4 American Metal Ware P300 & 400 Shuttle®Brewers

Installation (continued)

Unpacking Instructions

Carefully unpack the machine and inspect immediately

for shipping damage. The packaging may contain un-

attached parts. Your machine was shipped in a carton

designed to give it maximum protection in normal

handling. It was thoroughly inspected before leaving

the factory. In case of damage, contact the shipper, not

Grindmaster-Cecilware.

NOTICE: The person installing this appliance is

responsible for ensuring that electric and water

connections meet the requirements of the national

electric code, national plumbing code, and any local

ordinances.

See rough-in drawings on previous page for dimensions

and locations of electric and water input.

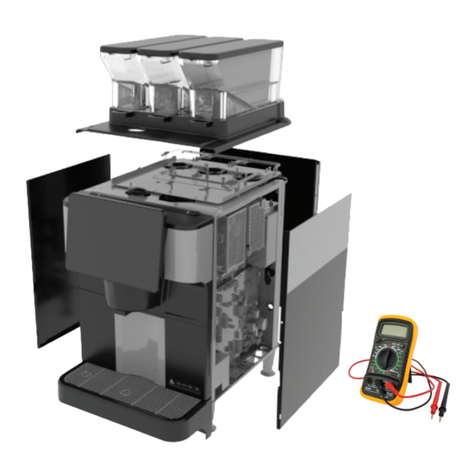

The electric and water hook-up locations are behind the

front panel. Remove the four screws fastening this

panel for access to these connections.

Mechanical Installation

NOTICE: This brewer should be installed by a

knowledgeable and experienced commercial

equipment installer.

1. Inspect unit to see if any damage occurred in

shipment.

2. Remove the brewer from the packing material and

attach its legs.

3. Position the brewer on a strong, stable table or

counter.

4. With bubble level, check to see that the brewer is

level on countertop. Check the level front to back

and side to side. Adjust the legs to the correct level.

Water Hook-up

NOTICE: This equipment must be installed in

compliance with applicable Federal, State and/or Local

plumbing codes having jurisdiction. This product

requires an approved back flow prevention water

device, such as a double check valve, to be installed

between the machine and the water supply. Incoming

pressure should be greater than 30 psi and not more

than 80 psi (207 - 552 kPa).

1. The water line may enter through holes on the rear

or the bottom of the brewer. Use the right hand

opening for water.

2. Use 3/8" copper or flexible water line to prevent

strain. Do not use low temperature plastic tubing.

The connection to the fill valve is 3/8" flare.

3. Prior to installing the brewer, flush out the water

line by running approximately 1 gal. of water into

a pail. This will ensure no sediment from a new

installation can get in the brewer.

4. Water line pressure must be from 30 to 80 psi (207

- 552 KPa).

5. Hot (up to 160°F) or cold water may be used. Hot

water offers faster recovery between brews.

6. Make sure brewer is unplugged. Connect the water

line to the brewer with the hose connector.

7. Install a shut-off valve near the brewer.

8. Installing a filtering system can improve the taste of

brewed coffee and extend the life of the brewer. If

your water has high calcium (lime), chlorine, or iron

content, this is especially important. The filter

should be the lime inhibiting type if cold water is

used. Contact your local water treatment

professional regarding the type of filter you should

use based on water quality and volume of water

used.

Electrical Hook-up

NOTICE: This equipment must be installed in

compliance with applicable Federal, State and/or Local

electrical codes having jurisdiction. Do not use

extension cords. Make sure that the outlet the brewer

plugs into is grounded.

1. The electric ratings for your brewer are printed on

its nameplate. Typical electric ratings are:

Standard 120/208V, 5.0kW, 24A or 120/240V

6.6kW, 28A, 1 phase

Optional 120/208V, 3.8kW, 18A or 120/240V

5.0kW, 21A, 1 phase

If the brewer includes the three heater tank option

C21A, the ratings will be different. Always check the

nameplate for correct ratings.

2. The brewer should be connected to its own circuit

with a fused disconnect switch or a circuit breaker

near the brewer.

3. Attach the appropriately sized cord to the brewer

with a cord grip for the 1 1/2" electric input

opening. The cord may enter through the rear or

bottom on the left side of the brewer. Use an oil

resistant cord such as type SO, SOO, SAO, STOO,

SEO, SJO, SJOO, SJTO, SJTOO, SJEO, HSO, HSOO,

HSJO, or HSJOO. Alternatively, flexible conduit and

type THHN wires may be used. Use only copper

conductors.

WARNING: ELECTRIC SHOCK HAZARD!

Installation of this appliance should be performed by

qualified service personnel only. Improper installation

could result in electrocution.

WARNING: ELECTROCUTION HAZARD!

Never use the ground conductor as a neutral. Do not

use ground eliminating adaptors. Unit must be

properly grounded.