Table of Contents

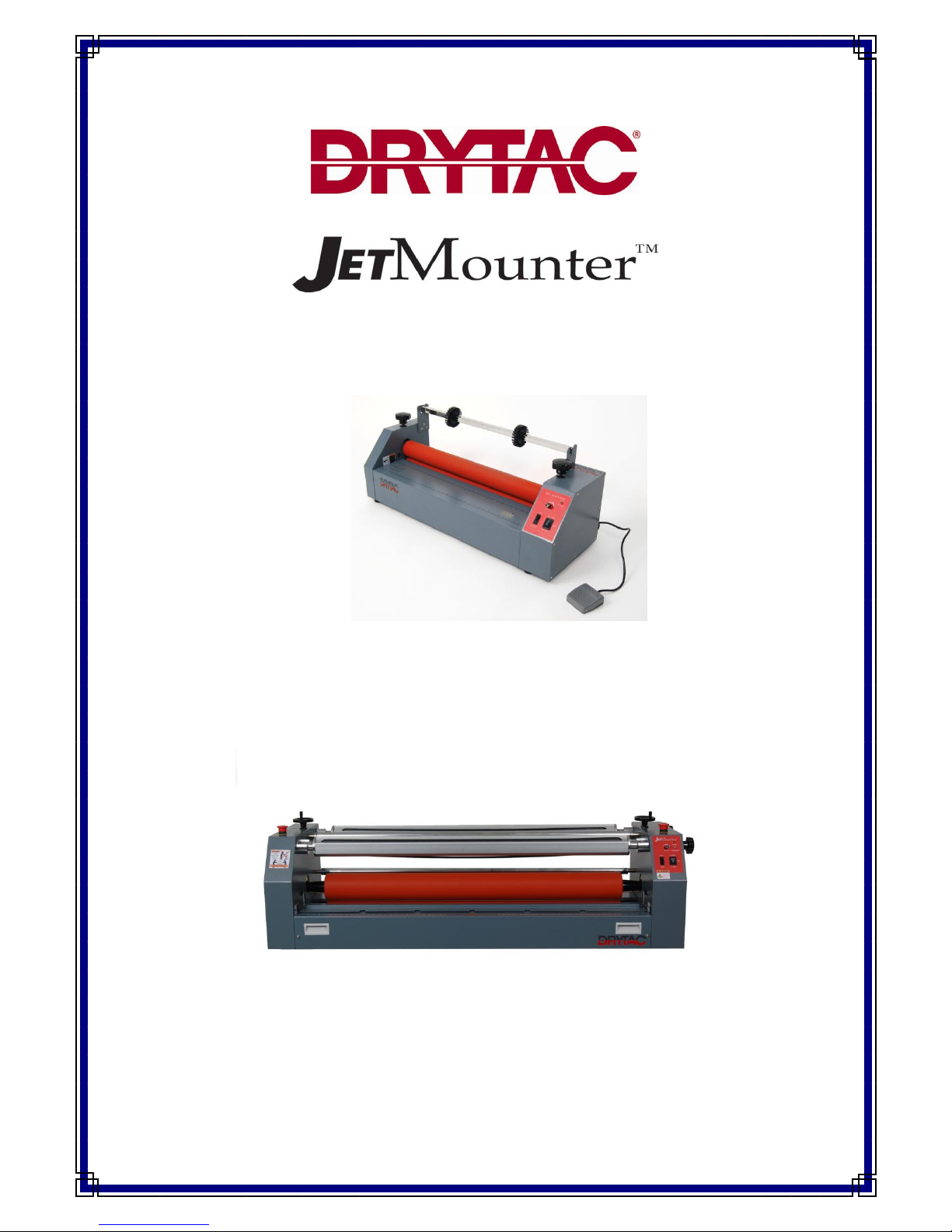

Overview..........................................................................................................................6

Important Safety Information .........................................................................................6

Specific Moving Instructions..................................................................................10

Unpacking and Installation.....................................................................................11

JM Components....................................................................................................12

Component Illustrations ........................................................................................14

Setting Roller Pressure..........................................................................................15

JM44SHA/JM54SHA Roller Pressure Adjustment .................................................16

Adjusting Shaft Tensions.......................................................................................17

Mounting With the JetMounter™Laminators

Mounting Board Selection......................................................................................18

Adhesive Selection................................................................................................18

Pre-coating the Mounting Board............................................................................18

Mounting a Graphic to a Pre-Coated Board...........................................................20

Laminating with the JetMounter™Laminators

Selecting a Laminate Film .....................................................................................21

Single Unmounted Graphic....................................................................................22

Single Mounted Graphic........................................................................................23

Laminating Multiple Mounted Images....................................................................24

Using a Leader Board............................................................................................25

Carrier Boards.......................................................................................................26

Preparing Mounting Boards...................................................................................26

Care and Maintenance....................................................................................................27

Service..................................................................................................................28

Technical Specifications........................................................................................29

Contact Information...............................................................................................30

Warranty..........................................................................................................................31

Appendix

Replacement Parts................................................................................................32

B Revision Functional Requirements.....................................................................33

JM44SHA/JM54SHA Nip Adjustment Procedure ......................................................34