Curved Onyx by Draper Page 2 of 3

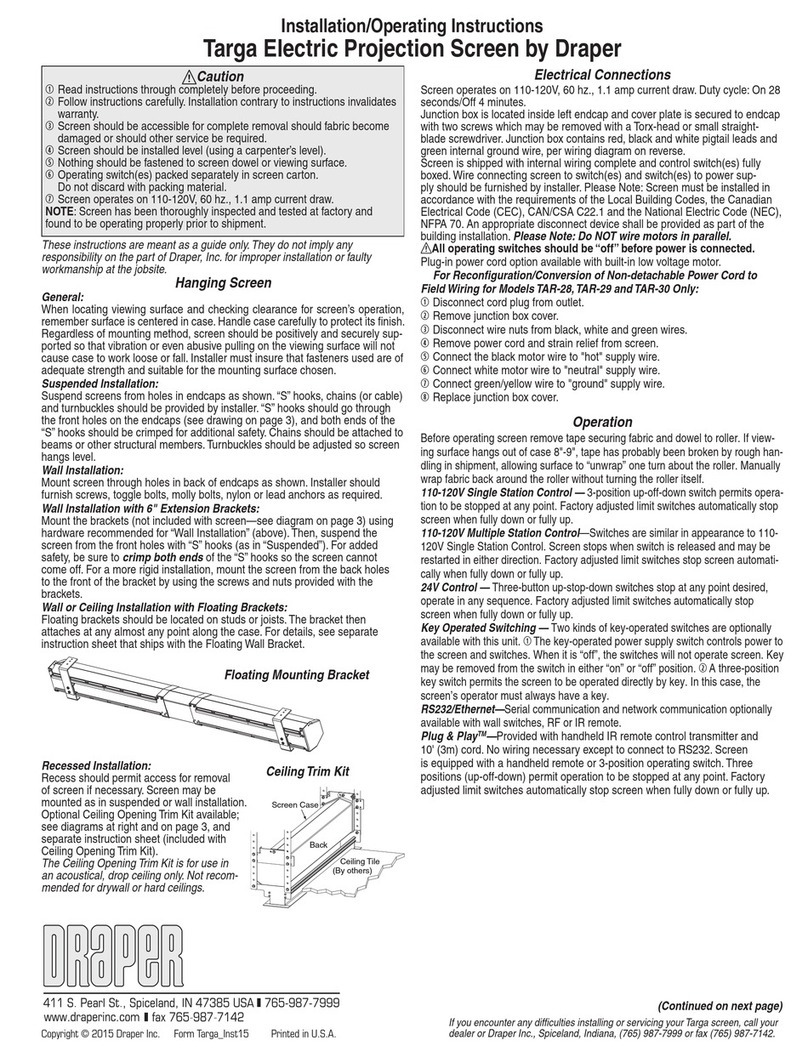

Figure 8

Mounting Screen to Wall

1Determine height at which screen is to be mounted.

Please Note: Top edge of screen frame will be located 1.5"above mounting

bracket hole centerline when mounted to wall.

2Mark hole centerline so that brackets can be mounted parallel and at equal

height.

3Install brackets so that the outermost edges are safely within the overall

length of the aluminum frame extrusion to allow for minor horizontal screen

adjustments. Installer is responsible for providing attachment hardware.

4The bottom center bracket on the Curved Onyx acts as a locking bracket.

Slide the center plate up, then push the screen back against the wall,

releasing the center plate. The tongue on the center plate will then slide

down into the frame extrusion, locking the frame in place.

5Position screen slightly above brackets on wall.

