Copyright 2004 Baker Hughes Company.

2 | IDOS UPM Instruction Manual–English

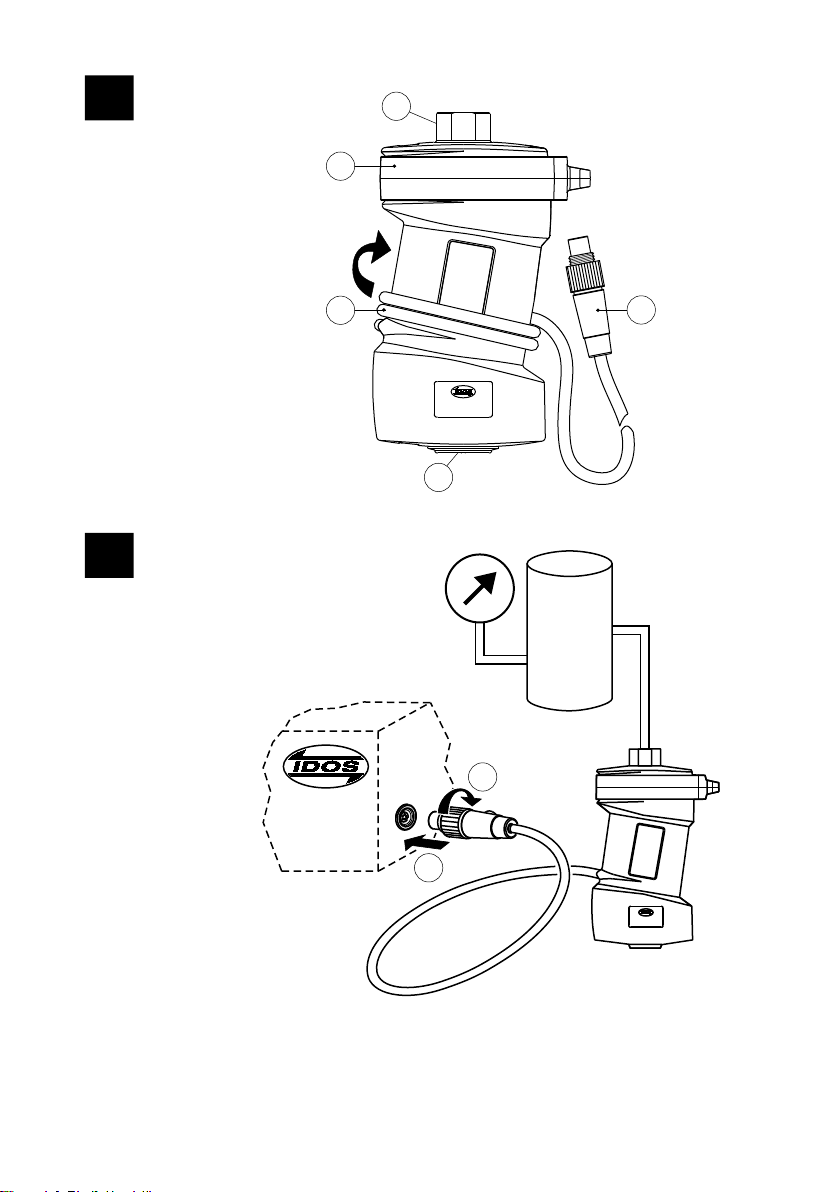

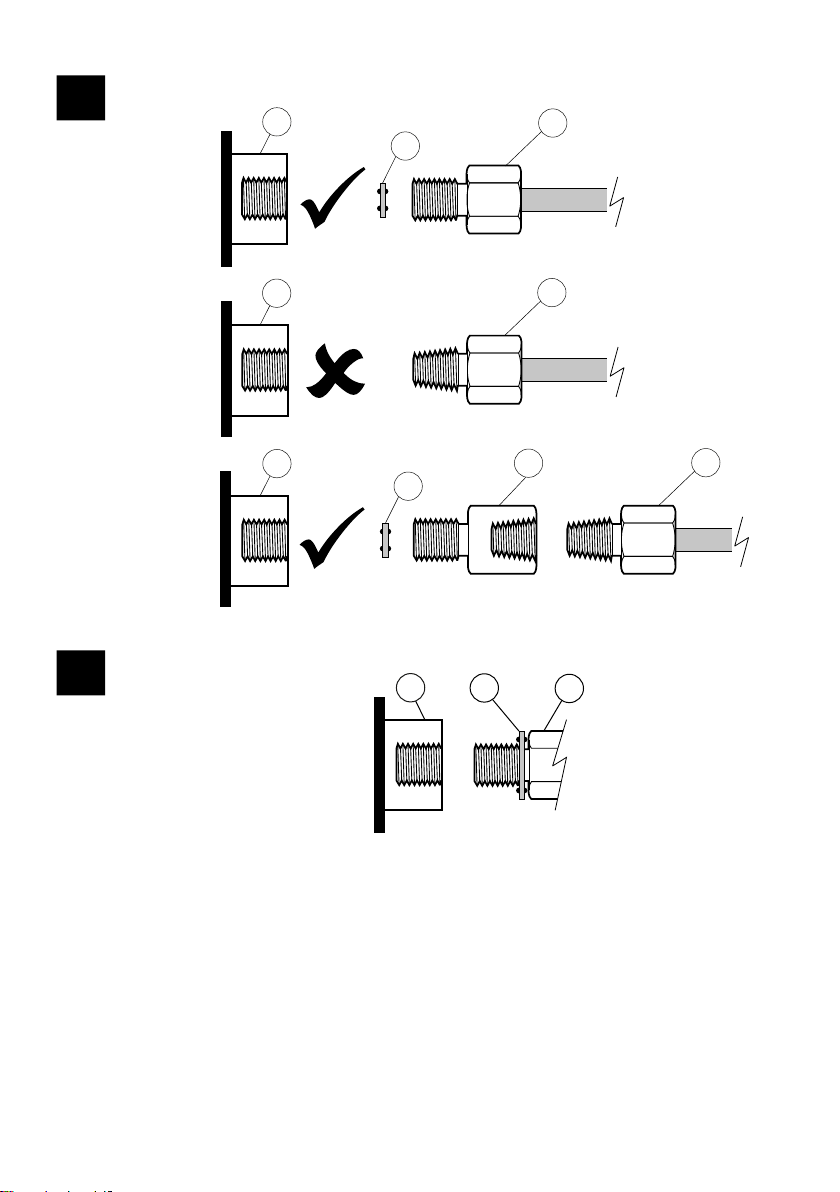

2. NPT pressure connector.

3. ISO 228/1 G1/8 pressure connector.

Pressure port connection to the UPM reference port is

shown in Figure C4.

1. UPM 1/8 reference port pressure connector. M5 or

10-32 UNF, refer to Table 3.

2. Pressure connector.

Electrical Connection

The equipment has a single electrical cable, item 5 in

Figure A1. This is for connecting to a Druck DPI 8xx series,

DPI 620G or PACE.

Pressure Safety

This equipment meets the requirements of the European

Pressure Equipment Directive 2014/68/EU for pressure

safety.

Maintenance

Clean the case with a moist, lint-free cloth and a weak

detergent. Do not use solvents or abrasive materials.

Return Goods/Material Procedure

If the unit requires calibration or is unserviceable, return it

to the nearest Druck Service Centre listed at: Druck.com

Contact the Service Department to obtain a Return

Goods/Material Authorization (RGA or RMA). Provide the

following information for a RGA or RMA:

• Product (i.e. UPM)

• Serial number.

• Details of defect/work to be undertaken.

• Calibration traceability requirements.

• Operating conditions.

Operation

Connect the UPM pressure sensor to the IDOS port of the

IDOS compatible test instrument.

The power can be on or off when you attach the UPM cable

to the test instrument.

To measure the pressure, refer to the user manual of IDOS

compatible instrument.

Calibration

Note: Druck can provide a calibration service that is

traceable to international standards.

We recommend that you return the UPM to the

manufacturer or an approved service agent for calibration.

If you use an alternative calibration facility, make sure that

it uses these standards.

Equipment and Conditions

To do an accurate calibration, you must have:

• An IDOS compatible instrument, for example: Druck

DPI 8xx series, DPI 620G or PACE.

• An suitable pressure standard (primary or secondary)

with a total uncertainty of 0.01% reading or better.

• A stable temperature environment: 21 ±1°C

(70 ±2°F).

