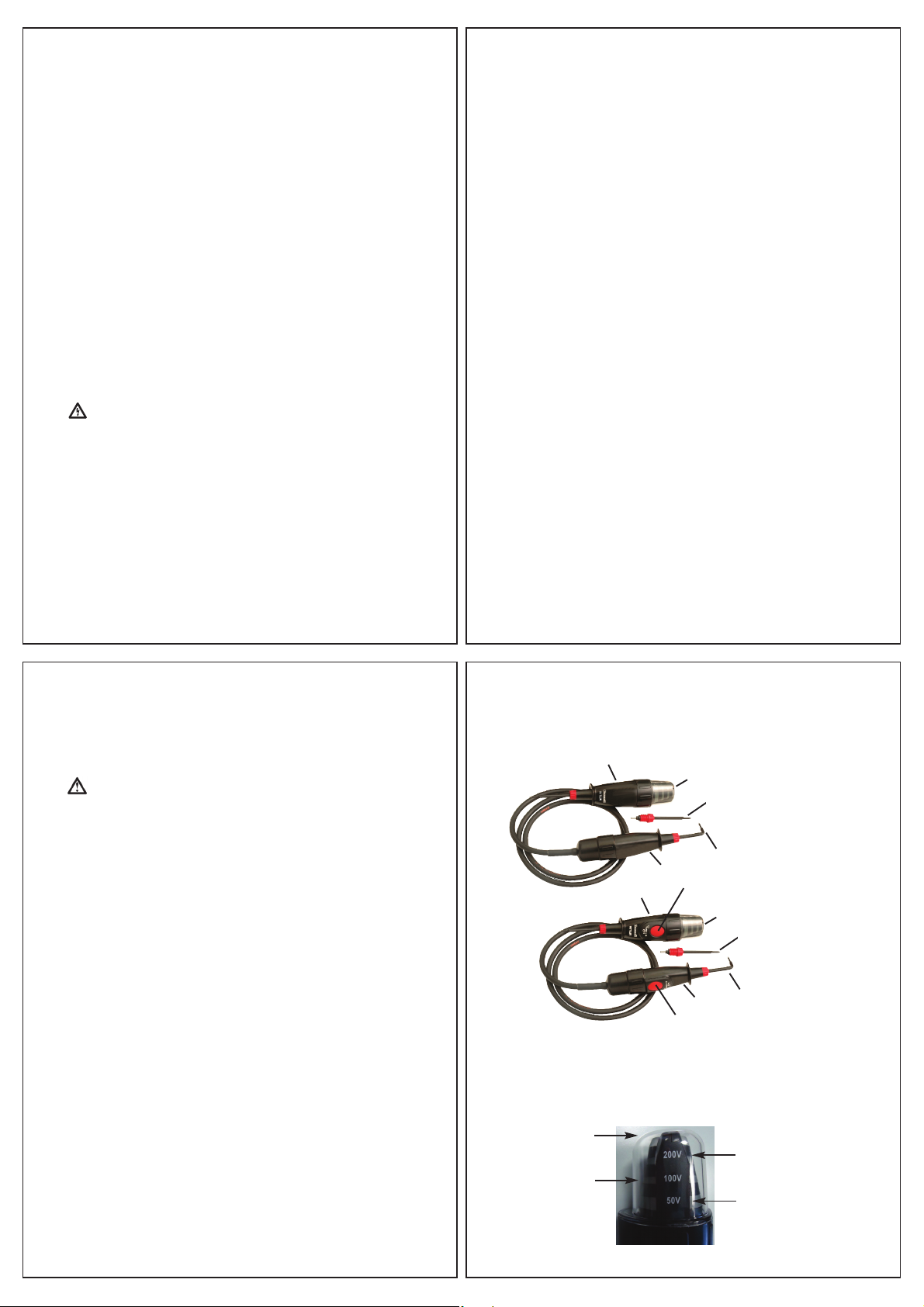

The magnitude of a voltage is indicated by the illumination of LED’s

in four separate bands around the top of the instrument body.