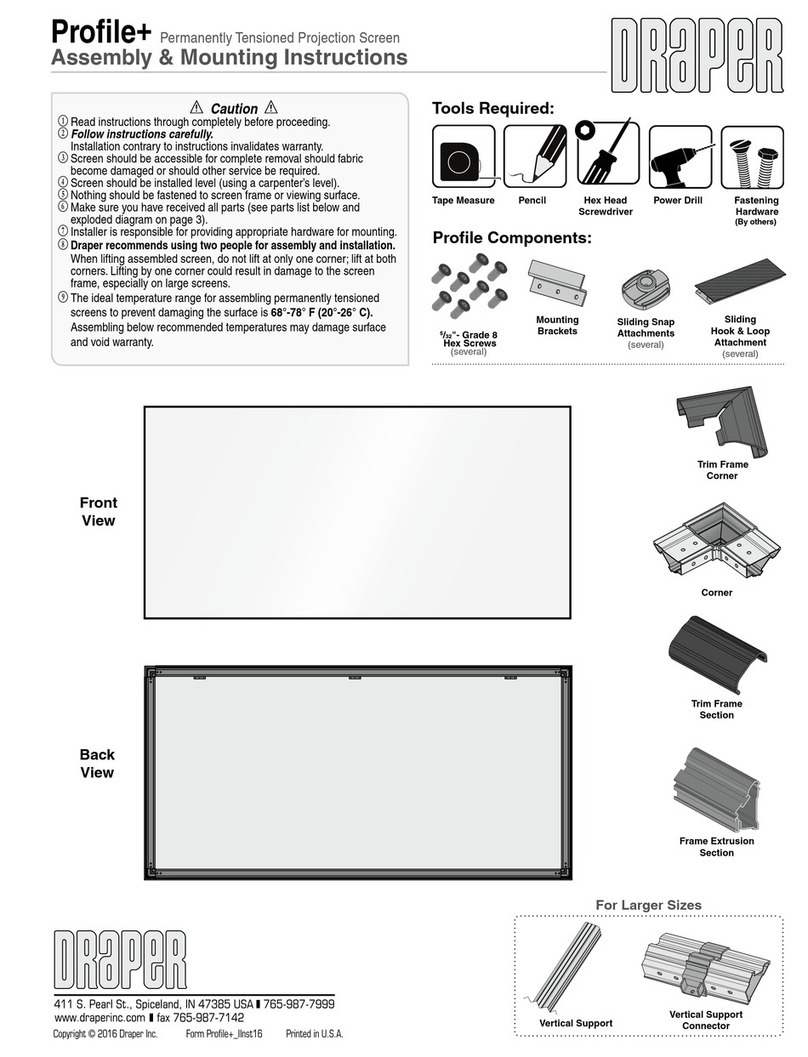

Surface to Frame Assembly

1Return frame onto clean surface, face down, and drape completed surface

assembly over completed frame profile with rounded edges of surface

retention extrusions visible.

2Hook surface retention extrusions on any side of surface to notch #2 on

corresponding side of frame extrusion (see Fig. 8).

Figure 10

6Lower screen until it engages over brackets. Center screen horizontally

on brackets as necessary.

Please Note: Make sure screen is installed level.

Figure 6

Surface Preparation

1Move frame assembly out of the way, unroll viewing surface and place on

smooth/clean surface. (Orient viewing surface so that folded side of hem is

visible.)

2Insert plastic tubing inside pocket formed by hem on all 4 edges of viewing

surface (see Fig. 6).

3Divide surface retention extrusions up so they will be evenly spaced all the

way around the screen.

4Carefully slide surface retention extrusions (rounded edge visible) along

hem and onto surface on all 4 edges of fabric (see Fig. 7). Caution: Do

not allow fabric to snag on ends of extrusions. If the screen

fabric is not parallel with the surface retention extrusion, then

it may slit and tear during installation.

