WORT CHILLER: Used at the end of your boil to quickly cool your wort to yeast

pitching temperatures. (The included Convoluted Heat Exchanger can be used as an

immersion chiller.)

INGREDIENTS: Sounds like a no-brainer, but it’s best to ensure all grains / hops

are there prior to starng!

FERMENTERS: It’s best to have your fermenter or fermenters cleaned and ready

to sanize before you brew, but if not, have them around so they can be cleaned during

the brew.

OTHER TOOLS: Spoon, mash paddle, refractometer, note pad, etc.

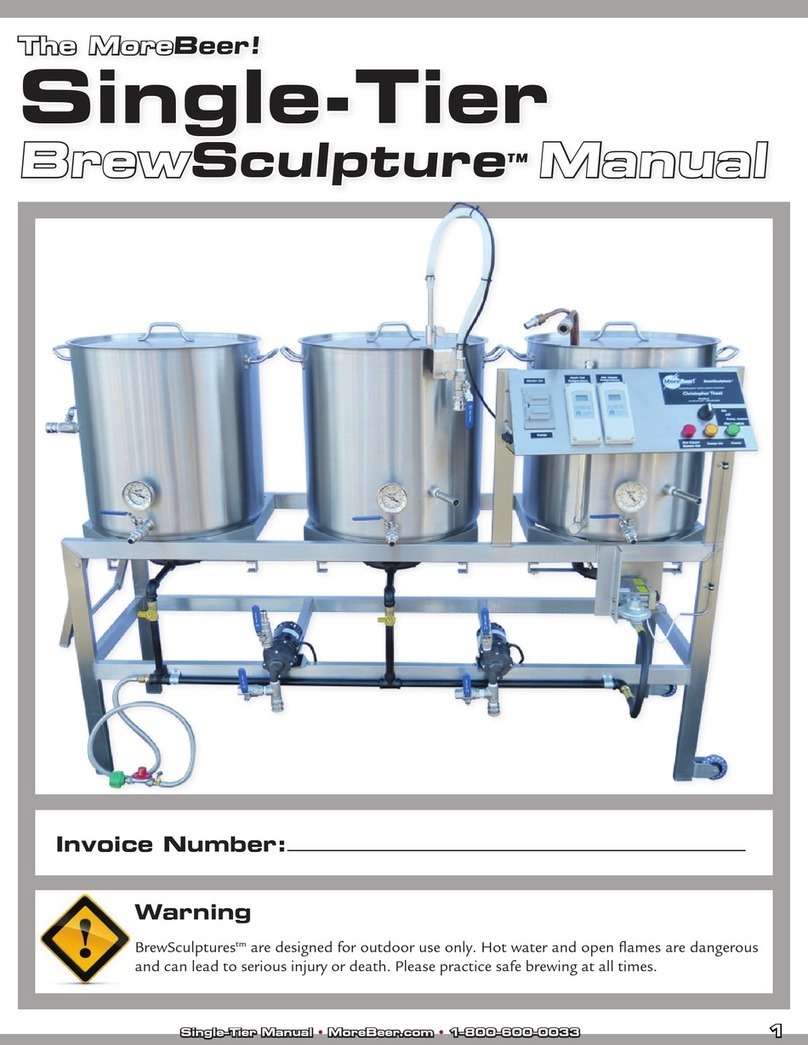

So you’ve goen your whole BrewSculpture™setup, and can’t wait to

start brewing! We’ll go through the process of doing so, and will try to

help keep your brew day as quick, easy, and ecient as possible. We

would like to start by recommending that once all of your keles have

been setup, you may want to do a water run starng with 4–5 gallons in

your mash tun and hot liquor tanks. Re-circulate the water in the mash

tun, then move the tubing around to mimic a sparge into your boil ket-

tle. This is not only done to remove any dust or stainless shavings from

manufacturing, but is also recommended so that you understand how

everything connects and ows prior to brewing with wort. Another thing

to look for while performing the water run is any leaky threads or tubing

– beer to leak water than wort!

At this point, all of your keles should be setup, and now you probably

have a couple pieces of equipment sing around. These would be your

pieces of tubing with quick disconnects, the copper heat exchanger, and

your stainless steel sparge arm. The stainless sparge arm will install on

the mash tun’s kele wall, and the height is adjustable. Make sure to

plug it into the control panel.

It’s important to have the following items ready at the start of your brew

day:

The le kele locaon is going to be where your boil kele goes. With

this kele in front of you, we’ll want to install four things: Two ball valves

and quick disconnects, the 3" Face x 2" Probe thermometer, and the

stainless steel whirlpool/maximizer. One ball valve will thread on to the

boom coupler, the thermometer will thread into the top coupler, and

the whirlpool/maximizer aach to the quick disconnect threaded into

the inside of the boom coupler’s threads, inside the kele (no plumb-

ers tape required - if it leaks it will just be leaking inside the kele). The

second ball valve will install on your whirlpool coupler.

Your pump assemblies should come with mounng brackets already

mounted to the frame. To install your pumps, simply slide the pumps’

mounng plate into the BrewSculpture™ mounted bracket. Your pump

should be installed so the “inlet” faces down towards the ground and the

pump “outlet” faces up. NOTE: The pump outlet will be labeled on your

pump head with the word “out”. The pumps will need to be plugged into

the power box on the control panel, rather than into the wall. Make sure

the “Pump” indicator on the control panel is NOT on prior to plugging in,

to avoid running the pump dry!

The wheels and control panel should come pre-mounted. If these are

not included or installed, please call our customer service department.

You will need to connect the cables from the keles to the control panel.

These are color coded for easy aachment.

Hang the boom box at a convenient place on the top rail of the stand.

Place close to your power outlet if possible. Connect the 8 pin connector

from the boom box to the control panel. Plug the two female L6-30P

plugs into your elements. The plug on the right goes to the HLT and the

plug on the le goes to the Boil Kele. Plug the male plug into your GFCI.

BREW DAY

3