[EN] English - K0463 Revision A Quick Reference 1

ATEX Approved Models

Introduction

These instructions detail the requirements for using the PV 62X-IS intrinsically safe pressure station in

a hazardous area. Read the whole publication before starting.

Application

PV 62X-IS pressure stations marked with certificate numbers Baseefa10ATEX0011X and

IECEx BAS 10.0003X are permitted for use in conjunction with DPI 620G-IS and PM 620-IS under the

“Intrinsic Safety Approval”.

Compatibility

The DPI 620G-IS series of pressure stations are not permitted for use in conjunction with DPI 620G or

PM 620.

Intrinsic Safety Approval

Marking details

Special Condition of Safe Use

• The lower ambient temperature is limited to -10°C.

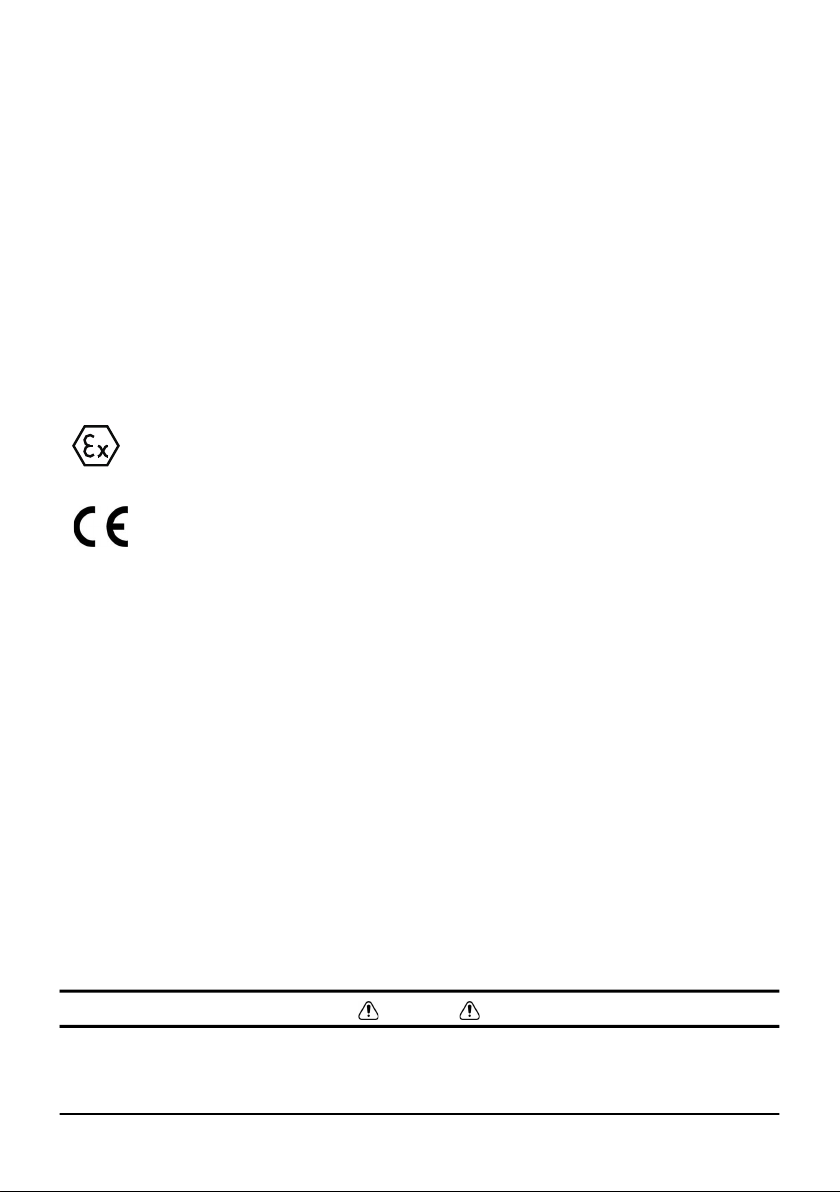

• When the PV 62X-IS Series Pressure Station is used with the DPI 620-IS Advanced Modular

Calibrator the position for the pressure transducer must be occupied with either a pressure

transducer or a dummy pressure transducer before connecting to the DPI 620-IS Advanced

Modular Calibrator and remains in position until the assembly is removed from the DPI 620-IS

Advanced Modular Calibrator.

