Keg King Thermentor King Operator's manual

Other Keg King Brewing System manuals

Keg King

Keg King Guten Nanobrewery User manual

Keg King

Keg King APOLLO SNUB NOSE User manual

Keg King

Keg King KegMaster Solstice User manual

Keg King

Keg King Fermenter King Junior User manual

Keg King

Keg King KegMaster 4 Series User manual

Keg King

Keg King KEGMASTER XL User manual

Keg King

Keg King King Junior User manual

Popular Brewing System manuals by other brands

Curtis

Curtis ThermoPro G4 Series user guide

Animo

Animo ComBi CB5 user manual

MoreBeer

MoreBeer BrewSculpture manual

Keurig Hot

Keurig Hot Commercial Series owner's manual

Blichmann Engineering

Blichmann Engineering BrewEasy Compact TC Assembly operation maintenance

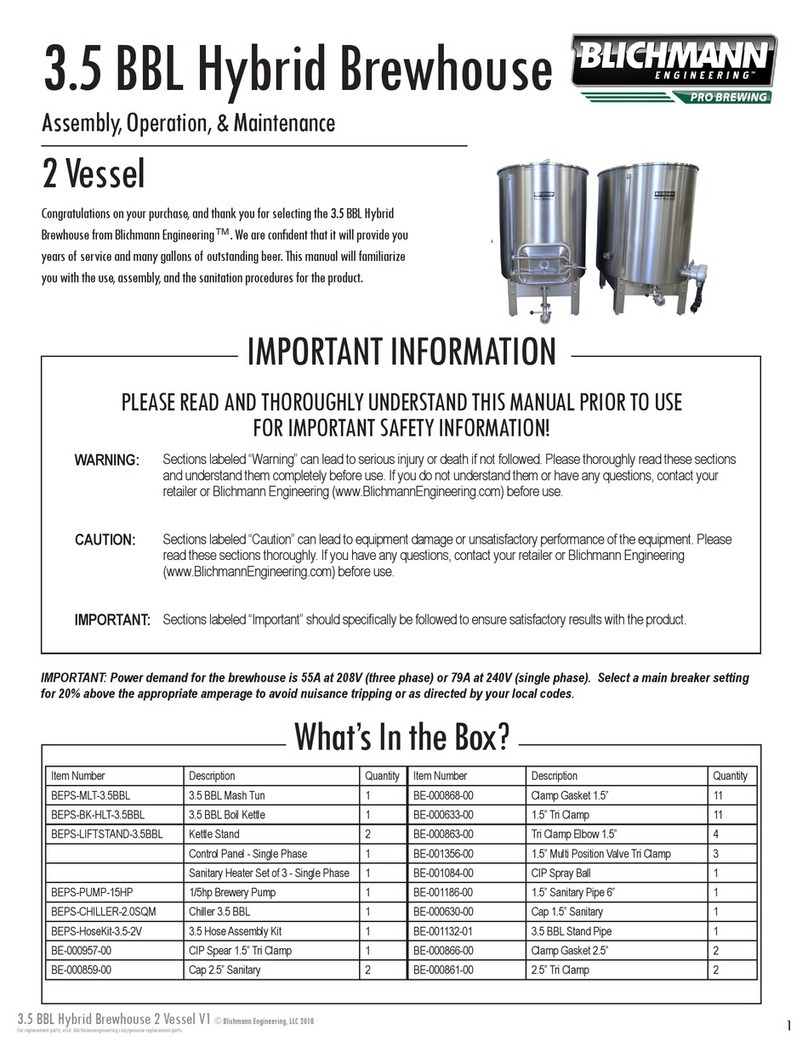

Blichmann Engineering

Blichmann Engineering 3.5 BBL Hybrid Brewhouse Assembly operation maintenance