TECHNO PRO™5000 OWNER’S MANUAL

2

4. Plug the unit into a grounded

alternating current circuit and switch

on the unit.

5. Secure the 40 feet pump hose to a

sink or alternative drain.

6. To use the gravity drain, connect the

hose to the fitting on the back of the

unit under the drip tray. Place the

hose into a suitable receptacle or

drain connection.

7. Residual water left in the collection

tray can be removed by using the

manual purge switch. Continue to

depress switch until all water is

removed.

8. If the unit is shut down for any

reason, allow at least five minutes

before restarting. This will avoid

damage to the compressor.

9. Assure that the fan and compressor

are properly functioning before

leaving a running unit unattended.

MAINTENANCE

Warning!

Disconnect the unit from the power

supply before cleaning or servicing.

Filter Cleaning: The filter shroud must

be cleaned after every job. The filter

itself should be vacuumed frequently to

control the build-up of soil. On a

periodic basis, the filter should be

removed completely from the unit. It

can be washed with water and mild

detergent. Allow the filter to thoroughly

dry before reinstalling it in the unit.

Coil Cleaning: As the coils accumulate

soil, their heat transferring properties are

reduced. This can diminish water

extraction and create undue pressure on

the refrigeration system.

The coils should be cleaned about every

8 to 12 weeks. If the Techno Pro™5000

Dehumidifier is used in a dusty

environment, cleaning may need to be

performed more frequently. The coils

should be dry before the following

cleaning operation is performed.

Dry Method. Inject compressed air

through each coil. Clean the unit’s front

grill with a vacuum equipped with a

brush attachment. After removing the

dry particle contamination, a wet

cleaning process may be used.

Caution!

Do not use a hose to flush the coils

and do not permit water to leak

into the electrical compartment.

Wet method. Use a soft brush and soapy

water. If soils have been allowed to

accumulate over time, they may be dry

and hard. Soak time may be required to

dissolve and release these soils from the

coils. A spray bottle or a syringe can be

used to apply controlled amounts of

cleaning solution. After cleaning, make

sure that the drain port, the condensate

tray and drain tubing are free of any

residual soil.

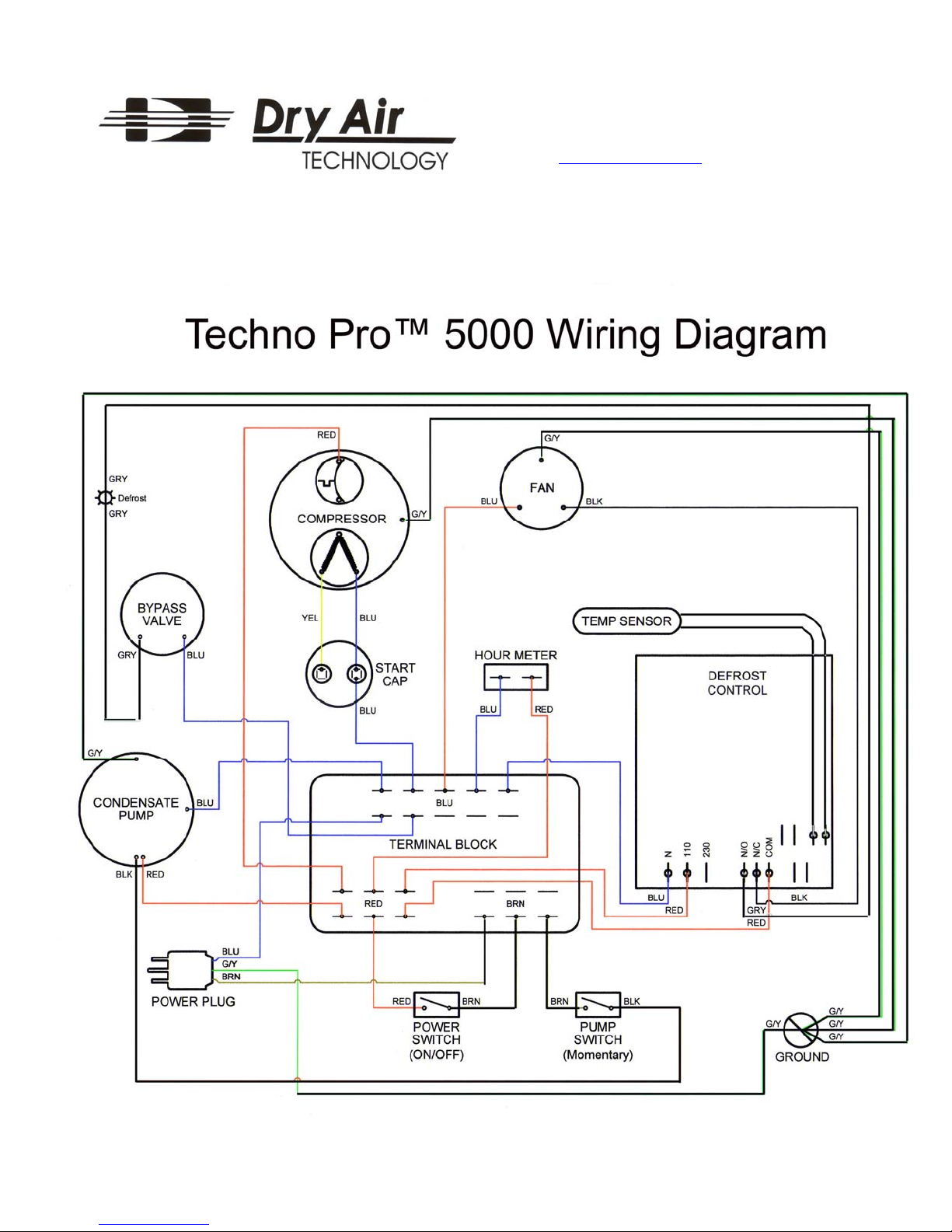

Electrical Wiring & Cord: Inspect the

power cord periodically to make sure

that the insulation is in good condition.

Replace worn or damaged cords.

Remove the dehumidifier cover to

expose the wiring and terminal block.

Inspect wires to assure that they are

secured away from the fan blade.

Inspect the terminal block connections

and wires for abrasions, nicks or cuts.

Repair or replace as needed.