IECEx Approvals

For the IECEx certificate (IECEx BAS 10.0003X), visit the IECEx website at: www.iecex.com

Declaration Requirements – EU Directive 2014/34/EU

This equipment is designed and manufactured to meet the essential health and safety requirements

not covered by EU Type Examination Certificate Baseefa10ATEX0011X when installed as detailed in

this guide.

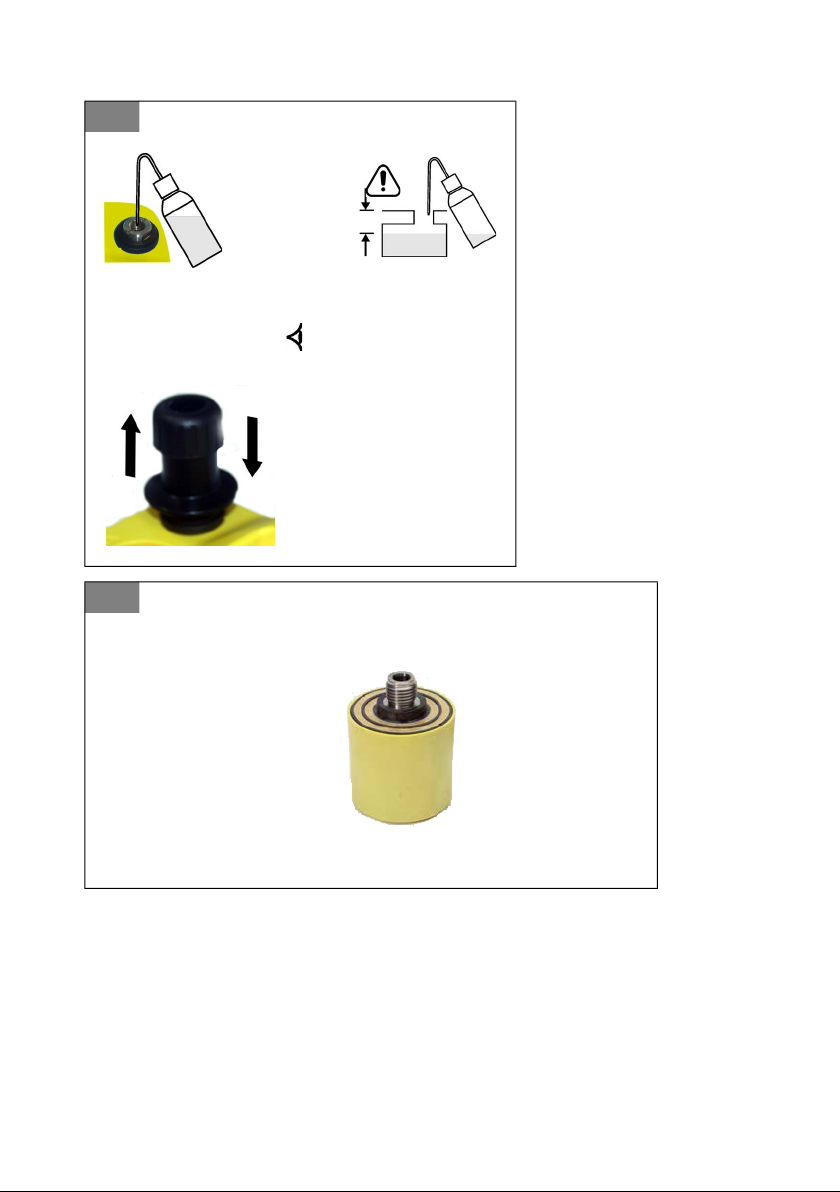

Installation

WARNING

• Do not use tools on the Pressure Station that might cause incendive sparks - this can cause

an explosion.

Baseefa10ATEX0011X.………………........................ ATEX Certificate number

II 2 G…………………...........…..…………… Equipment group & category

Ex ia IIC T4 Gb (-10°C ≤ Ta ≤ +40°C) .……............... Hazardous location markings

IECEx BAS 10.0003X…………………………............. IECEx Certificate number

####…………………………………….......... CE Mark

PV 62X-IS…............…………………….………..……. Specific apparatus type

(Pressure in bar or psi)…...........……………………… Maximum working pressure rating

Druck LTD. Groby, LE6 0FH, UK…………….........…. Manufacturer’s name and address

S/N *******……………………………………............… Serial number

DoM MMM YYYY……………………………...........…. Date of manufacture, Month and Year