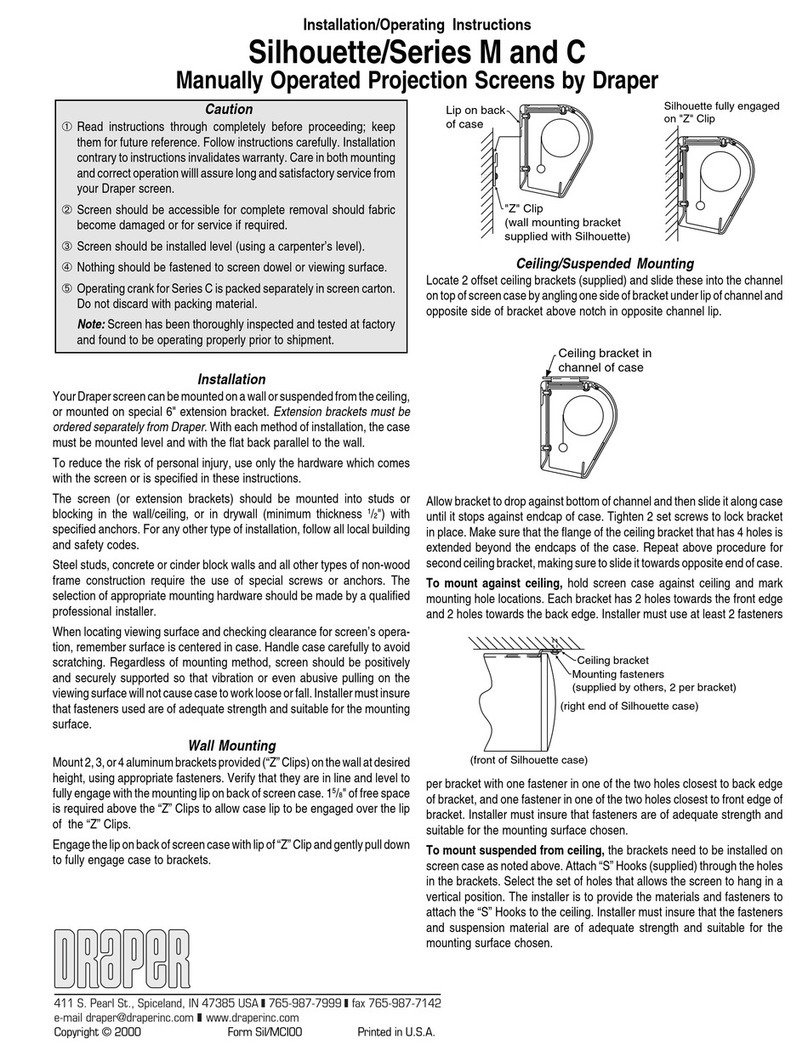

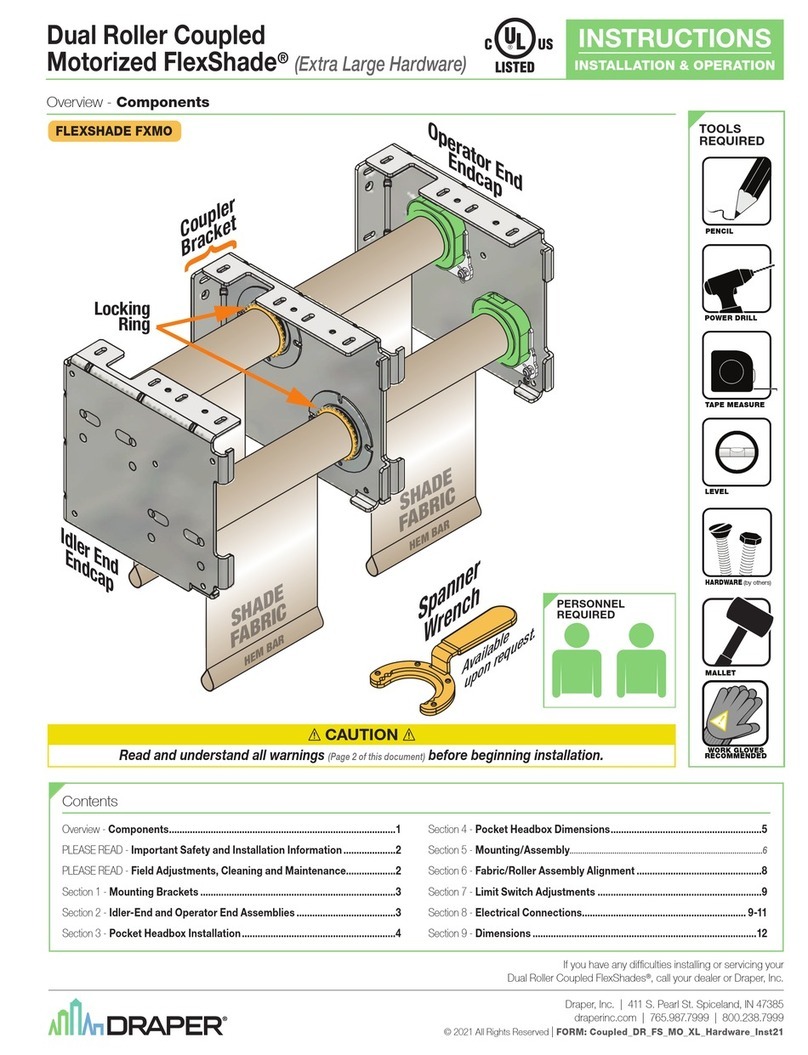

Figure 7

Plastic Tubing

Surface Retention

Extrusion

Back of

Viewing Surface

Surface

Retention

Extrusion

Fabric Attachment Extrusions

Viewing

Surface

Notch #1

Notch #2

Notch #3

