Operations Manual

Page 3

TALON 44/64 CE

©2004 General Binding Corporation

Table of content

Cover .................................................................1

Table of Content ............................................... 3

Important Safety Instructions ........................ 5

Important Safeguards ..................................... 7

General ..............................................................7

Electrical ............................................................ 7

Service ...............................................................7

Warranty ........................................................... 9

Specifications ................................................ 11

Talon 44 ........................................................... 11

Talon 64 ........................................................... 12

Pre-Installation ............................................... 13

Installation ...................................................... 15

Control Guide ................................................. 17

Power ON/ OFF ............................................... 17

Control Panel Display ...................................... 17

Control Panel ................................................... 17

Rewinder Selection Switch .............................. 18

Upper Rewinder Direction Switch .................... 19

Lower Rewinder Direction Switch .................... 19

Rear Control Switch ......................................... 19

Foot SW Enable ............................................... 19

Features Guide ...............................................20

E-Stop ..............................................................20

Safety Shield Interlock Latch ........................... 20

Safety Shield .................................................... 20

Feed Table .......................................................20

Heat Rollers .....................................................20

Pull Rollers ....................................................... 20

Roller Handle ...................................................20

Idler Bar ........................................................... 21

Chill Idler .......................................................... 21

Cooling Fans .................................................... 21

Film Shaft ......................................................... 21

Core Adaptors .................................................. 21

Lower Shaft Lock ............................................. 21

Unwind/ Rewind Tension ................................. 21

Rewind Shaft .................................................... 21

Rewind Tube .................................................... 21

Rewind Adaptors .............................................. 21

Rear Table ........................................................ 22

Rear Slitter .......................................................22

Film Web ..........................................................22

Nip Point ...........................................................22

Foot Switch ......................................................22

Print Unwind Basket ......................................... 22

Separator Bar Option .......................................22

Rewind Kit Option ............................................22

Operating Instructions .................................. 23

Film Loading and Threading ............................23

Load a Roll of Film ...........................................23

Loading Top Thermal Film ............................... 24

Loading Top PSA Film .....................................24

Loading Top Mount Adhesive ........................... 25

Loading Bottom Thermal Film .......................... 25

Loading Bottom PSA Film ................................ 26

Loading Bottom Mount Adhesive .....................26

Threading Card Procedure .............................. 27

Start Laminating ............................................... 28

Tacking New Film To Existing Film .................. 29

To Unweb The Laminator .................................30

Clearing A Film Jam ......................................... 30

Applications ................................................... 31

Pre-Coating Boards ......................................... 31

Using Rear Rollers ........................................... 31

Mounting Pre-Coated Boards .......................... 31

PSA Encapsulation ..........................................32

Thermal Encapsulation .................................... 32

Accushield ........................................................ 32

The Art Of Lamination ...................................33

Basic Rules ......................................................33

Film Tension ..................................................... 33

Heat ..................................................................34

Output ..............................................................34

Maintenance ................................................... 35

Caring for the Talon 44/64 .............................. 35

Disclamer ........................................................ 37

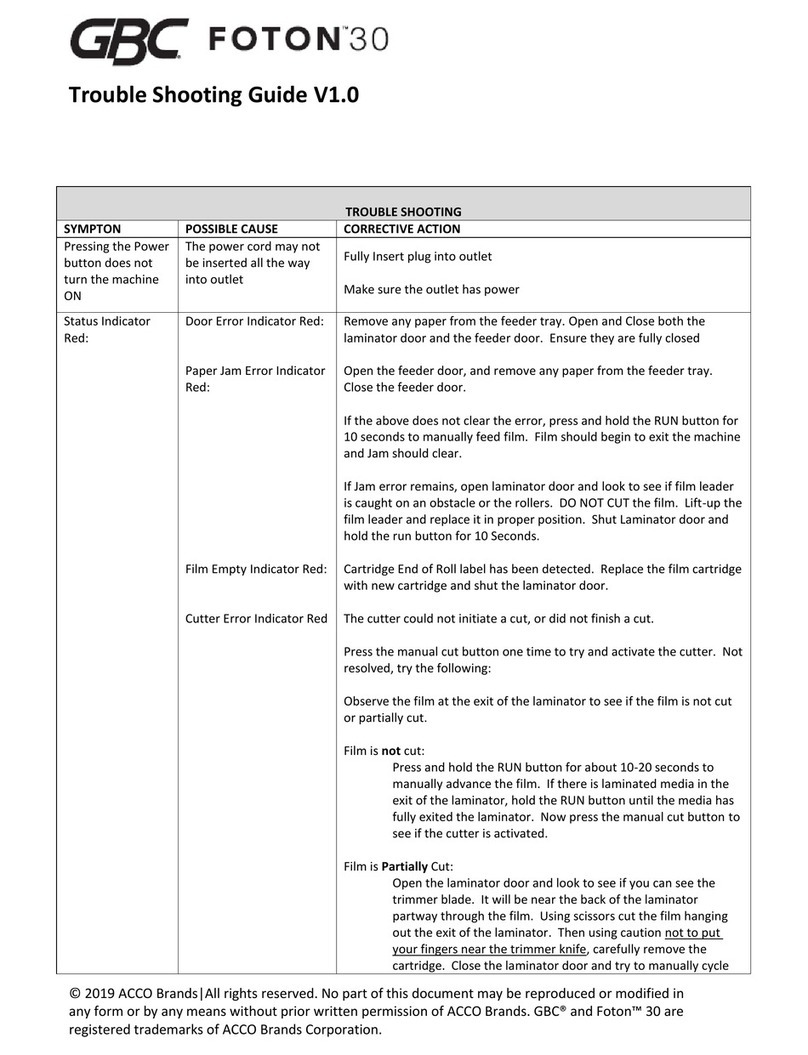

Troubleshooting Guide ................................ 39

Service Agreement ........................................39