FLOW - FIG.19

Check the flow of chain oil. See how much is thrown

from the tip of the bar at full throttle on to a piece of

clean white paper. A light spray of oil should be cast on

to the paper. If it appears excessive or too light, adjust

as necessary.

– With the engine stopped, adjust the oil flow

adjustment screw clockwise to increase the flow

or anticlockwise to decrease it.

– Start the engine and test the flow again. When

sufficient is being thrown from the tip, the adjustment

is complete.

– A reservoir full of chain oil will run dry long before the engine runs out of fuel. Continually check

the oil level during use, refilling the reservoir before it is empty.

11.2 WORKING TECHNIQUES - FIGS.20 - 21

Beware of hidden objects. Check there are no cables or other objects hidden within the tree

branches that will damage this machine or cause injury if cut by the pruner.

– This machine must not be used in any circumstances that cause it to be within 15M of overhead

power lines.

– Before beginning any overhead work, the ground must be cleared first. Remove any debris that

is likely to trip or obstruct a quick exit to safety. You must plan an 'escape route' should anything

fall suddenly.

– Inspect the condition of the tree. Check that there are no loose branches that are likely to fall

unexpectedly as a result of what you intend cutting. Check for signs of decay within the tree that

may cause part or all of the tree to fall on you.

Do not attempt to cut wind fallen trees or timber.

– Work systematically starting from the lowest branches first. This prevents falling branches from

becoming hung.

– Do not work in windy conditions as this increases the risk of personal injury.

– Remove the transport guard before starting the engine.

Warning: Before cutting, make sure the chain is correctly fitted and tensioned.

DELIMBING

The best practice is to cut branches in to manageable sections.

Due to the weight of the branch on it's self, simply

cutting through from top to bottom will result in it

splitting along the branch damaging the tree. An initial

relief cut on the underside, followed by a final cut from

above will stop this from happening.

– Position the cutting head near the tree limb making

sure it is not touch any other branches.

– With the saw chain running at full speed, begin

cutting the underside of the branch using the chain

on the top of the guide bar. Cut approximately one

third of the way through. Beware of hidden branches

as contact with the tip can cause the saw to

kickback.

- 19-

First

cut

Final

cut

11. OPERATING THE TREE PRUNING ATTACHMENT

– Finish cutting down through the remaining two

thirds. Let the chain do the cutting:

Do not force it!

– Safely and quickly get out of the way from the

falling debris.

– Small branches can be removed in one cut.

– Do not cut too close to the trunk as it creates a

larger diameter 'wound' and takes longer to 'heal'. It

can also speed up the spread of decay. A 'wound'

will 'heal' fine without the need for any treatment.

– The guide bar and chain are consumable items.

11.3 HAZARDS - FIGS.22 - 24

There are several dangers specific to cutting timber

with a saw chain.

Kickback is the term used to describe the reaction

when the tip of the guide bar is thrown upwards in an

arc. On a chainsaw this is very dangerous as it is

generally thrown up toward the users face; however, on

this type of machine it can still be hazardous and result

in a loss of control or injury.

The chain is driven out, away from the head, along the

top of the guide bar. If the chain stops suddenly

[pinched by the limb being cut] within the kickback

zone it will drive the guide bar back and upward in the

opposite direction.

Pull-In is the result of the chain becoming pinched

along the underside of the guide bar, the reaction doing

as the name suggests, whipping the machine away

from you. To avoid this, make sure the chain is running

at full speed before starting the cut.

Generally, the best way to avoid these hazards are:

– Maintain a sharp and correctly tensioned chain.

– Cut one branch at a time.

– Avoid all other branches while performing the cut.

– Butt the housing up to the branch.

– Begin the cut only with the chain at full speed.

– Concentrate at all times and firmly grip the machine

with both hands.

If the machine remains trapped in a partial cut stop the

engine. Support the weight of the machine while trying

to lift [or pull down, depending on the side of the chain

trapped] the branch to release the chain.

FIG. 21

FIG. 22

FIG. 23

FIG. 24

Kickback

zone

Direction of

Kickback

Direction

drive

Kick Back

Push Back

Kick Back

Pull-in

- 20-

Other manuals for GTP33

1

Table of contents

Other Draper Lawn And Garden Equipment manuals

Popular Lawn And Garden Equipment manuals by other brands

Fieldmann

Fieldmann FZK 2004 E manual

Wolf Garten

Wolf Garten Li-Ion Power 60 Original operating instructions

Rowlinson Garden Products

Rowlinson Garden Products Shiplap Patio Chest Assembly instructions

red roo

red roo DHS9-5 operating instructions

Worx

Worx WG801E manual

Simplicity

Simplicity 4572 Illustrated parts list