- 8 -

OPERATION AND USE

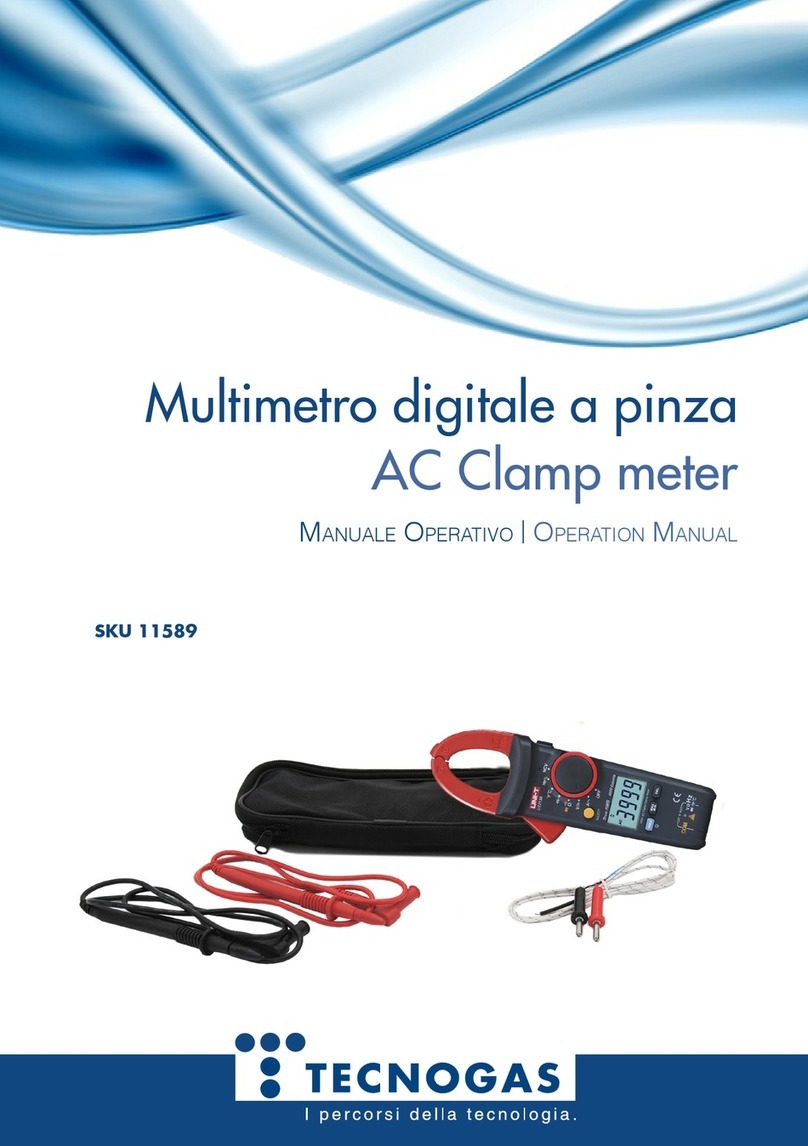

-WARNINGS: Each time before you use this instrument, inspect the test leads, connectors and

probes for damage, e.g. cracks or breaks in the insulation. Any defective leads should be

replaced by a qualified person. If the voltage to be measured is not known, set the selector

switch to the highest range and reduce until a satisfactory reading is obtained.

- DC VOLTAGE MEASUREMENT:

1. Connect the red test lead to the ‘V/ ’ jack socket and the black lead to the ‘com’ jack

socket.

2. Set the selector switch to the desired DCV range.

3. Connect the test leads to the circuit to be measured.

4. Turn on the power to the circuit to be measured, the voltage value should appear on the

digital display along with the voltage polarity (if reversed only).

- DC CURRENT MEASUREMENT:

1. Connect the red test lead to the ‘10A’ jack socket and the black lead to the ‘com’ jack socket

(max 10A).

2. Set the selector switch to the 10A range.

3. Open the circuit to be measured, and connect the test leads in series with the load to be

measured, see Fig.2 on page 7.

4. Turn on the power to the circuit to be measured, the ‘current’ value should appear on the

digital display.

- RESISTANCE MEASUREMENT:

- WARNING - If the resistance to be measured is part of a circuit, turn off power and discharge

all capacitors before measurement.

1. Connect the red test lead to the ‘V/ ’ jack socket and the black lead to the ‘com’ jack

socket.

2. Set the selector switch to the desired OHM range.

3. Connect the test leads to the circuit to be measured.

4. The resistance value should now appear on the digital display.

-TACH (RPM) MEASUREMENT:

- IMPORTANT: For detailed and concise information on the correct use of this tool always refer

to the vehicle manufacturer’s service handbook.

1. Connect the red test lead to the ‘V/ ’ jack socket and the black test lead to the ‘com’ jack

socket.

2. Set the selector switch to the desired TACH range.

3. Connect the red test probe to the breaker points or the ‘-’ terminal on the ignition coil.

4. Connect the black test probe to the ‘-’ terminal of the battery or ground. Refer to Fig.1 on

page 7.