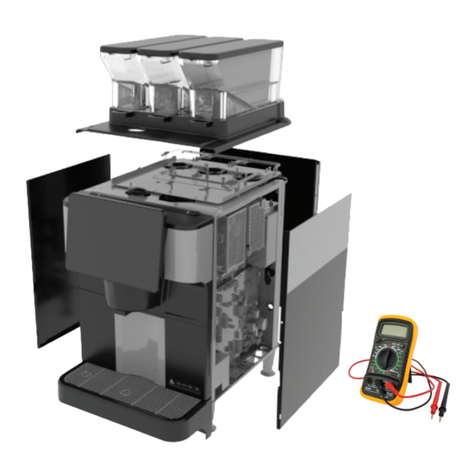

As operators start getting customers back up and running following emergency shutdown, they may be faced

with an overwhelming task. This document is to help aid with common parts that may need to be replaced

and provide some guidance on what to look for when restarting various models.

ACE, IA, FC, AK, AKH, R/L, 20:1, GX, GK, KB and NK Brewers:

Please read in entirety before restarting equipment!

Treat any recovery from emergency shutdown with more detail than a fresh install. Water levels could be

depleted and in a dry re status requiring tanks be lled before powering up (refer to installation and operation

manuals if required for specic models). If the unit is not heating after startup, the high limit could be tripped

and requires reset.

Newco does not recommend poly lines, as they can be transparent which allows light to possibly create algae

growth in the water line feeding machine if used. These lines may need to be replaced or sanitized before

feeding water into the equipment. Refer to separate attached document regarding lters (Pentair) and start

up procedures before turning water lines back on. Water left in equipment can be drained and replaced.

Further evaluation may be required to identify if sanitation is required.

If wanting to drain tanks, disassembly is required. Contact technical support group for assistance if not familiar

with process. Open tank systems (Ace, IA, FC, KB and R/L) can all be turned over to drain after removing top

cover and tank lid. Disconenct machine from power and water supply line before emptying water. Closed

tank models (AK, 20:1, GX, NK, GK) can require more disassembly to drain. Check for any discoloration or odor

in the dispensed water indicating that sanitization is required.

If equipment was started up without draining, cycle the brewer 3-4 times to cycle water that was in brewer.

Further inspection inside tank might be required to identify if there is any sanitation required. The baskets

and dispensers used should be thoroughly cleaned and sanitized especially if left with product.

After restarting equipment, check for any discoloration or odor indication sanitization being required. Below

are common part numbers for heating circuit components and baskets.

Refer to sanitizing document for regular external cleaning to prevent surface contamination during normal

operation. 70% alcohol wipes are sucient.

Restarting Equipment after Emergency Shutdown

110985 – 12 Cup Basket

(ACE, IA, FC, AK, R/L, 20:1, KB AND NK)

701714-BLK – 13x5 basket plastic (GX)

704215 – Thermostat (Ace, FC)

110190 – EGO thermostat (AK, R/L)

100551 – Robert Shaw thermostat 5”

(alternate thermostat for AK, R/L)

500502 – Robert Shaw thermostat 8” (NK and GK)

101299 – Sun/Peco Thermostat (GX)