Procedure

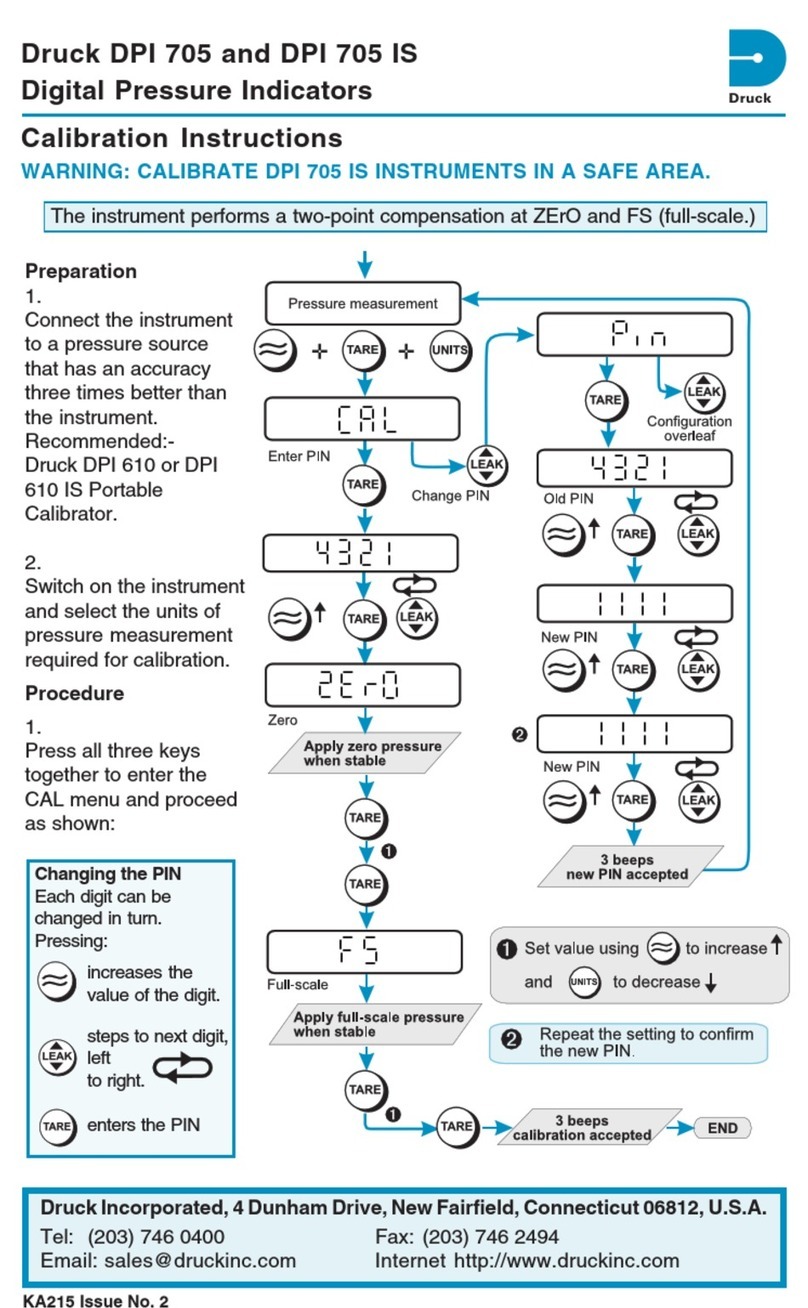

1. Connect the UPM to the IDOS instrument and to the

pressure standard, see Figure B1.

2. Allow the equipment to achieve a stable temperature.

Leave powered on for a minimum of 30 minutes.

3. Use the calibration menu on the IDOS instrument to do

a two-point calibration (Zero and +FS) or a three-point

calibration (-FS, Zero and +FS). Refer to Table 1.

4. The display shows the applicable instructions to

complete the calibration.

5. To make sure that the calibration is correct, apply these

pressures to the UPM and record the results:

• Ranges g/d or sg: 0, 20, 40, 60, 80, 100 (%FS)

a. Then: Go back to 0 in the same steps.

b. Then (three-point calibration only): -20, -40,

-60, -80, -100 (%FS)

c. Then: Go back to 0 in the same steps.

• Ranges a: 0, 20, 40, 60, 80, 100 (%FS)

a. Then: Go back to 0 in the same steps.

Standard Accuracy

The specified accuracy (refer to Specification data)

includes an allowance for temperature changes, reading

stability for one year, and the uncertainty of the standard

used for calibration.

In step 5, make sure that the error between the applied

pressure and the reading on the unit is not more than

0.015% FS.

Premier Precision

The specified precision (refer to Specification data)

includes an allowance for temperature changes and the

uncertainty of the standard used for calibration. In step 5,

make sure that the error between the applied pressure and

the reading on the unit is not more than the specified value

for Premier precision.