.draperinc.com (765) 987-799

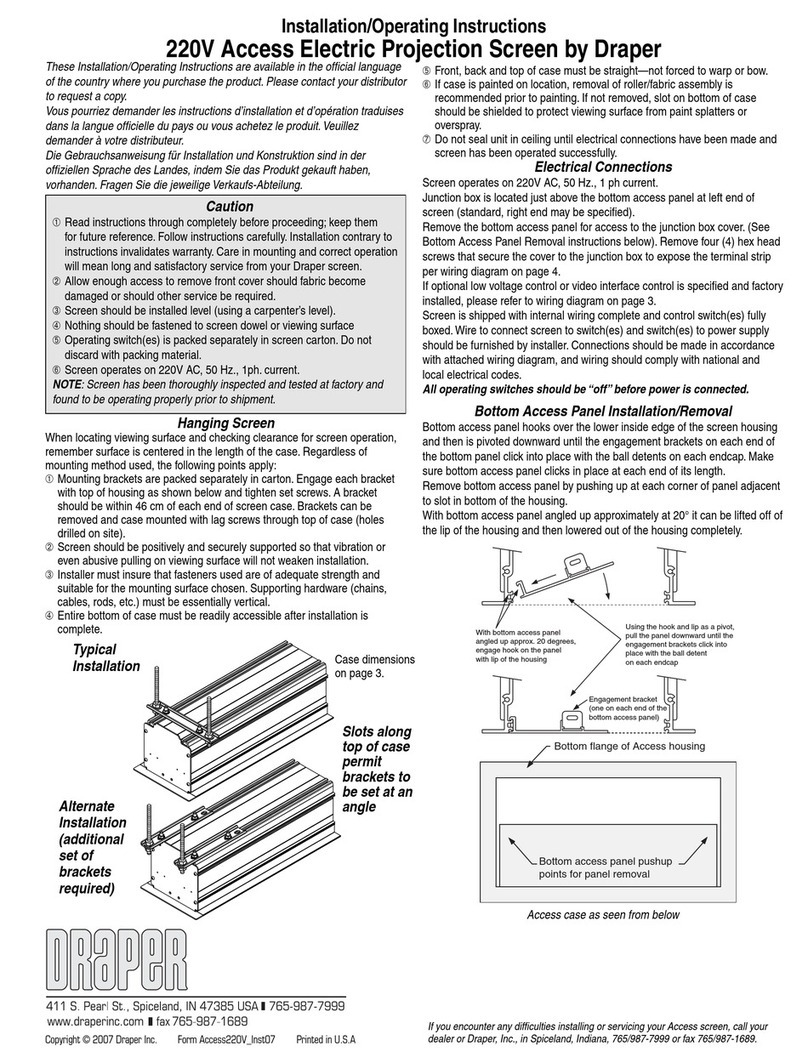

Corner Reinforcement Kit (Part No. 253696)

1If screen is being flown (suspended), or is 120" (viewing area) or larger in

height or width, install Corner reinforcement Gussets to all four corners

(see Fig. 9)