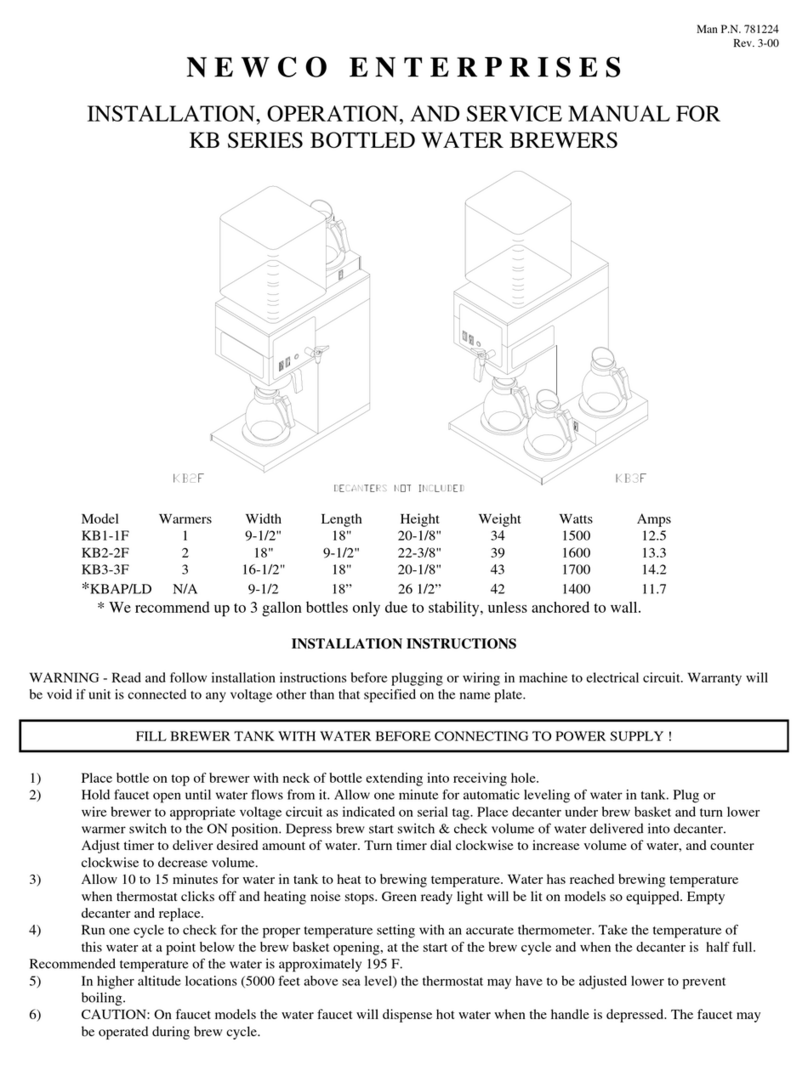

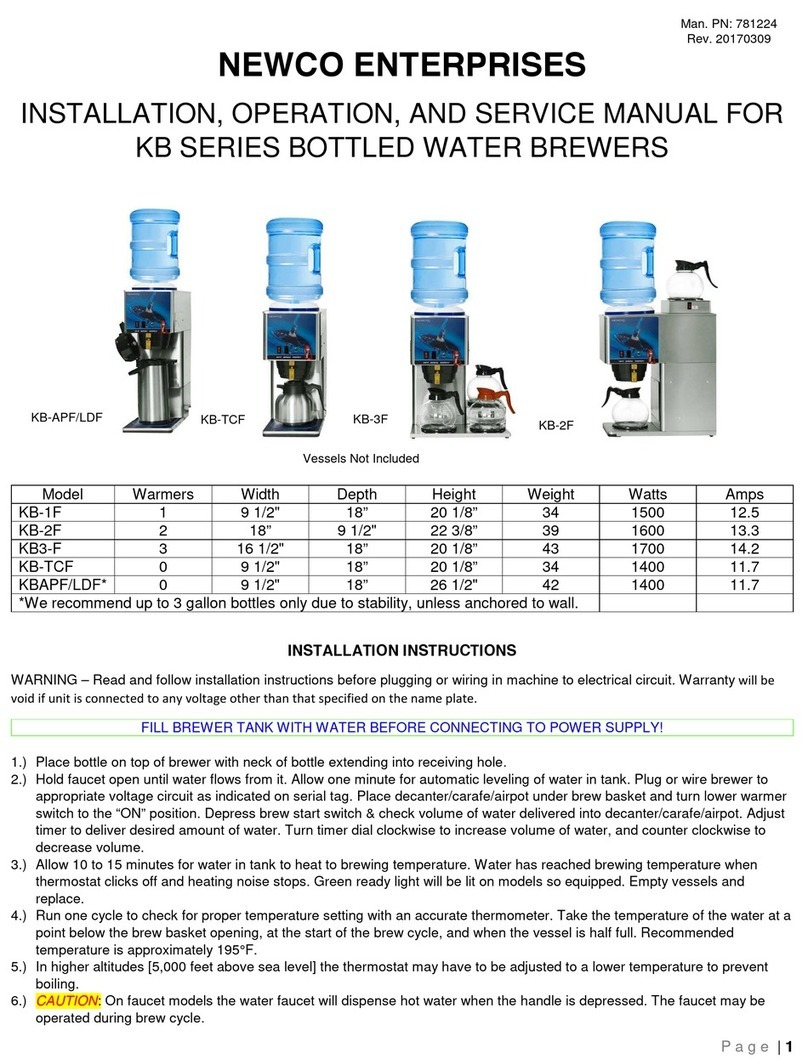

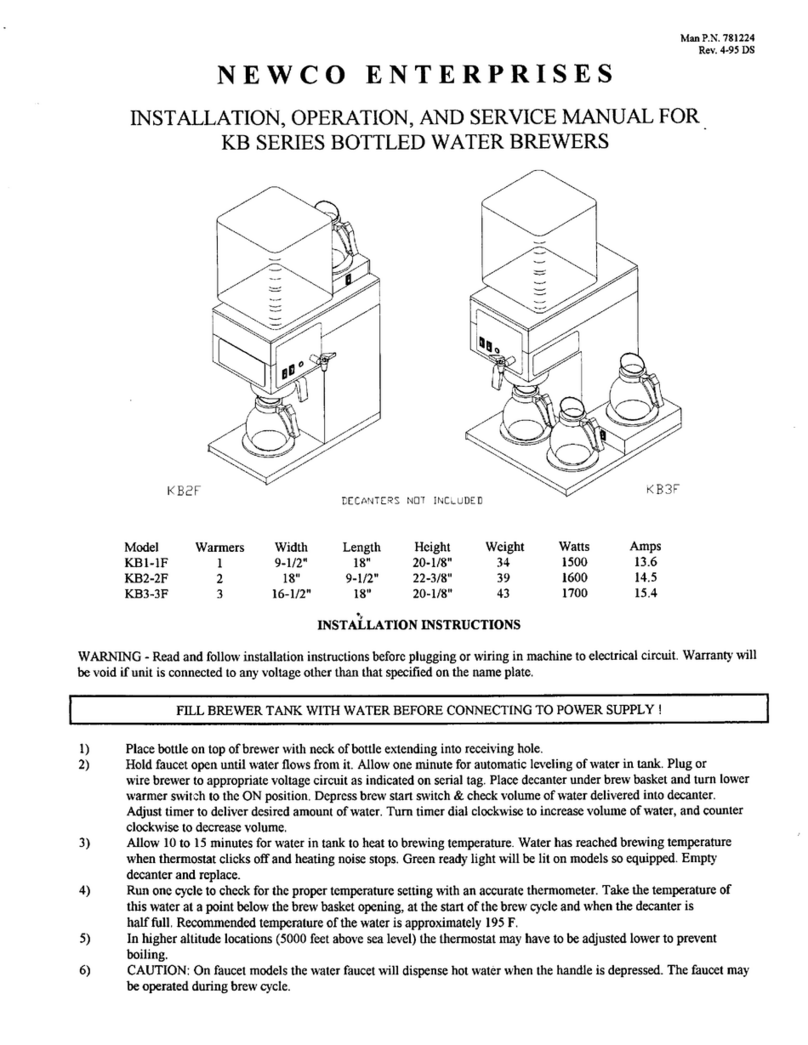

773300 – Robert Shaw 5” assly (KB)

111592 – High limit horizontal spade connection