The nominal voltage thresholds of the indicator LED bands are 50V,

100V, 200V and 400V and are marked next to the relevant band.

The indicator LED bands will illuminate when the magnitude of the

voltage source is at a value approaching or greater than the

corresponding marked voltage. For example if the voltage source is

55V AC rms then only the 50V indicator LED band will illuminate, if

450V AC rms all four indicator LED bands will illuminate.

3.3 Operating Duty Ratio

The voltage indicator should be operated (ON) for a maximum

period of 30 seconds. This should be followed by a recovery period

(OFF) of 4 minutes.

The operating duty ratio is 8 to 1, so if the voltage indicator is only

ON for 2 seconds then the OFF period need only be 16 seconds.

3.4 Proving Check

Before and after use, verify the voltage indicator is functioning

correctly with a proving device (PD430 or PD440 is recommended),

or a known good voltage source. Do not use the voltage indicator if

any LED’s fail to illuminate correctly during proving.

Warning

If the proving device or voltage source exceeds the specified limits of

the voltage indicator the voltage indicator may be damaged and the

operator exposed to a shock hazard. Always check the specification

of the proving device or the voltage magnitude of the voltage source

before proceeding with a proving check.

6

The LED bands that illuminate during proving will depend on the

magnitude of the proving unit output or the voltage source.

For example if the voltage source is 230V AC rms then all LED

bands except the 400V LED band must illuminate. If a PD440 is

used then all LED bands must illuminate.

During this verification emphasis should also be place upon the

flexing of the voltage indicators cable along its length, and

particularly at the entry points to the hand held elements, to

confirm that the cable has not been fractured.

If using a PD430 or PD440 for proving, the press button switches

on the MTL20 can also be functionally checked. In this case when

both buttons are pressed simultaneously the 400V LED band will

cease to illuminate, indicating that the added load of the MTL20

has caused the output voltage of the PD unit to drop, thereby

proving the functionality of the switches and loading circuit.

3.5 Testing for the Presence of Hazardous Live Voltage

Warning

Hold the unit and test leads behind the finger guards in a manner

that will not obscure the voltage band indication LED’s. Never

touch the exposed metal test prods or any part of the instrument

forward of the finger guards while applied to hazardous voltages.

While taking all required safety precautions connect the test prods

across the test points where a voltage difference may be present.

The voltage level of any voltage present between the test points

will be indicated by the illumination of the relevant voltage indicator

LED bands.

7

3.6 Push Button Switches (MTL20 only)

The purpose of the push button switches on the MTL20 is to provide

additional load to the circuit under test where the presence of

interference (phantom) voltage may be suspected (see section 3.7).

Simultaneous depression of both switches (one on the probe

handle and one on the instrument body) introduces a load of

approximately 8.8kΩto the circuit being tested.

Note: Interference (phantom) voltages can rise again after the

push buttons are released. If a voltage indication re-appears on the

LED bands while the buttons are not pressed, there may be a

hazardous voltage that must be treated with caution.

3.7 Interference (Phantom) Voltage

It is possible for wiring that is ‘dead’ to indicate the apparent

presence of voltage at power frequency.

If wiring that is live is running in close proximity to the ‘dead’ wiring

being tested, there can be capacitive or inductive coupling between

the two, thereby causing interference (phantom) voltage.

Voltage indicators that draw a relatively low current when testing for

hazardous live voltage may not be able to suppress the

interference voltage to a low enough level so as not to indicate the

presence of a hazardous live voltage where there is not one.

The MTL10 & MTL20 will suppress typical levels of interference

voltage as defined by the test for interference voltage in the

standard EN 61243-3:2010.

Interference voltage that may be of a higher level than ‘typical’ may

not be suppressed by the MTL10 but should be suppressed by the

8

MTL20 when the push button switches are pressed to introduce a

higher load.

If there is any doubt as to whether a voltage indication is

hazardous live or interference, then alternative tests should be

performed.

9