Figure 9

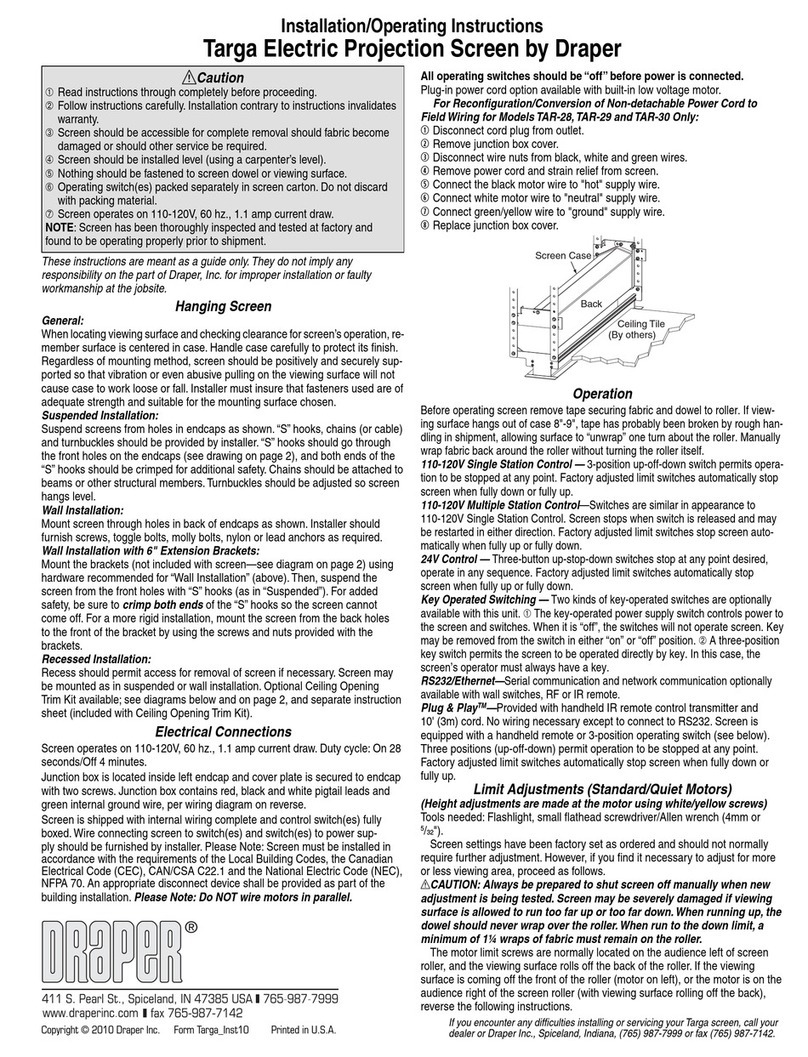

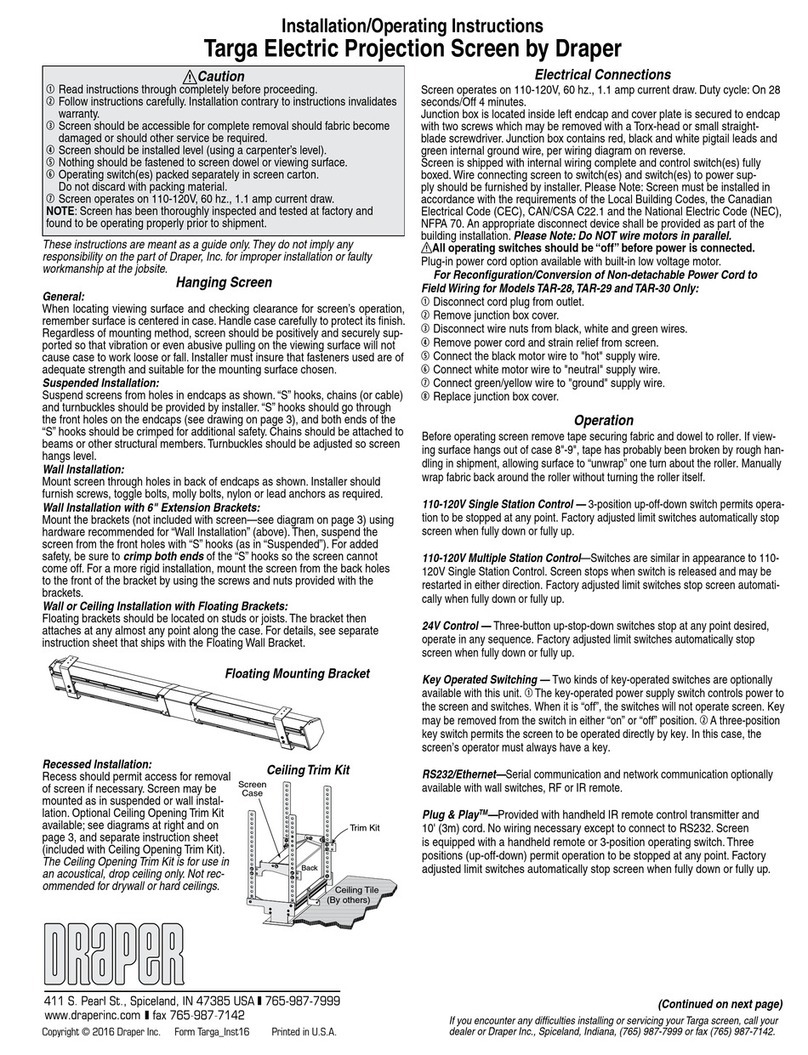

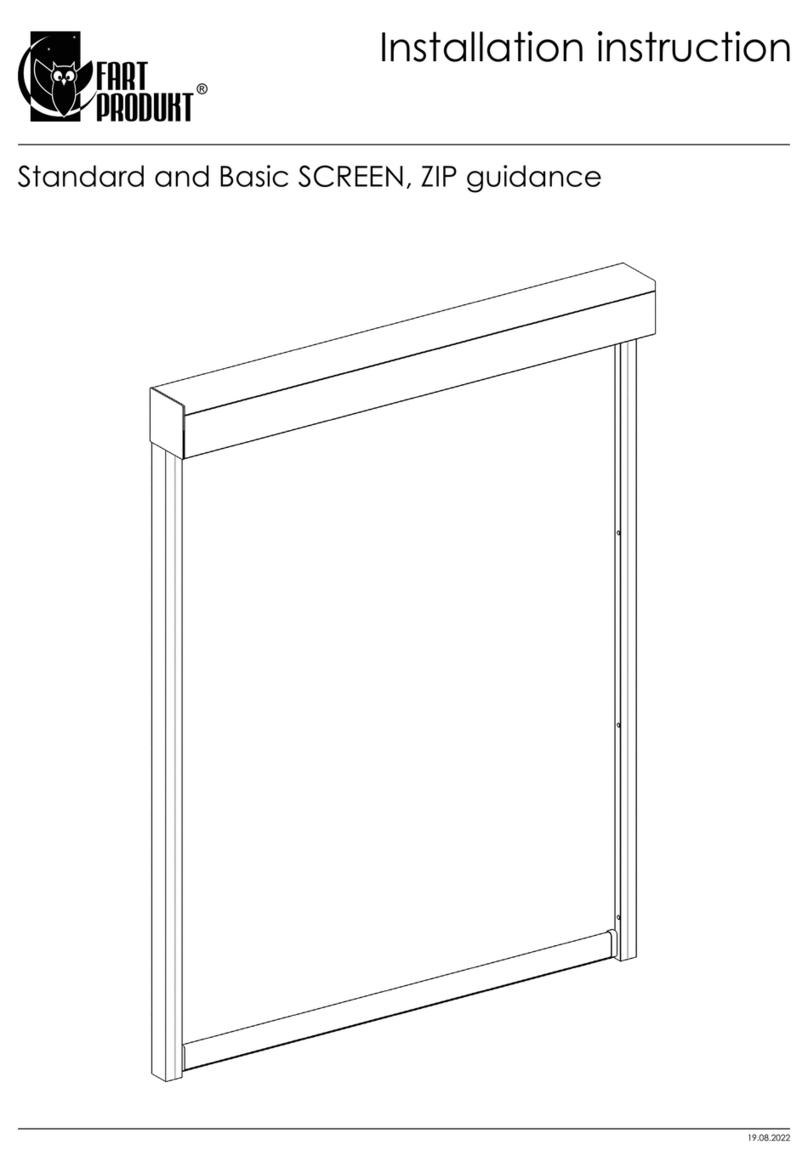

Onyx Brackets

Outer Brackets Center Brackets

To p

Bottom

(locking)

C264.049SA

C501.324

C501.325

C501.326

Please Note: To make this step easier, pinch the end of the pocket closed

before sliding it into the surface retention extrusions.

5The top and bottom of the screen should have the ssame number of

surface retention extrusions. The two sides should also have the same

number. This will allow even spacing all the way around the screen.

.6Verify that all surface retention extrusions are installed with rounded edge

visible and are centered on surface material.

3Repeat on opposite side of surface, again using notch #2.

4Repeat steps 2-3 with remaining edges of surface.

5Ensure surface retention extrusions are centered lengthwise in tension

slots on all 4 edges of surface.

6If additional tension in certain areas of the screen is desired, adjust surface

retention extrusions to notch #1 or #3 as necessary.

Please Note: It is not necessary to adjust more than one edge at a time to

increase surface tension.