(R/L, NK, GK, KB)

111593 – High limit vertical spade connection

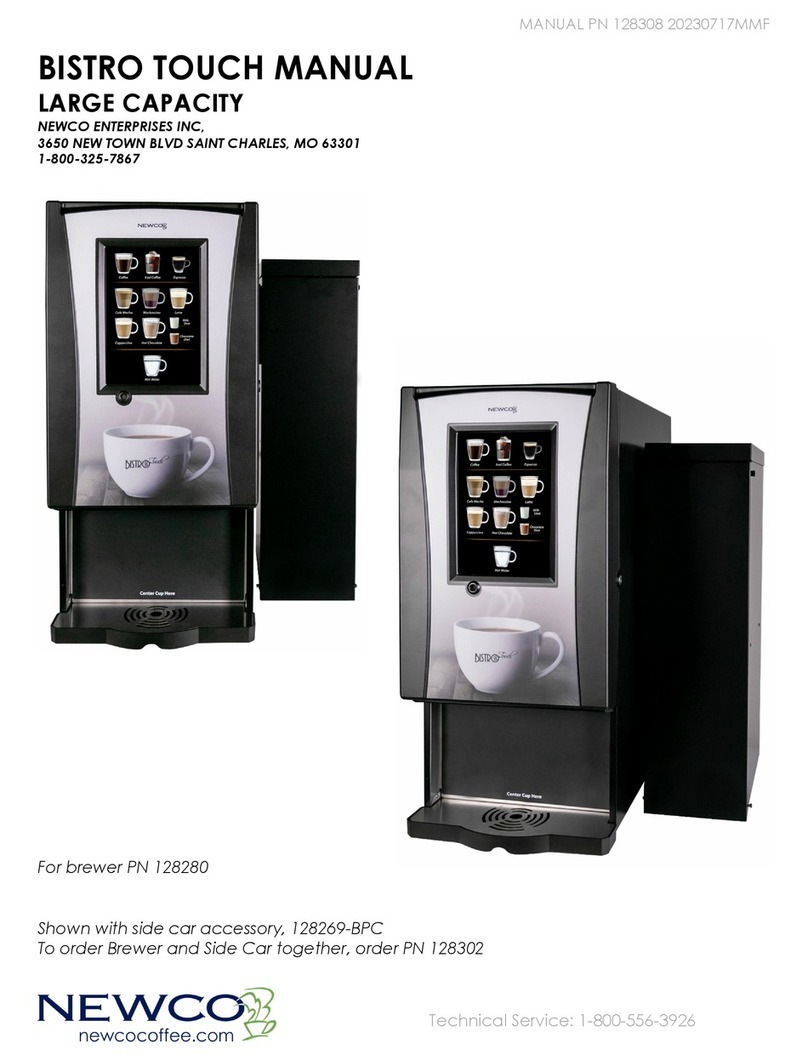

(Ace, IA, FC, 20:1, LCD, Bistro, FK, CX)

701305 – High Limit 25A (GX)