18 19

EVERY 6 WEEKS WHEN NECESSARY

Version 3.0

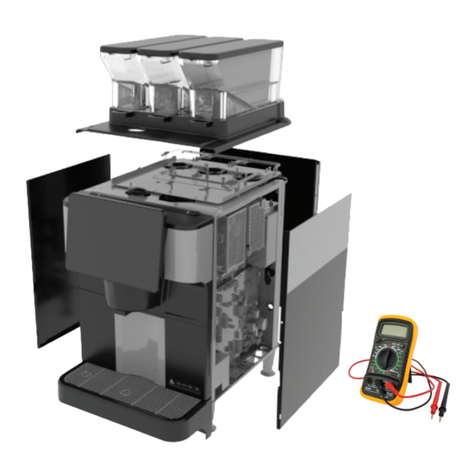

MODULAR 20 CLEANING CYCLE

01

Remove the empty

container.

04

Fit the filter on the suction

hose and pass the tube

through the stopper

of the container.

02

Remove the stopper

of the new container.

05

Screw the stopper

and tube onto the

container.

03

Clean the filter, the valve and the

suction hose: Use hot water only.

Do not use detergents.

Wear protective goggles.

06

Position the detergent

container in its specified

location. The cleaning cycle

can now begin.

3. FILLING THE LINES WITH BEER

2. RINSING PROCEDURE

1. CLEANING PROCEDURE

1 Place a sign at the tapping point that indicates that a cleaning cycle is in progress.

2 Open the water inlet valve.

3 Press the Clean button ( ).

4 At the tapping point, open the taps one by one.

5 The pipes are emptied of beer and detergent starts to emerge. It is green. Close the tap and open the

next one. Repeat this procedure for all taps. Repeat the procedure from the first tap until the colour

of the detergent is purple (it may be necessary to repeat the procedure more than once for an indivi-

dual tap). NOTE During the cleaning procedure, the container for the mixture is cyclically filled

and the flow of detergent is stopped for approx. 40 seconds as it fills. This is a normal part of the

procedure – do not close the tap and the cleaning procedure will continue.

6 When the detergent changes colour and becomes purple at all taps and the display flashes,

wait at least 20 minutes before moving on to phase 2.

7 Move on to phase 2.

NOTE Only detergent approved by Carlsberg may be used. The use of any other detergent could

damage the system and cause safety issues.

In the final phase, the lines are drained of water and prepared for tapping of the beer.

1 Press the beer button (X).

2 Close the water inlet valve ( ).

3 Open the taps one by one.

4 Water comes out first, followed by beer.

5 Now you can begin tapping the beer.

NOTE Remember to note the date of every cleaning cycle on the report.

SAFETY STANDARDS

If the detergent accidentally comes into contact with the eyes, rinse immediately

with plenty of water and, if necessary, consult a doctor. If possible, show them the

label / Wear protective clothing, gloves and a mask to protect the face and eyes /

The liquid detergent and its container are to be treated as toxic waste.

1 Press the rinse button ( ). This mode stops the flow of detergent and rinses the lines with

water. This rinsing procedure must be carried out accurately to ensure that every residue of

detergent is removed before moving on to the next step. Allow the water to flow until it is

completely clean and transparent.

2 The display flashes when the rinsing procedure is finished. Move on to phase 3.

NOTE The rinsing procedure can also be used separately to rinse the system with water

before the complete cleaning cycle.

REPLACING THE DETERGENT CONTAINER

The display flashes alternately blue and green. The container for the mixture is filled in beer

mode > the water valve is not closed correctly.

If the machine temperature rises above 65°, the compressor switches o and a thermometer

symbol appears on the display.

The process is stopped if there is insucient detergent in the container during cleaning.

For the procedure to resume, check the detergent container and the peristaltic pump.

The display flashes alternately red and white.

If cleaning is due while the machine is in operation, the beer block alarm appears on the display.

The display flashes alternately red and white.

The display flashes alternately red and white.

1 The compressor doesn't start due to an unstable current.

2 The compressor continues to function for 15 minutes, causing loss of air

or a malfunction of the pressure sensor.

If the display flashes alternately red and white:

1 The peristaltic pump is blocked.

2 The peristaltic pump is defective.

If a cleaning procedure is overdue, an alarm is shown on the display and the beer block

is activated. If it is not possible to carry out a cleaning procedure, the system permits

an additional day once only. The display flashes alternately red and white.

Close the valve/water inlet tap. Clean the water valve with compressed

air and, if necessary, contact Carlsberg Technical Customer Services.

The compressor restarts when the temperature goes below 50°.

Replace the detergent container.

Carry out a cleaning procedure.

Restart the machine. Contact Carlsberg Technical Customer Services

if the problem persists.

Check the pump and, if necessary, contact Carlsberg Technical

Customer Services.

Carry out a cleaning procedure immediately.

IF THE PROBLEM PERSISTS DESPITE THE ABOVE INSTRUCTIONS,

PLEASE CONTACT CARLSBERG TECHNICAL CUSTOMER SERVICES.

MODULAR 20 SOLVING TECHNICAL PROBLEMS

SCREEN WARNING CAUSES SOLUTION

Version 3.0

6.5 APPENDIX E

CLEANING CYCLE