Specification

Pressure Measurement

All accuracy statements are for one year. The % full scale

(FS) statements for Standard accuracy and Premier

precision are only applicable if there is a regular zero

correction by the IDOS instrument.

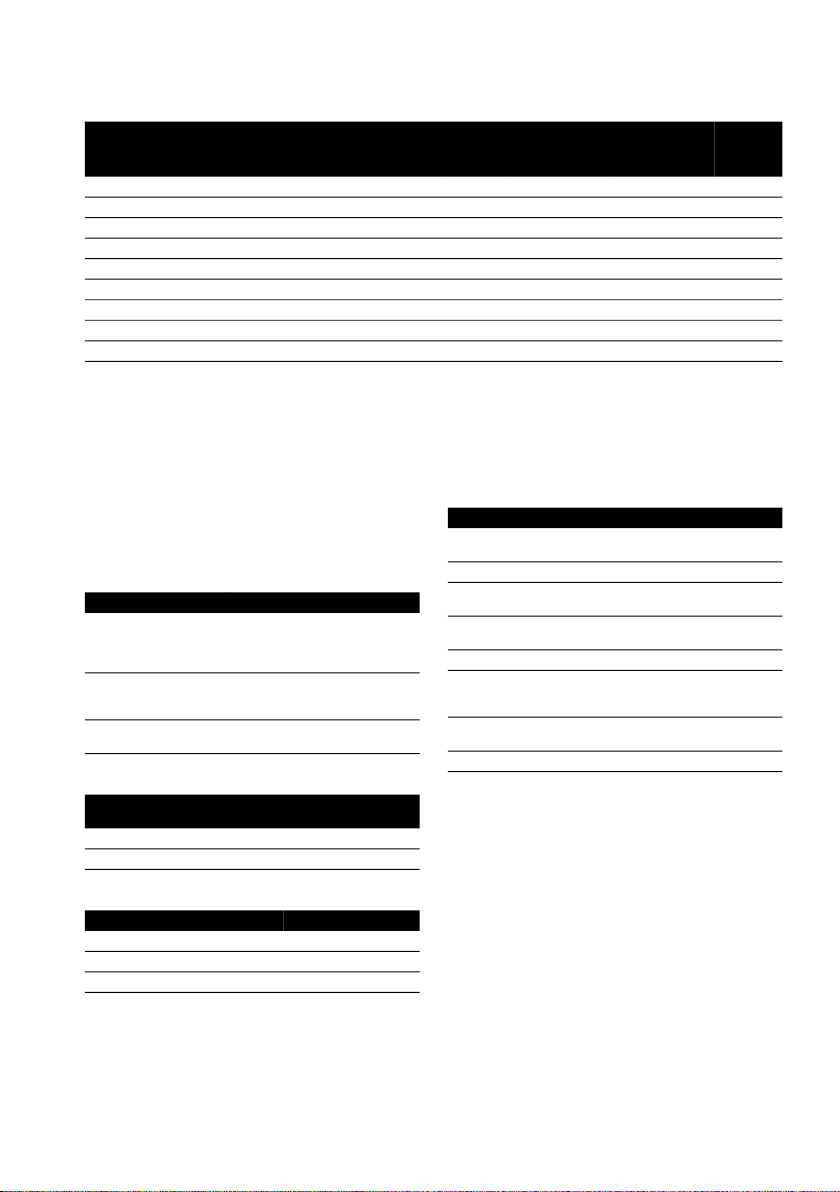

Table 1: Calibration Pressures

Type Pressure Nominal applied pressure

psi (mbar)

-FSa

a. For a three-point calibration, do not apply more than

-90% of the specified FS for the unit.

Zero +FS

g/d ≤ 10.0 psi

(700 mbar)

-FS 0 +FS

g/d > 10.0 psi

(700 mbar)

-13.1

(-900)

0 +FS

a 5.00 psi

(350 mbar)

n/a < 0.02

(1.0)

+FS

a 30.0 psi

(2 bar)

n/a < 0.07

(5.0)

+FS

a 100.0 psi

(7 bar)

n/a < 0.29

(20.0)

+FS

a 300.0 psi

(20 bar)

n/a < 0.73

(50.0)

+FS

sg ≥ 5000 psi

(350 bar)

n/a 0b

b. For sg sensors, use atmospheric pressure as zero.

+FS